A kind of rhenium-free nickel-based single crystal superalloy and preparation method thereof

A technology of nickel-based single crystal and superalloy, which is used in the field of rhenium-free nickel-based single crystal superalloy and its preparation, aero-engine turbine blade materials, and can solve the problem of deteriorating the uniformity of alloy structure and thermal corrosion resistance, and increasing the tendency of TCP phase formation. , the activity increases the difficulty of smelting the master alloy, and achieves the effect of wide melting temperature range, small solidification interval and low alloy cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

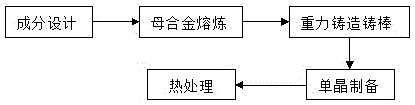

Method used

Image

Examples

Embodiment 1

[0034] (1) Alloy composition design

[0035] The rhenium-free nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.5%Cr, 5.0%Co, 2.0%Mo, 8.0%W, 6.5%Ta, 6.1%Al, 0.15%Hf, 0.05%C, 0.004%B, 0.015%Y, the balance of Ni. The composition of the designed alloy has the following characteristics: the number of electron vacancies is 2.17; the content of refractory elements (W, Ta, Mo) is 16.5%, of which W+Mo is 10%; the content of γ′ phase-forming elements (Al, Ta) is 12.6% .

[0036] (2) Master alloy smelting

[0037]According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was melted in a calcium oxide crucible with a melting power of 25kW and a melting time of 15 minutes.

[0038] (3) Master alloy casting rod preparation

[0039] After the master alloy was remelted in a ...

Embodiment 2

[0052] (1) Alloy composition design

[0053] The rhenium-free nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.25%Cr, 4.8%Co, 1.8%Mo, 7.8%W, 6.3%Ta, 6.0%Al, 0.12%Hf, 0.04%C, 0.003%B, 0.010%Y, the balance of Ni. The composition of the designed alloy has the following characteristics: the number of electron vacancies is 2.07; the content of refractory elements (W, Ta, Mo) is 15.9%, of which W+Mo is 9.6%; the content of γ′ phase-forming elements (Al, Ta) is 12.5% .

[0054] (2) Master alloy smelting

[0055] According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was melted in a calcium oxide crucible with a melting power of 22.5kW and a melting time of 22.5 minutes.

[0056] (3) Master alloy casting rod preparation

[0057] After the master alloy was remelte...

Embodiment 3

[0063] (1) Alloy composition design

[0064] The rhenium-free nickel-based superalloy of the present invention has the following alloy components by mass percentage: 7.75%Cr, 5.2%Co, 2.2%Mo, 8.2%W, 6.7%Ta, 6.2%Al, 0.18%Hf, 0.06%C, 0.005%B, 0.03%Y, the balance of Ni. The composition of the designed alloy has the following characteristics: the number of electron vacancies is 2.30; the content of refractory elements (W, Ta, Mo) is 17.1%, of which W+Mo is 10.4%; the content of γ′ phase forming elements (Al, Ta) is 12.7% .

[0065] (2) Master alloy smelting

[0066] According to the mass percentage of different alloying elements obtained by (1) composition design, the required alloy is configured by using high-purity metal components. Under high vacuum conditions, the master alloy was melted in a calcium oxide crucible with a melting power of 20kW and a melting time of 30 minutes.

[0067] (3) Master alloy casting rod preparation

[0068] After the master alloy was remelted in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com