Patents

Literature

30results about How to "Increased creep life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

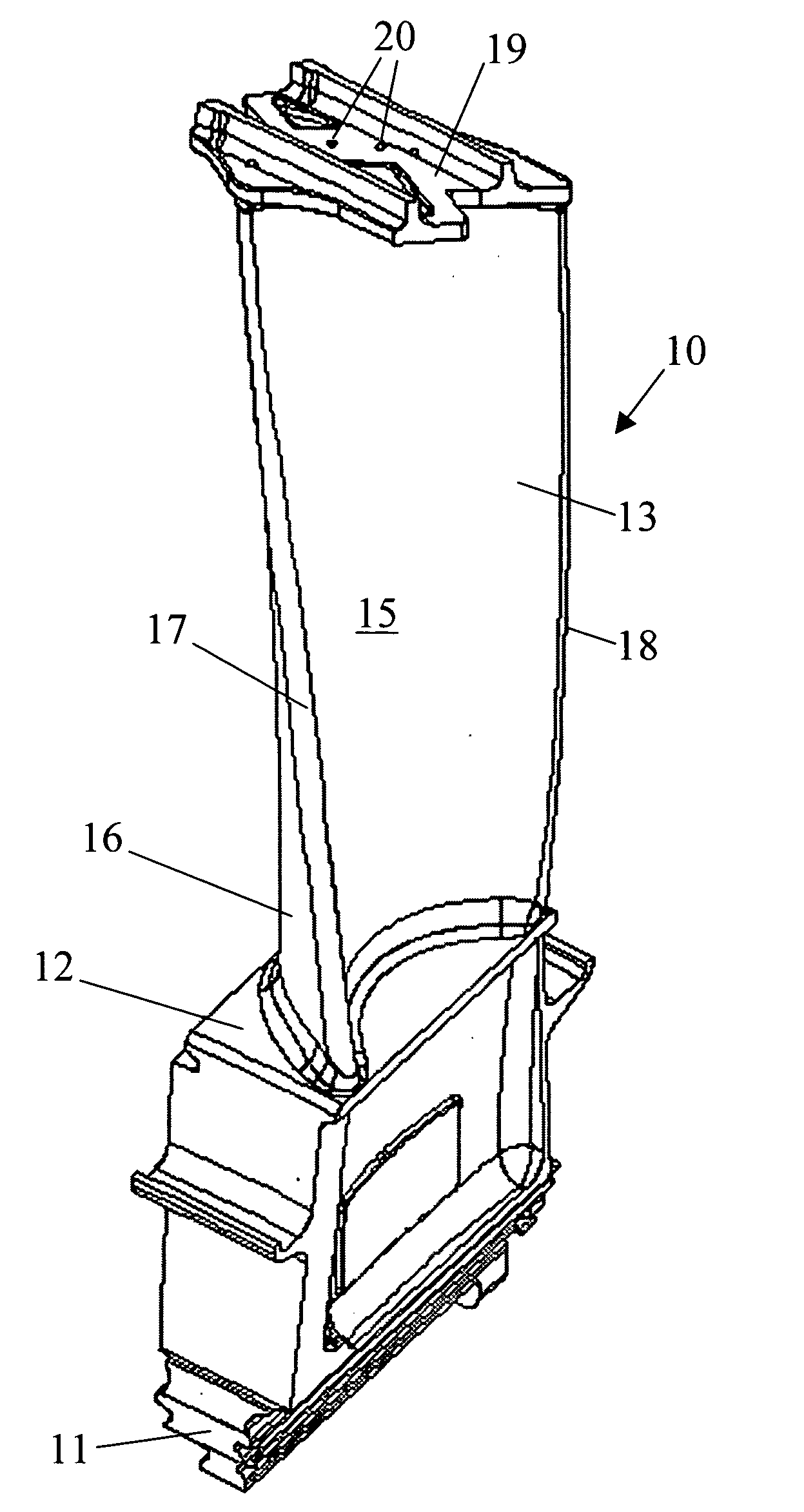

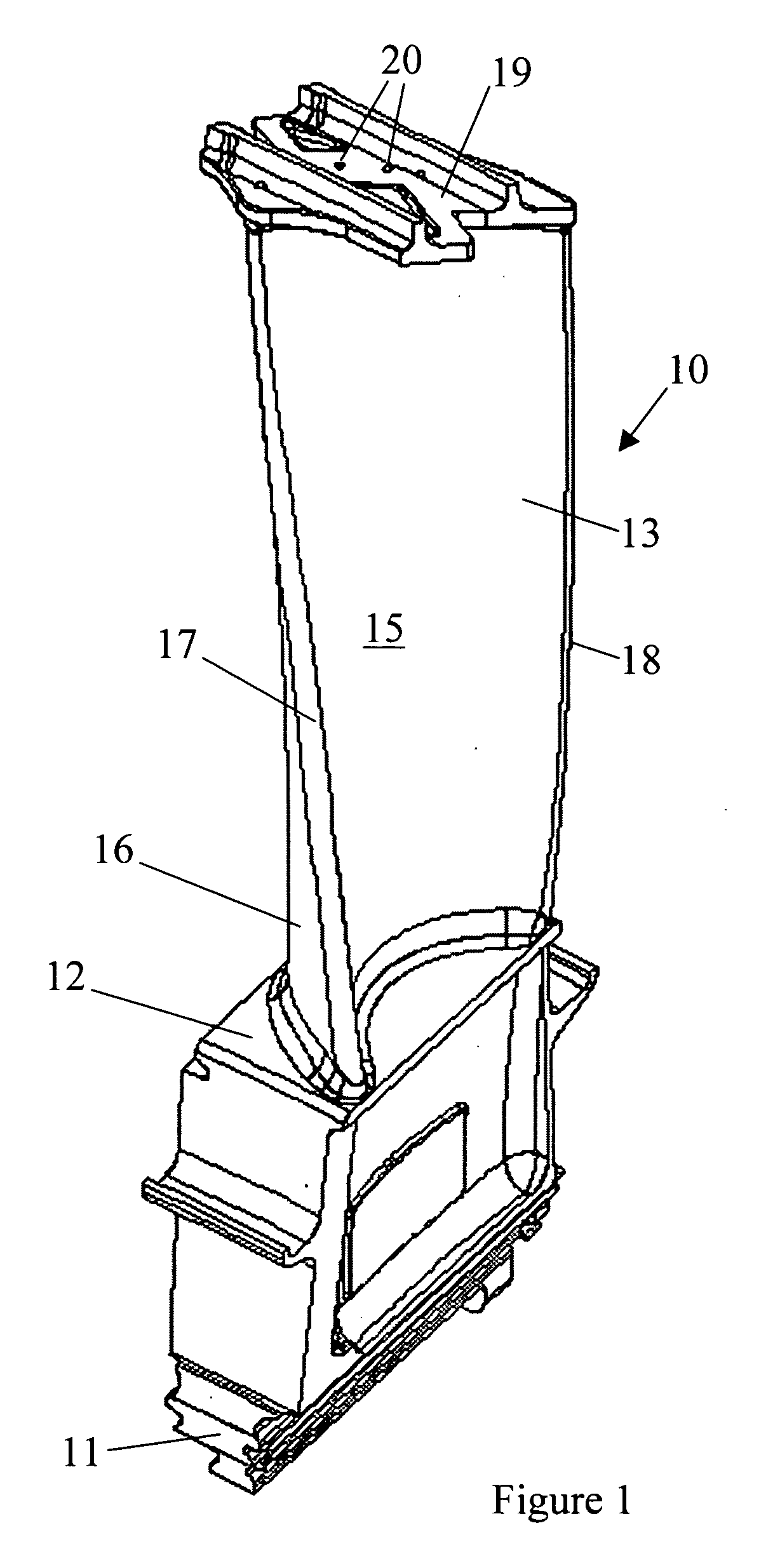

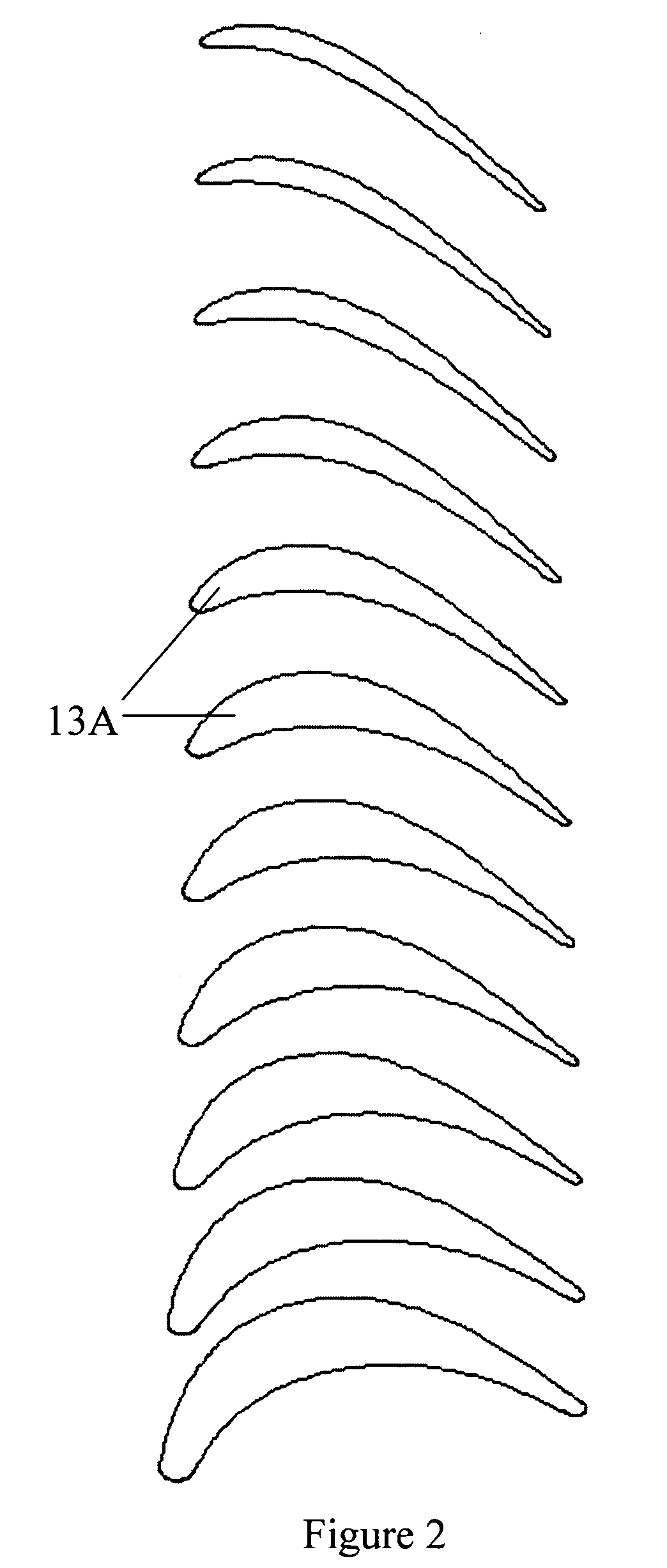

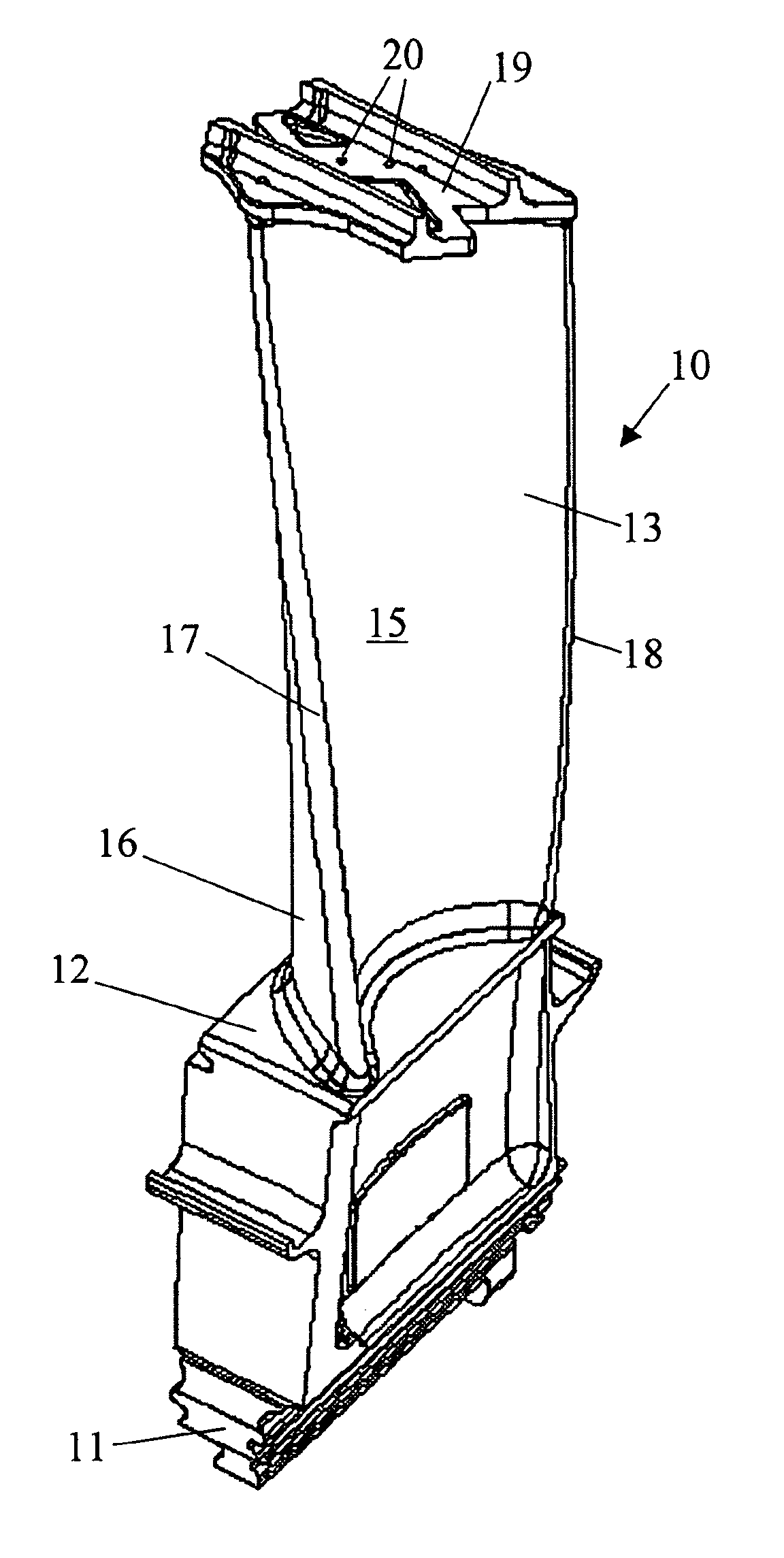

Turbine blade airfoil having improved creep capability

ActiveUS20050111978A1Increased creep lifeIncrease exposureRotary propellersBlade accessoriesTurbine bladeEngineering

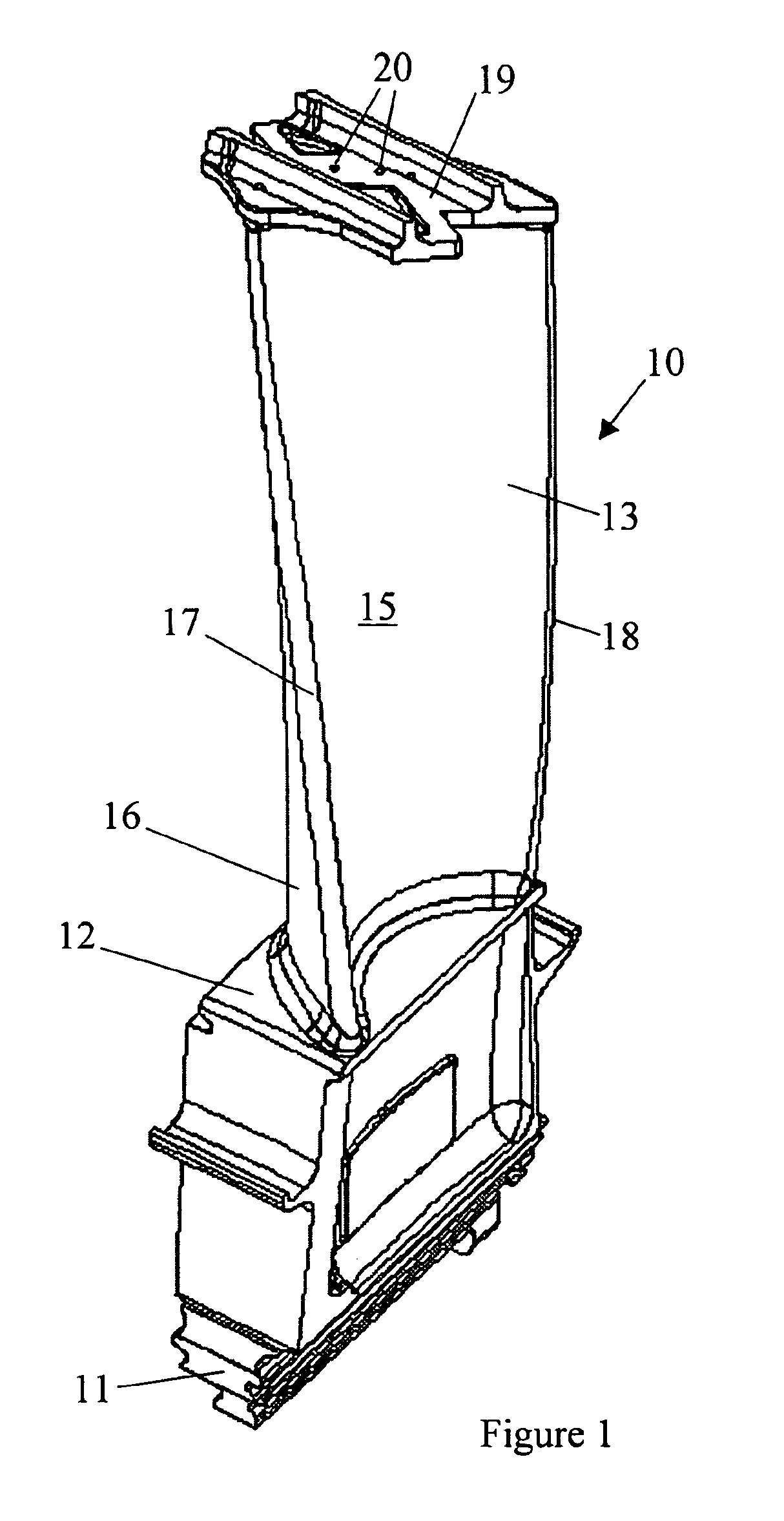

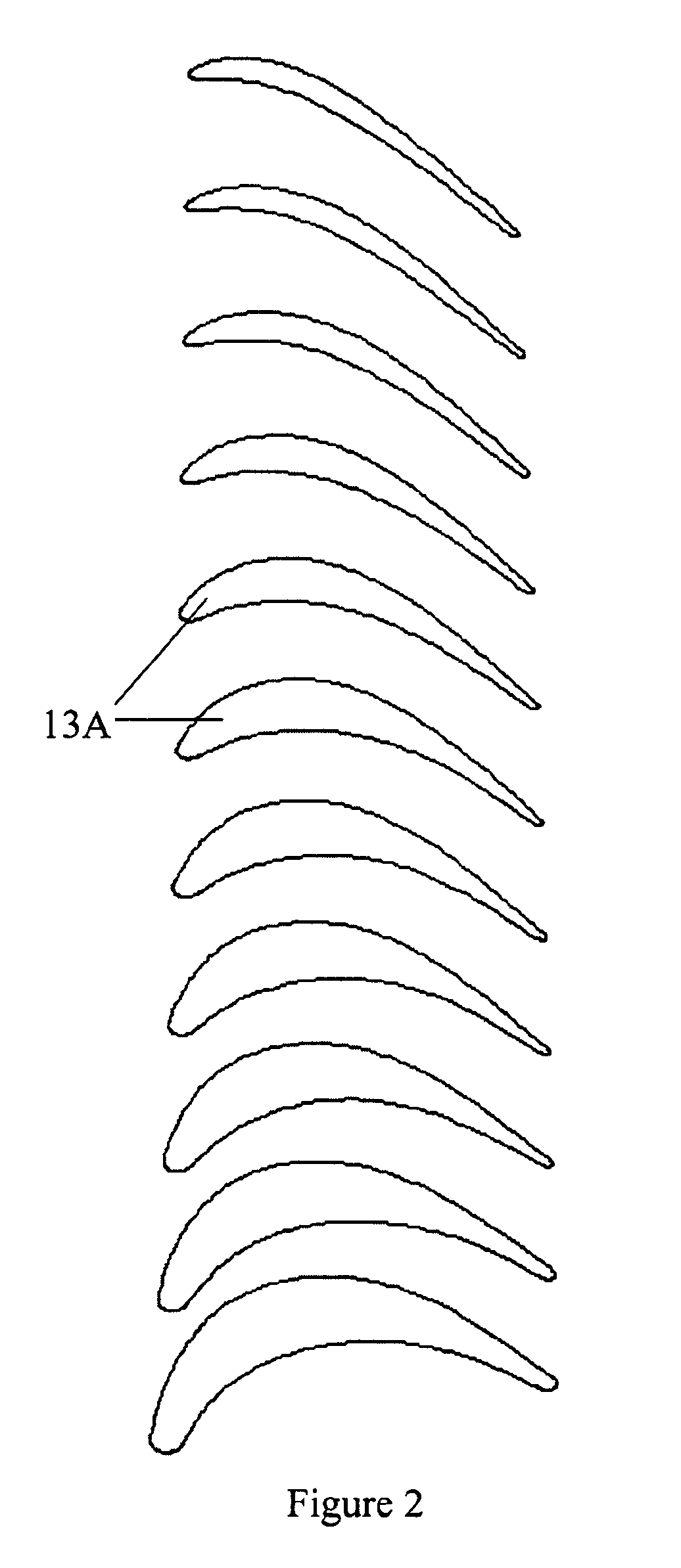

A turbine blade including an airfoil having a profile in accordance with Table 1 is disclosed. The turbine blade has a plurality of cooling passages extending radially outward through the airfoil. The aerodynamic profile of the airfoil has been reconfigured to reduce airfoil stress for a given operating temperature, thereby resulting in increased creep rupture life of the airfoil.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Turbine blade airfoil having improved creep capability

ActiveUS6932577B2Increased creep lifeReduce mechanical loadRotary propellersBlade accessoriesTurbine bladeOperating temperature

A turbine blade including an airfoil having a profile in accordance with Table 1 is disclosed. The turbine blade has a plurality of cooling passages extending radially outward through the airfoil. The aerodynamic profile of the airfoil has been reconfigured to reduce airfoil stress for a given operating temperature, thereby resulting in increased creep rupture life of the airfoil.

Owner:ANSALDO ENERGIA SWITZERLAND AG

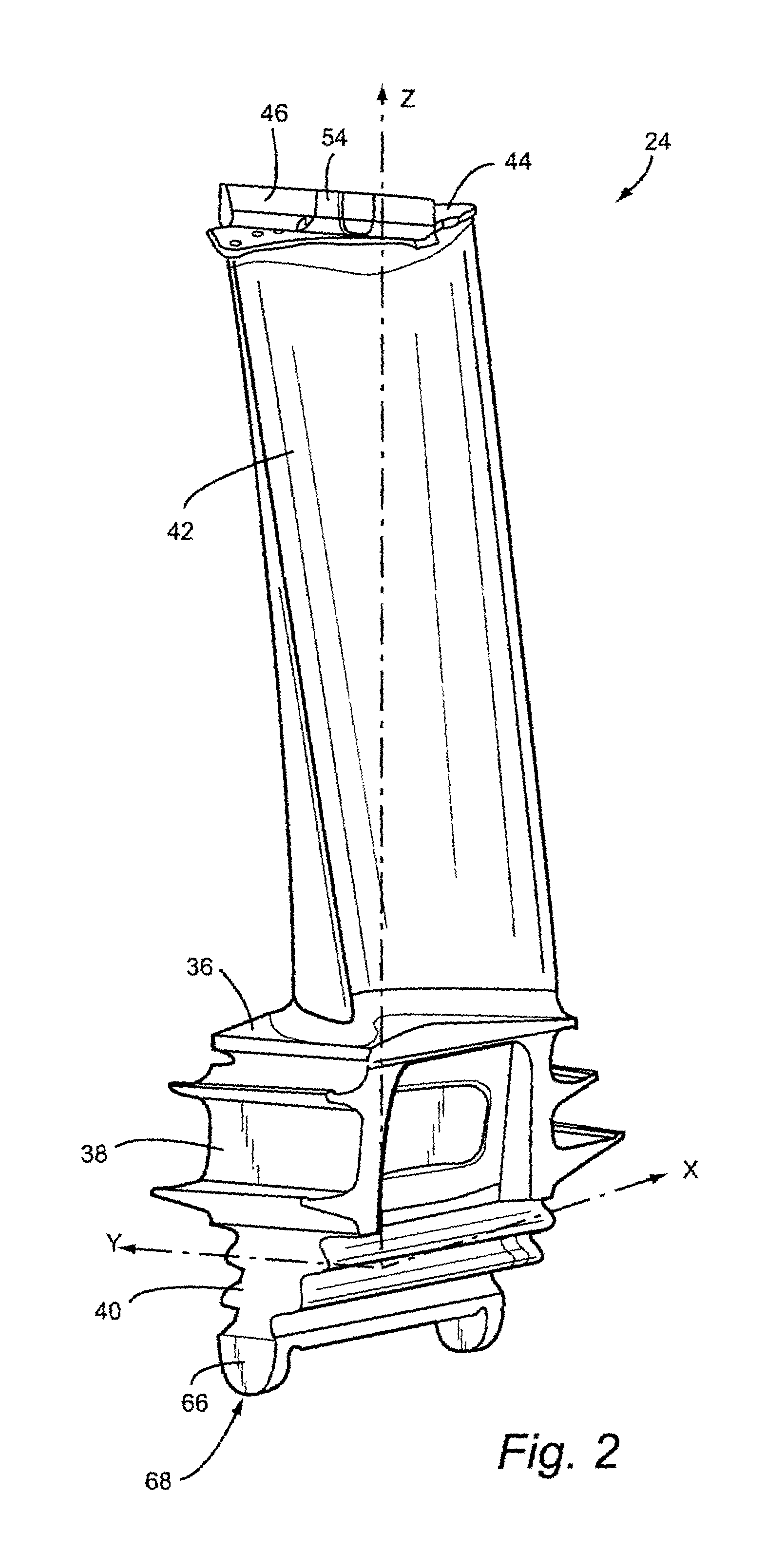

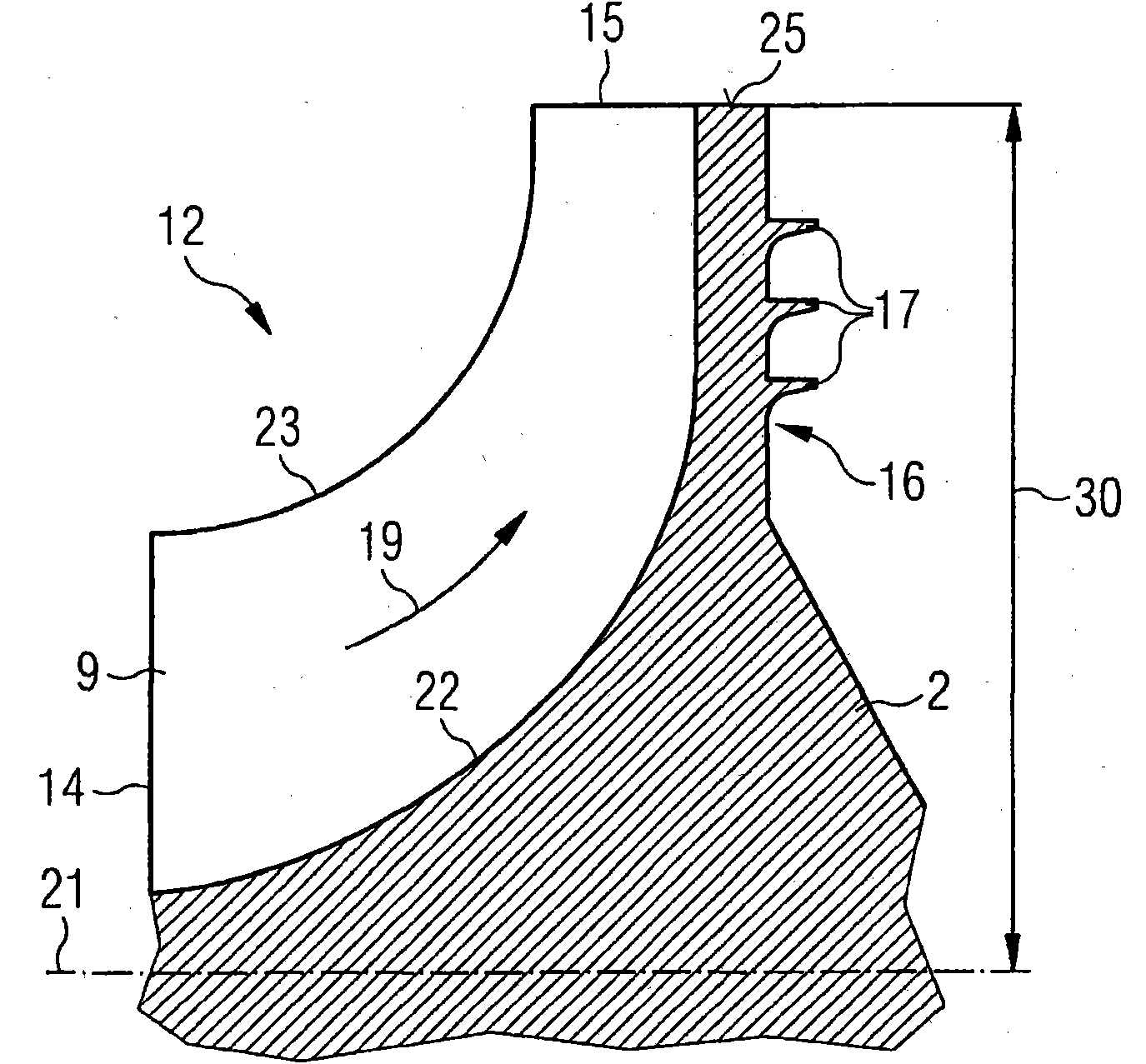

Center-located cutter teeth on shrouded turbine blades

InactiveUS6890150B2Stress minimizationIncreased creep lifeEngine sealsPump componentsTurbine bladeEngineering

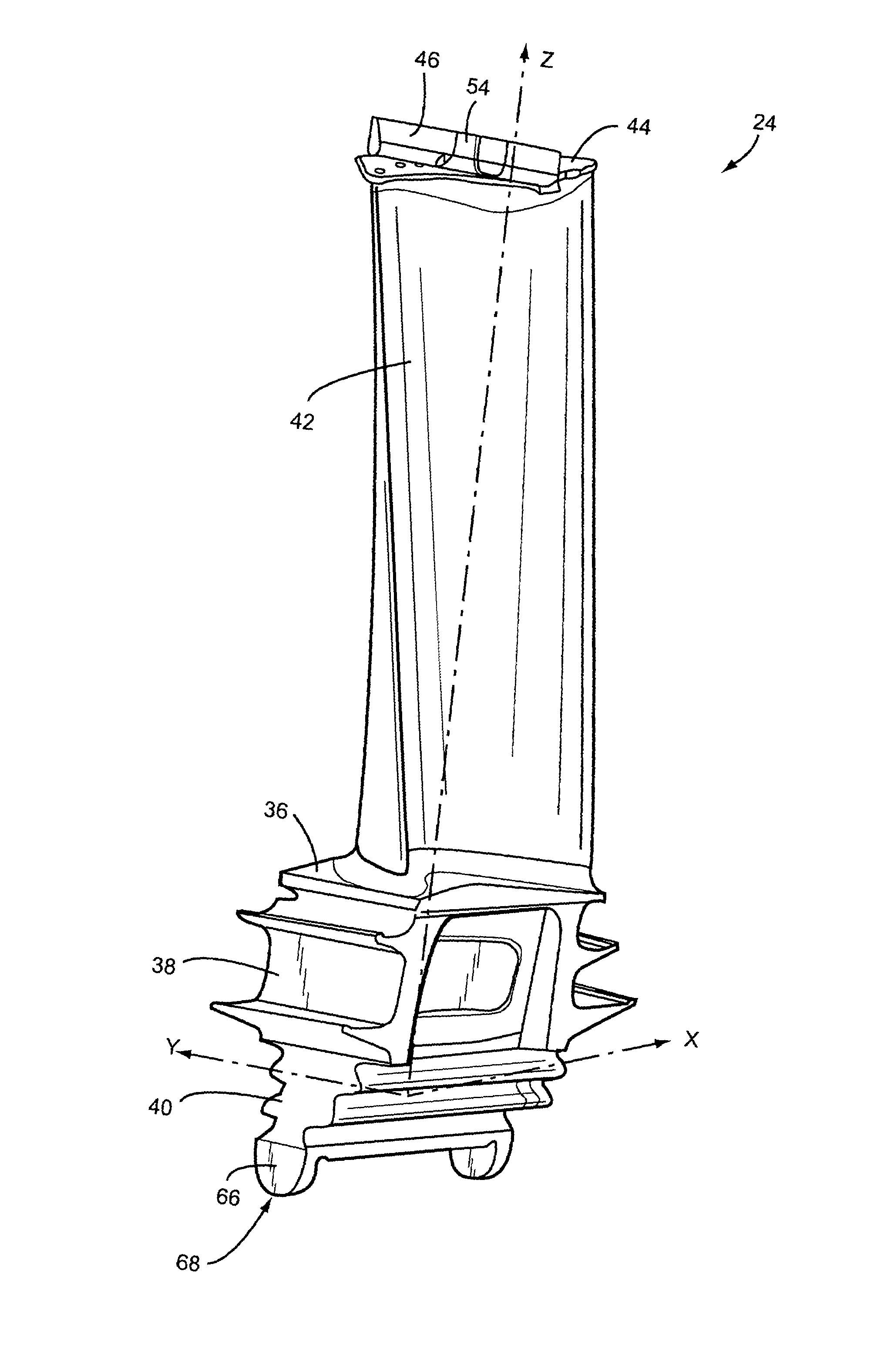

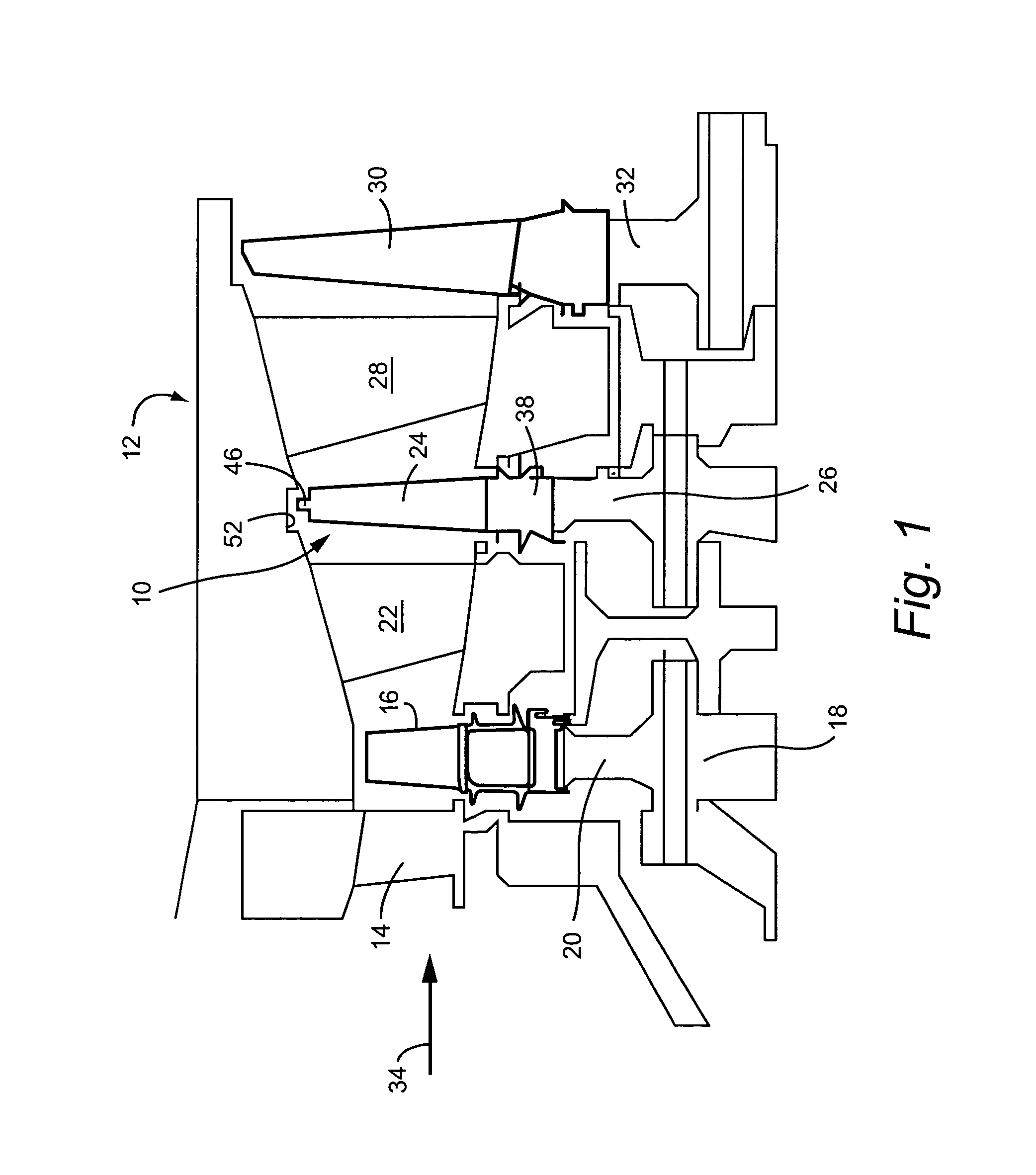

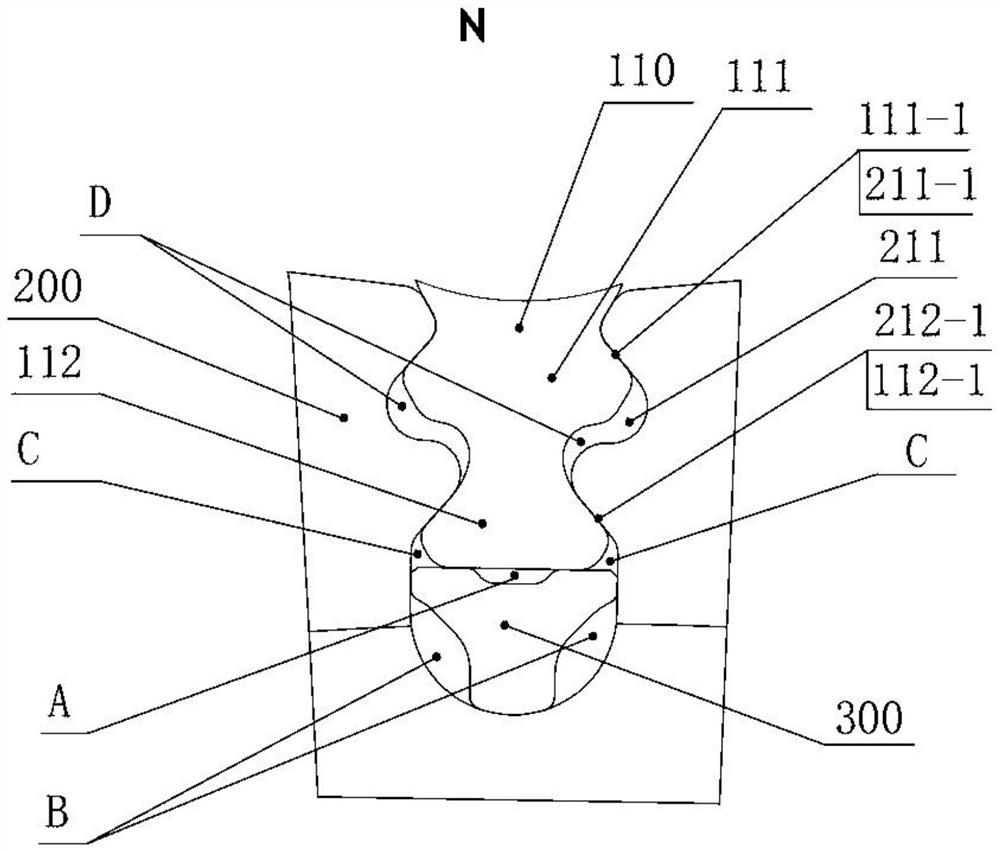

A turbine bucket includes an airfoil having a tip shroud, a shank and an entry dovetail; a tip shroud seal projecting radially outwardly from the tip shroud and extending continuously between end edges of the tip shroud in a direction of rotation of the airfoil about a turbine axis; a cutter tooth carried by the tip shroud seal for enlarging a groove in an opposing fixed shroud, the cutter tooth having a center point located with reference to X, Y and Z axes, where the X-axis extends axially in an exhaust flow direction; the Y-axis extends in a direction of rotation of the turbine bucket; and the Z-axis extends radially through the intersection of the X and Y axes; wherein the center point is located about ½ inch along the Y-axis from the X=0 position, and wherein the Z-axis is located 0.517 inches from an outside edge of a seal pin extending along said entry dovetail, as measured in a direction normal to the shank of the bucket.

Owner:GENERAL ELECTRIC CO

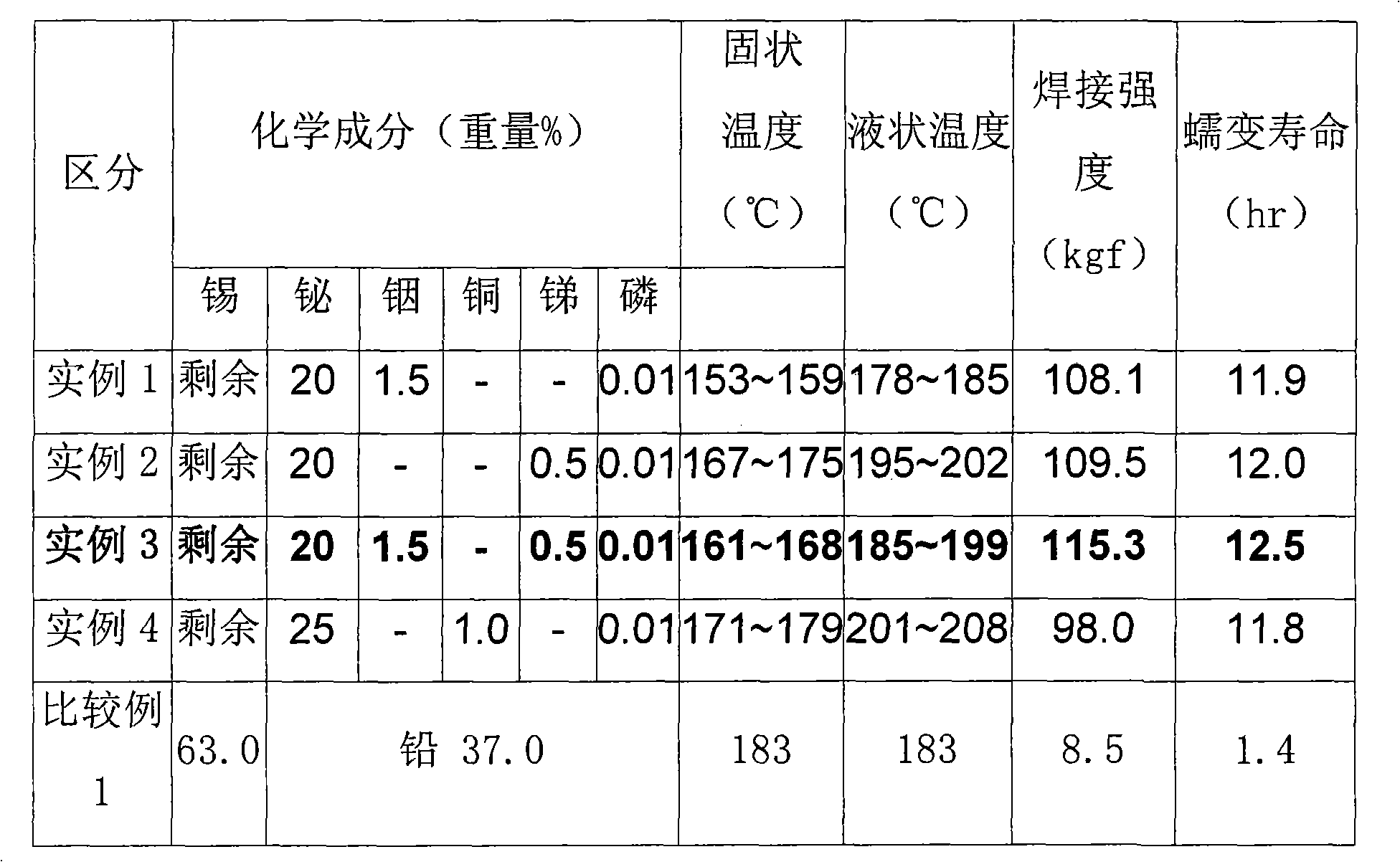

Lead-free alloy for low-temperature welding welder

InactiveCN101537545AReduce lead poisoning and other disadvantagesIncrease stickinessWelding/cutting media/materialsSoldering mediaIndiumPhosphor

The invention relates to lead-free alloy, which is suitable for use in welding for fixing parts on a substrate and for use on an external electrode for EEFL during the production of electric appliance and electronic products, so that a melting point and welding strength which are better than the prior welding can be obtained without lead. In addition, the alloy is free from lead and can reduce the influences of coal gas and the like generated during welding on human bodies to the maximum degree. Meanwhile, the lead-free alloy has the characteristic that: tin (Sn) is added with 10 to 30 weight percent of bismuthism (Bi), 0.001 to 2.0 weight percent of indium (In), and 0.001 to 0.5 weight percent of phosphor (P), as well as one or more of stibium (Sb), silver (Ag), copper (Cu), germanium (Ge) and gallium (Ga) as additives.

Owner:HEESUNG MATERIAL

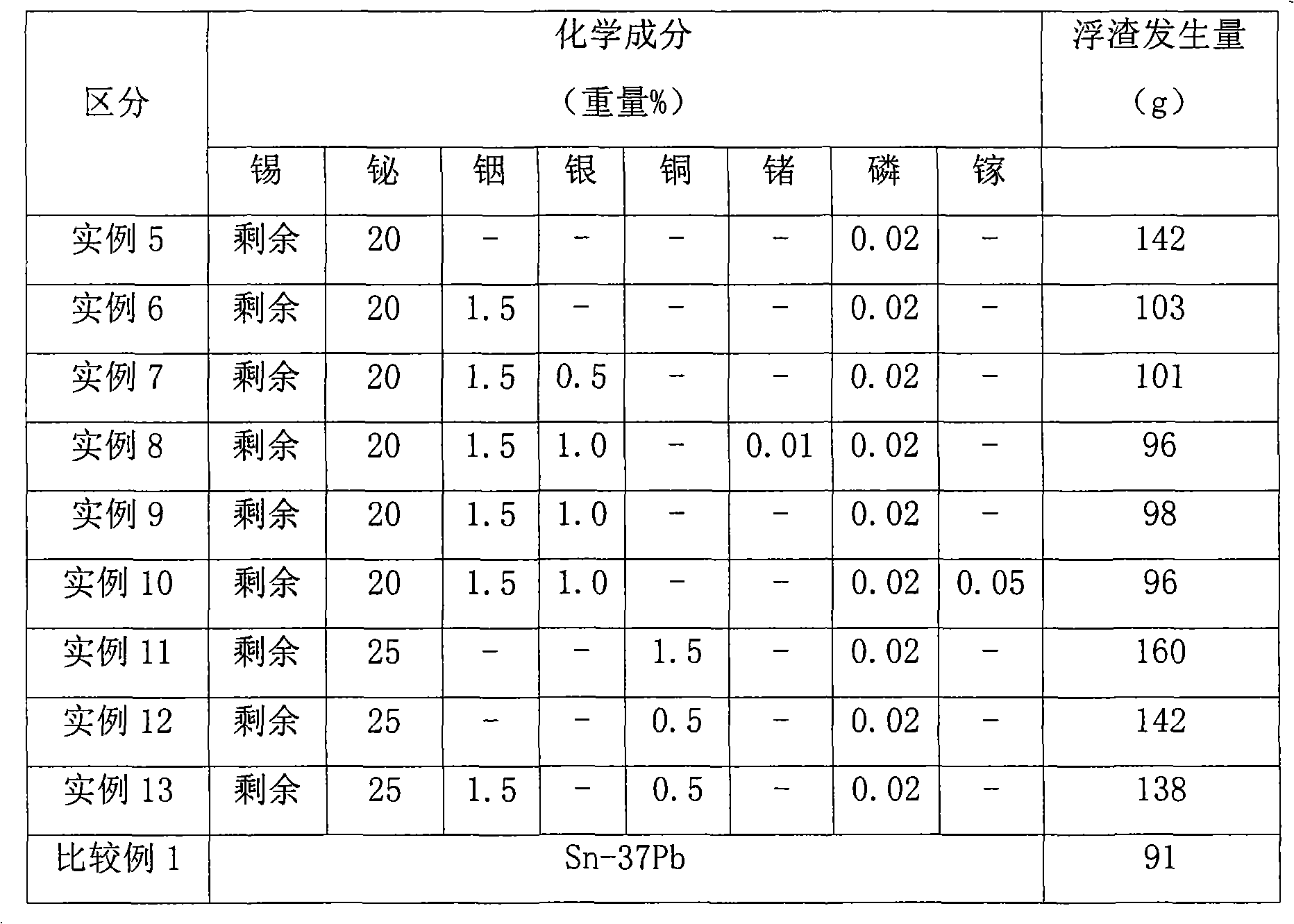

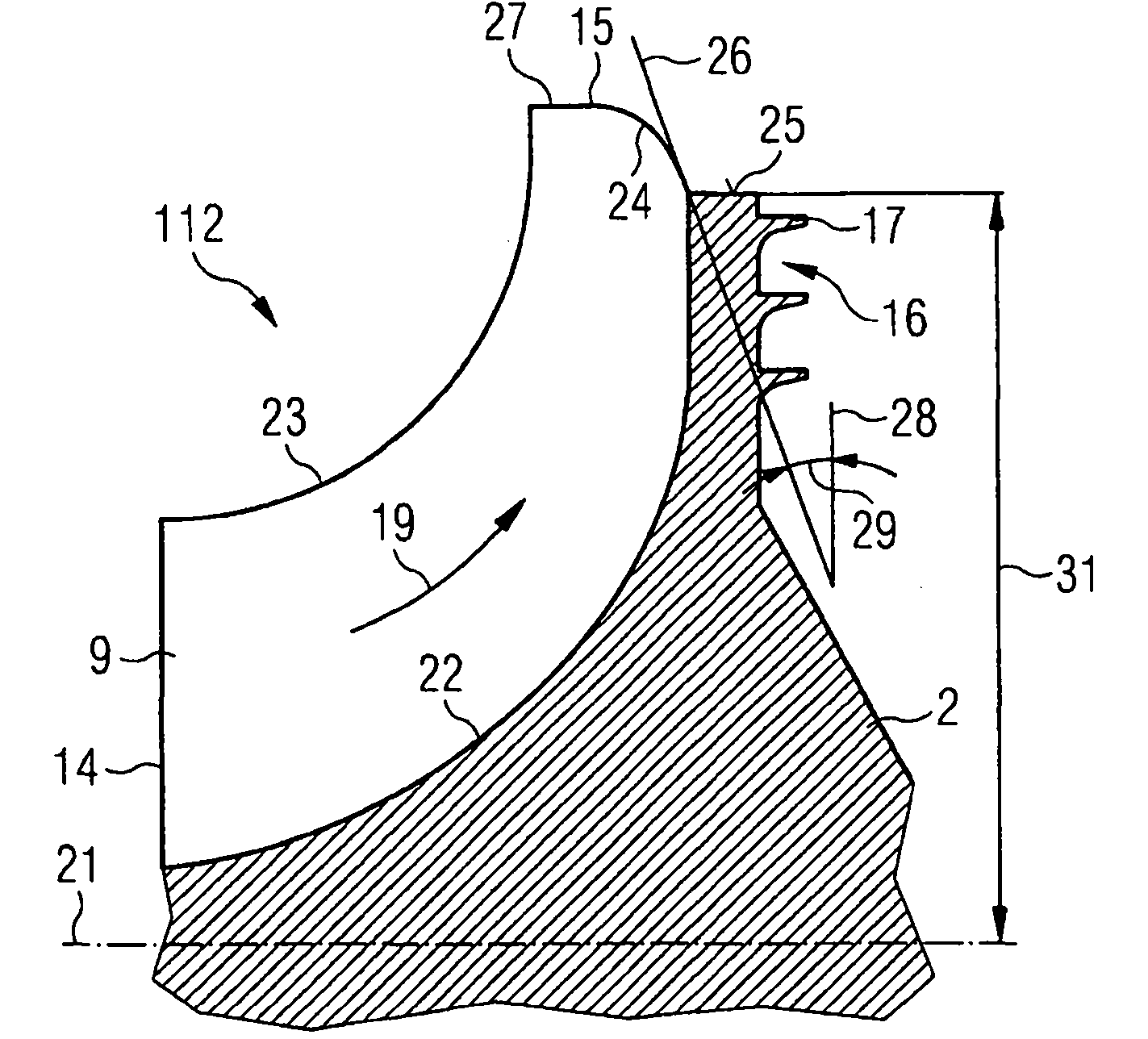

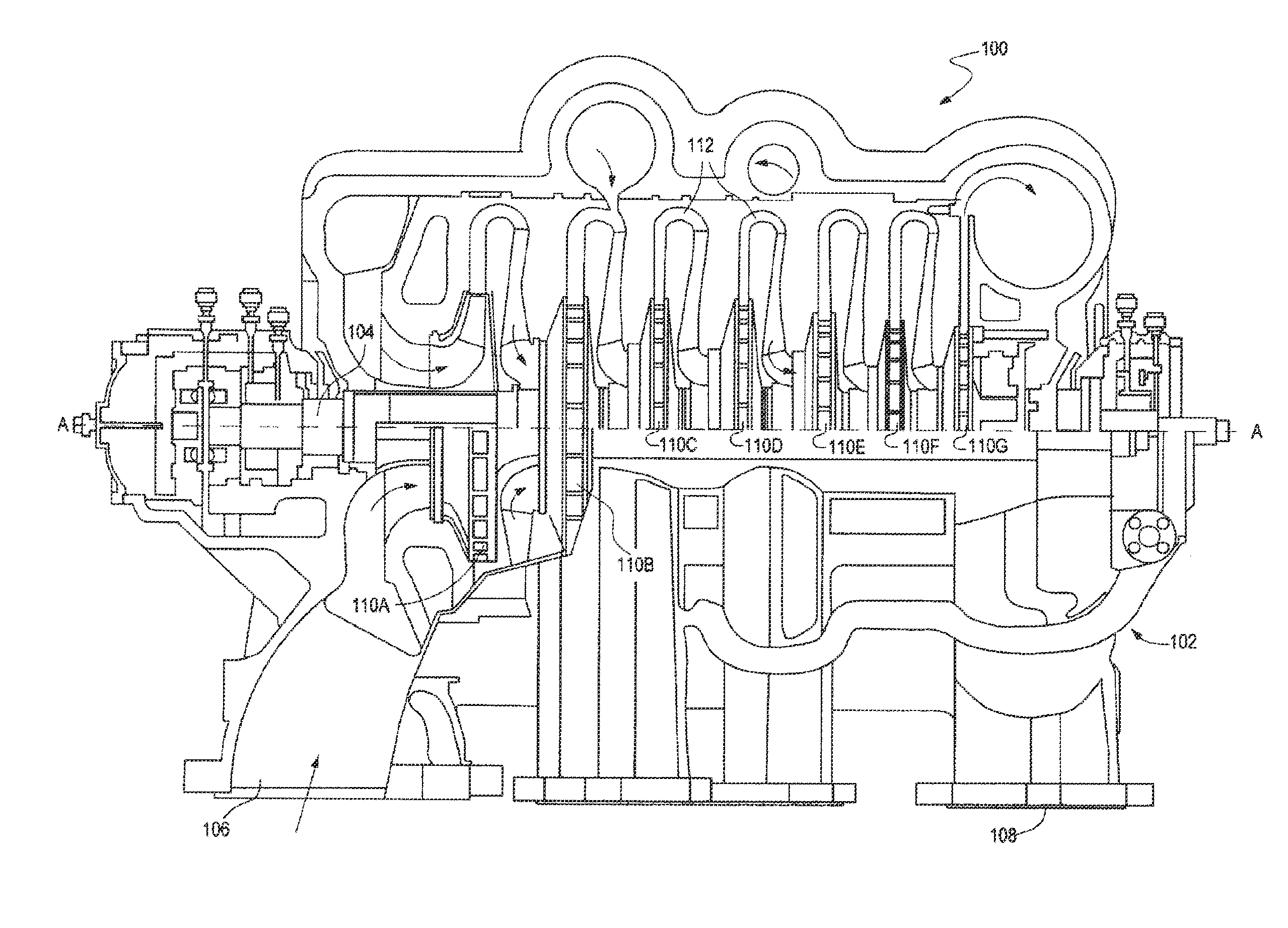

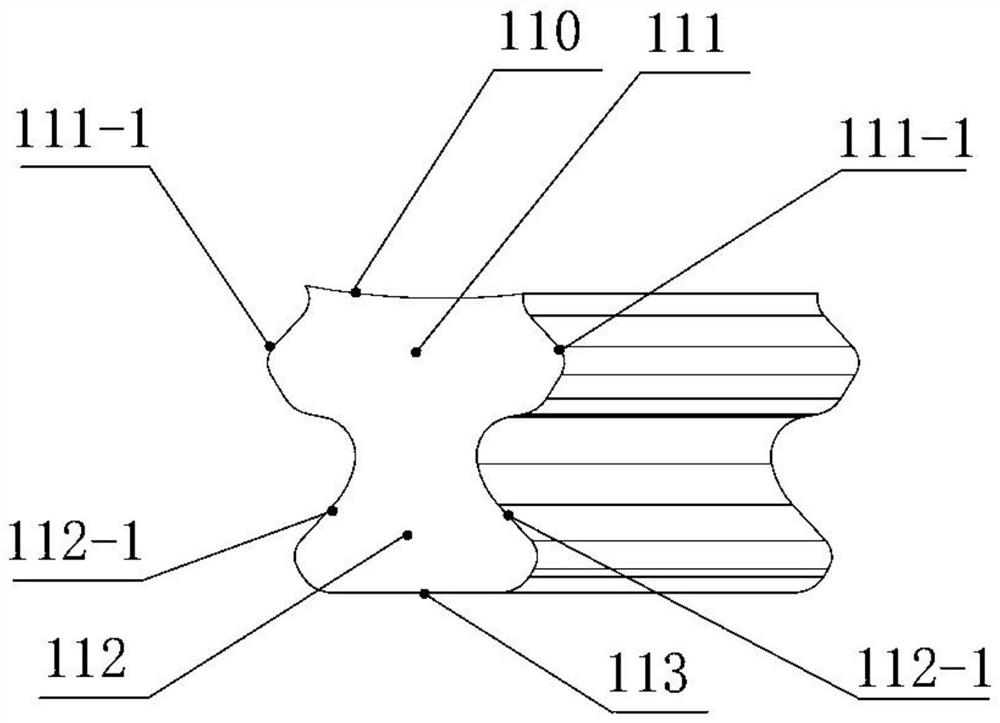

Impeller and turbocharger

An impeller (112, 212) comprising a rotation axis (21), a radial direction, a backplate (2) and a number of vanes (9) which are connected to the backplate (2) at a line of connection (22) is provided. Each vane (9) comprises an upstream side (14), a downstream side (15) and an outer side (23). The downstream side (15) of each vane (9) comprises an edge portion (27) which is located near the outerside (23). The vanes (9) project radially over the backplate (2) and the downstream side (15) further comprises a connecting portion (24) connecting the edge portion (27) to the backplate (2) and including an angle with the radial direction. The connecting portion (24) comprises a convex rounded portion which is located near the line of connection (22). Moreover, a turbocharger comprising an inventive impeller (112, 212) is disclosed.

Owner:NAPIER TURBOCHARGERS LTD

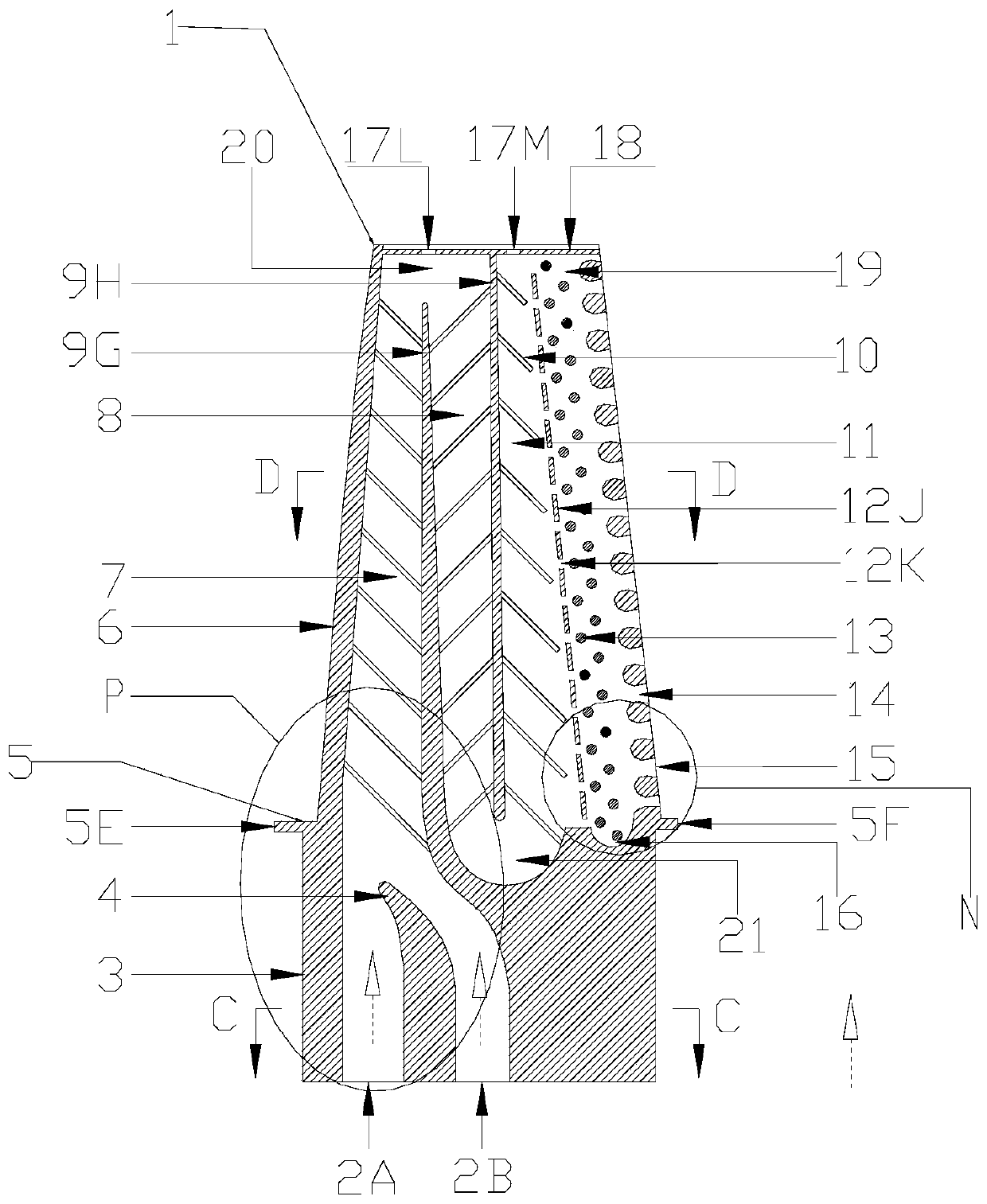

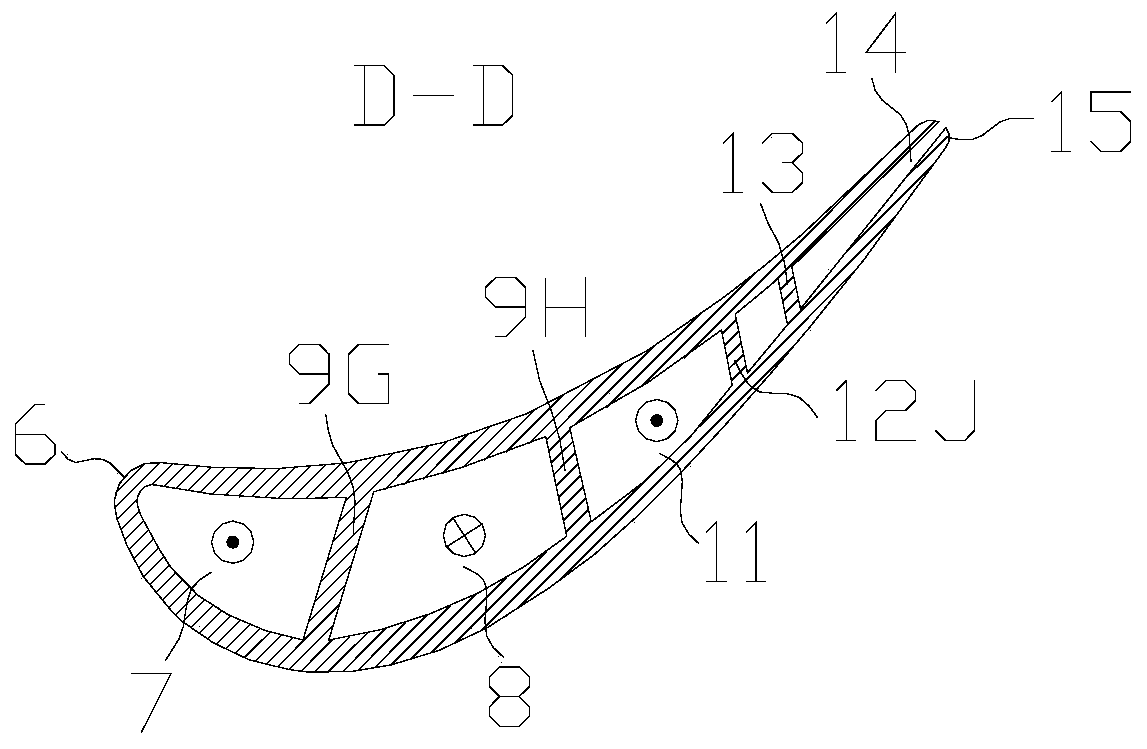

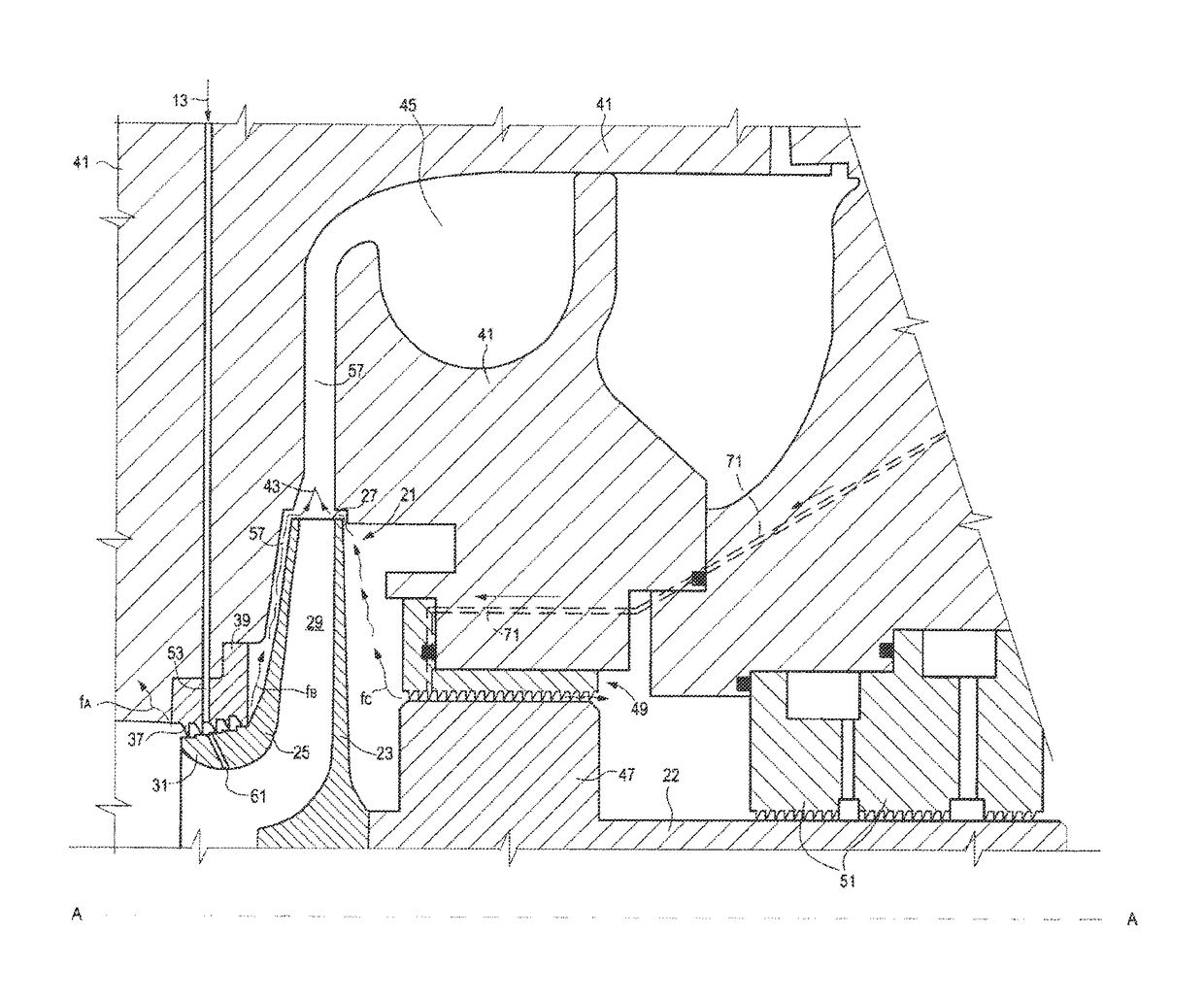

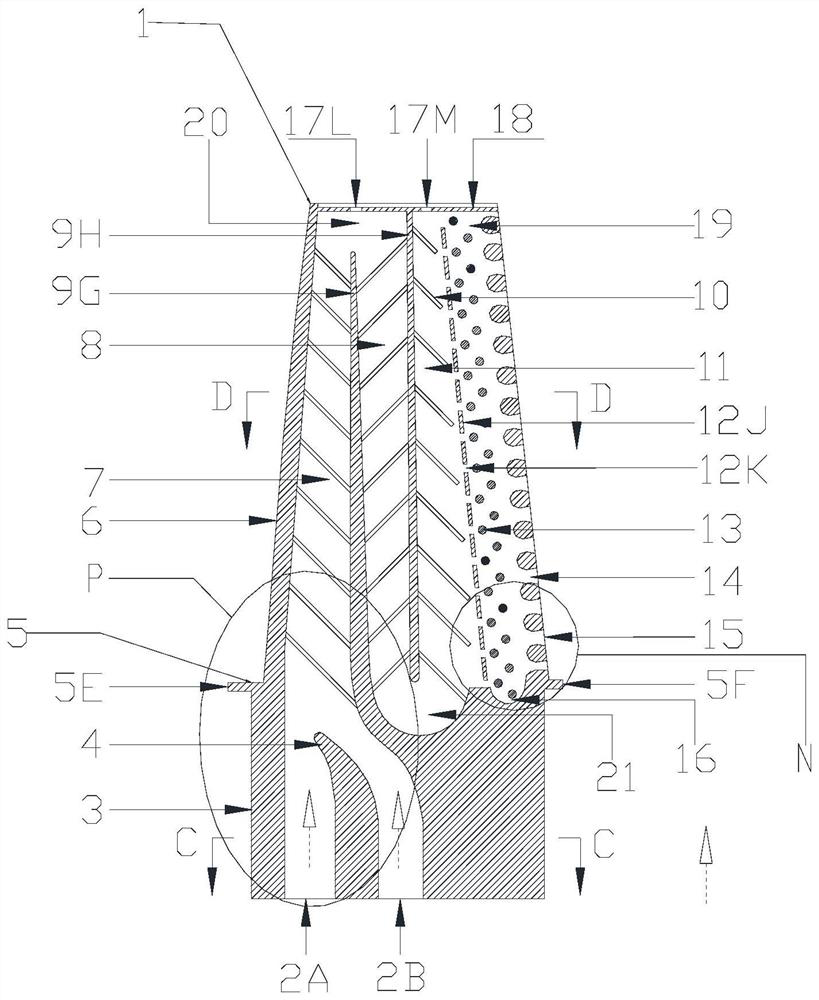

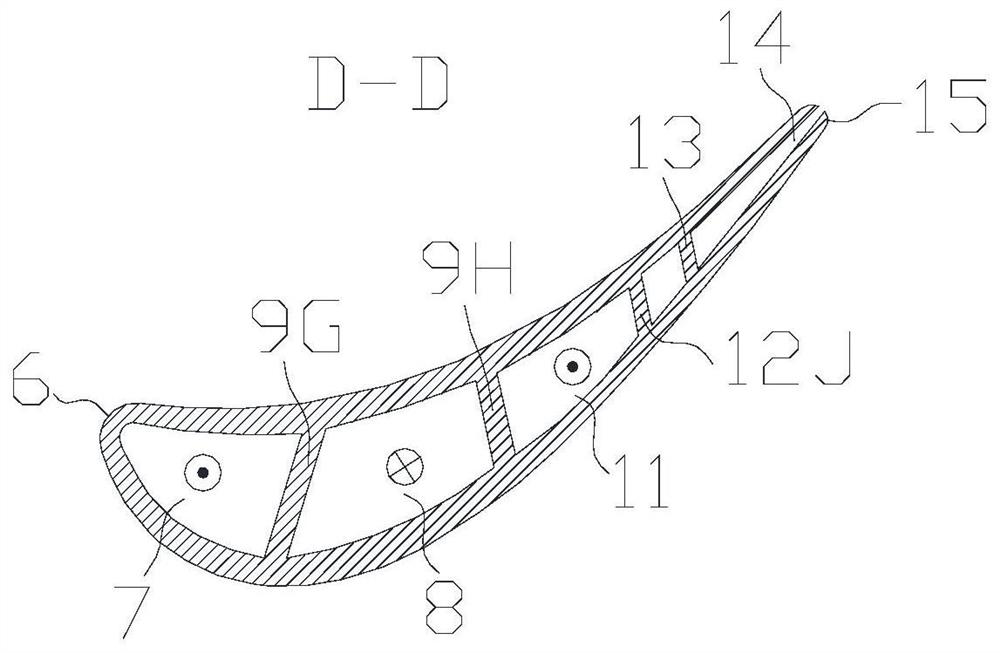

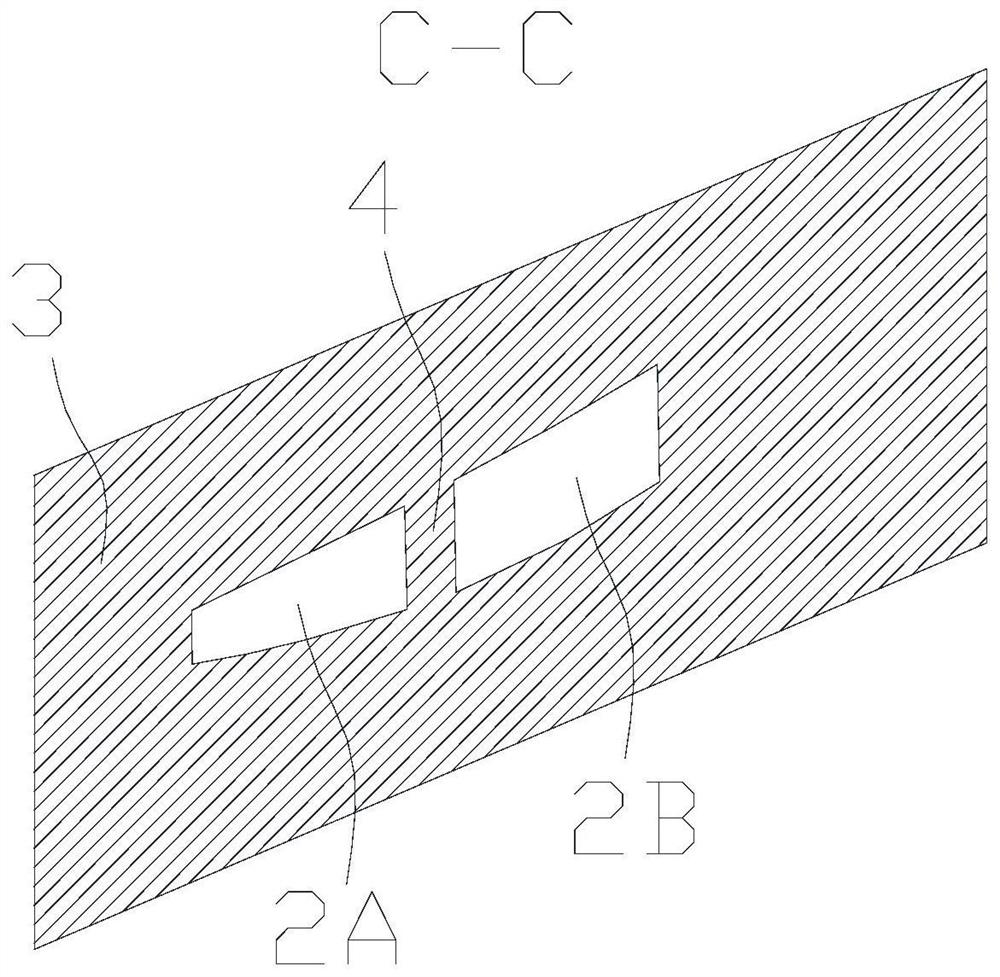

Turbine rotor blade of gas turbine

ActiveCN110410158AImprove heat transfer effectEnhanced convective heat transferBlade accessoriesMachines/enginesBlade plateLeading edge

The invention relates to a turbine rotor blade of a gas turbine. The turbine rotor blade of the gas turbine comprises a blade profile, a blade platform, a blade top and a blade root, wherein a coolingair channel loop is arranged in the blade, a cooling air channel and a cooling air channel inlet are arranged in the loop, and ribs are arranged in the cooling air channel; and the blade surface is divided into a blade leading edge and a blade trail edge by a pressure surface and a suction surface. The blade tail edge is provided with a tail edge exhaust slot, a tail edge channel is provided witha guide groove structure, and at least one turbulence column is arranged in the guide groove structure; and the blade root cooling air channel is divided into at least two channels by a partition plate, and the partition plate is gradually bent towards the front edge side of the blade in the airflow direction. According to the turbine rotor blade of the gas turbine, the heat exchange effect of aleading edge channel, the tail edge exhaust slot and cooling air in the blade can be improved, and the leading edge metal temperature close to the blade platform and the metal temperature of the tailedge, the blade platform close to the tail edge and the blade root can be reduced.

Owner:HANGZHOU TURBINE POWER GRP

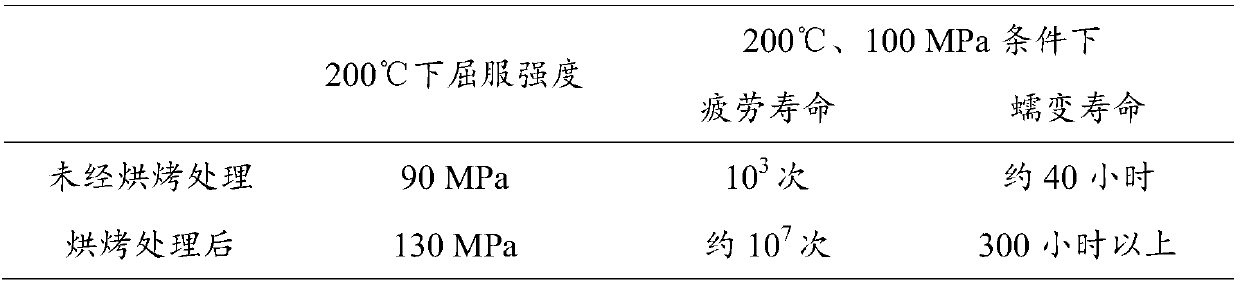

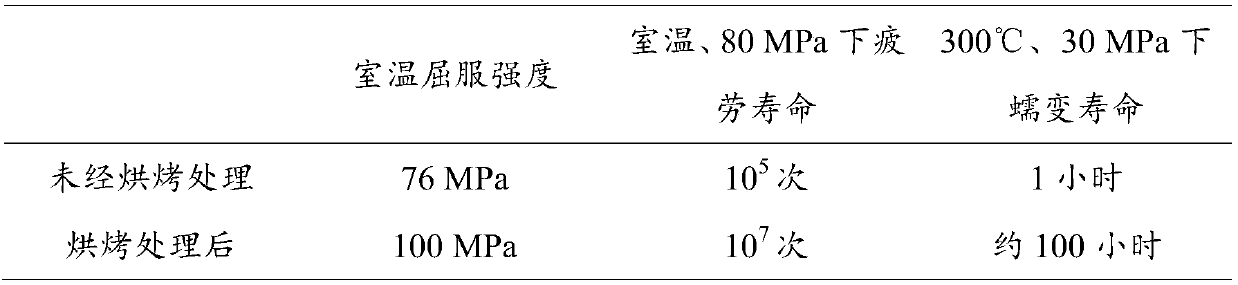

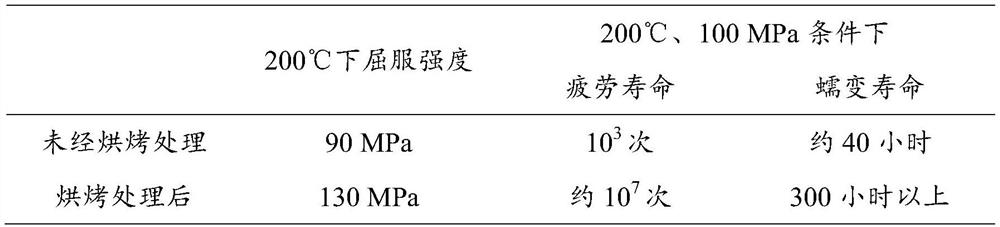

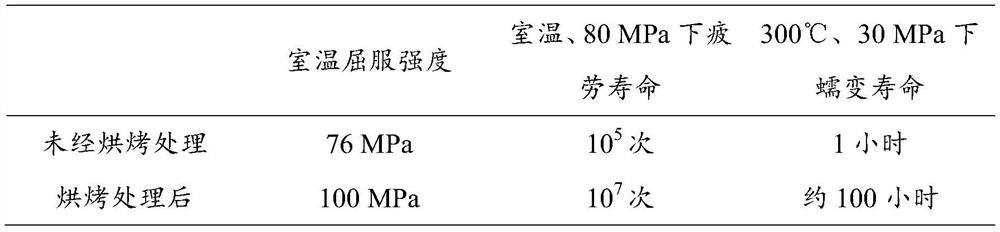

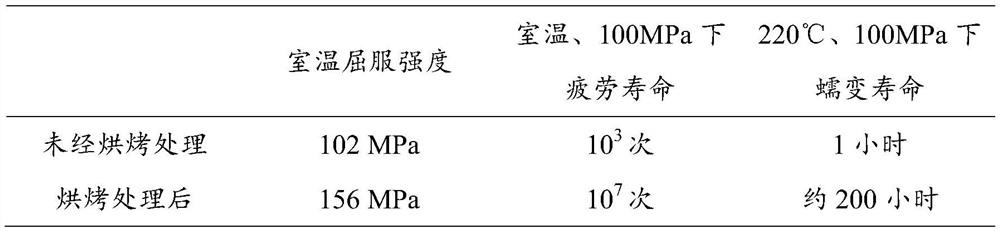

Method for prolonging long-time service life of magnesium alloy through drying

The invention discloses a method for prolonging the long-time service life of a magnesium alloy through drying. The magnesium alloy comprises, by mass, 0.1-0.65% of calcium, 0.05-1.2% of zinc and thebalance magnesium, and the mass percentage ratio of calcium to zinc is greater than or equal to 0.4; or comprises, by mass, 0.1-0.65% of calcium, 0.05-0.6 % of silicon and the balance magnesium, and the mass percentage ratio of calcium to silicon is greater than or equal to 0.9. The method comprises the steps of preparing a magnesium alloy ingot blank through a semicontinuous casting method, conducting hot rolling or hot extrusion on the magnesium alloy ingot blank to form a plate with the thickness of 2-20 mm, conducting solution treatment on the plate, conducting cold deformation on the plate at true strain of 0.01-0.07 at indoor temperature, conducting baking on the plate at 150-230 DEG C for 10-120 min and then conducting water quenching. Compared with a magnesium alloy not subjected to baking treatment, the yield strength of the magnesium alloy subjected to baking can be improved by 30% or more, and the fatigue and creep life of the magnesium alloy can be prolonged by at least 5 times under the long-time service conditions.

Owner:CENT SOUTH UNIV

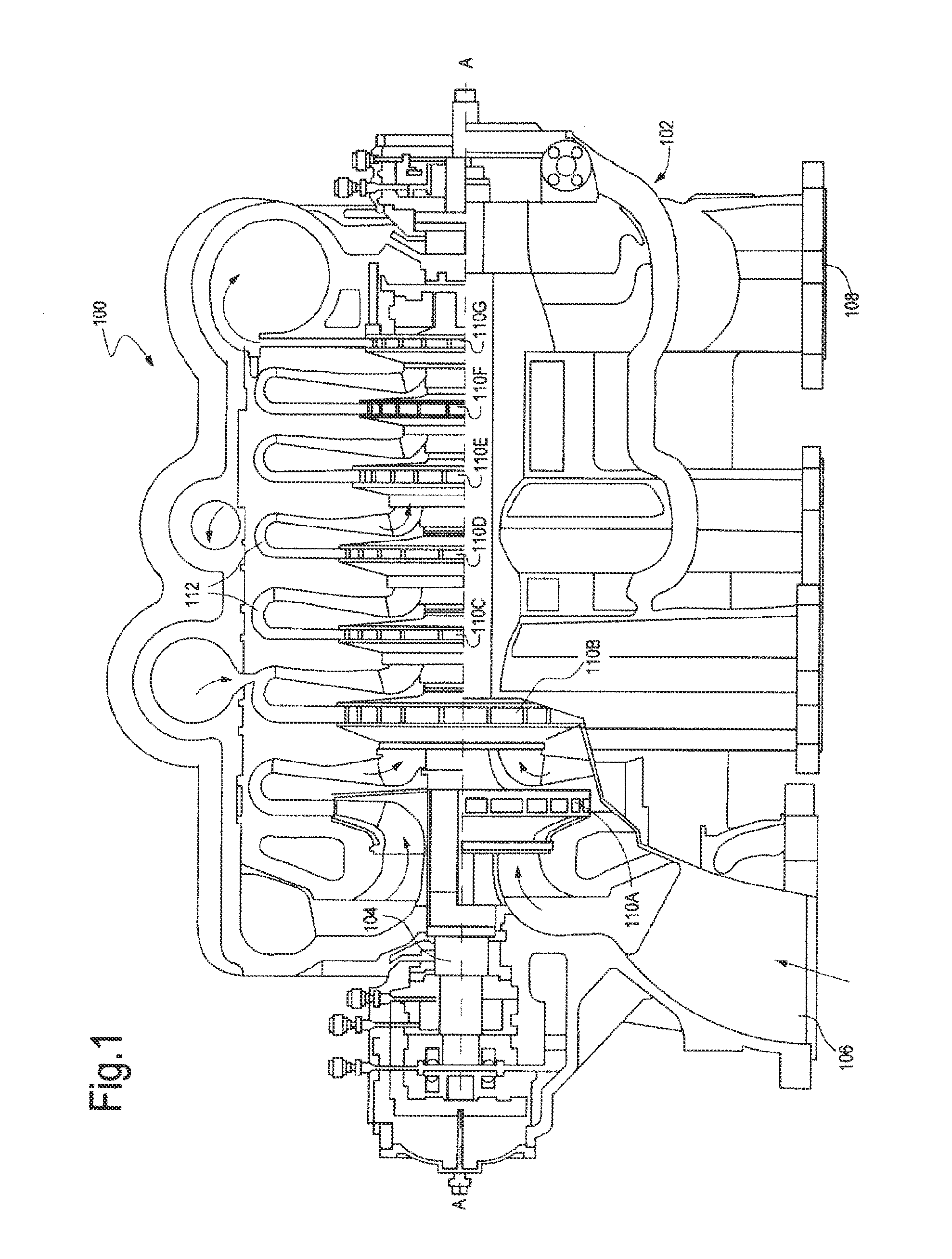

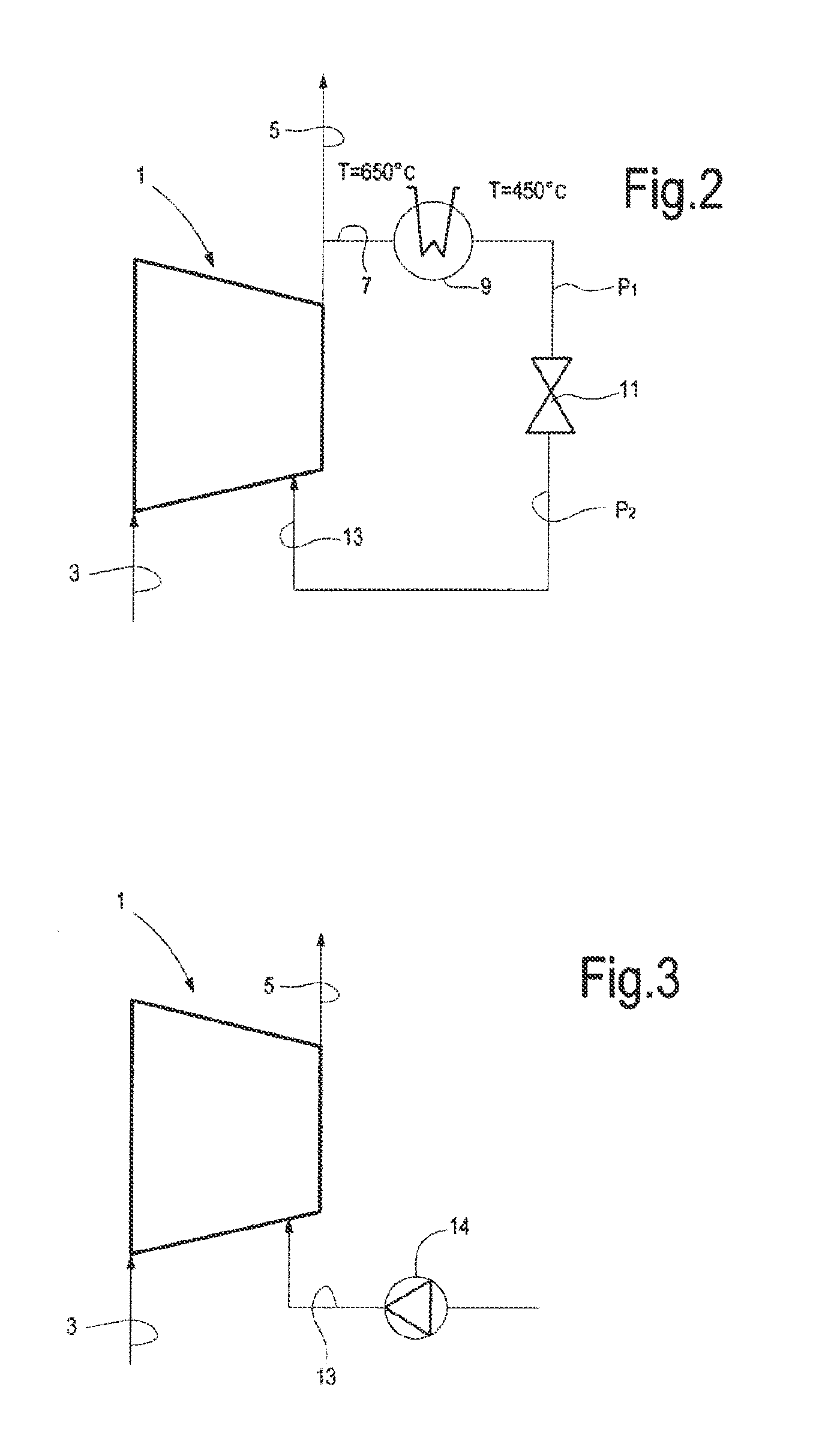

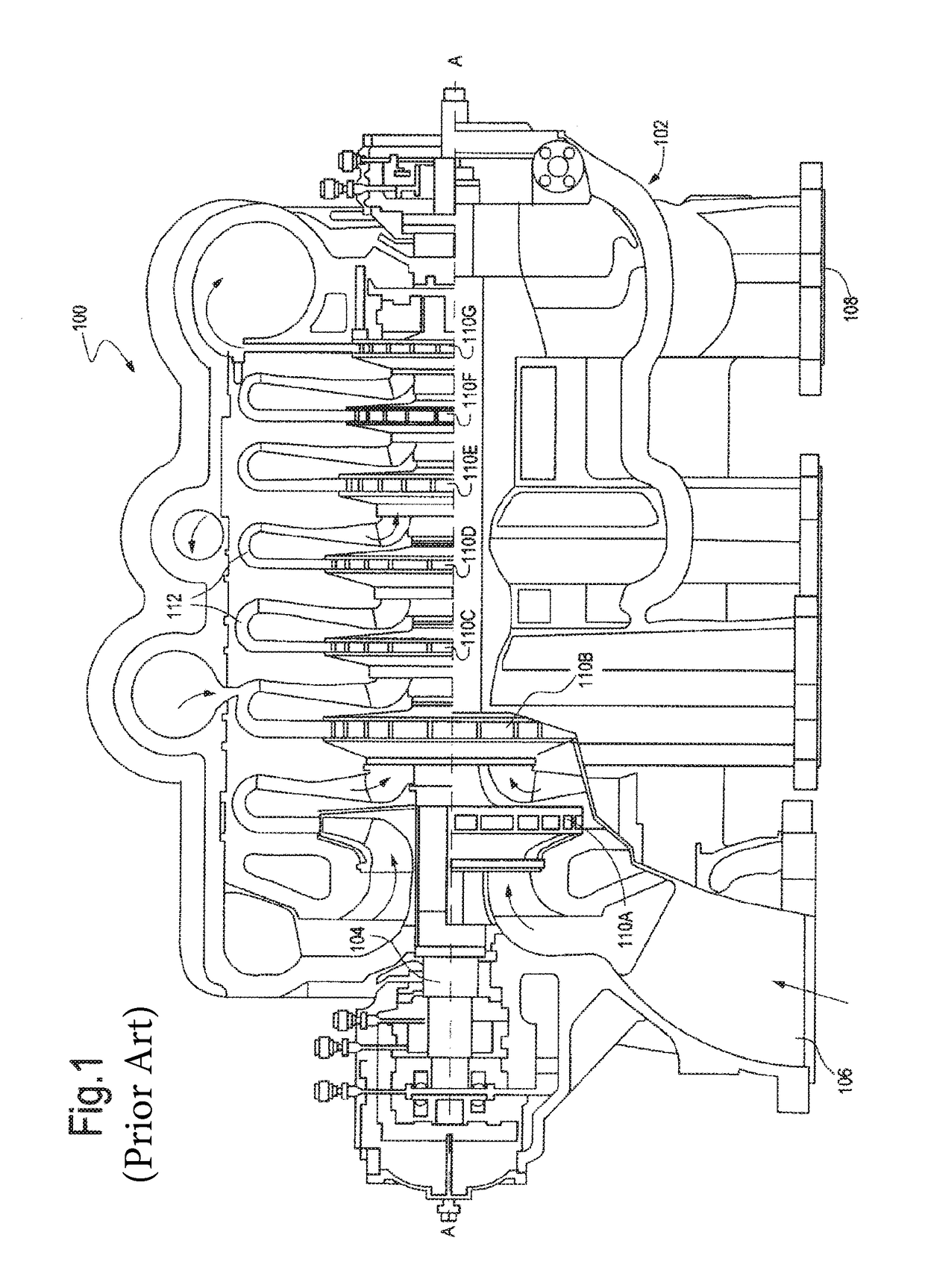

Centrifugal compressor impeller cooling

ActiveUS20150240833A1Efficiently coolIncreased creep lifePropellersRotary propellersCentrifugal compressorEngineering

A centrifugal compressor including: a casing; at least one impeller supported for rotation in the casing and provided with a hub, a shroud and an impeller eye; an impeller-eye sealing arrangement, for sealing the impeller in the region of said impeller eye. The centrifugal compressor further includes at least one cooling-medium portlocated at the impeller-eye sealing arrangement, arranged for delivering a cooling medium around the impeller eye.

Owner:NUOVO PIGNONE TECH SRL

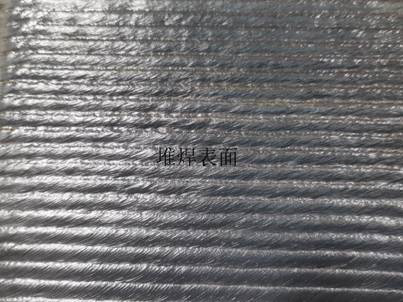

Nickel-based welding wire, manufacturing method of nickel-based welding wire and welding process of nickel-based welding wire

ActiveCN114505619AGuaranteed high temperature oxidation resistanceGuaranteed solid solution strengtheningNuclear energy generationWelding/cutting media/materialsHeat transfer tubeDuctility

The invention provides a nickel-based welding wire, a manufacturing method of the nickel-based welding wire and a welding process of the nickel-based welding wire, relates to the technical field of welding materials, and aims to solve the problem of poor welding effect of a heat transfer tube made of an Incoloy800H material. The nickel-based welding wire comprises an outer skin and a flux core filled in the outer skin. The outer skin is an Inconel 625 belt, and the flux core comprises, by mass, 28.0%-32.0% of Co, 19.0%-23.0% of Cr, 7.0%-9.0% of Mo, 1.5%-3.5% of Nb, 1.0%-1.5% of Cu, 1.5%-3.5% of W, 0.6%-1.0% of B, 0.4%-0.6% of La and the balance Ni. According to the nickel-based welding wire provided by the invention, a joint part can keep relatively high tensile strength and ductility under normal-temperature and high-temperature conditions.

Owner:XIAN THERMAL POWER RES INST CO LTD

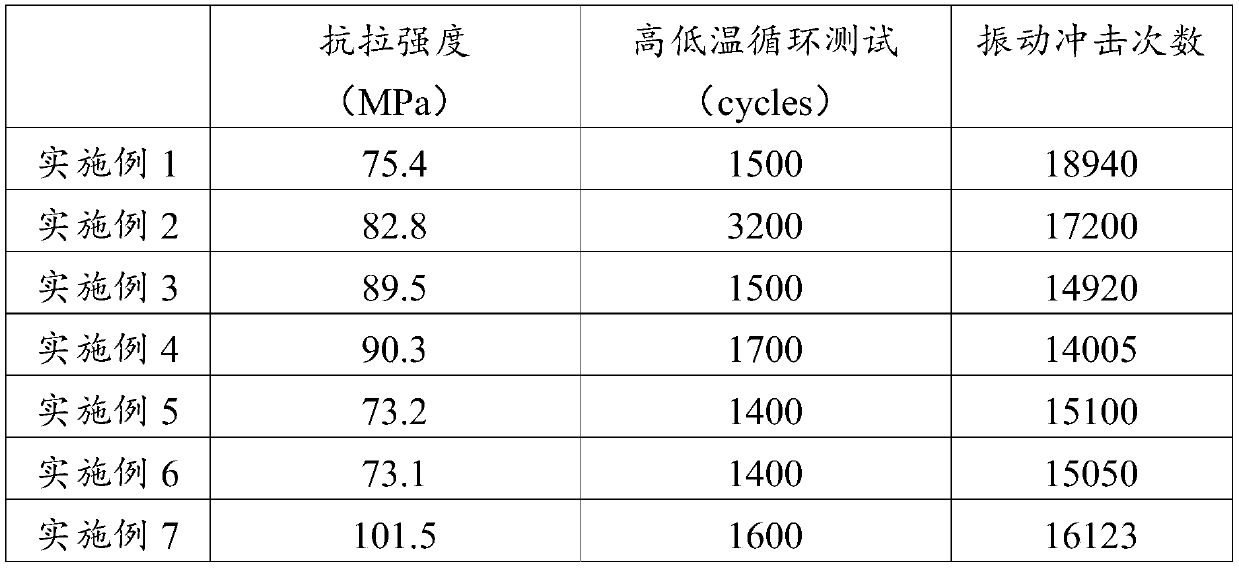

Sn-based soldering flux and preparation method thereof

ActiveCN110153587AAvoid reunionSolve difficultyWelding/cutting media/materialsSoldering mediaMolten stateNanoparticle

The invention relates to a Sn-based soldering flux and a preparation method thereof. The Sn-based soldering flux is mainly prepared by uniformly mixing nano-alumina dispersion strengthened copper Cu-Al2O3 with a molten-state Sn-based alloy. According to the Sn-based soldering flux and the preparation method thereof, the problem of non-uniform dispersion distribution of nano-particles in the Sn-based alloy is solved; and compared with an existing product, the soldering flux has the advantages of being high in tensile strength, high in elongation, high in bonding strength after welding, excellent in high-temperature and low-temperature cyclic impact resistance, high in welding reliability, and the like.

Owner:BEIJING COMPO ADVANCED TECH

High Nb-TiAl alloy added with nano yttrium oxide and preparation method of high Nb-TiAl alloy

The invention discloses a high Nb-TiAl alloy added with nano yttrium oxide and a preparation method of the high Nb-TiAl alloy, relates to the field of intermetallic compounds and preparation processesthereof, and aims to solve the technical problems of poor high-temperature mechanical property and weak creep resistance of an existing TiAl alloy. The alloy comprises, by mole: Al: 45-48%, Nb: 6-10%, V: 2.5-3.5%, nano yttrium oxide: 0.05-3%, and the balance Ti. The preparation method comprises the steps of briquetting and shaping raw materials; melting alloy block materials, and adding an yttrium oxide prefabricated block for smelting to obtain an alloy ingot; and then carrying out homogenization annealing treatment to finish the preparation. According to the high Nb-TiAl alloy added with the nano yttrium oxide and the preparation method of the high Nb-TiAl alloy, the high-temperature mechanical property and high-temperature creep resistance of the high Nb-TiAl alloy are improved; and the high Nb-TiAl alloy added with the nano yttrium oxide is applied to the field of high-temperature structural materials.

Owner:HARBIN INST OF TECH

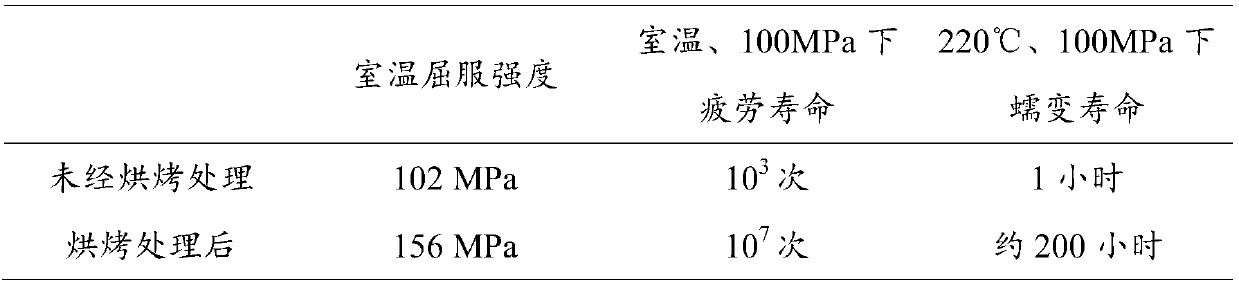

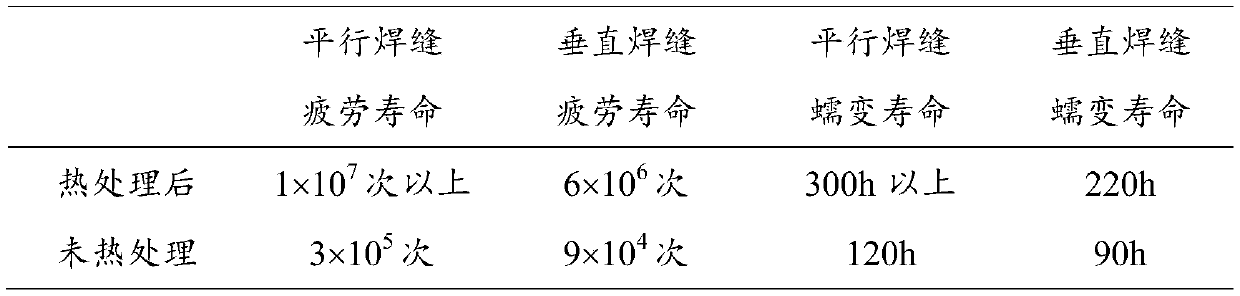

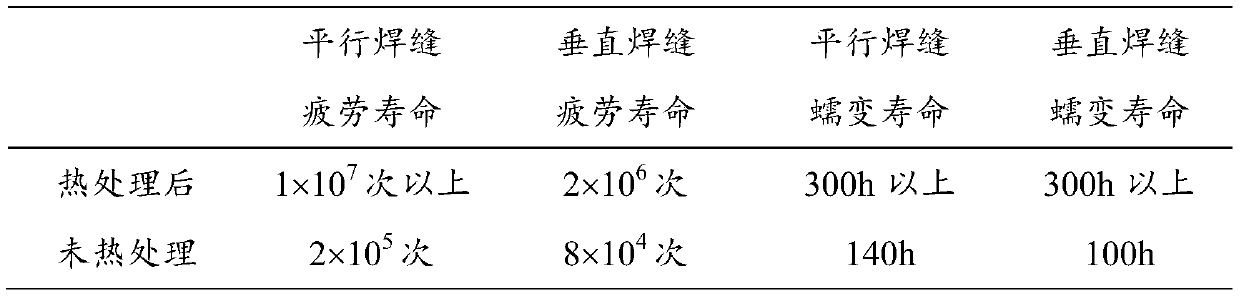

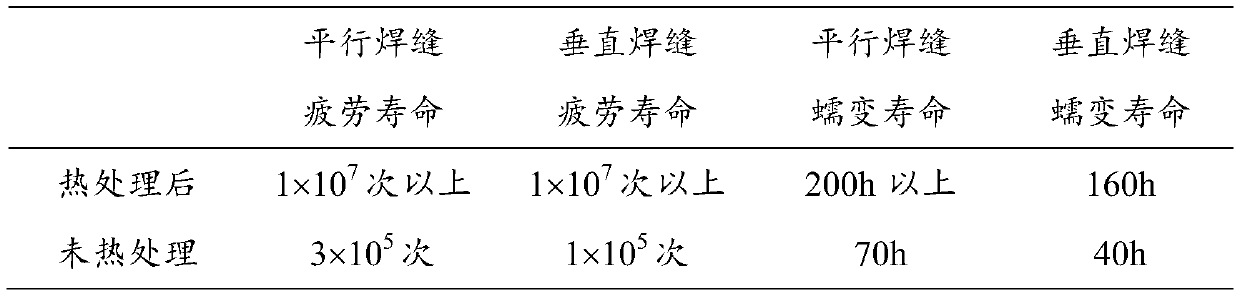

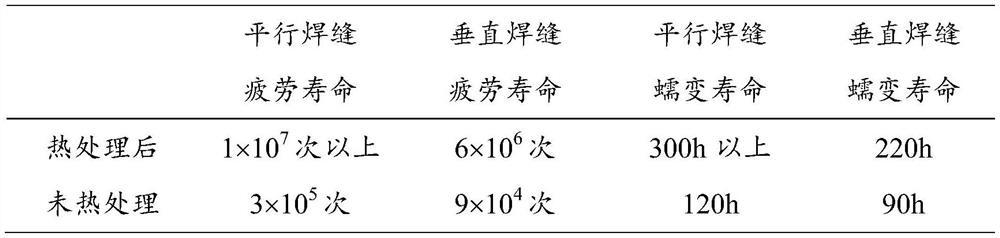

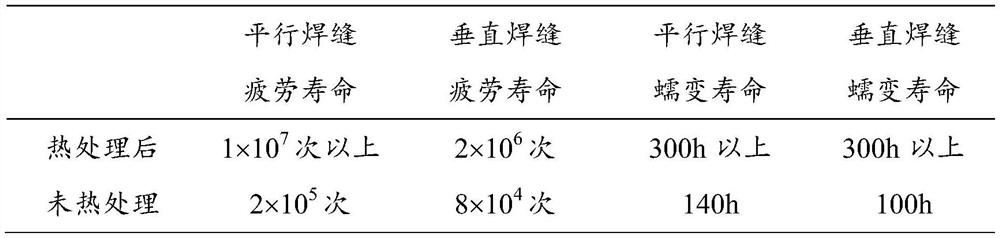

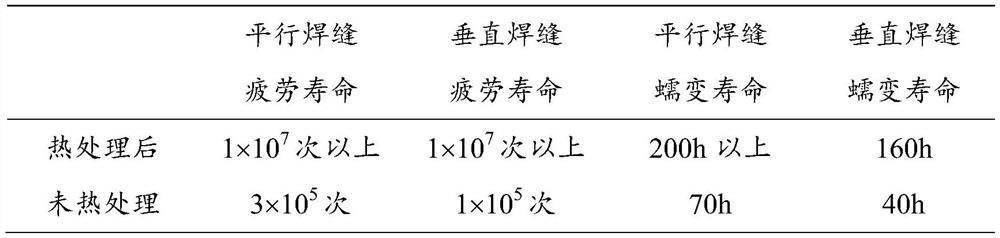

Thermal treatment method capable of prolonging long-time service life of welding seams in magnesium-alloy friction stir welding process

InactiveCN110438325AIncrease the degree of lattice distortionIncrease recrystallization nucleation pointFurnace typesHeat treatment furnacesQuenchingWeld seam

The invention discloses a thermal treatment method capable of prolonging the long-time service life of welding seams in the magnesium-alloy friction stir welding process. The method comprises the steps that aging treatment and water quenching are conducted on a magnesium alloy subjected to solution treatment for 0.5 h to 72 h at 180 DEG C to 280 DEG C; friction stir welding is conducted at room temperature, wherein the rotating speed ranges from 100 rpm to 1,000 rpm, and the welding speed ranges from 20 mm / min to 120 mm / min; and annealing treatment is conducted on the welded magnesium alloy for 0.5 h to 10 h at 250 DEG C to 350 DEG C, the magnesium alloy is directly cooled to 100 DEG C to 200 DEG C after being annealed, and then aging treatment and water quenching are conducted for 0.5 h to 6 h. According to the thermal treatment method, a precipitated phase is introduced for the magnesium alloy, the lattice distortion degree is increased, and the crystallization rate is increased; andrare earth magnesium alloy or high-alloyed magnesium alloy which is difficult to recrystallize is rapidly crystallized in the friction stir welding process, so that the yield strength of the weldingseams is improved, and synchronous improvement of the long-time service lives in the directions parallel to or perpendicular to the welding seam direction is achieved.

Owner:CENT SOUTH UNIV

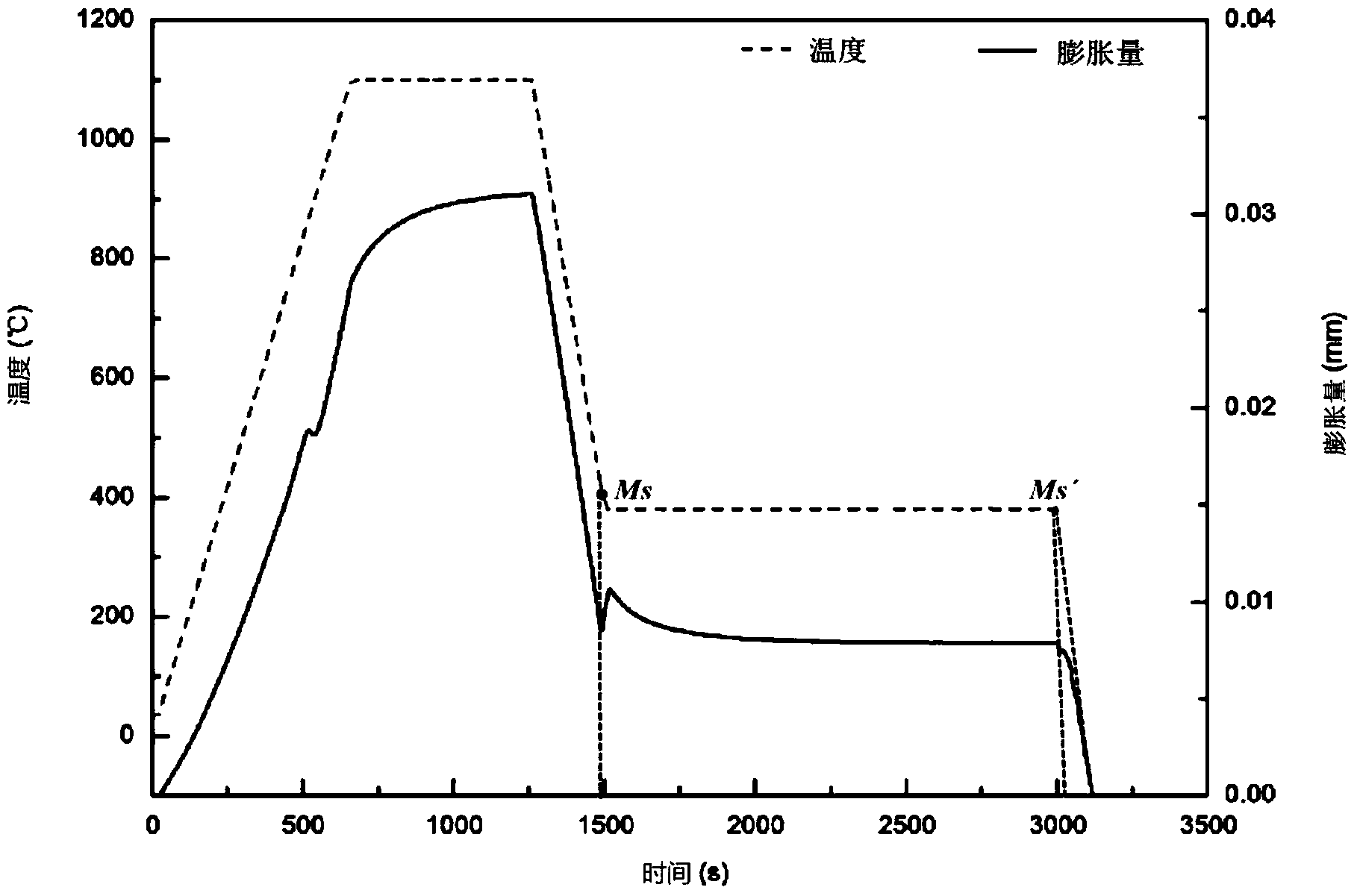

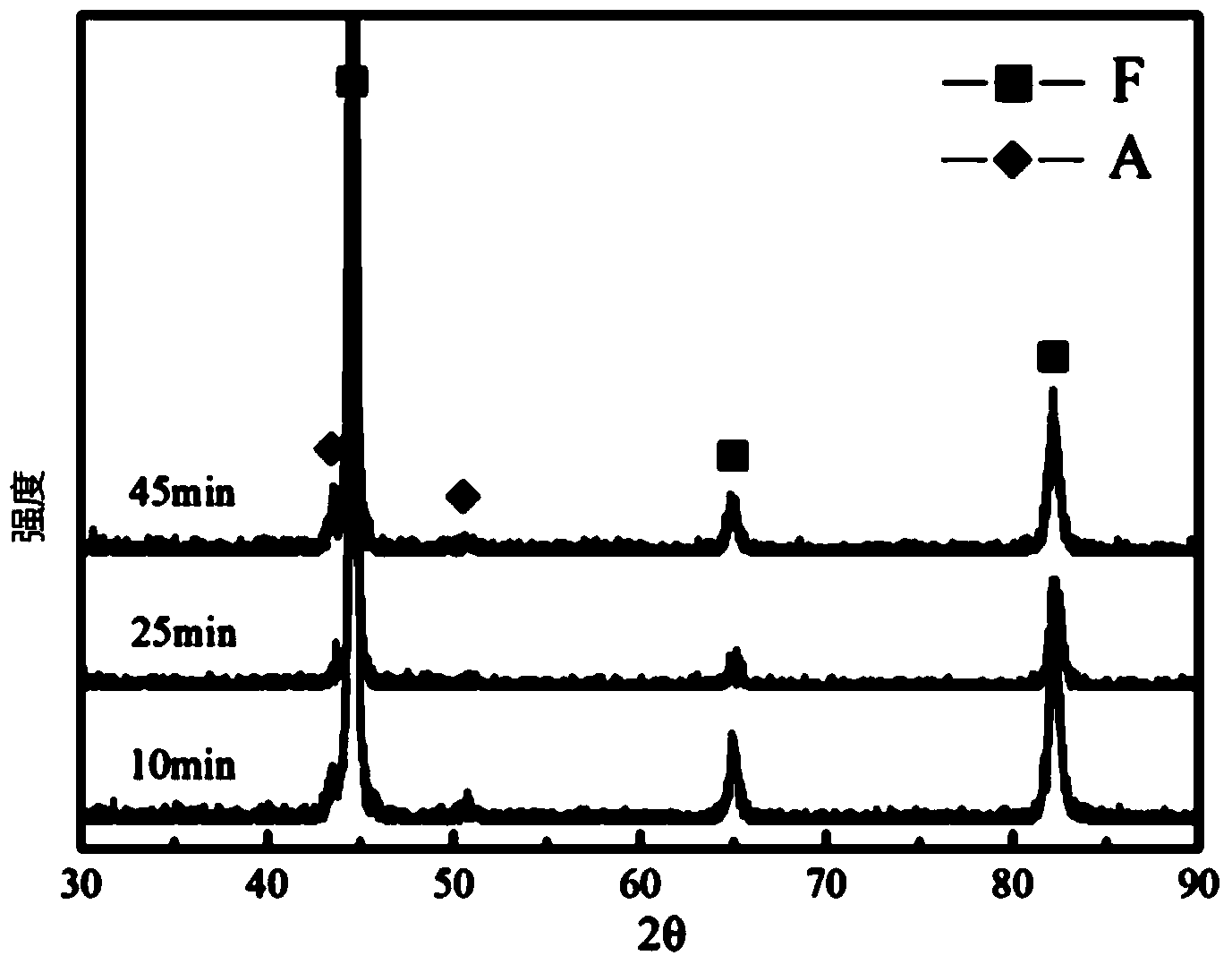

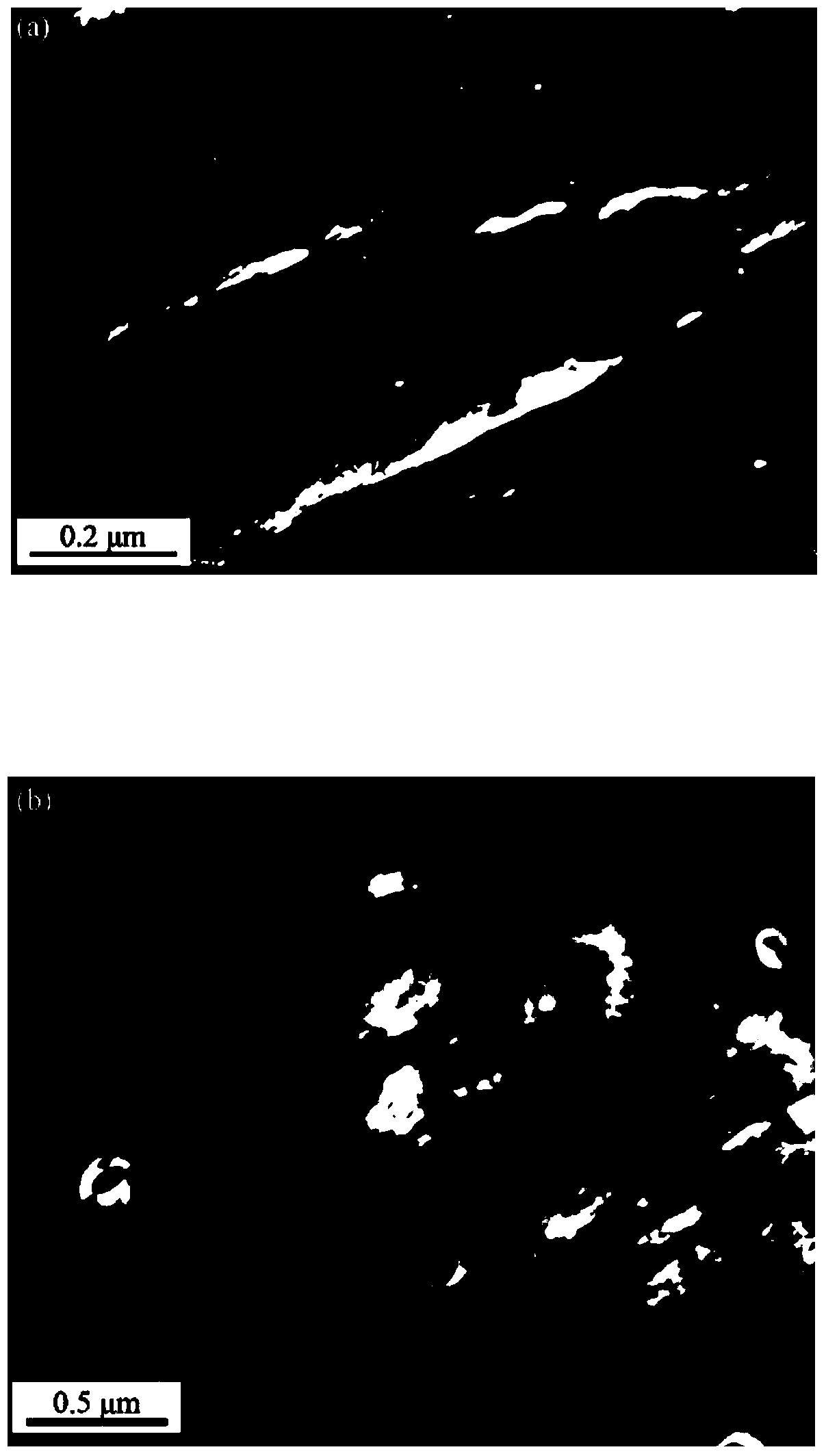

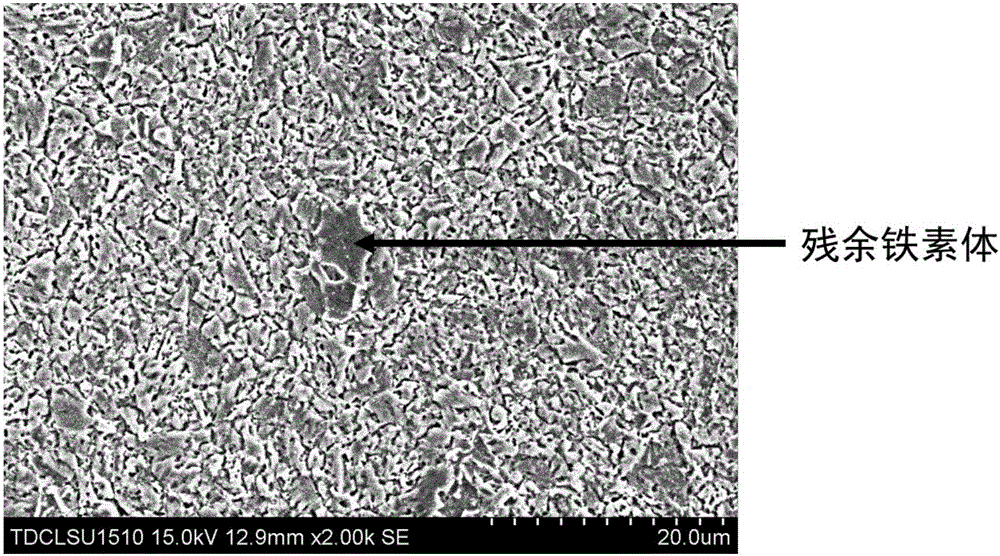

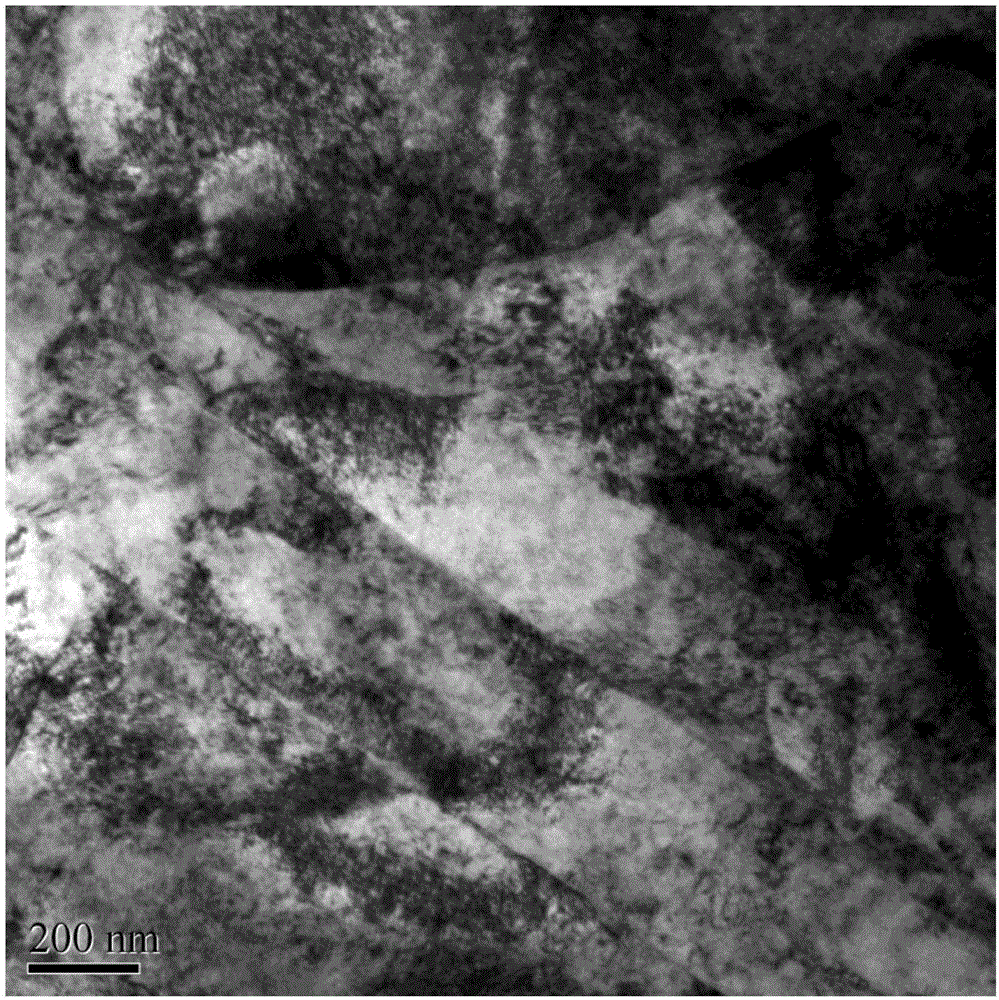

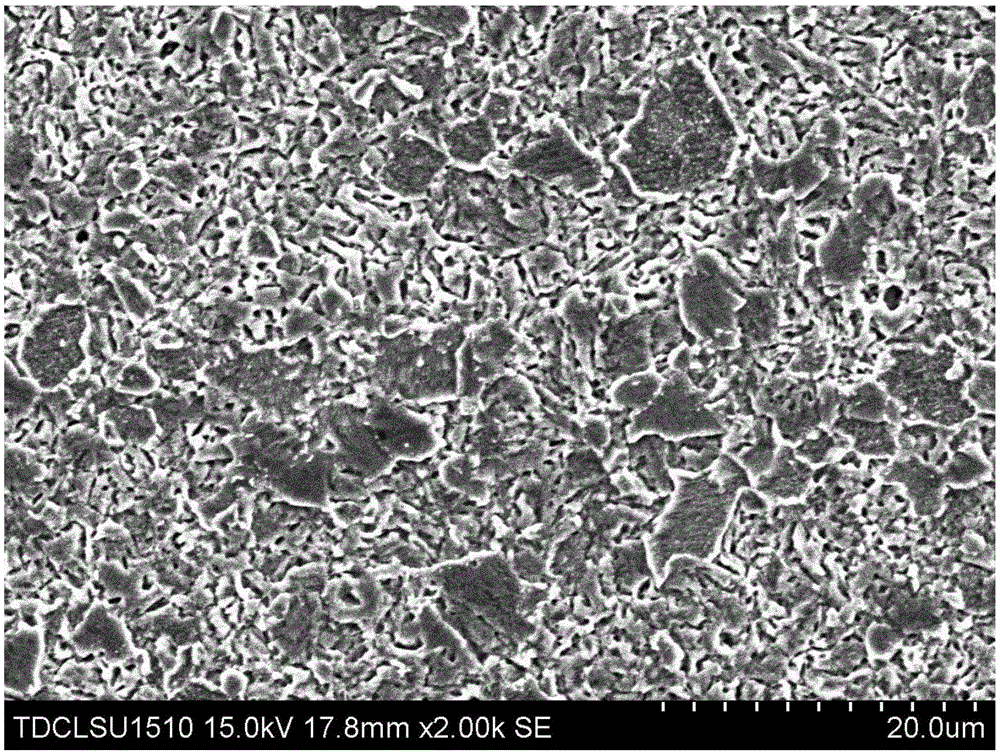

Method for obtaining retained austenite in ferrite heat resistant steel T91

InactiveCN103866101AIncreased creep lifeHigh strengthHeat treatment process controlProcess efficiency improvementLathRoom temperature

The invention relates to a method for obtaining retained austenite in ferrite heat resistant steel T91. The heat treatment process comprises the following steps: performing heat treatment on a T91 steel pipe subjected to hot rolling, namely heating to the temperature of 1100-1200 DEG C at a speed of 4 DEG C per second, and preserving the temperature for 10-20 minutes; continuously cooling to room temperature at a speed of 3 DEG C per second; determining the initial temperature (Ms) and ending temperature (Mf) of martensite phase transformation of the T91 steel in the heat treatment continuous cooling process according to a changing curve of the obtained linear expansion amount along with temperature; heating another identical T91 steel pipe to the temperature of 1100-1200 DEG C at a speed of 4 DEG C per second, and preserving the temperature for 10-20 minutes; and cooling to an optional temperature between Ms and Mf obtained in the step 1 at a speed of 3 DEG C per second, preserving the temperature for 10-45 minutes, and continuously cooling to room temperature at the speed of 3 DEG C per second. The retained austenite existing in a martensite lath boundary in a film form can be obtained in a sample subjected to heat treatment.

Owner:TIANJIN UNIV

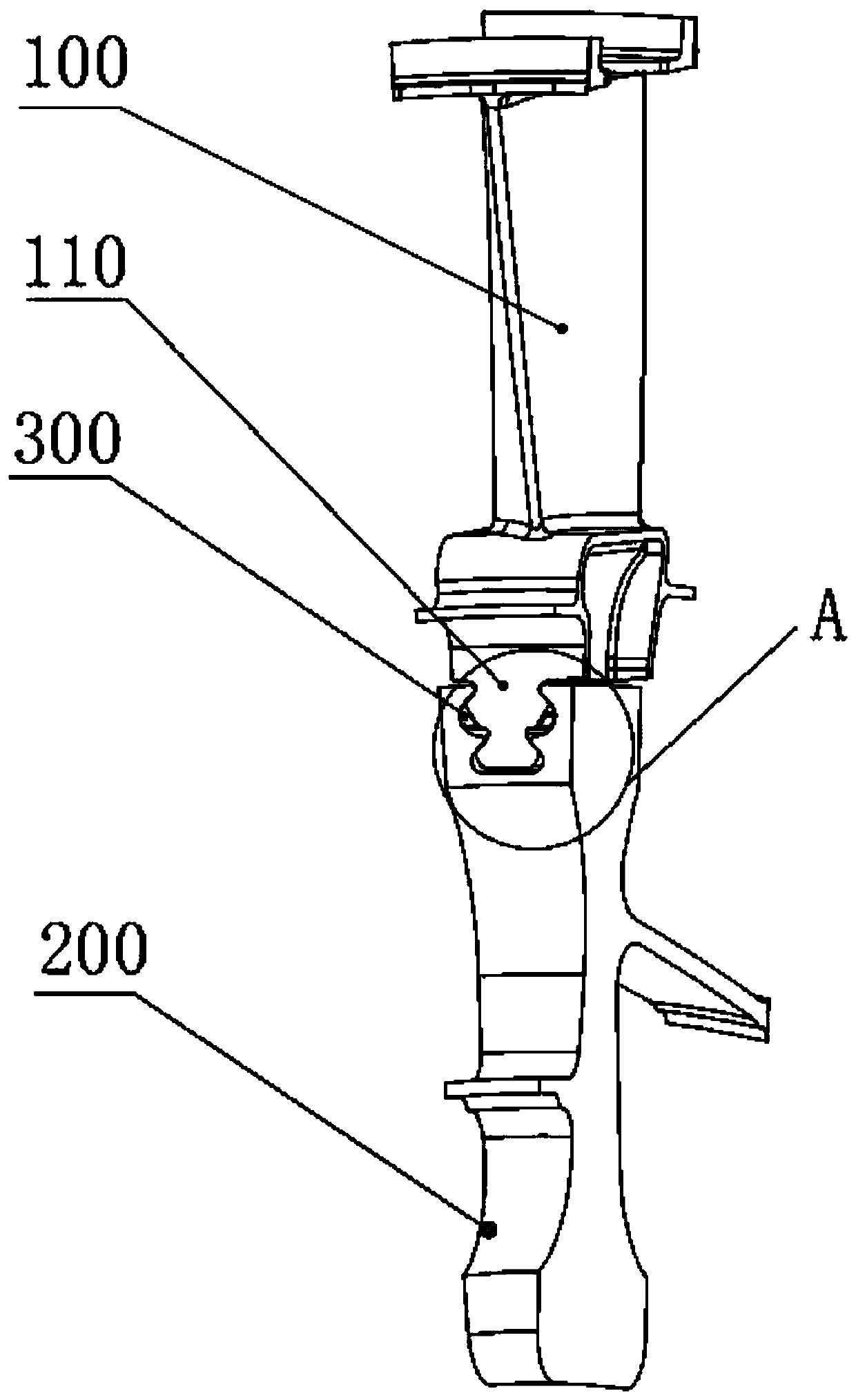

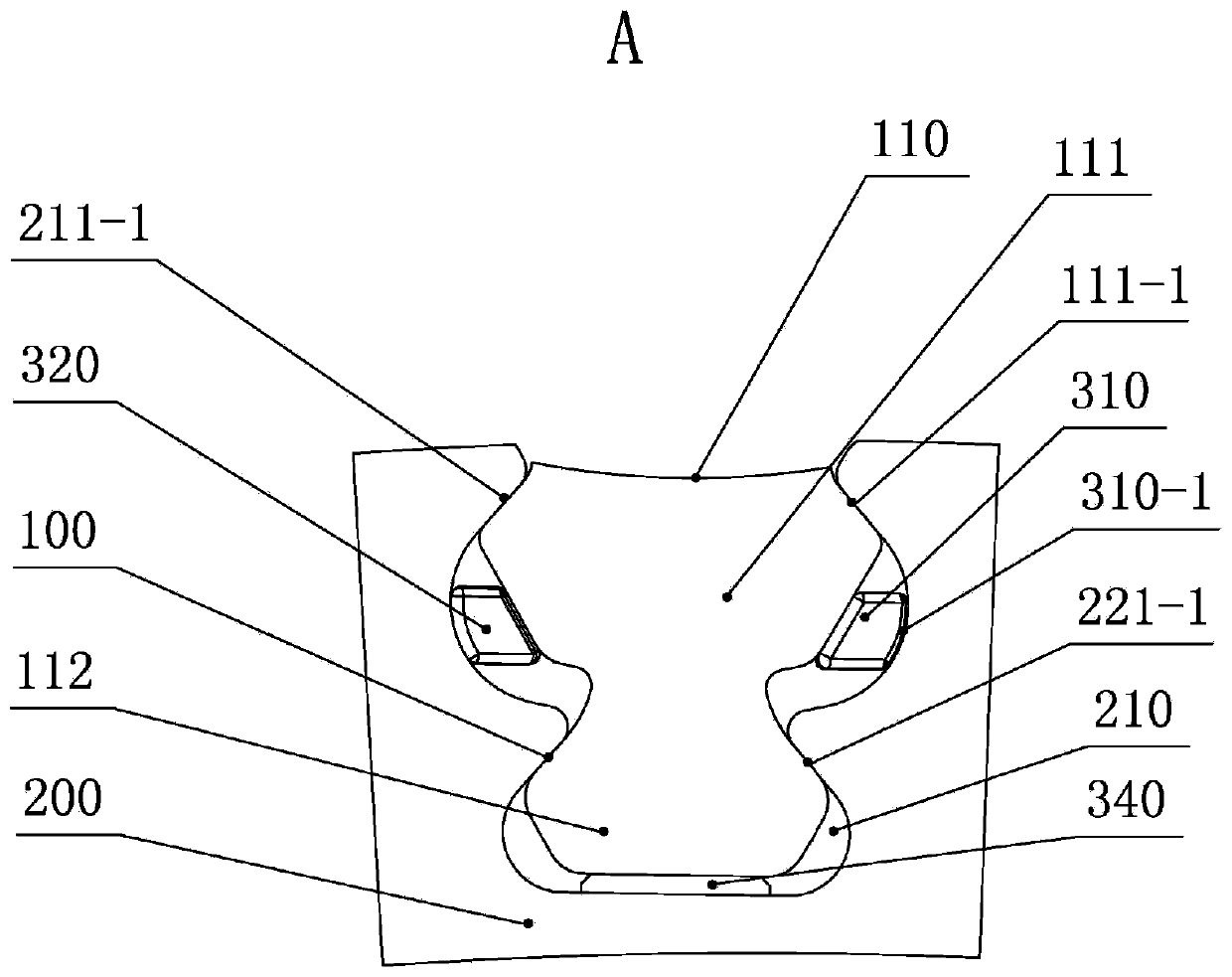

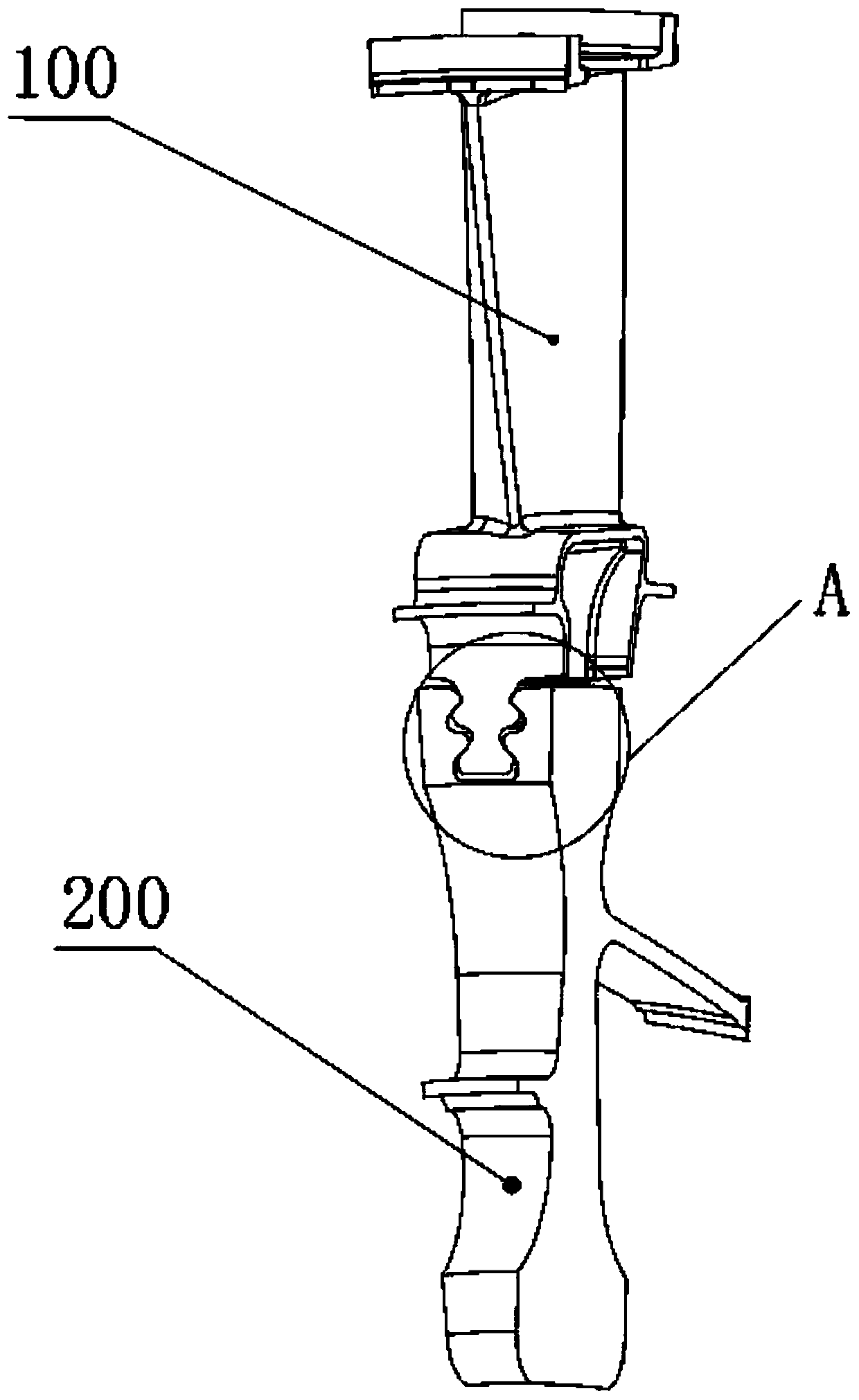

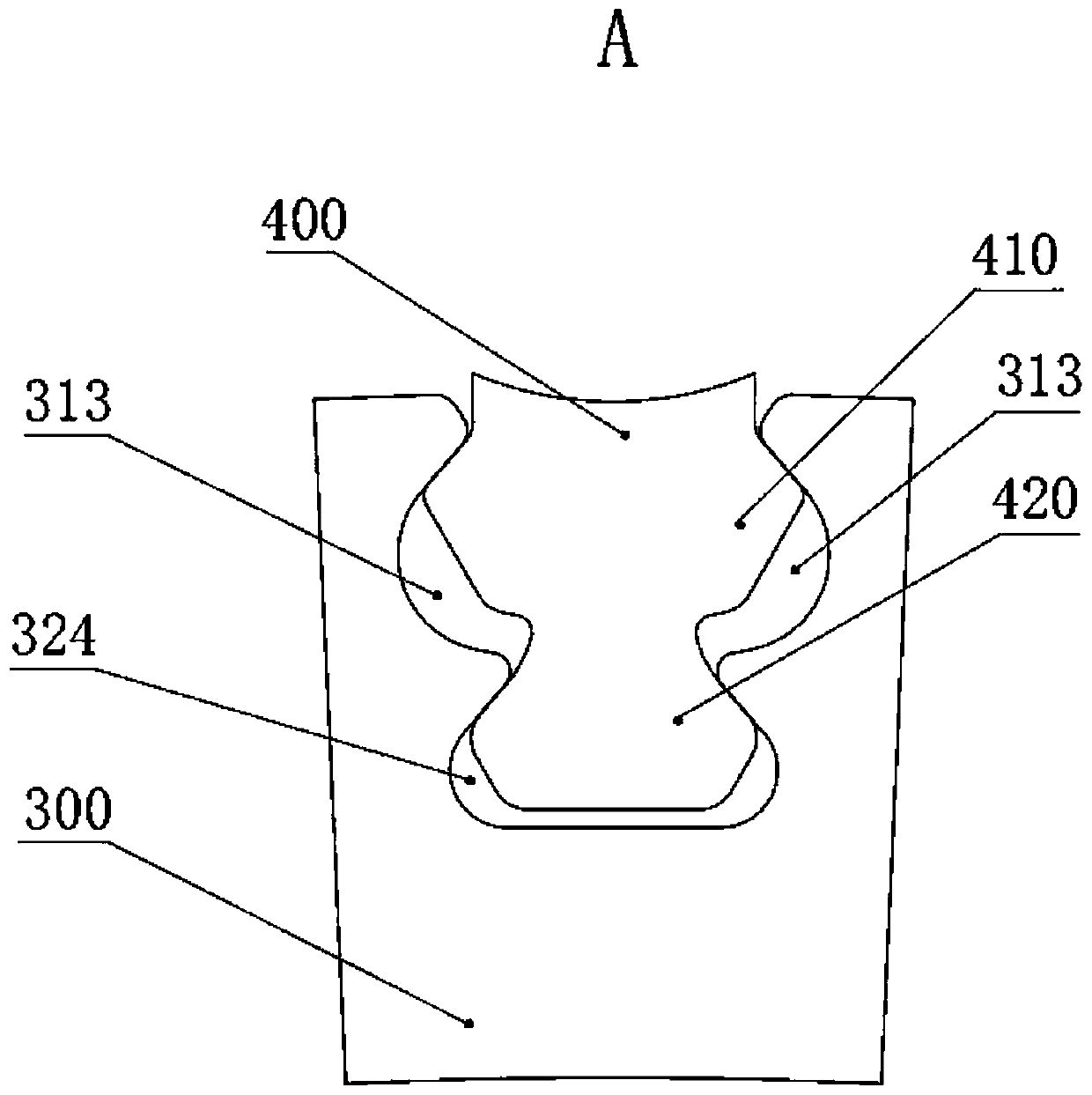

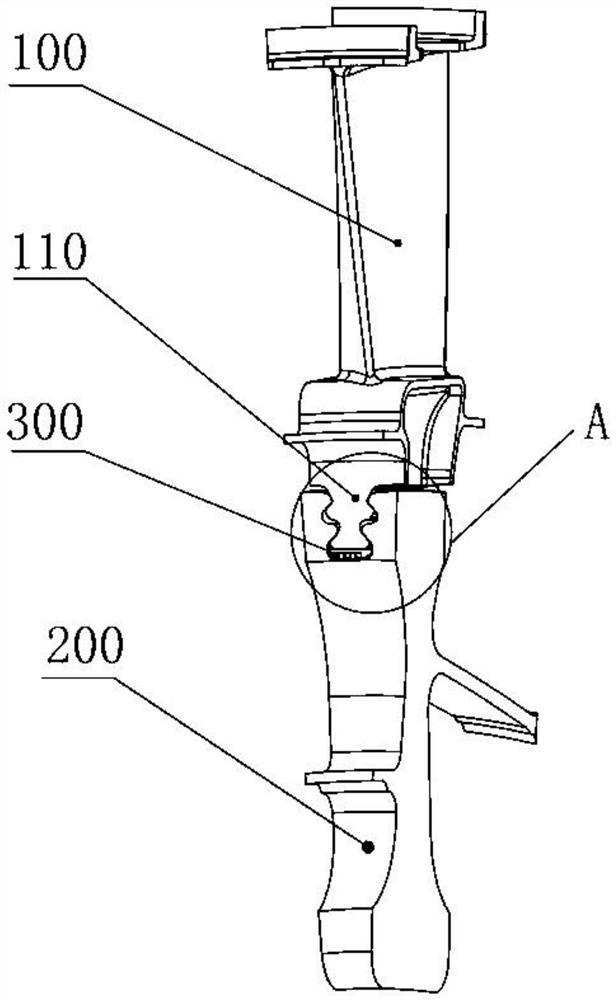

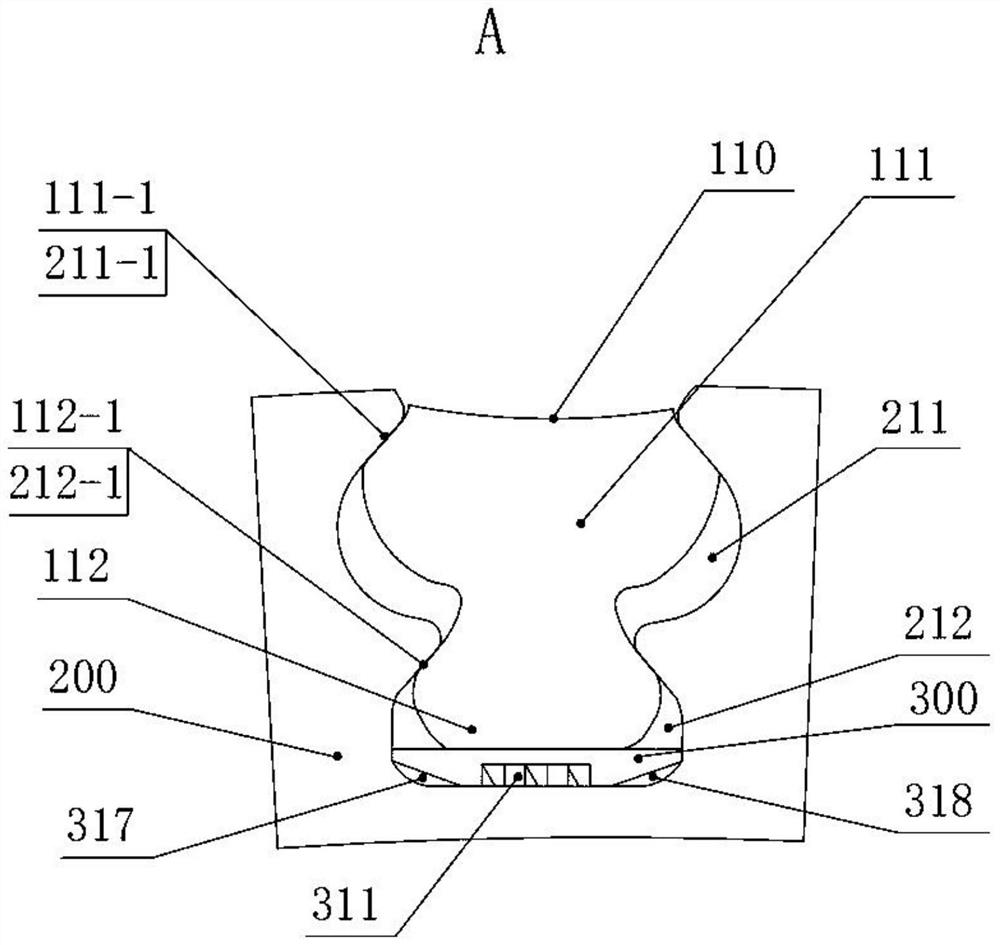

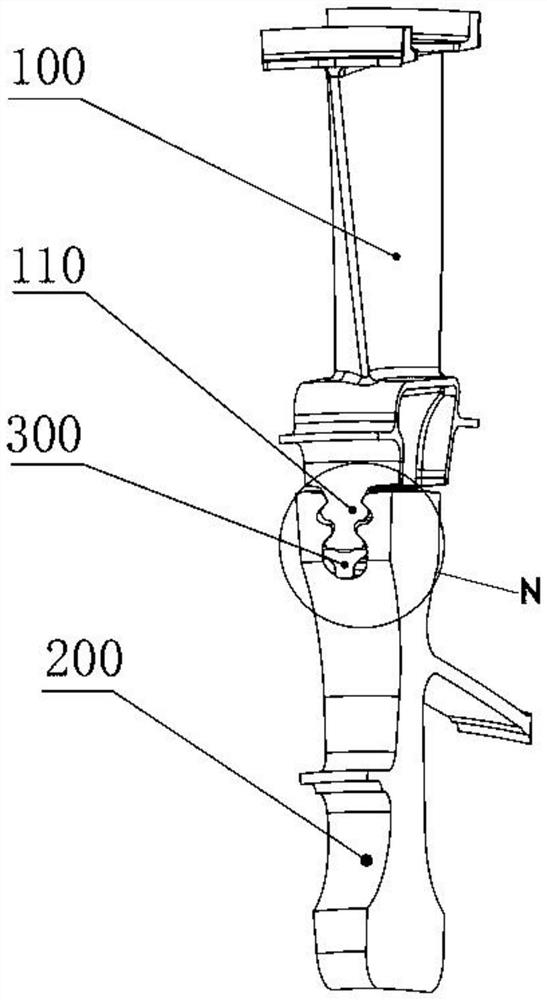

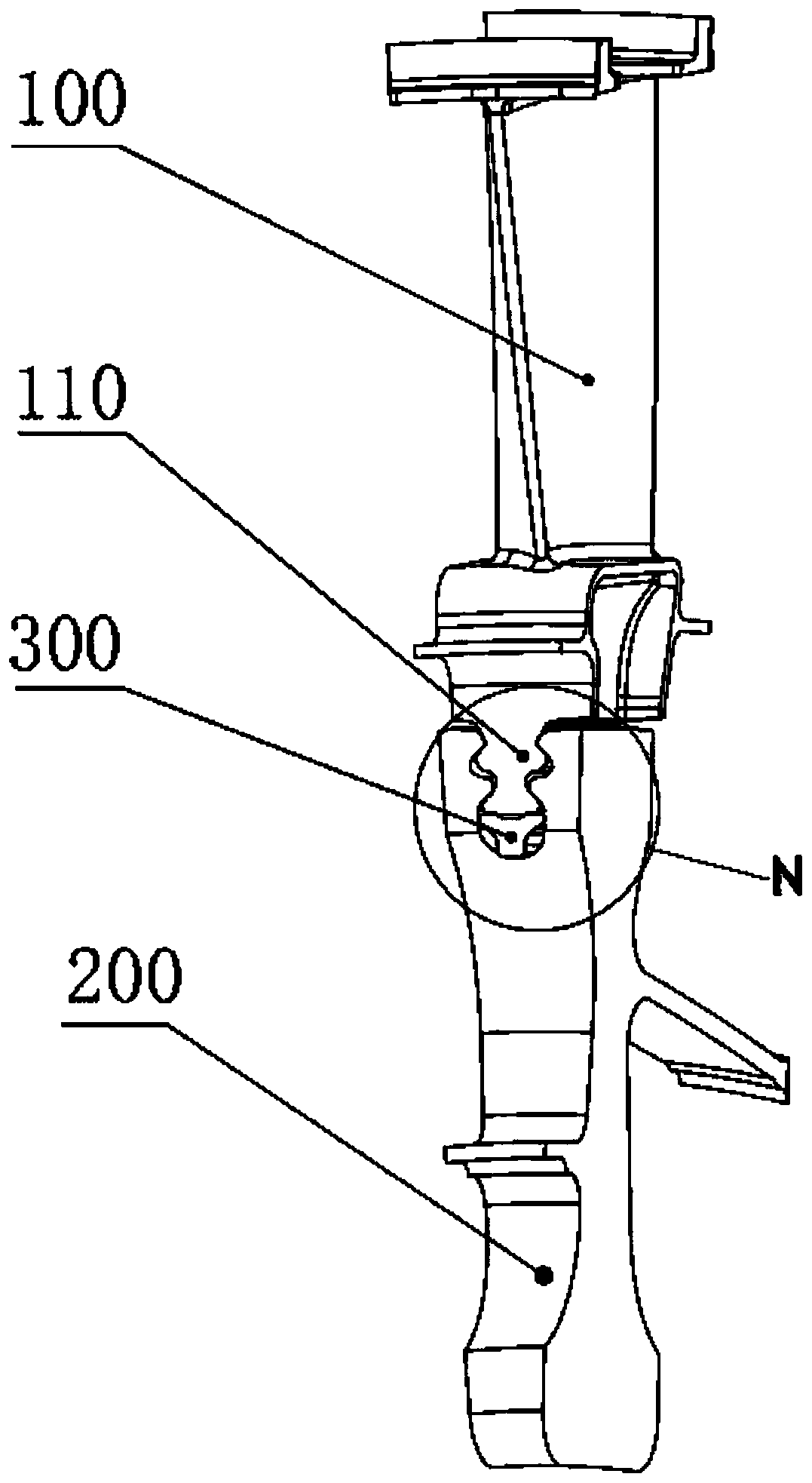

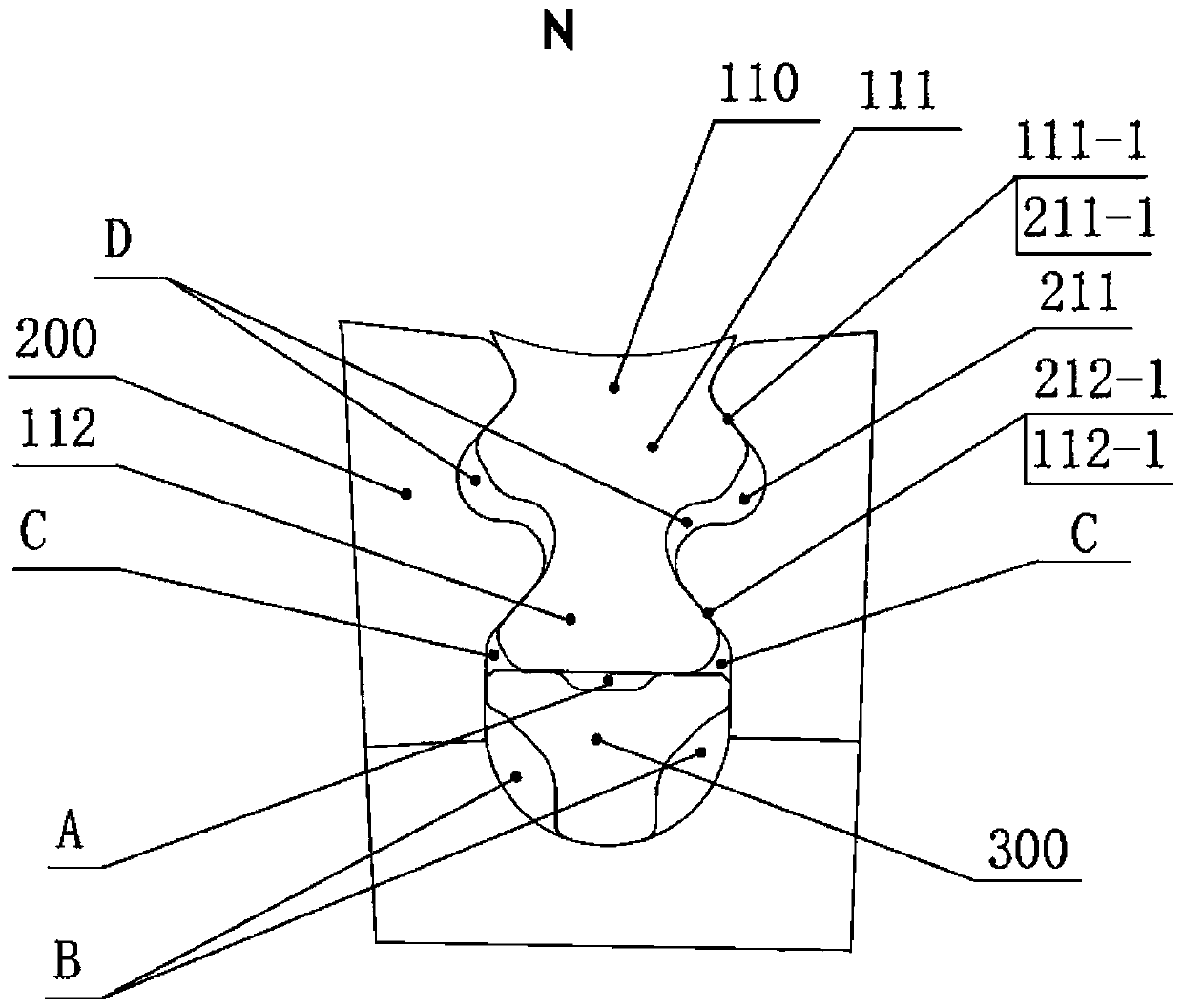

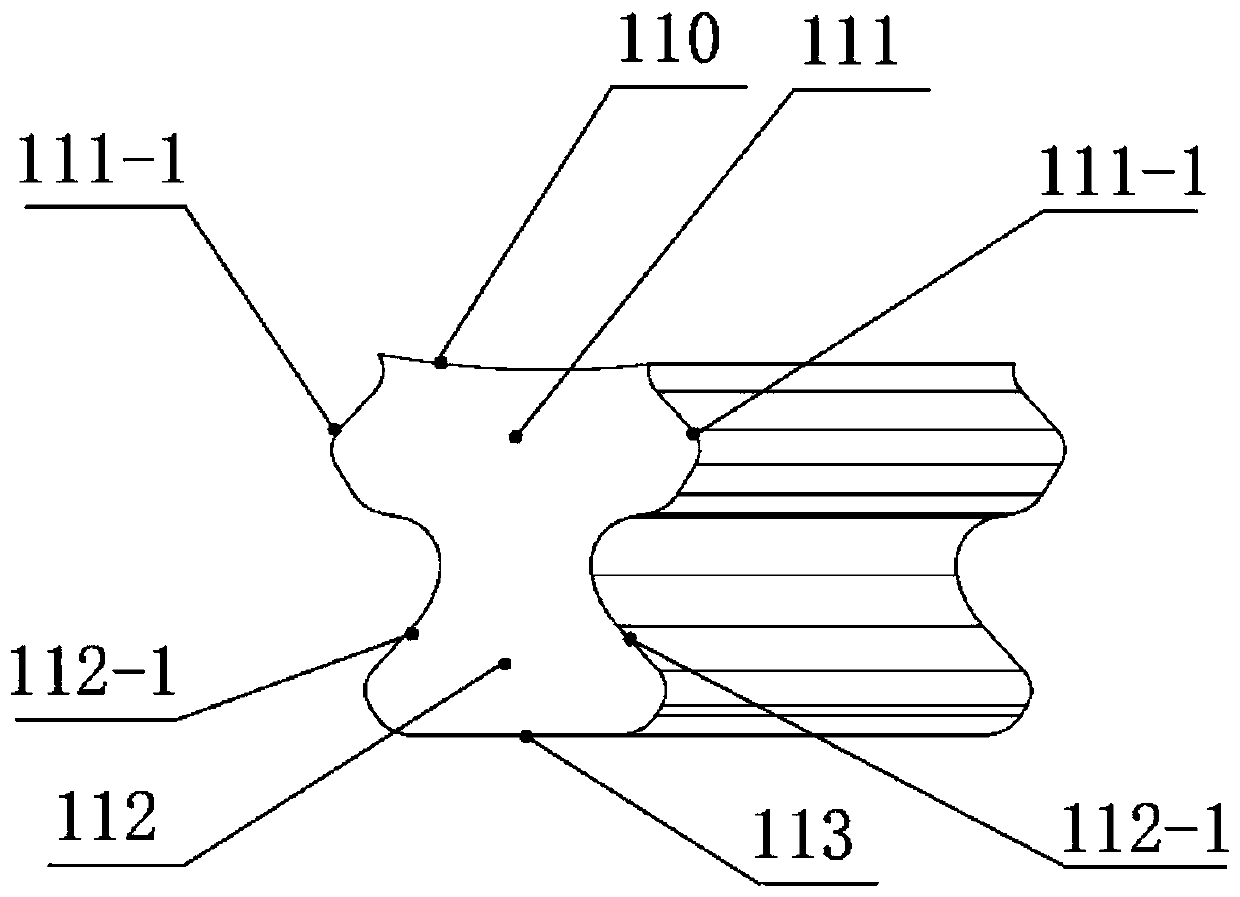

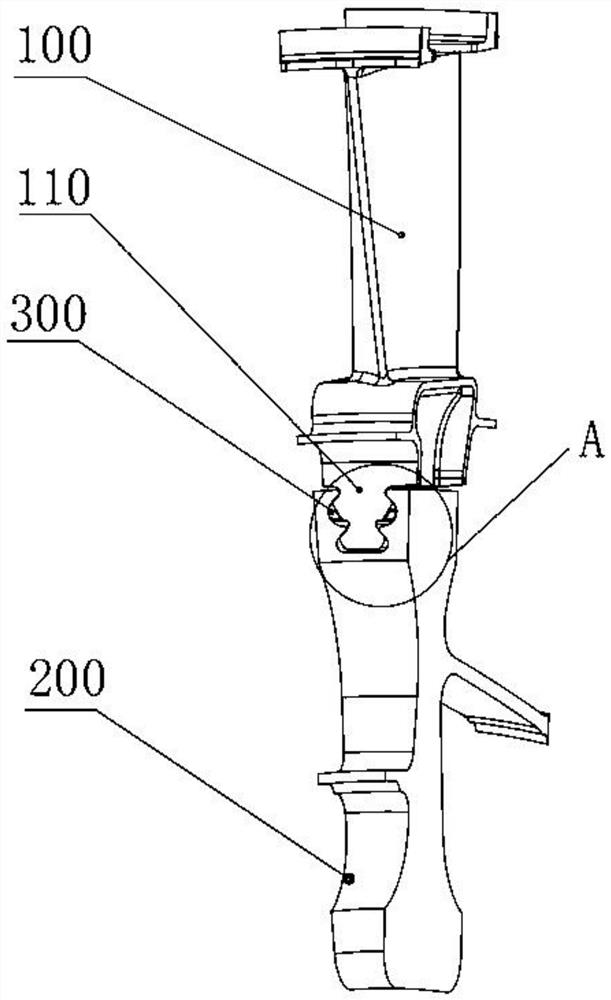

Turbine rotor device with pressing structure

ActiveCN111305908AStable positionBig spaceBlade accessoriesMachines/enginesCold airClassical mechanics

The invention relates to a turbine rotor device with a pressing structure. The turbine rotor device comprises a blade and a wheel disc which are connected through a fir-shaped tenon and mortises in amatched mode, and further comprises a pressing device installed in a gap between the tenon and the mortises in an interference mode, a bottom face supporting plate arranged on the pressing device is located at the bottom of the mortises and attached to the end face of the tenon, and supporting columns are symmetrically arranged in gaps between the two sides of tenon teeth of the tenon and the mortises, so that the tenon teeth are pressed on the inner walls of the mortises. According to the turbine rotor device, the relative positions of the tenon teeth and the mortises are fixed, the area of gaps where cold air passes through is increased, the temperature of a wheel flange part and the connecting positions of the blade tenon and the wheel disc mortises is reduced, the thermal stress of theblade tenon is reduced, and the creep life of the blade tenon, the wheel disc mortise structure and a wheel disc wheel flange is prolonged.

Owner:BEIJING SNECMA SAIC TURBOTECH CO LTD

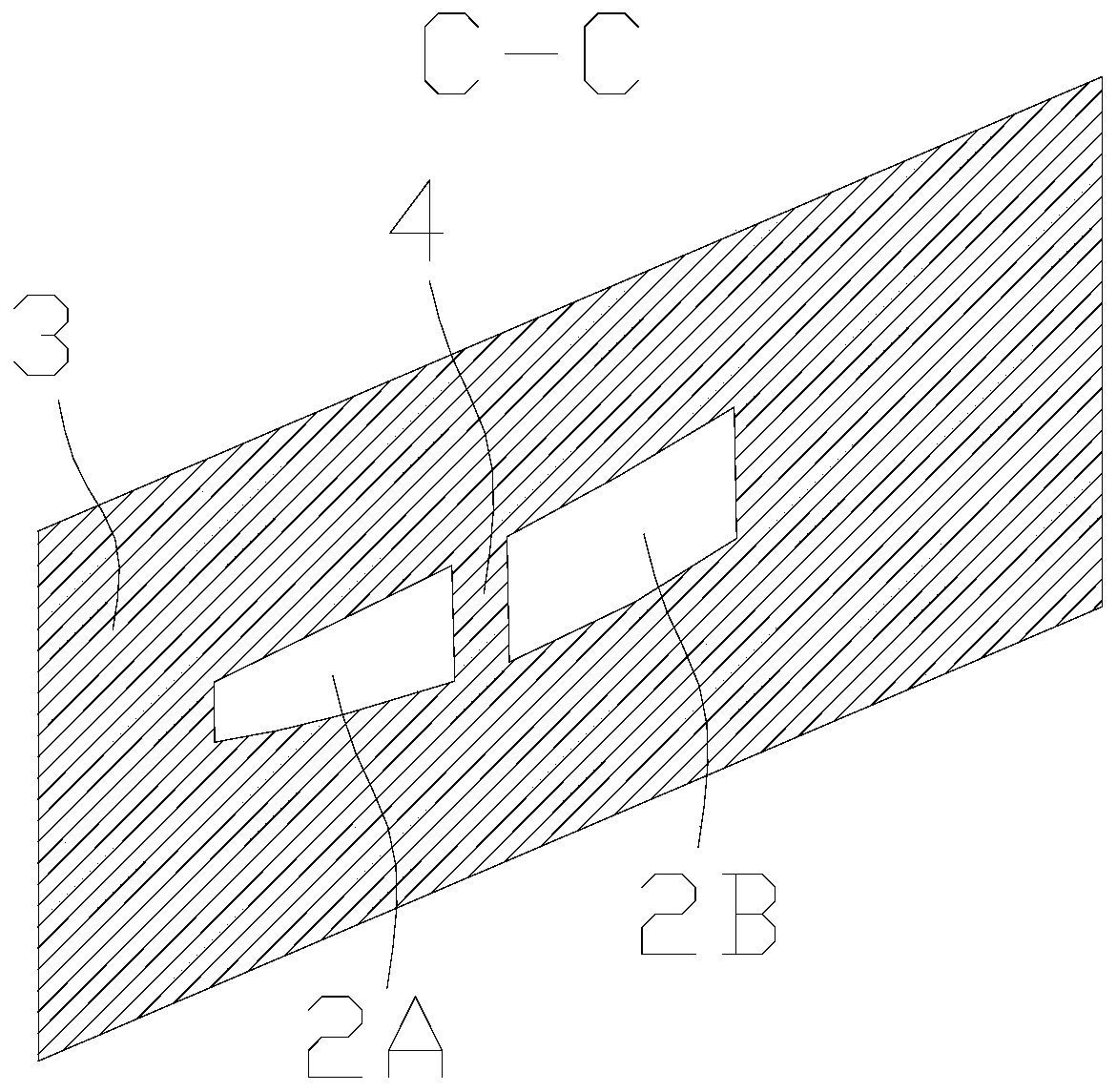

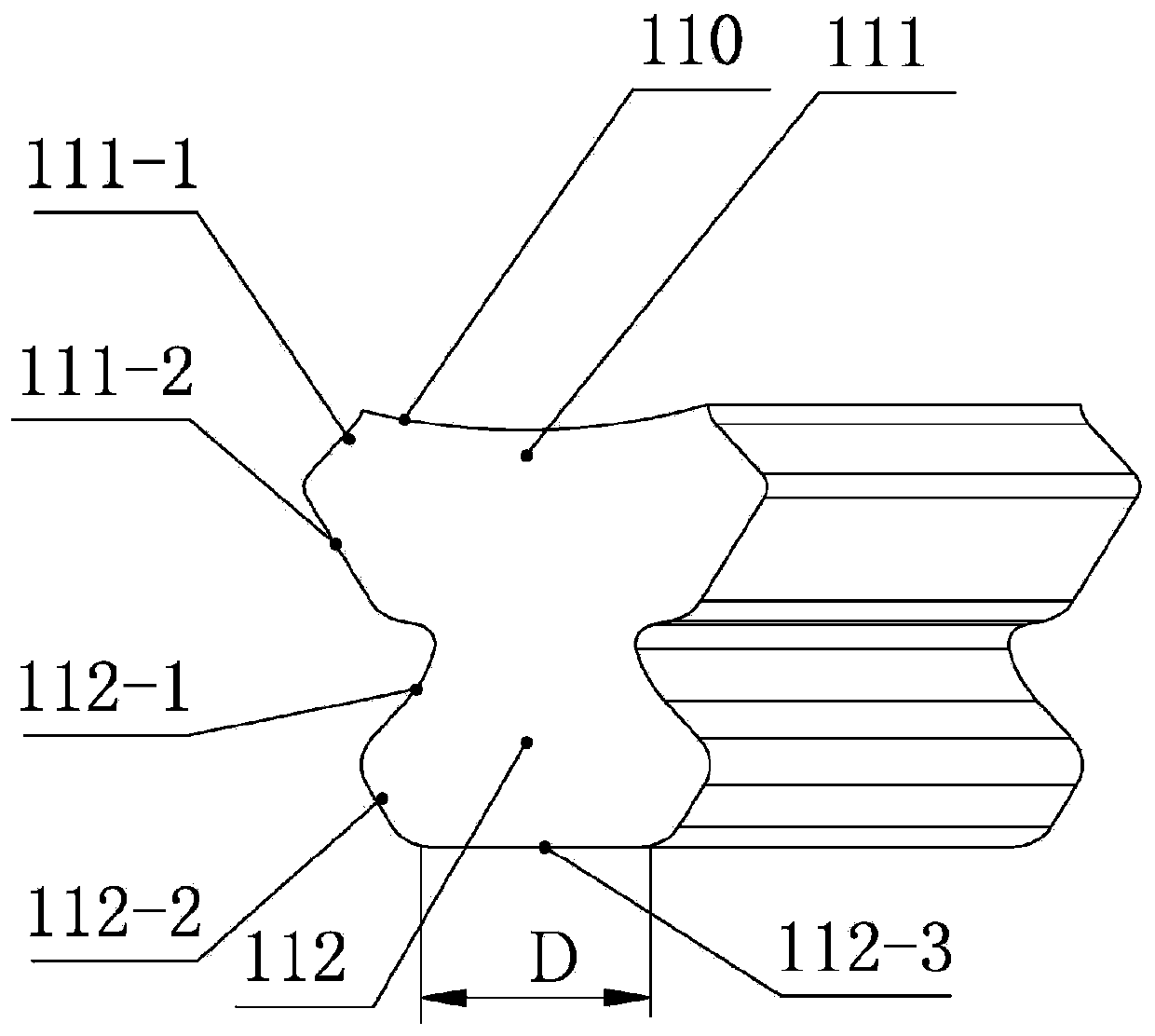

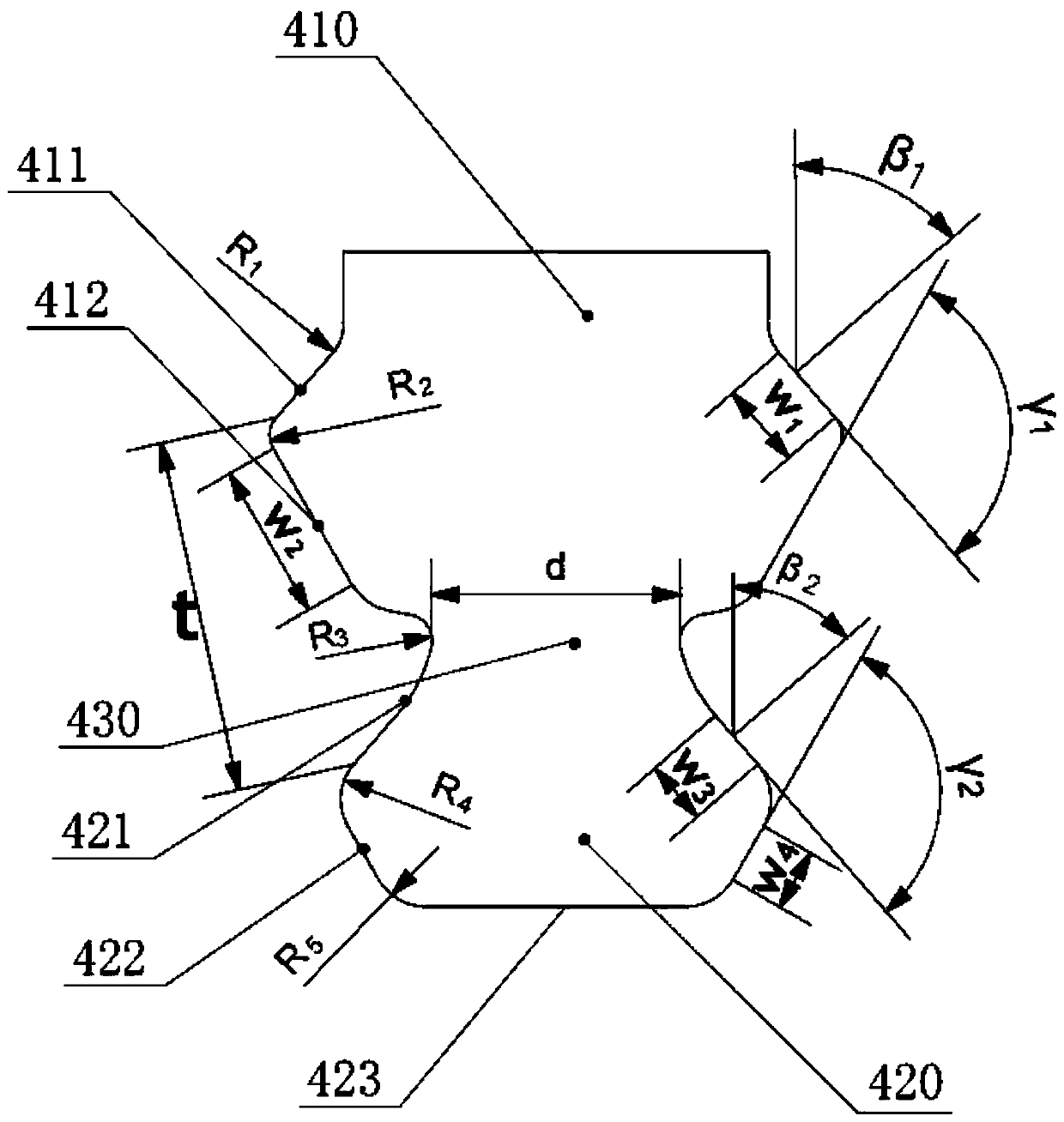

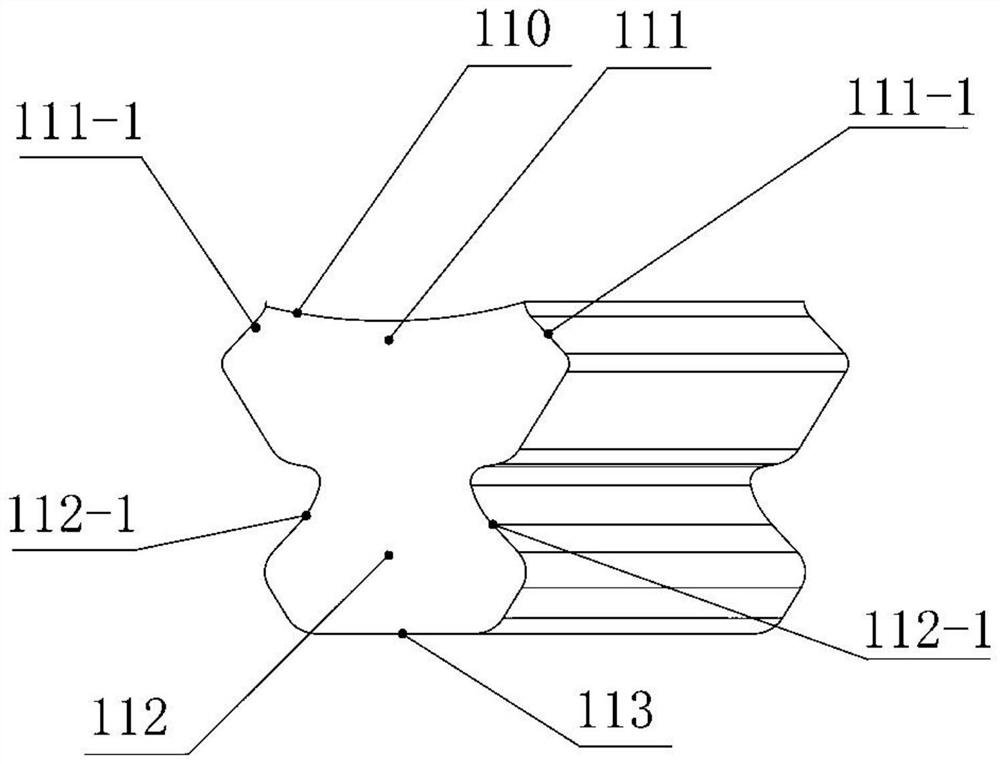

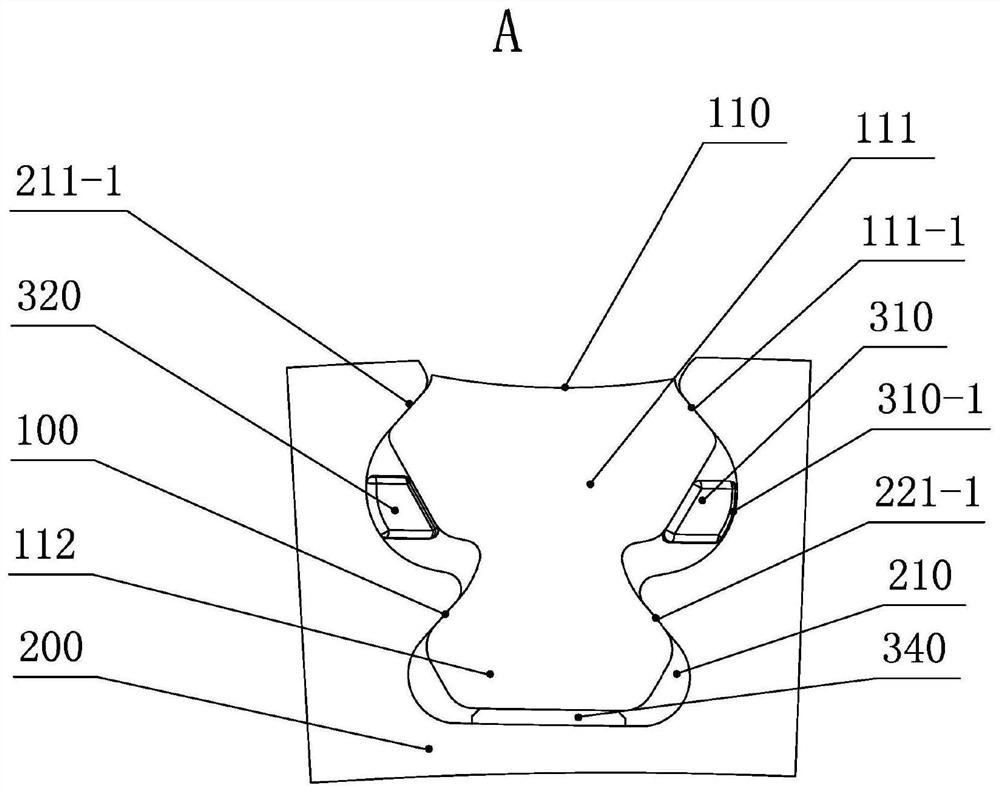

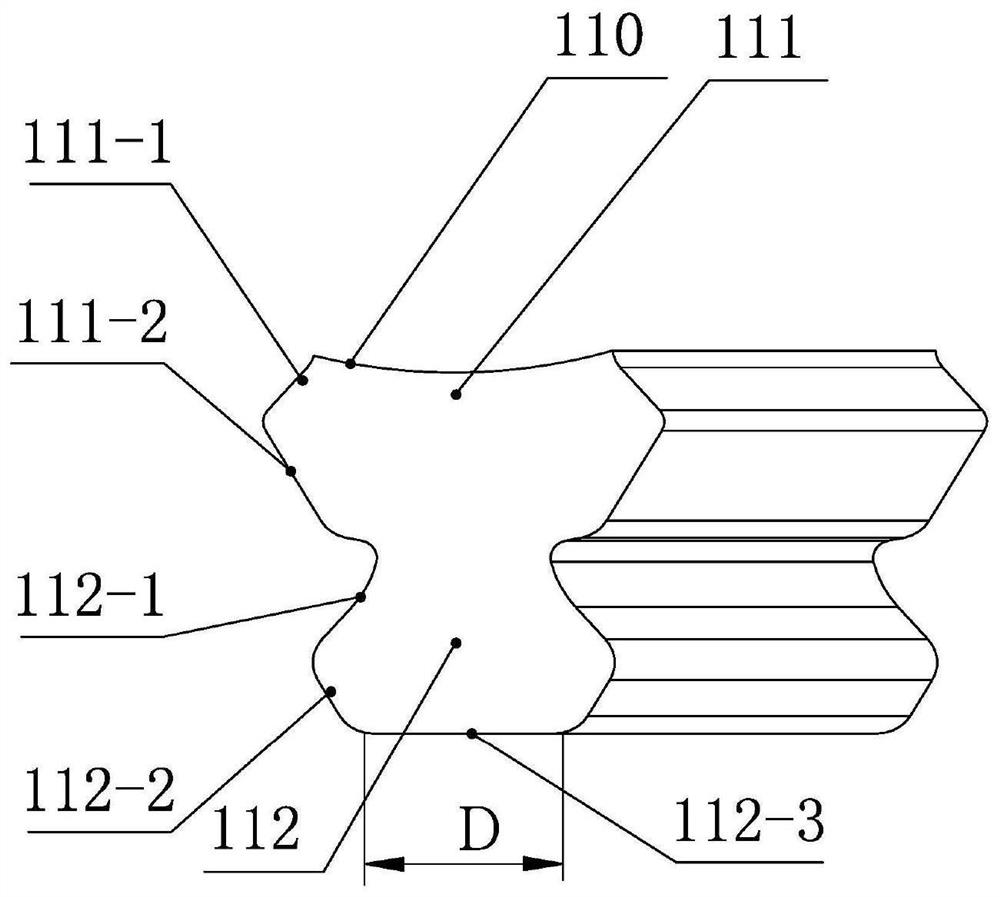

Fir-tree type disc tenon connecting device

InactiveCN111255526AImprove stress concentrationReduce the temperatureBlade accessoriesMachines/enginesEngineeringAero engine

The invention relates to a fir-tree type disc tenon connecting device. The fir-tree type disc tenon connecting device comprises a tenon and a tenon groove which are connected in a matched mode, wherein the tenon comprises a first tenon tooth and a second tenon tooth which are symmetrically arranged in structures; tooth widths of tooth surfaces which are arranged on the first tenon tooth and the second tenon tooth are equal; tooth widths of lower planes which are arranged on the first tenon tooth and the second tenon tooth are equal; pressure angles of the tooth surfaces are the same; a tooth end surface of the second tenon tooth is a plane; the tenon groove comprises a first tenon groove and a second tenon groove, and the first tenon groove and the second tenon groove are correspondingly arranged; the first tenon groove and the second tenon groove are each provided with a plane groove surface adhered to the corresponding tooth surface and a large circular arc connected with the corresponding groove surface in a cutting mode; and the bottom of each groove is a plane. By adopting the fir-tree type disc tenon connecting device, the problem of stress concentration at a connecting partof the blade tenon and the wheel disc tenon groove is greatly improved, so that a cooling air channel between the tenon and the tenon groove is enlarged, the temperature of the connecting part is greatly reduced, the working reliability is good, and the high-quality requirement of an aeroengine for a turbine rotor is met.

Owner:BEIJING SNECMA SAIC TURBOTECH CO LTD

Centrifugal compressor impeller cooling

ActiveUS9829008B2Increased creep lifeImproved cooling of the impeller eyePump componentsRadial flow pumpsEngineeringCentrifugal compressor

A centrifugal compressor including: a casing; at least one impeller supported for rotation in the casing and provided with a hub, a shroud and an impeller eye; an impeller-eye sealing arrangement, for sealing the impeller in the region of said impeller eye. The centrifugal compressor further includes at least one cooling-medium portlocated at the impeller-eye sealing arrangement, arranged for delivering a cooling medium around the impeller eye.

Owner:NUOVO PIGNONE TECH SRL

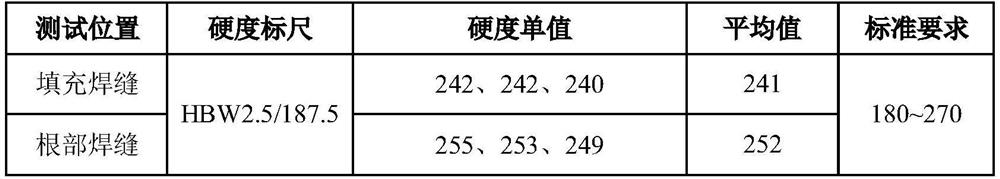

Large-wall-thickness P92 steel welding method

InactiveCN111805063AQuality improvementReduce temperature gradientWelding accessoriesThermal treatmentWelding process

The invention discloses a large-wall-thickness P92 steel welding method. The method comprises the following steps of forming and cleaning a welding groove; preheating the welding groove before welding, and then performing backing by adopting a GTAW welding method; welding a welded joint with a welding rod of phi3.2 with an SMAW welding method, wherein a weaving method for a swinging fast thin layer is adopted during welding; performing polishing inspection on a welding layer, and determining the crack cleaning method; repeating the steps above till welding of the whole welding groove is finished; facing the welding groove by adopting the SMAW welding method; and performing thermal treatment on the welded joint. Through reasonable optimization of parameters in the welding process, a properpreheating temperature, inter-layer temperature and thermal treatment temperature are kept. The performance of the welded joint is matched optimally through adoption of a reasonable welding process, so that the P92 steel welding quality is improved, and beneficial guarantee is provided for the normal running of equipment pipelines.

Owner:陕西榆林能源集团横山煤电有限公司

A kind of high nb-tial alloy adding nanometer yttrium oxide and preparation method thereof

The invention discloses a high Nb-TiAl alloy added with nano yttrium oxide and a preparation method of the high Nb-TiAl alloy, relates to the field of intermetallic compounds and preparation processesthereof, and aims to solve the technical problems of poor high-temperature mechanical property and weak creep resistance of an existing TiAl alloy. The alloy comprises, by mole: Al: 45-48%, Nb: 6-10%, V: 2.5-3.5%, nano yttrium oxide: 0.05-3%, and the balance Ti. The preparation method comprises the steps of briquetting and shaping raw materials; melting alloy block materials, and adding an yttrium oxide prefabricated block for smelting to obtain an alloy ingot; and then carrying out homogenization annealing treatment to finish the preparation. According to the high Nb-TiAl alloy added with the nano yttrium oxide and the preparation method of the high Nb-TiAl alloy, the high-temperature mechanical property and high-temperature creep resistance of the high Nb-TiAl alloy are improved; and the high Nb-TiAl alloy added with the nano yttrium oxide is applied to the field of high-temperature structural materials.

Owner:HARBIN INST OF TECH

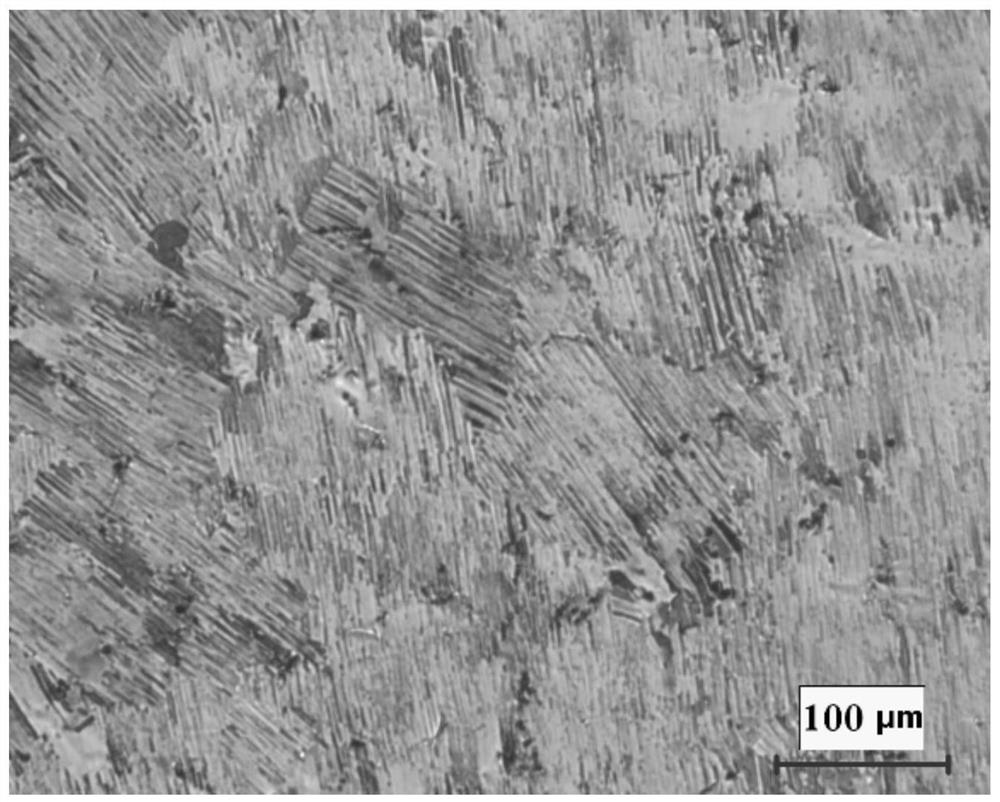

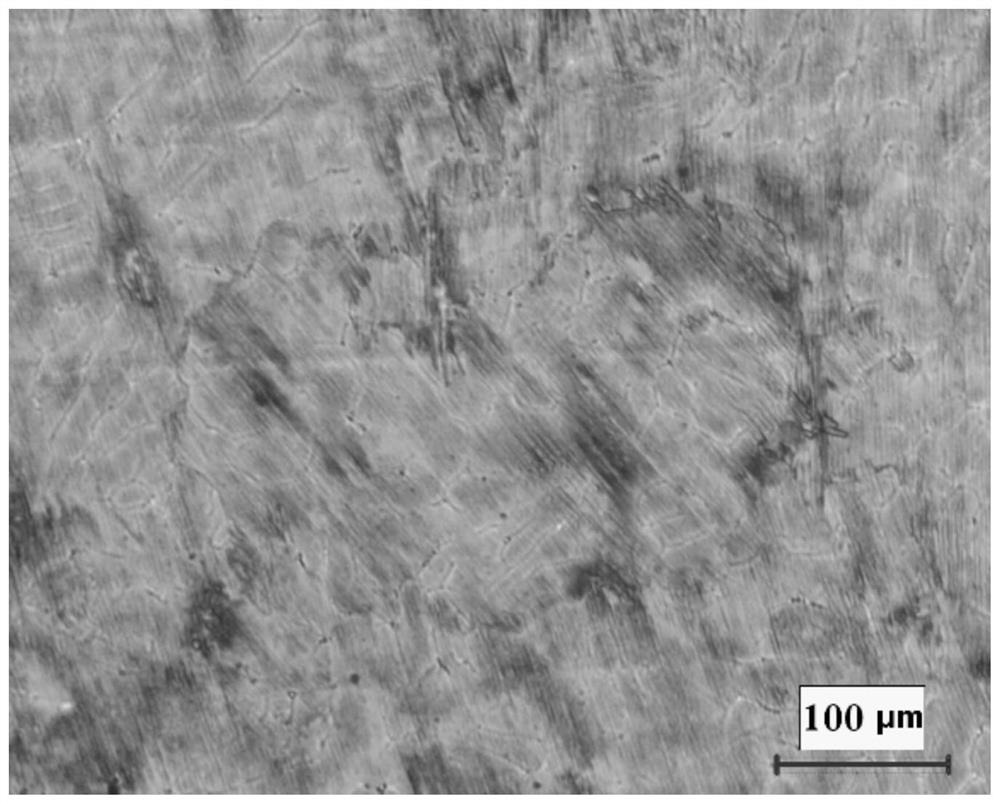

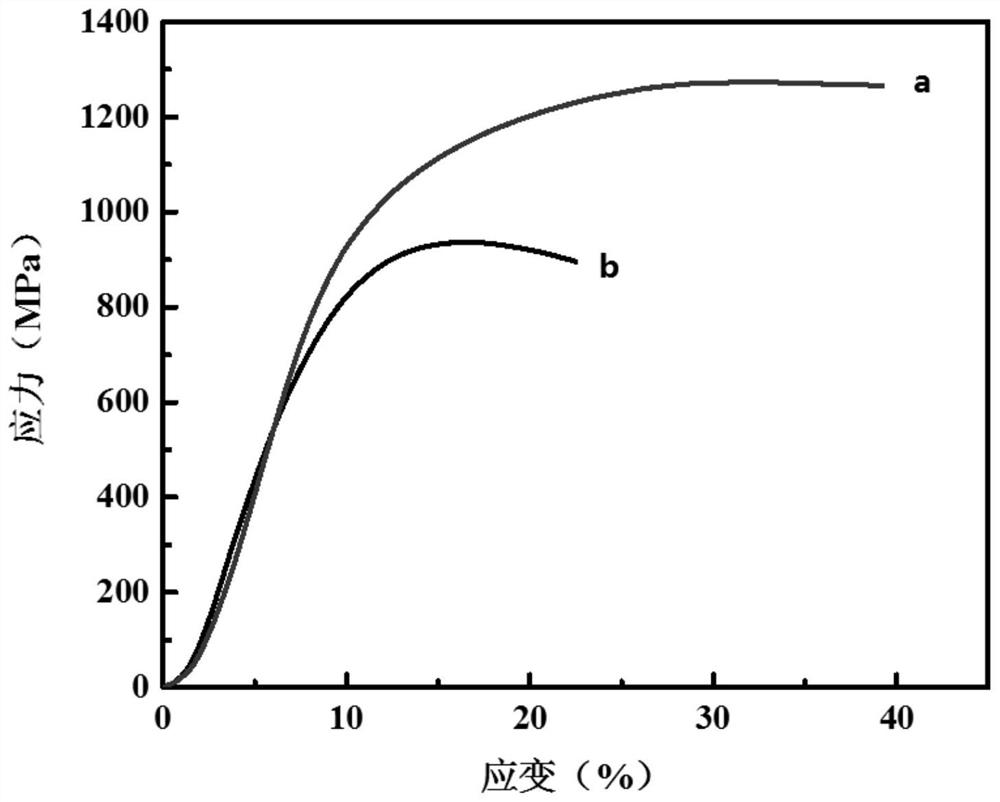

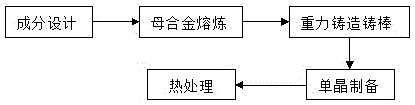

A kind of rhenium-free nickel-based single crystal superalloy and preparation method thereof

ActiveCN103436740BImprove antioxidant capacityAccelerated corrosionPolycrystalline material growthFrom frozen solutionsRheniumSolution treatment

Owner:NANJING UNIV OF SCI & TECH

Turbine rotor blade of a gas turbine

ActiveCN110410158BImprove heat transfer effectEnhanced convective heat transferBlade accessoriesMachines/enginesThermodynamicsSuction force

The invention relates to a turbine rotor blade of a gas turbine, which includes a blade profile, a blade platform, a blade top and a blade root. There is a cooling air passage loop inside the blade, and a cooling air passage and a cooling air passage inlet are installed in the cooling air passage. Ribbed; blade surface is divided into blade leading edge and blade trailing edge by pressure surface and suction surface. The trailing edge of the blade has a trailing edge exhaust slot, and the trailing edge channel has a diversion groove structure, and there is at least one spoiler column in the diversion groove structure; the cooling air passage of the blade root is divided into at least two passages by a partition plate, The partition plate is gradually bent toward the leading edge side of the blade along the airflow direction. The invention can improve the heat exchange effect between the internal leading edge channel, the trailing edge exhaust slot and the cooling air, and reduce the metal temperature of the leading edge near the blade platform and the metal temperature of the trailing edge and the platform and blade root near the trailing edge.

Owner:HANGZHOU TURBINE POWER GRP

A heat treatment method for improving the long service life of friction stir welding welds of magnesium alloys

InactiveCN110438325BImprove completenessIncrease speedFurnace typesHeat treatment furnacesFriction weldingSolution treatment

The invention discloses a thermal treatment method capable of prolonging the long-time service life of welding seams in the magnesium-alloy friction stir welding process. The method comprises the steps that aging treatment and water quenching are conducted on a magnesium alloy subjected to solution treatment for 0.5 h to 72 h at 180 DEG C to 280 DEG C; friction stir welding is conducted at room temperature, wherein the rotating speed ranges from 100 rpm to 1,000 rpm, and the welding speed ranges from 20 mm / min to 120 mm / min; and annealing treatment is conducted on the welded magnesium alloy for 0.5 h to 10 h at 250 DEG C to 350 DEG C, the magnesium alloy is directly cooled to 100 DEG C to 200 DEG C after being annealed, and then aging treatment and water quenching are conducted for 0.5 h to 6 h. According to the thermal treatment method, a precipitated phase is introduced for the magnesium alloy, the lattice distortion degree is increased, and the crystallization rate is increased; andrare earth magnesium alloy or high-alloyed magnesium alloy which is difficult to recrystallize is rapidly crystallized in the friction stir welding process, so that the yield strength of the weldingseams is improved, and synchronous improvement of the long-time service lives in the directions parallel to or perpendicular to the welding seam direction is achieved.

Owner:CENT SOUTH UNIV

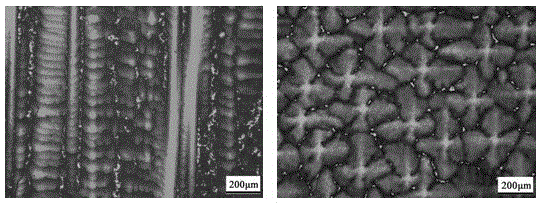

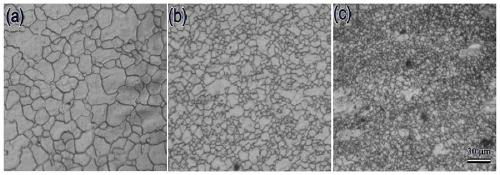

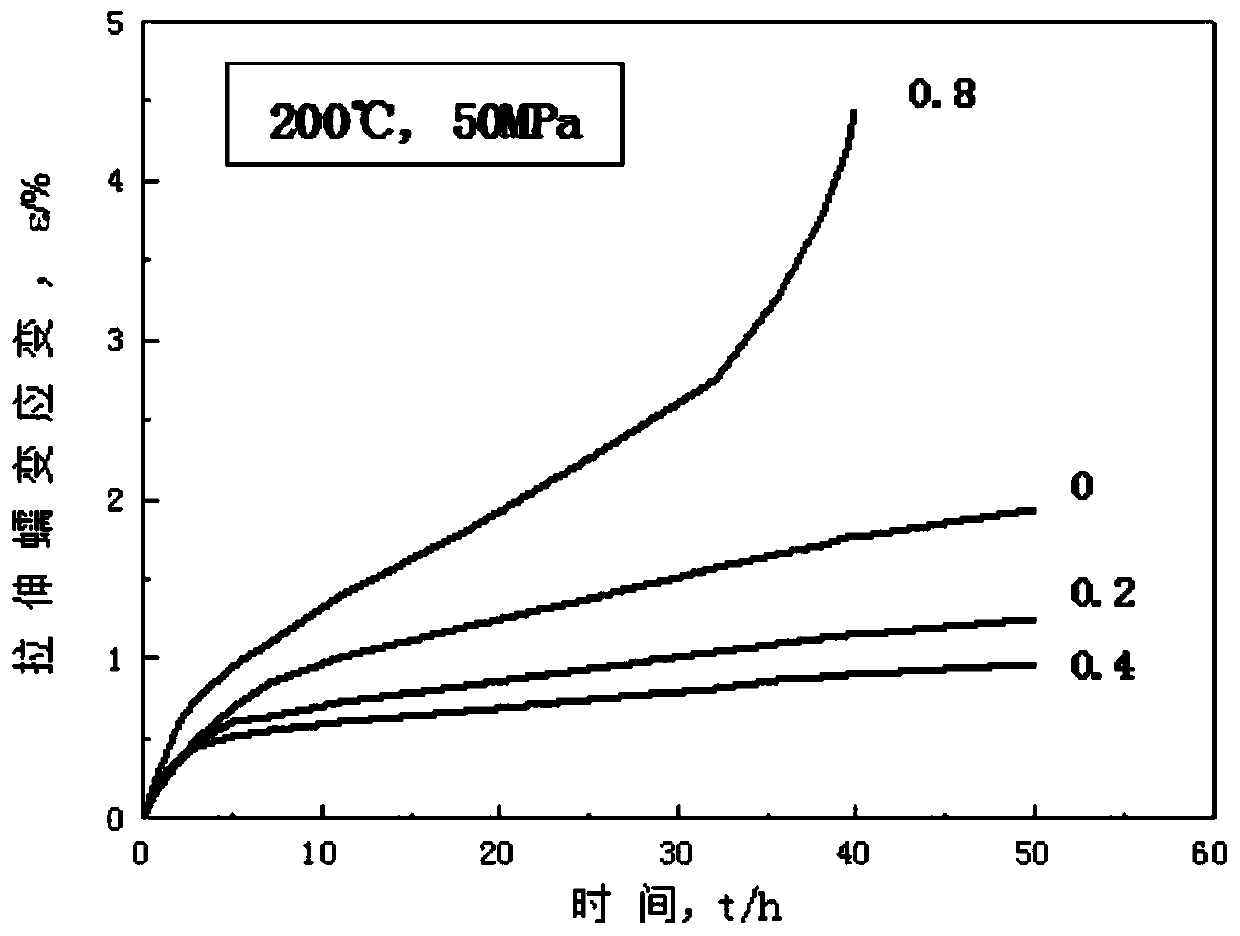

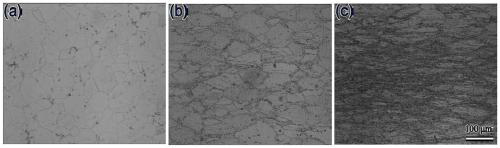

A Method for Improving High Temperature Creep Resistance of Magnesium Alloys Using Bending Grain Boundaries

The invention relates to a method for improving a high-temperature creep resistance performance of magnesium alloy by using curved grain boundaries. The method comprises the steps that as-cast or deformed magnesium alloy materials is subjected to pre-compression deformation in a temperature range of 400-550 DEG C, and the true strain is 0.2-1.2 to obtain the curved grain boundaries with differentdensities, and the corresponding fine grain ratio is 0.2-0.6. Tensile creep performance tests are carried out on undeformed samples, samples with fine grain ratio of 0.2 - 0.6 and samples with fine grain ratio of greater than or equal to 0.6 in the temperature range of 150-350 DEG C separately. Compared with undeformed samples and the samples with high fine grain ratio, creep strain and steady-state creep rate of the curved grain boundary samples with fine grain ratio of 0.2-0.6 under the same conditions are significantly reduced, and creep resistance performance is significantly improved. Theinvention provides a method for stably improving high-temperature creep resistance performance of magnesium alloy with reasonable design, simple equipment requirements, low cost, high efficiency andwide application range.

Owner:CENT SOUTH UNIV

A turbine rotor device with a cooling and compacting structure

The invention relates to a turbine rotor device with a cooling compression structure. The device comprises a blade and a wheel disc which are cooperatively connected with each other through a fir-shaped tenon and a mortise, and further comprises the cooling compression device installed in the gap between the end face of the tenon and the bottom of the mortise in an in interference fit mode. The cooling compression device is internally provided with a main cold air channel with the cross sectional area gradually changed, and multiple secondary cold air channels which communicate with the main cold air channel and are symmetrically formed in the two sides, so that the space of the cold air channels and the effective convection area are increased, the temperature of the connecting parts of awheel rim part, the tenon of the blade and the mortise of the wheel disc is reduced, the thermal stress of the tenon of the blade is reduced, and the creep life of the tenon of the blade, the mortisestructure of the wheel disc and the rim of the wheel disc is prolonged.

Owner:BEIJING SNECMA SAIC TURBOTECH CO LTD

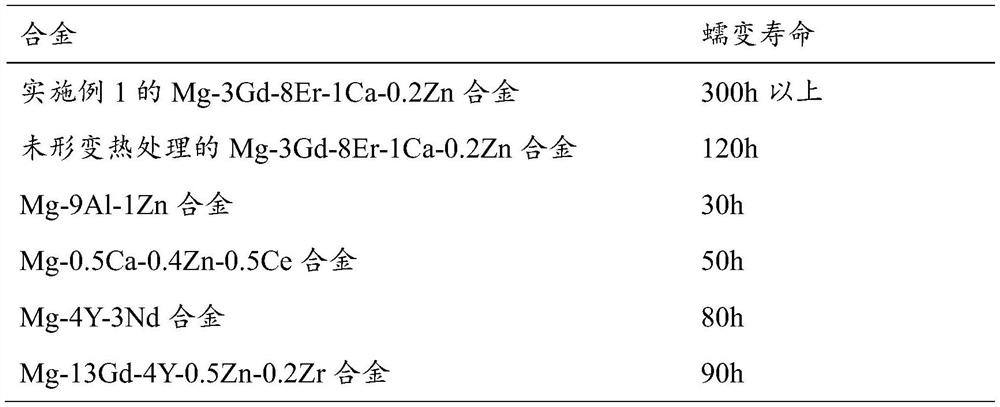

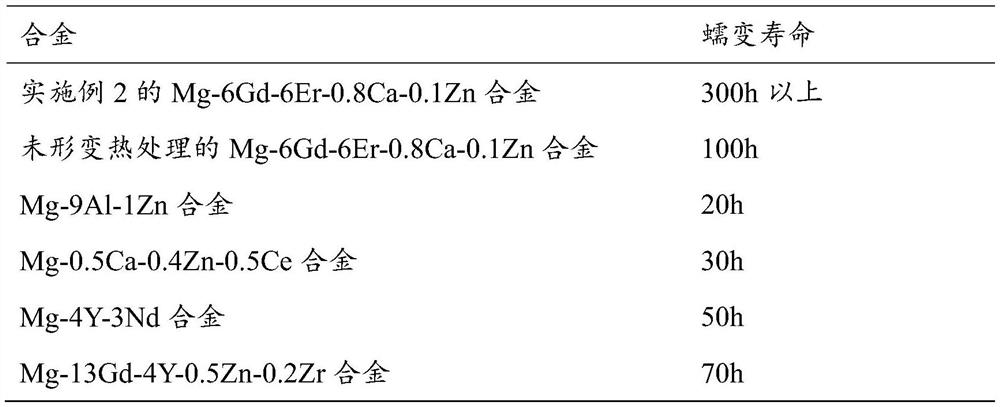

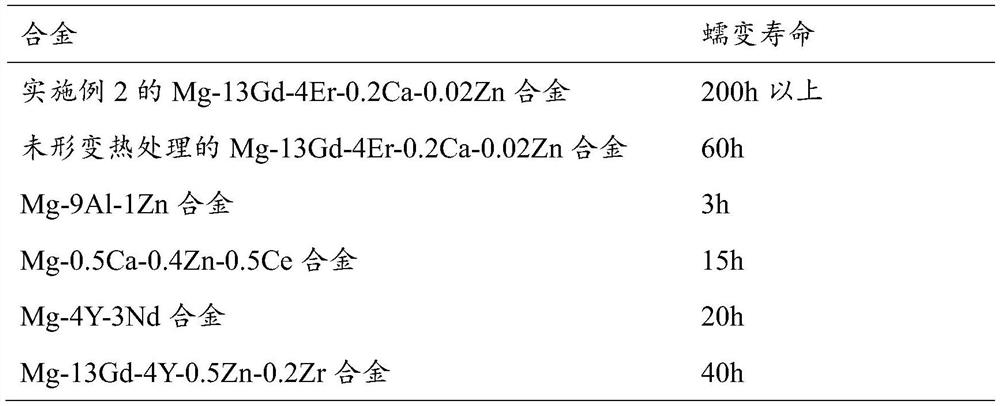

A heat-resistant flame-retardant magnesium alloy and its deformation heat treatment method

The invention discloses a heat-resistant flame-retardant magnesium alloy and a thermo-mechanical treatment method thereof. The magnesium alloy comprises the following elements by mass: 3-16% of Gd, 4-8% of Er, 0.2-1% of Ca, 0.02-0.2% of Zn and the balance being Mg, wherein the mass ratio of Ca to Zn is >= 3. Magnesium alloy ingot billets are prepared by semi-continuous casting, and subjected to hot rolling or hot extrusion to form a plate being 5-25 mm in thickness, the plate is subjected to solid solution treatment, aging is performed at 200-260 DEG C, and water quenching is performed; and then, true strain is performed between room temperature and 100 DEG C, then aging is performed at 150-220 DEG C, and water quenching is performed. The alloy prepared in the invention contains a honeycomb microstructure consisting of a prismatic-plane precipitated phase, a prismatic-plane dislocation, a basal-plane precipitated phase and a basal-plane dislocation; the effect of the synchronous improvement on the heat-resistant and flame-retardant properties of the magnesium alloy is significant; simple equipment, low production cost and high efficiency are achieved; and the magnesium alloy is suitable for use in the industries of aeronautics and astronautics, railway trains and automobile lightweight.

Owner:CENT SOUTH UNIV

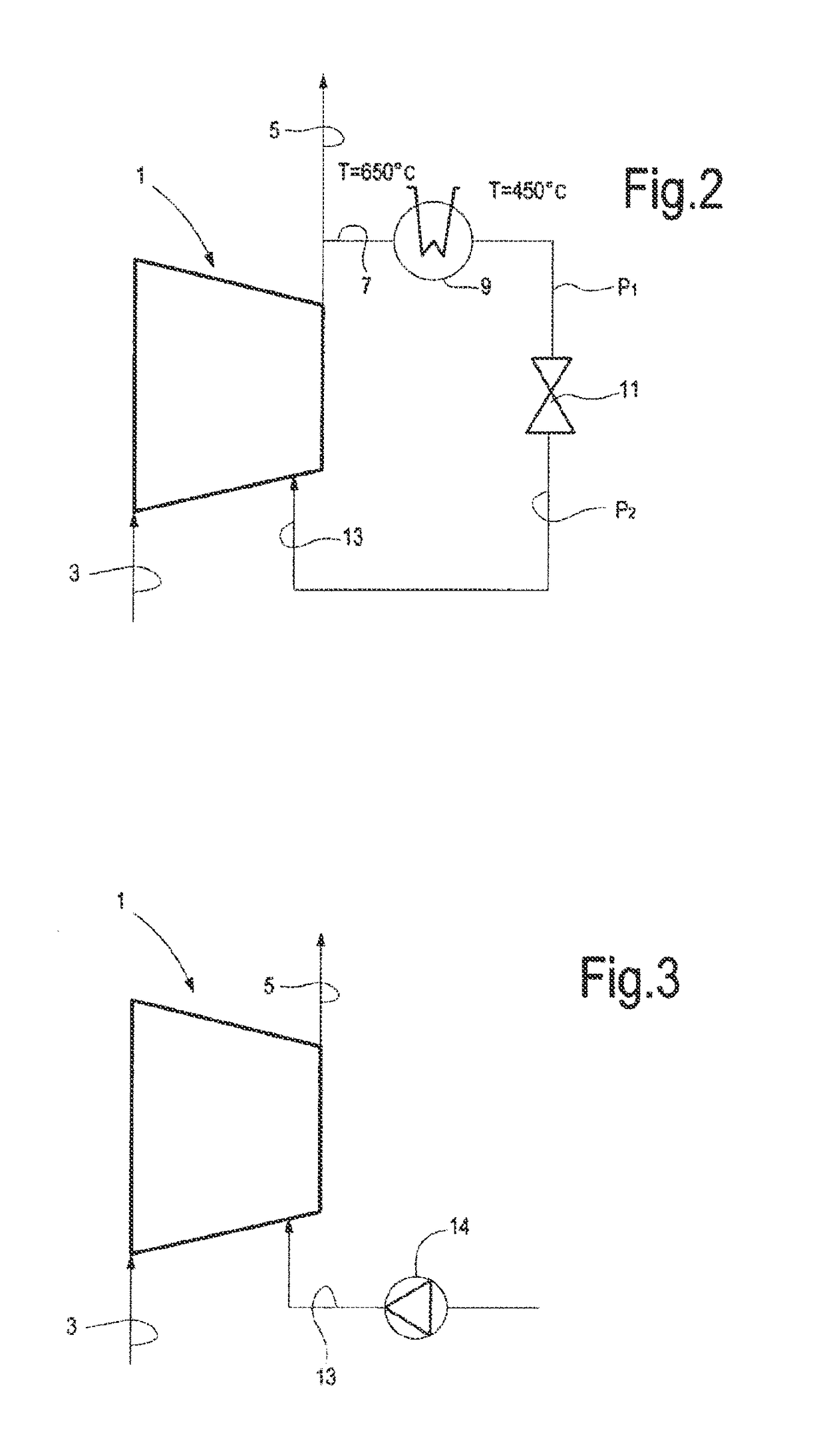

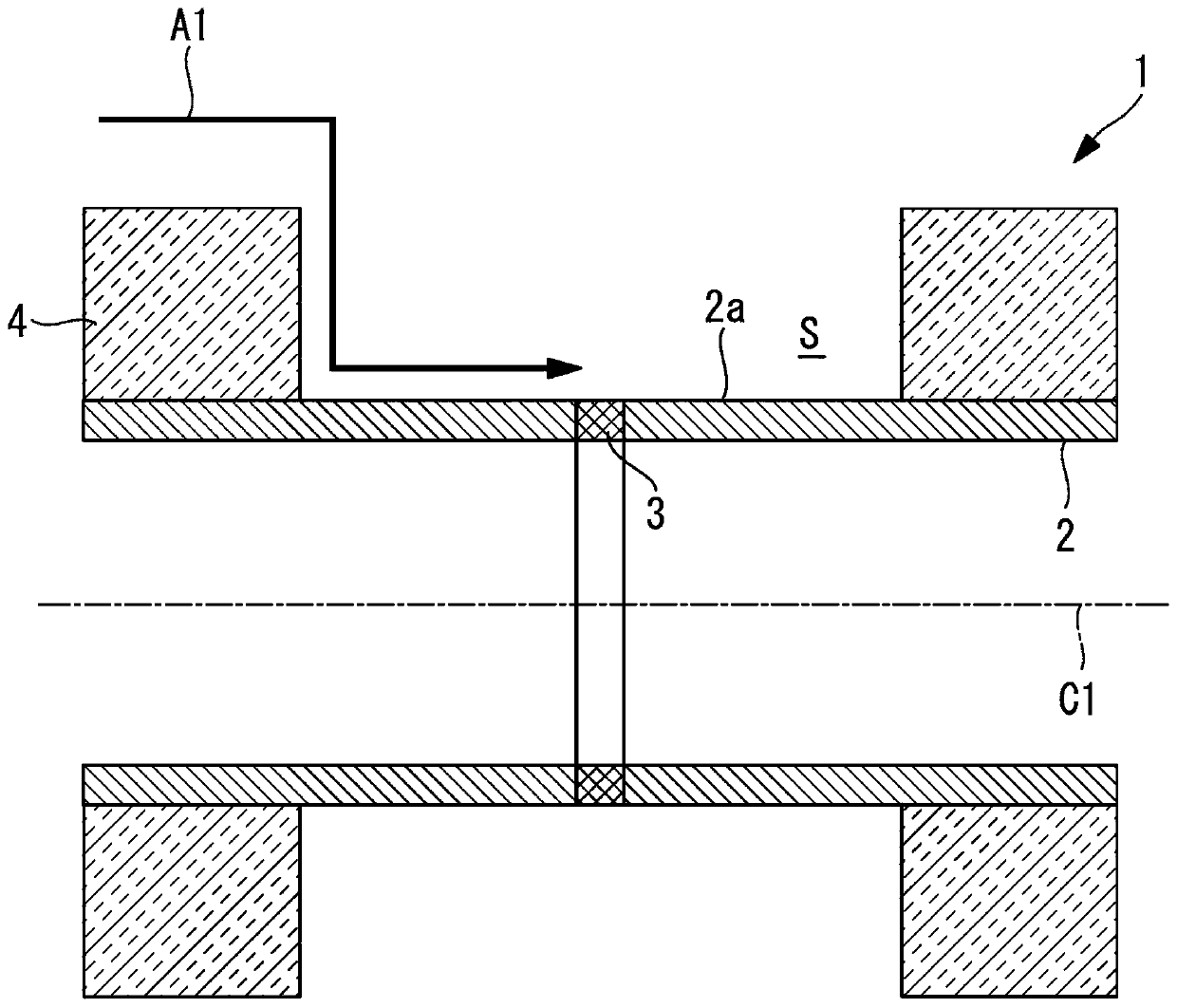

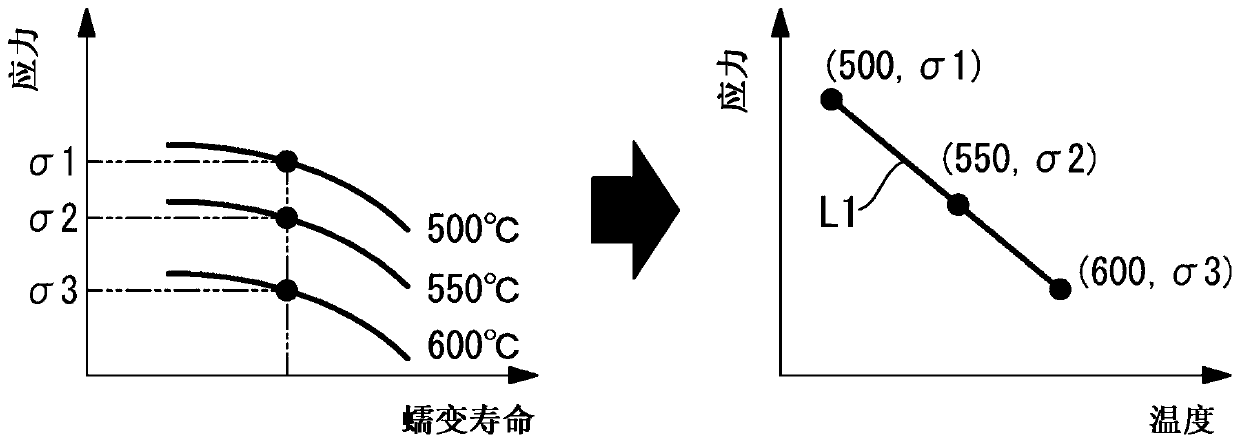

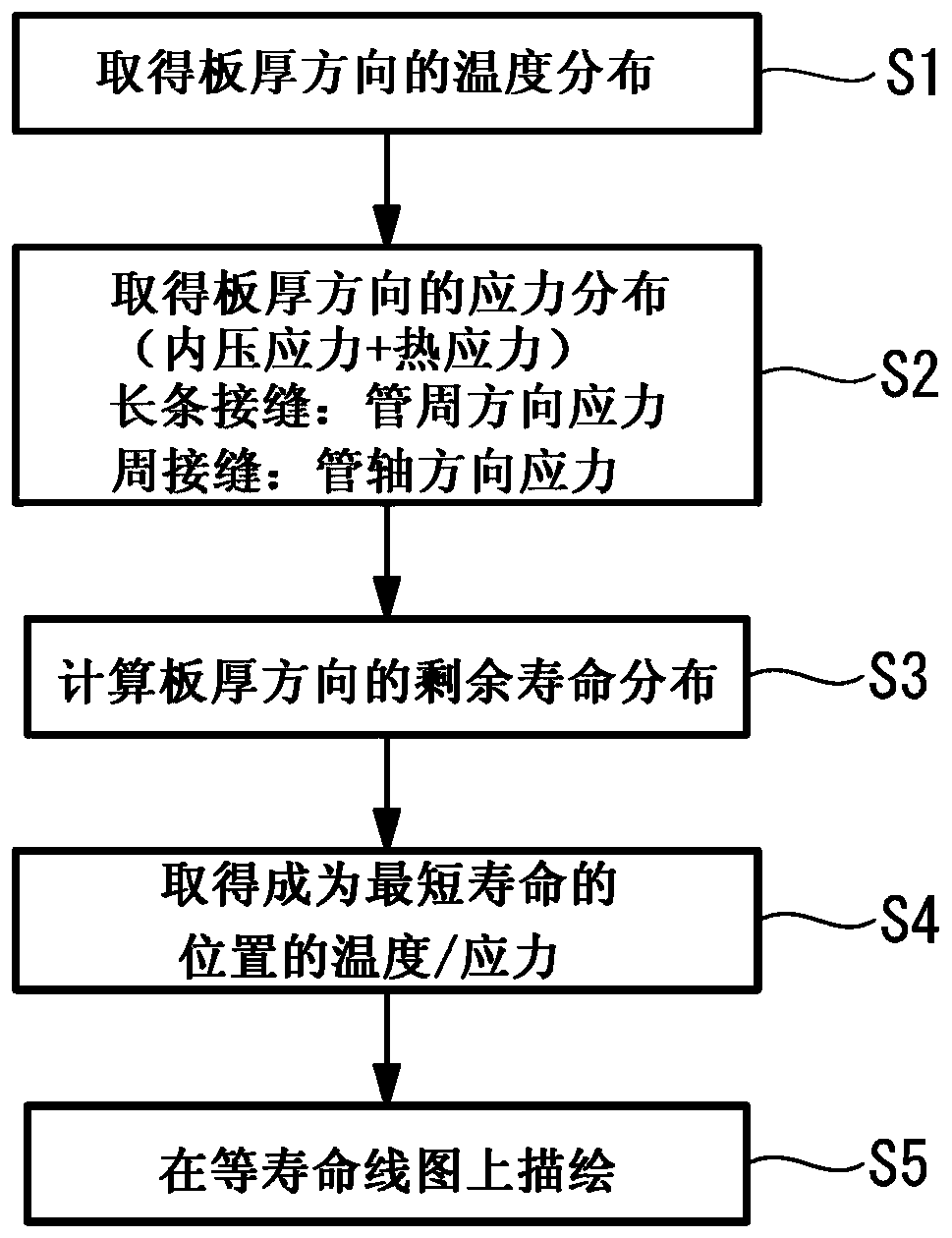

Metallic wall section cooling method

ActiveCN111094826AIncreased creep lifeAvoid damageNuclear energy generationPipe heating/coolingThermodynamicsEngineering

Provided is a metallic wall section cooling method for partially cooling the outer surface of a pipe for circulating steam. The temperature of a pressurized fluid is 500-700 DEG C and the temperatureof the outer surface of the pipe is at least 200 DEG C. The temperature difference in the plate thickness direction of the pipe is no greater than 300 DEG C. The temperature difference at a cooled portion in the pipe axial direction of the pipe is 500 DEG C if the dimension of the pipe in the pipe axial direction is within the range of + / -100 mm. The temperature difference in the pipe circumferential direction of the pipe is no greater than 50 DEG C.

Owner:MITSUBISHI POWER LTD

A turbine rotor device with cooling and compacting structure

ActiveCN111335965BExtend your lifeStable positionBlade accessoriesMachines/enginesCold airEngineering

The invention relates to a turbine rotor device with a cooling and pressing structure. The turbine rotor device comprises blades and a wheel disc which are matched and connected through a fir-shaped tenon and a mortise, and further comprises the cooling and pressing device which is arranged in a gap between the end surface of the tenon and the bottom of the mortise in an interference manner, the cooling and pressing device is provided with a lower main supporting column and upper branch supporting columns which are symmetrically arranged. According to the turbine rotor device with the coolingand pressing structure, the main supporting column and the branch supporting columns form a plurality of cold air channels with the tenon tooth end face and the mortise respectively, so that the relative positions of the tenon teeth and the mortise are fixed, the effective convection area of cold air is increased, the space of a cold air channel and the effective convection area are increased, thetemperature of the rim part and the temperature of the joint of the blade tenon and the wheel disc mortise are reduced, the thermal stress of the blade tenon is reduced, and the creep life of the blade tenon, the wheel disc mortise structure and the wheel disc rim is prolonged.

Owner:BEIJING SNECMA SAIC TURBOTECH CO LTD

A method for improving long-term service life of magnesium alloys by baking

The invention discloses a method for prolonging the long-time service life of a magnesium alloy through drying. The magnesium alloy comprises, by mass, 0.1-0.65% of calcium, 0.05-1.2% of zinc and thebalance magnesium, and the mass percentage ratio of calcium to zinc is greater than or equal to 0.4; or comprises, by mass, 0.1-0.65% of calcium, 0.05-0.6 % of silicon and the balance magnesium, and the mass percentage ratio of calcium to silicon is greater than or equal to 0.9. The method comprises the steps of preparing a magnesium alloy ingot blank through a semicontinuous casting method, conducting hot rolling or hot extrusion on the magnesium alloy ingot blank to form a plate with the thickness of 2-20 mm, conducting solution treatment on the plate, conducting cold deformation on the plate at true strain of 0.01-0.07 at indoor temperature, conducting baking on the plate at 150-230 DEG C for 10-120 min and then conducting water quenching. Compared with a magnesium alloy not subjected to baking treatment, the yield strength of the magnesium alloy subjected to baking can be improved by 30% or more, and the fatigue and creep life of the magnesium alloy can be prolonged by at least 5 times under the long-time service conditions.

Owner:CENT SOUTH UNIV

Turbine rotor device with cooling and pressing structure

ActiveCN111335965AExtend your lifeStable positionBlade accessoriesMachines/enginesCold airEngineering

The invention relates to a turbine rotor device with a cooling and pressing structure. The turbine rotor device comprises blades and a wheel disc which are matched and connected through a fir-shaped tenon and a mortise, and further comprises the cooling and pressing device which is arranged in a gap between the end surface of the tenon and the bottom of the mortise in an interference manner, the cooling and pressing device is provided with a lower main supporting column and upper branch supporting columns which are symmetrically arranged. According to the turbine rotor device with the coolingand pressing structure, the main supporting column and the branch supporting columns form a plurality of cold air channels with the tenon tooth end face and the mortise respectively, so that the relative positions of the tenon teeth and the mortise are fixed, the effective convection area of cold air is increased, the space of a cold air channel and the effective convection area are increased, thetemperature of the rim part and the temperature of the joint of the blade tenon and the wheel disc mortise are reduced, the thermal stress of the blade tenon is reduced, and the creep life of the blade tenon, the wheel disc mortise structure and the wheel disc rim is prolonged.

Owner:BEIJING SNECMA SAIC TURBOTECH CO LTD

Method for controlling residual ferrite and martensite slab structure in 9Cr-ODS steel

InactiveCN106834883AIncreased creep lifeVolume fraction controllableProcess efficiency improvementThermal insulationRoom temperature

The present invention relates to a method for controlling residual ferrite and martensite slab structure in a 9Cr-ODS steel. The method comprises: mixing pre-alloyed powder and nano-scale Y2O3 according to a mass ratio of 99.65:0.35, wherein the pre-alloyed powder comprises, by mass, 1 part of Fe, 9 parts of Cr, 1.5 parts of W, 0.2 part of V, 0.07 part of Ta, and 0.1 part of C; carrying out mechanical ball milling in a ball mill, heating to a temperature of 800 DEG C by using discharging plasma sintering, carrying out thermal insulation for 5-10 min, continuously heating to a temperature of 1100 DEG C, and carrying out thermal insulation for 10-15 min to obtain a 9Cr-ODS martensite steel having a molding compactness of more than 99%; and carrying out heat treatment on the sintering-state 9Cr-ODS martensite steel, heating to a temperature of 1100 DEG C at a heating rate of 10-40 DEG C / min, carrying out thermal insulation, and cooling to a room temperature. According to the present invention, with the method, the content of the residual ferrite in the 9Cr-ODS martensite steel is effectively controlled, and the ultrafine nano-scale martensite slab can be obtained during the cooling process.

Owner:TIANJIN UNIV

A turbine rotor device with a compact structure

ActiveCN111305908BStable positionBig spaceBlade accessoriesMachines/enginesCold airClassical mechanics

The invention relates to a turbine rotor device with a pressing structure. The turbine rotor device comprises a blade and a wheel disc which are connected through a fir-shaped tenon and mortises in amatched mode, and further comprises a pressing device installed in a gap between the tenon and the mortises in an interference mode, a bottom face supporting plate arranged on the pressing device is located at the bottom of the mortises and attached to the end face of the tenon, and supporting columns are symmetrically arranged in gaps between the two sides of tenon teeth of the tenon and the mortises, so that the tenon teeth are pressed on the inner walls of the mortises. According to the turbine rotor device, the relative positions of the tenon teeth and the mortises are fixed, the area of gaps where cold air passes through is increased, the temperature of a wheel flange part and the connecting positions of the blade tenon and the wheel disc mortises is reduced, the thermal stress of theblade tenon is reduced, and the creep life of the blade tenon, the wheel disc mortise structure and a wheel disc wheel flange is prolonged.

Owner:BEIJING SNECMA SAIC TURBOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com