Large-diameter double-metal composite pipe manufacturing technology and diameter expanding forming device

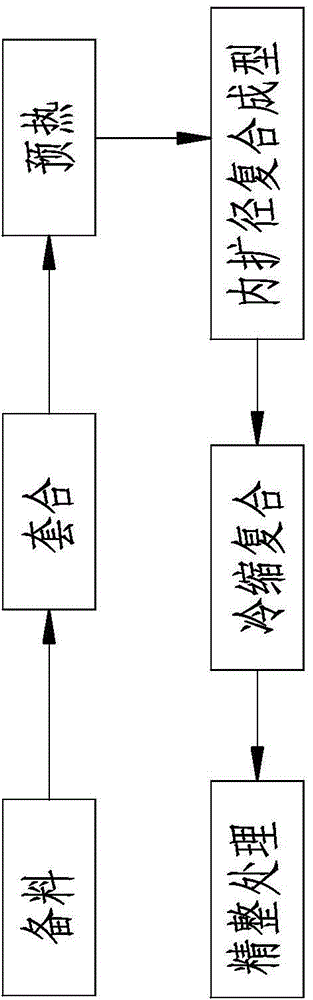

A bimetal composite pipe and manufacturing process technology, which is applied in the directions of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of poor reliability of composite quality between layers of composite pipes, and achieve stable pipe quality, resource saving, and service life extension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

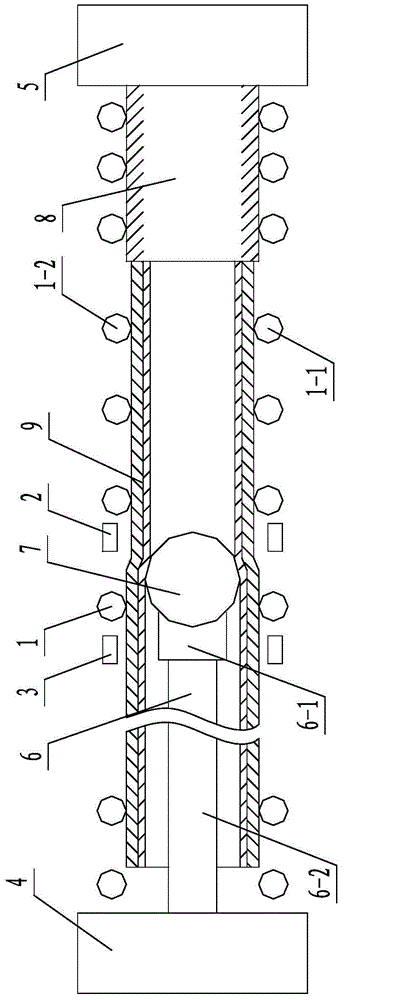

[0043] Example 1: The product produced is a wear-resistant large-diameter bimetal composite pipe for long-distance coal slurry transportation, with a specification of φ813×23×8000mm (inner layer 10mm) of No. 20 high-quality carbon steel and chromium-containing alloy steel Composite pipe. The specific process includes the following process steps:

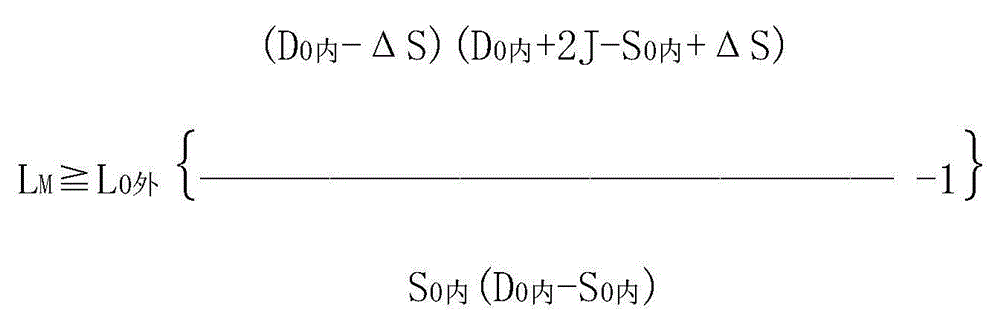

[0044] (1) Material preparation: At the same time, prepare Q235 carbon steel with a specification of φ813×13×8500mm as the outer tube to be compounded; chromium-containing alloy steel pipe with a size of φ767×10.5mm as the to be compounded Inner tube; the inner tube of chromium-containing alloy steel at the end of the double-layer material tube should extend out of the outer tube. The length of the inner tube extension ΔL is calculated according to the formula to be 52mm, multiplied by the adjustment factor of 1.2, and the value is 64mm , So the blanking size of the inner tube is φ767×10.5×8564mm;

[0045] (2) Sleeve: sleeve the inner t...

Embodiment 2

[0050] Example 2: The product produced is anti-H for long-distance transportation of sour oil and gas 2 , CO 2 Corroded large-diameter bimetallic pipe. The specification is a composite pipe of X65 steel pipe with φ914×42.9×8000mm (inner wall thickness 20mm) and high-grade niobium-containing chromium-containing alloy steel pipe. The specific implementation process includes the following process steps:

[0051] (1) Material preparation: At the same time, prepare X65 steel, with a specification of φ914×22.9×8500mm as the outer tube to be compounded, and the size of φ846.2×22.5mm containing niobium and chromium alloy steel pipe as the waiting material. Composite inner tube material; in the double-layer material tube, the inner tube of niobium-chromium alloy steel should protrude from the end of the outer tube. The length of the protruding part ΔL is calculated according to the formula 118mm, multiplied by the adjustment factor of 1.2, and take the value 142mm, the blanking size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com