Turbine rotor blade of gas turbine

A technology for turbine rotors and gas turbines, which is applied in the direction of blade support components, mechanical equipment, engine components, etc., and can solve problems such as failure to effectively solve the problem of heat dissipation at the leading edge and trailing edge of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with specific embodiment now.

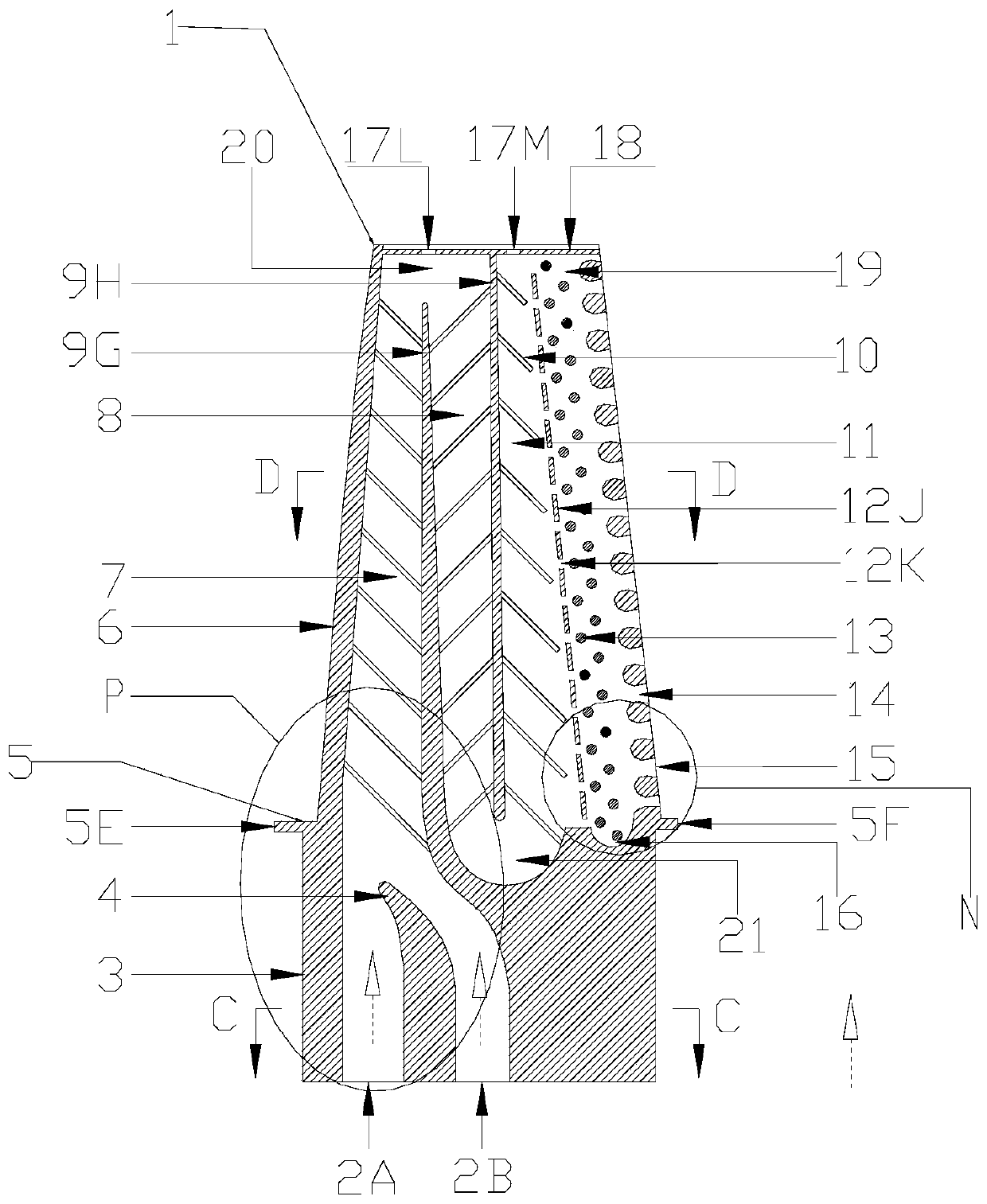

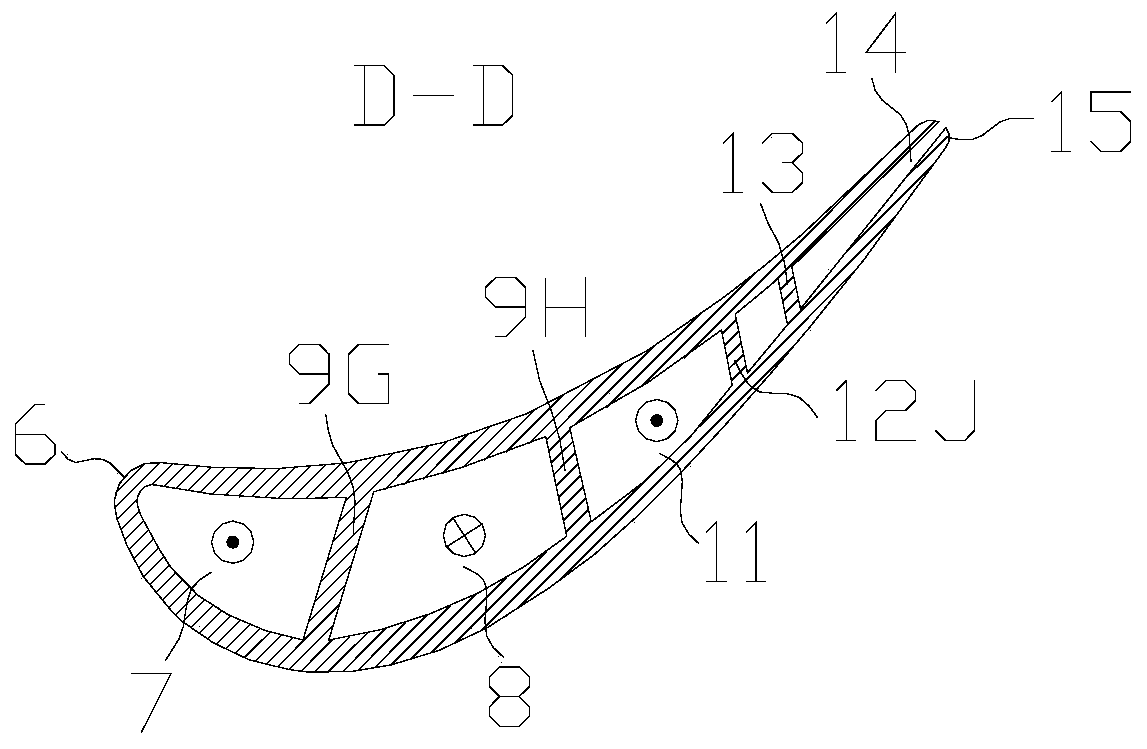

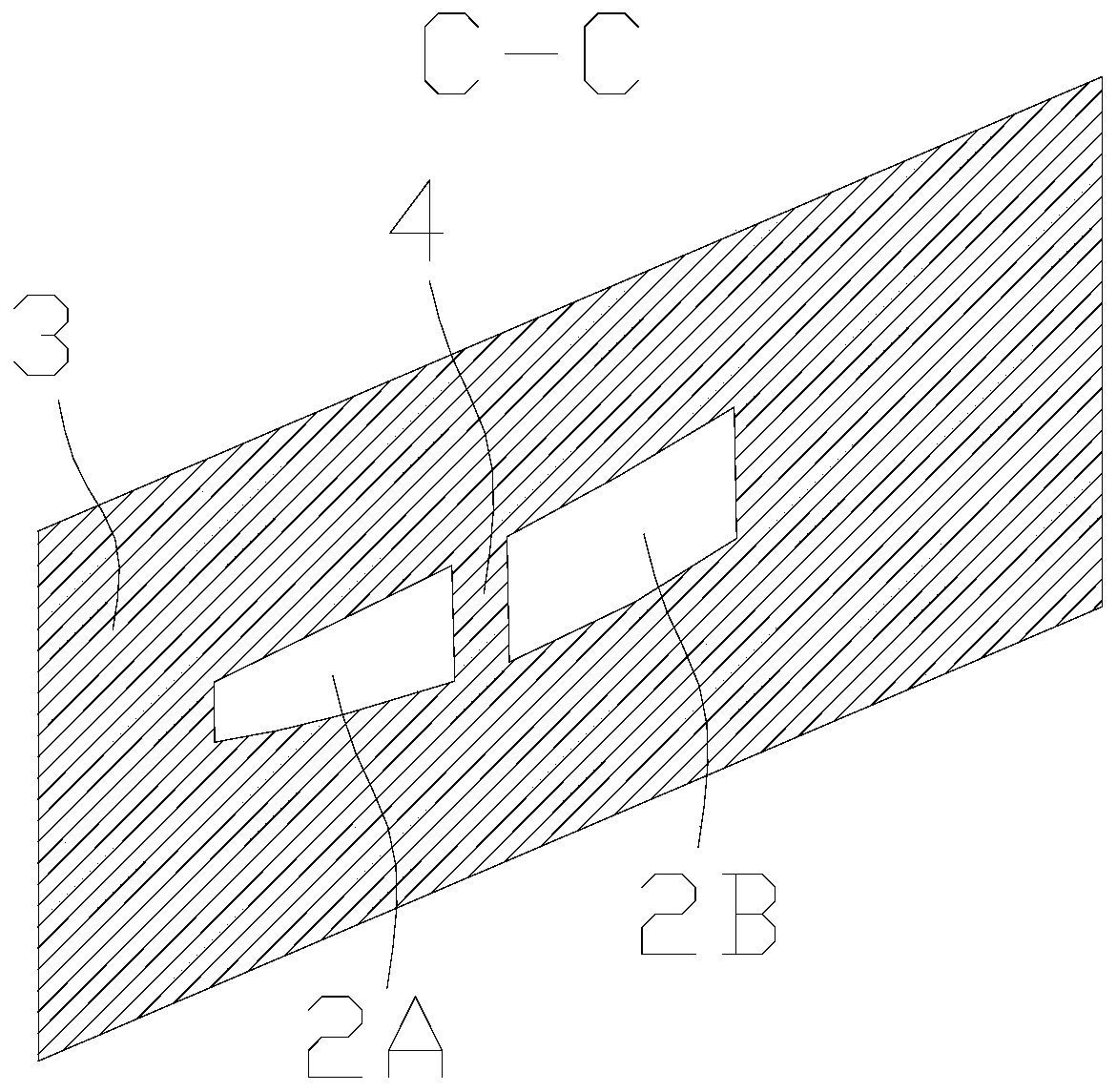

[0026] figure 1 is a longitudinal sectional view of a gas turbine rotor blade, figure 2 yes figure 1 D-D cross-sectional view. Such as figure 1 , figure 2 As shown, the blade is mainly divided into three parts: the blade shape 1 , the blade root 3 , and the blade platform 5 , and the blade platform 5 plays the role of connecting the blade shape 1 and the blade root 3 .

[0027] The outer surface of the blade airfoil is composed of a pressure surface and a suction surface. The concave side of the airfoil outer surface is the pressure surface, and the convex side is the suction surface. The junction area between the suction surface and the pressure surface forms the leading edge 6 of the blade and the trailing edge 15 of the blade. ; There is at least one cooling air channel circuit inside the blade airfoil 1, each circuit has at least one cooling air channel and a coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com