A service damage recovery method for precipitation-strengthened polycrystalline cast nickel-based alloys

A nickel-based alloy, precipitation strengthening technology, applied in the field of metallurgy, can solve the problems of different chemical composition service history and damage mechanism, it is difficult to determine the recovery heat treatment parameters of alloy materials, and the reference value of specific alloy recovery is not high, and achieve a wide range of heat treatment temperatures , Overcome the initial melting behavior and improve the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

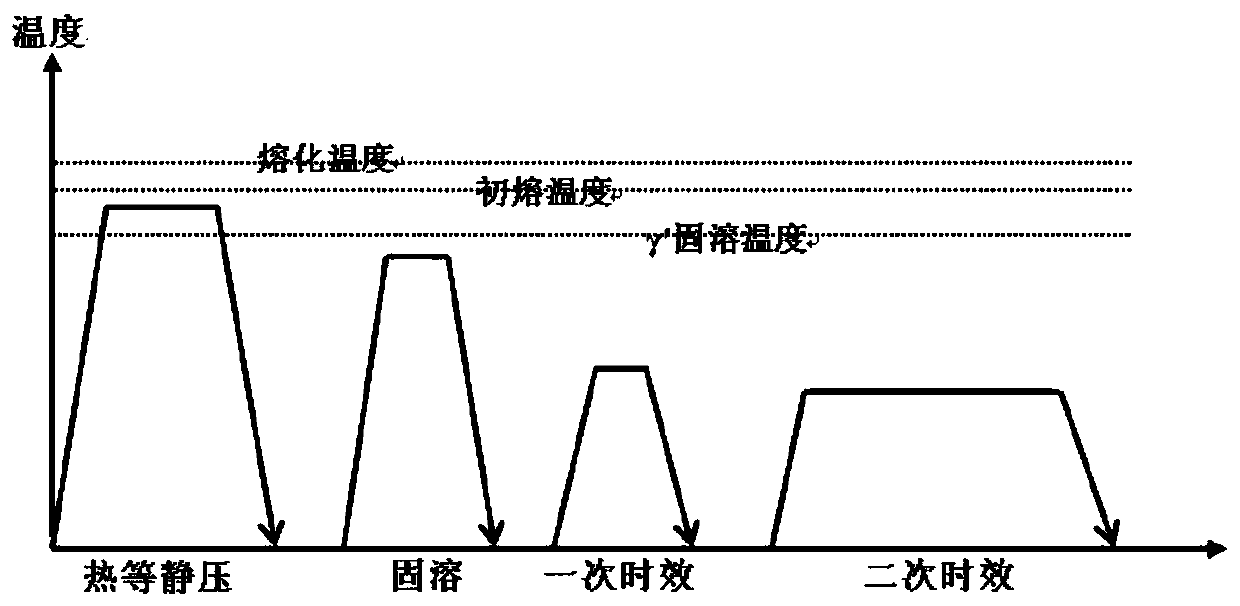

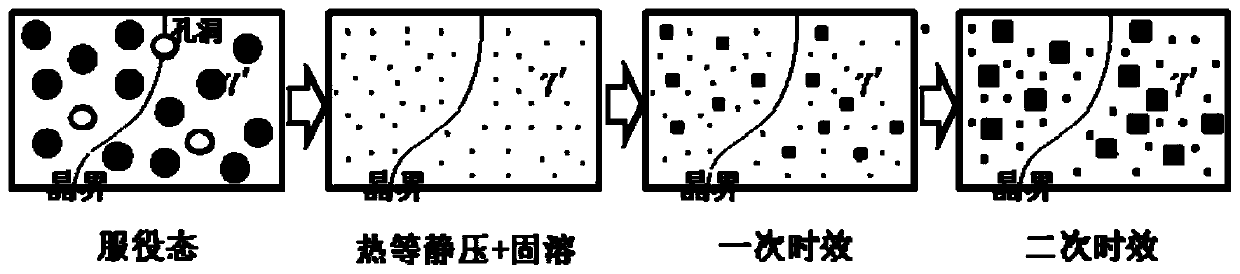

[0038] Use clamps to fix the turbine blades after service, then place them in the heat preservation area of the high-pressure vessel of the hot isostatic press, vacuumize, fill the pressure vessel with argon, repeat 2 to 3 times to ensure that the air inside the high-pressure vessel is exhausted, and then Under the action of inert gas, the internal pressure of the high-pressure container is kept at 100MPa, the temperature is raised to 1200°C, kept for 4 hours, and the furnace is cooled; exhausted to normal pressure, the temperature is raised to 1120°C, kept for 2 hours, and air-cooled; the temperature is raised to 920°C, kept for 1~ 4 hours, air cooling; heat up to 850°C, keep warm for 12-36 hours, air cooling.

Embodiment 2

[0040] Use clamps to fix the turbine blades after service, then place them in the heat preservation area of the high-pressure vessel of the hot isostatic press, vacuumize, and fill the pressure vessel with helium, repeat 2 to 3 times to ensure that the air in the high-pressure vessel is completely exhausted, and finally Under the action of inert gas, the internal pressure of the high-pressure vessel is kept at 100MPa, the temperature is raised to 1190°C, kept for 4 hours, and the furnace is cooled; exhausted to normal pressure, the temperature is raised to 1130°C, kept for 2 hours, and air-cooled; the temperature is raised to 1050°C, kept for 1~ 4 hours, air cooling; heat up to 840°C, keep warm for 12-36 hours, air cooling.

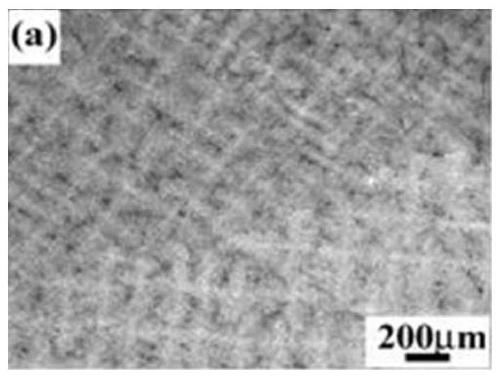

[0041] image 3 and Figure 4 Respectively, the metallographic structure and γ′ phase microstructure of GTD111 alloy material, Figure 5 and Figure 6 They are the microstructure of IN738 alloy material and the microstructure of γ′ phase (the turbine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com