Patents

Literature

31results about How to "Reduce metal temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

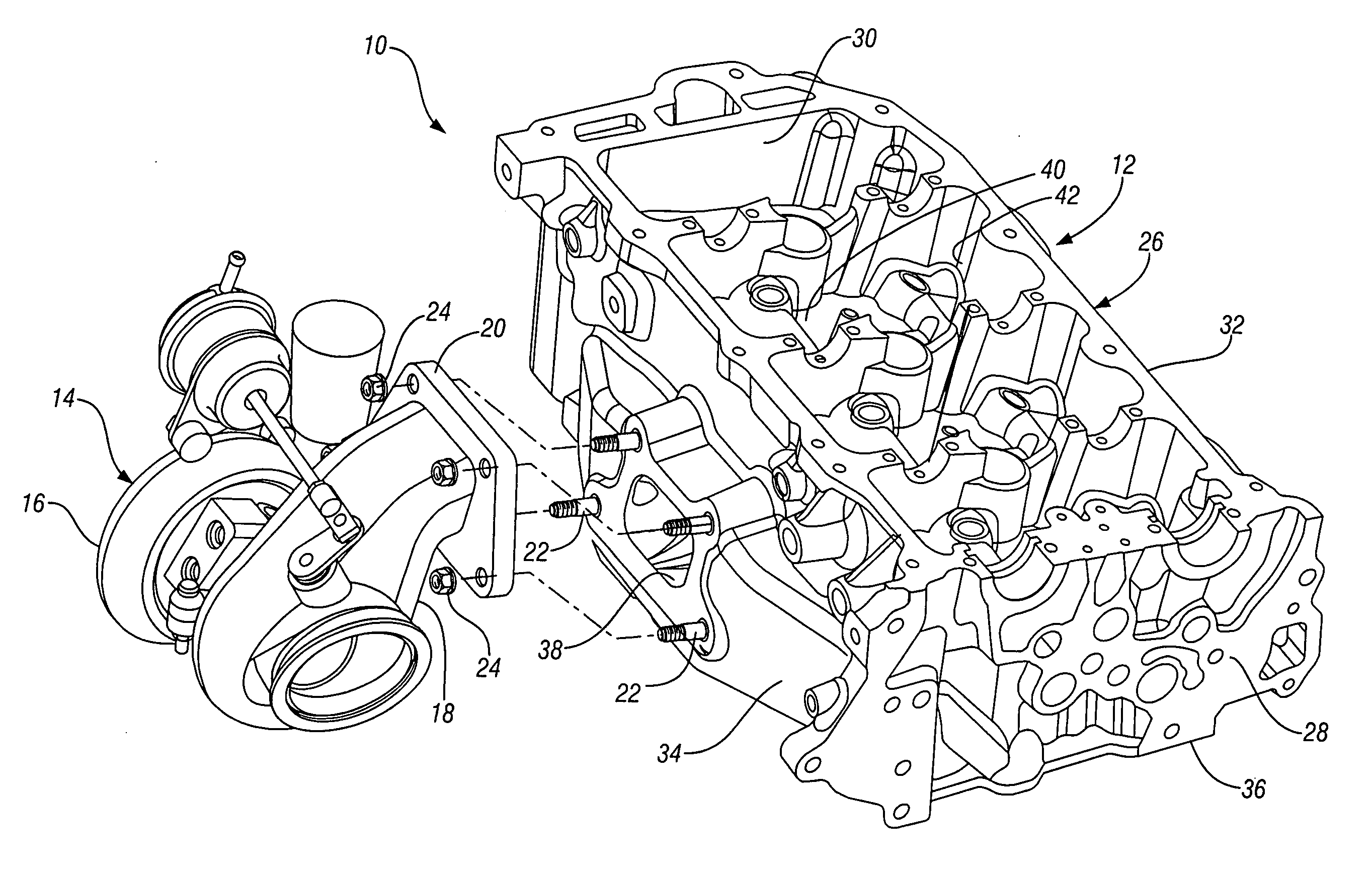

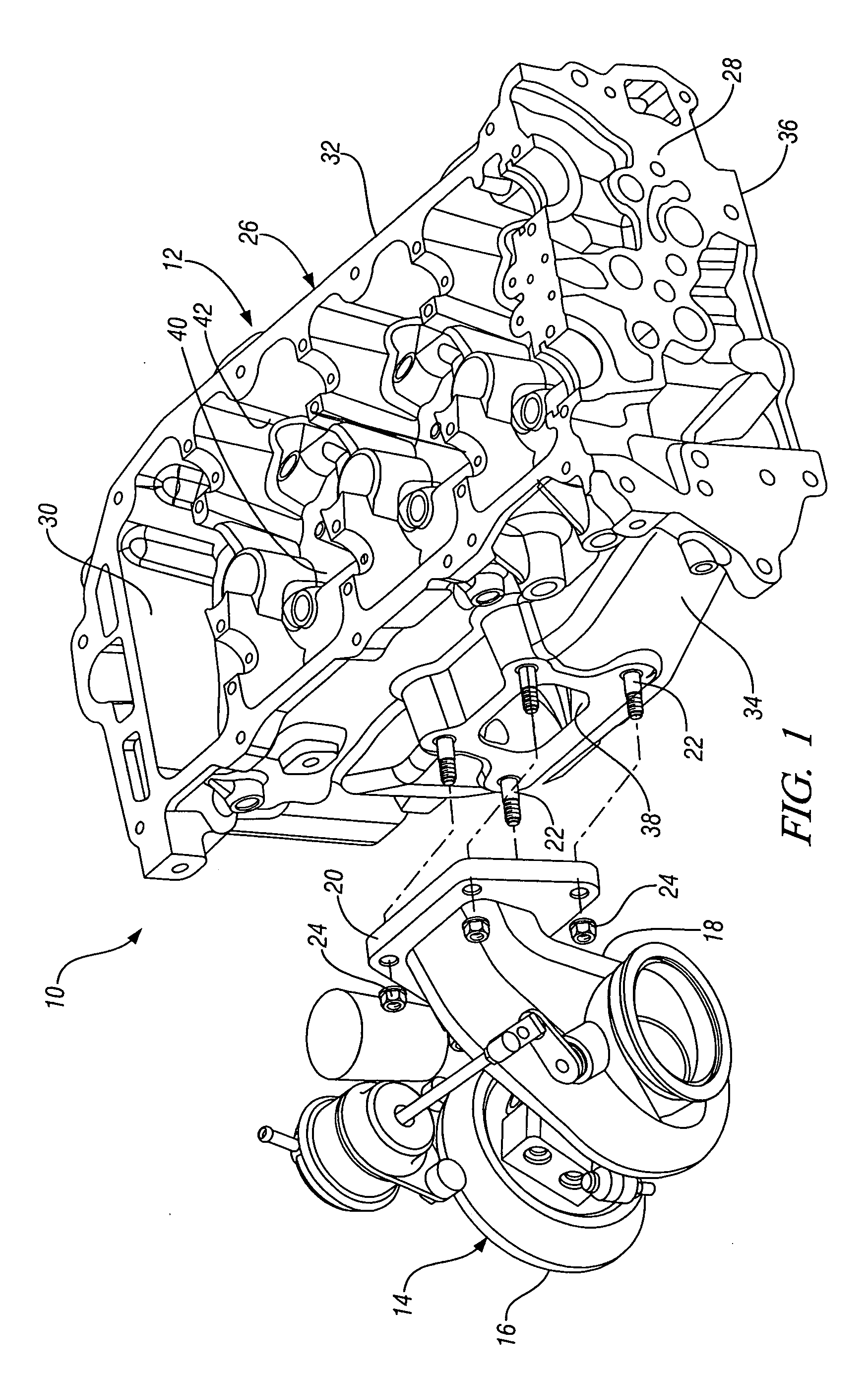

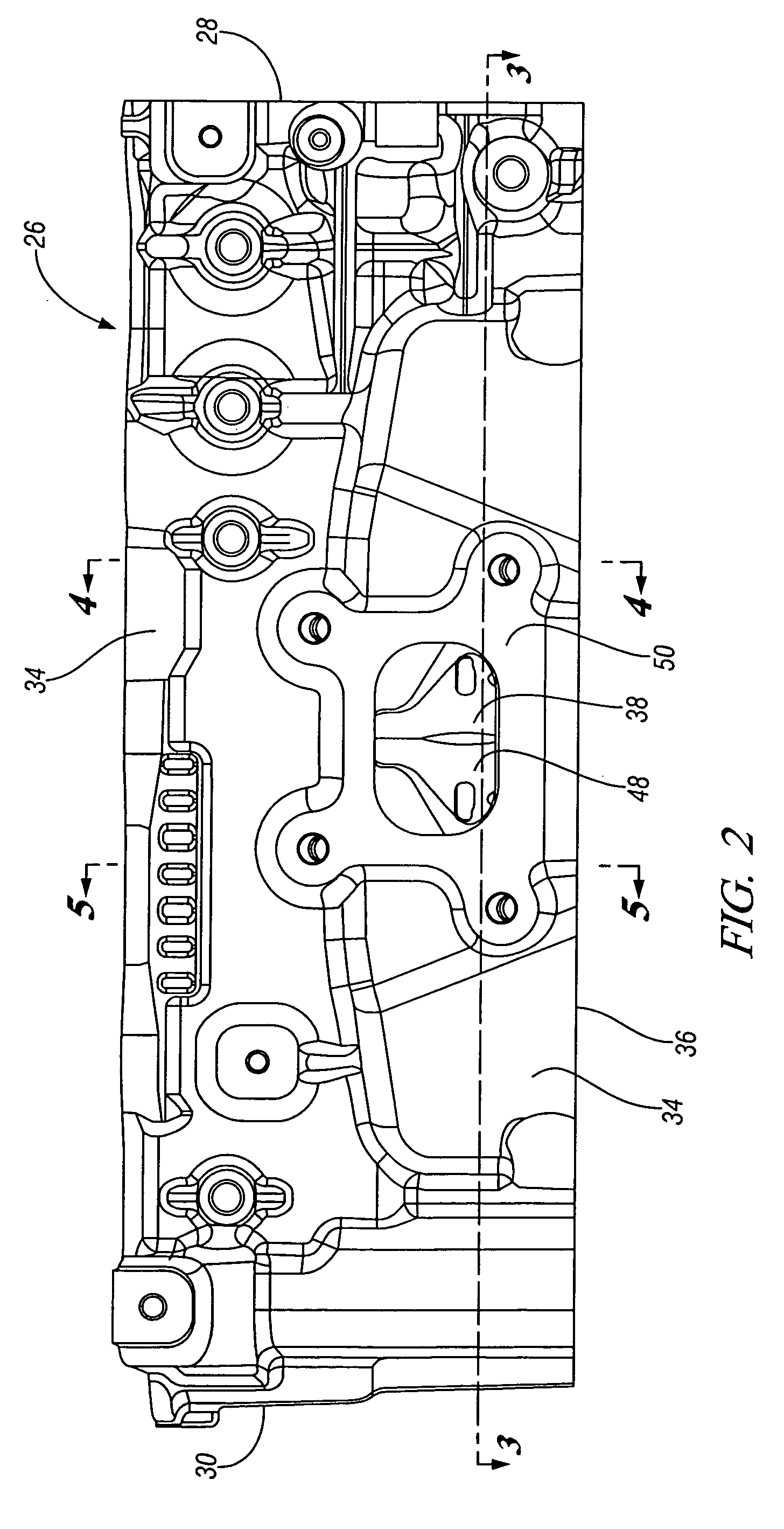

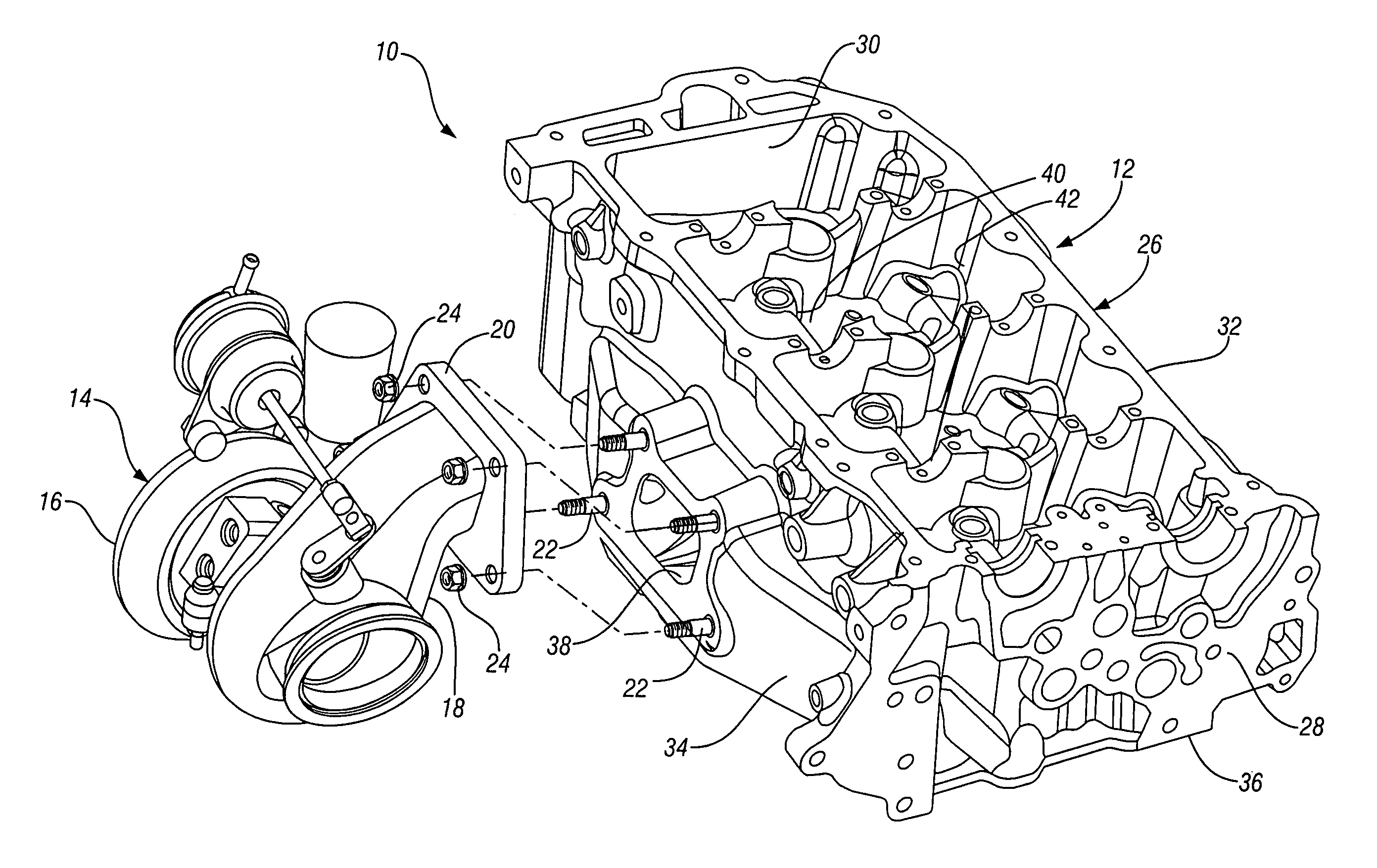

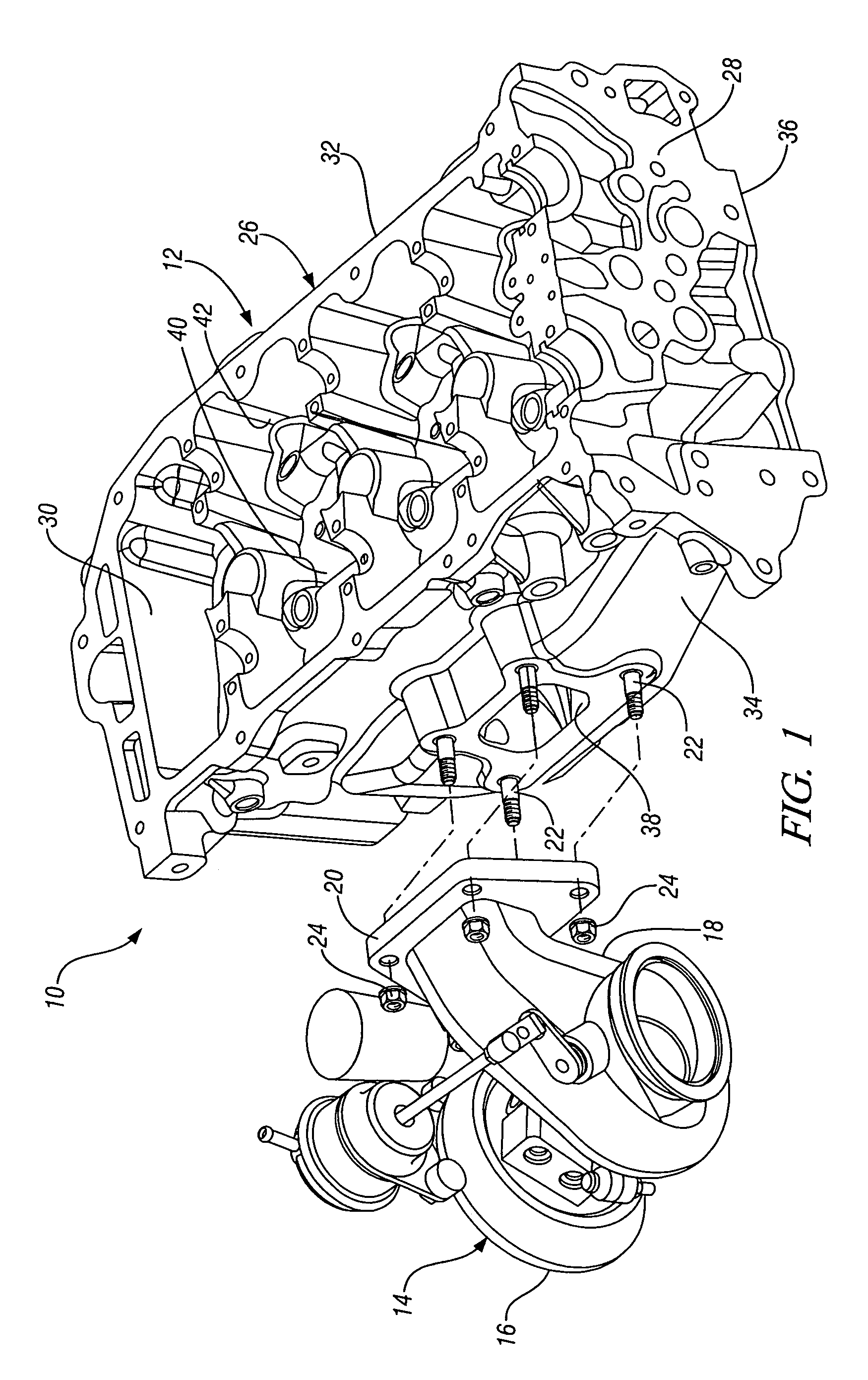

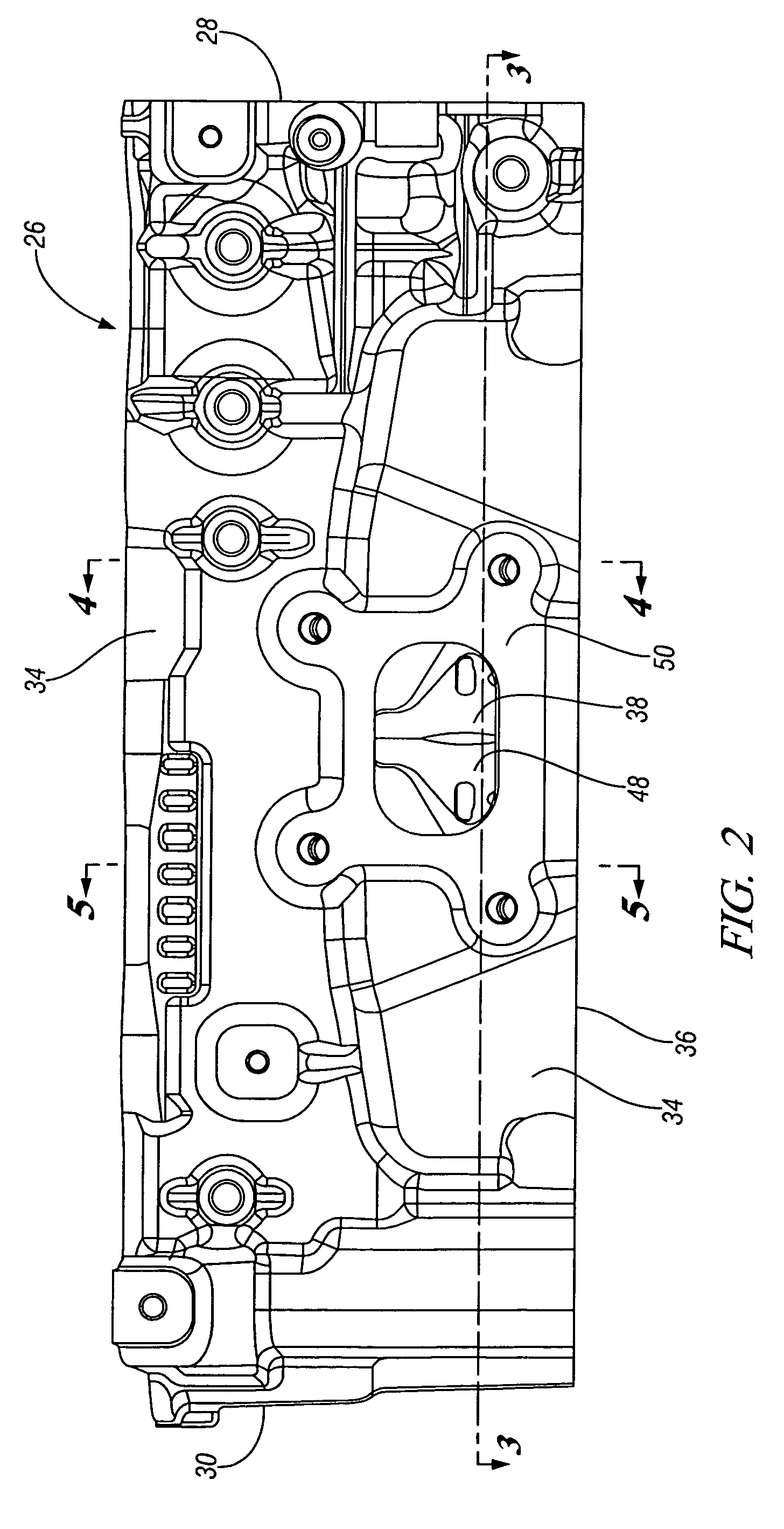

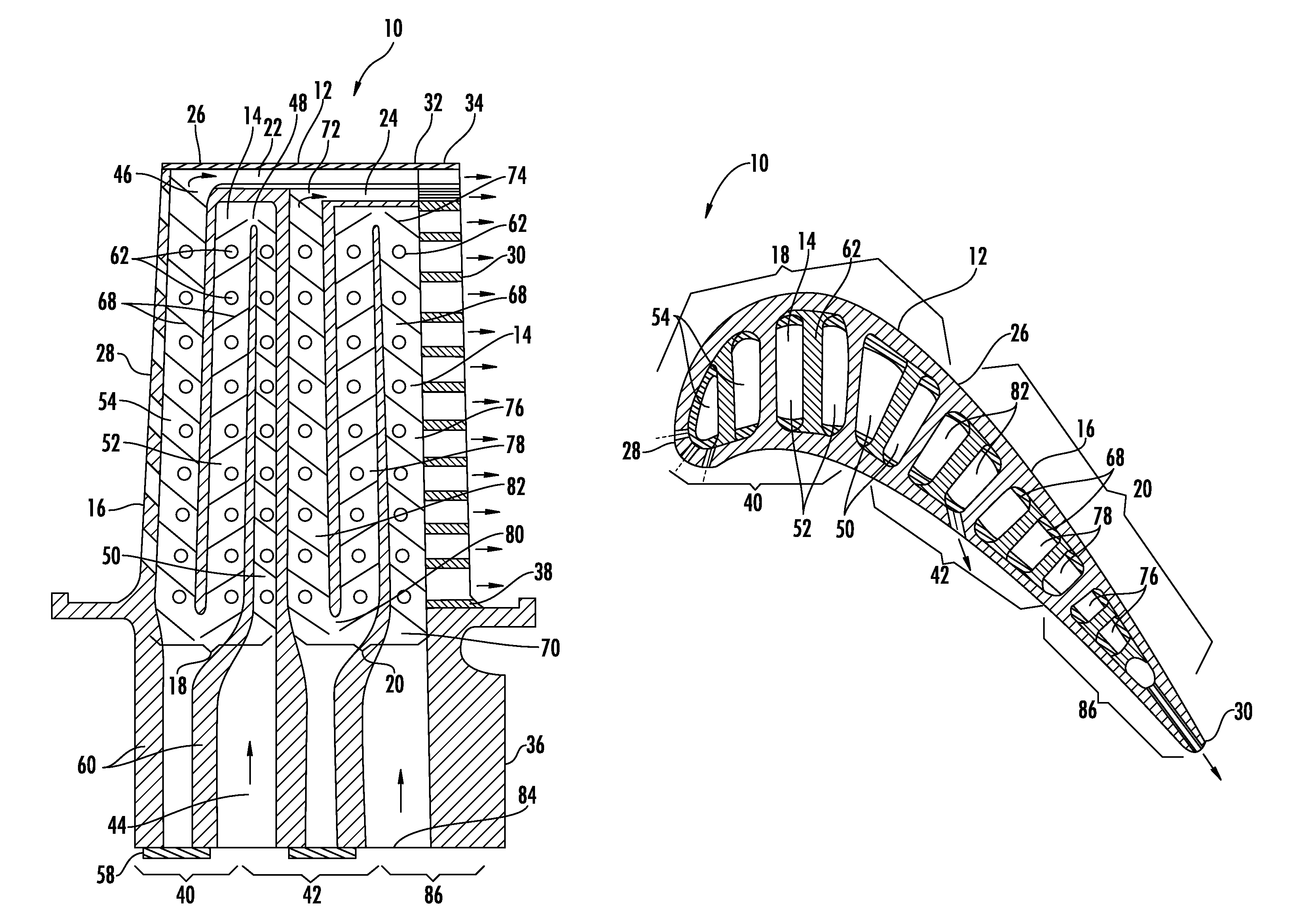

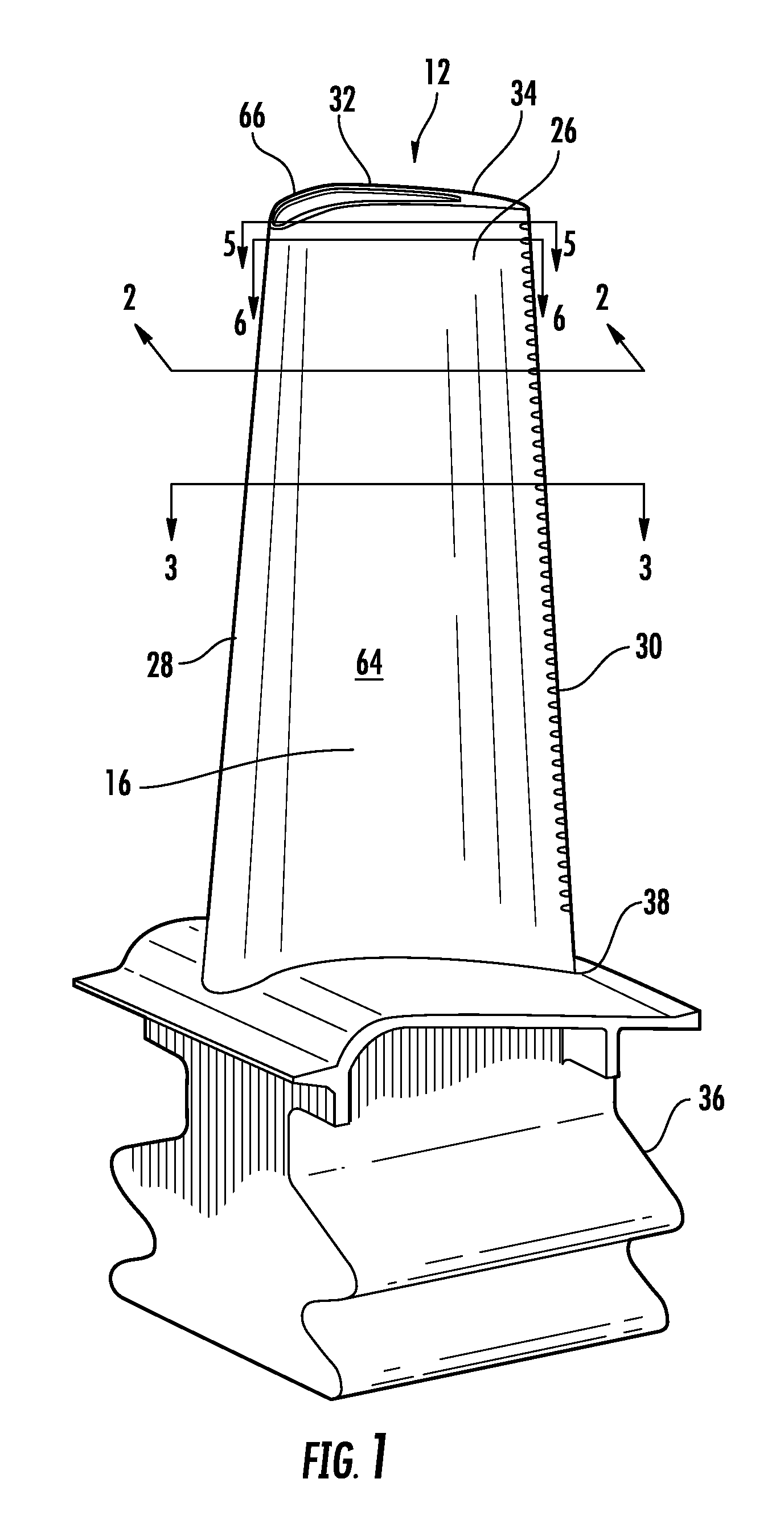

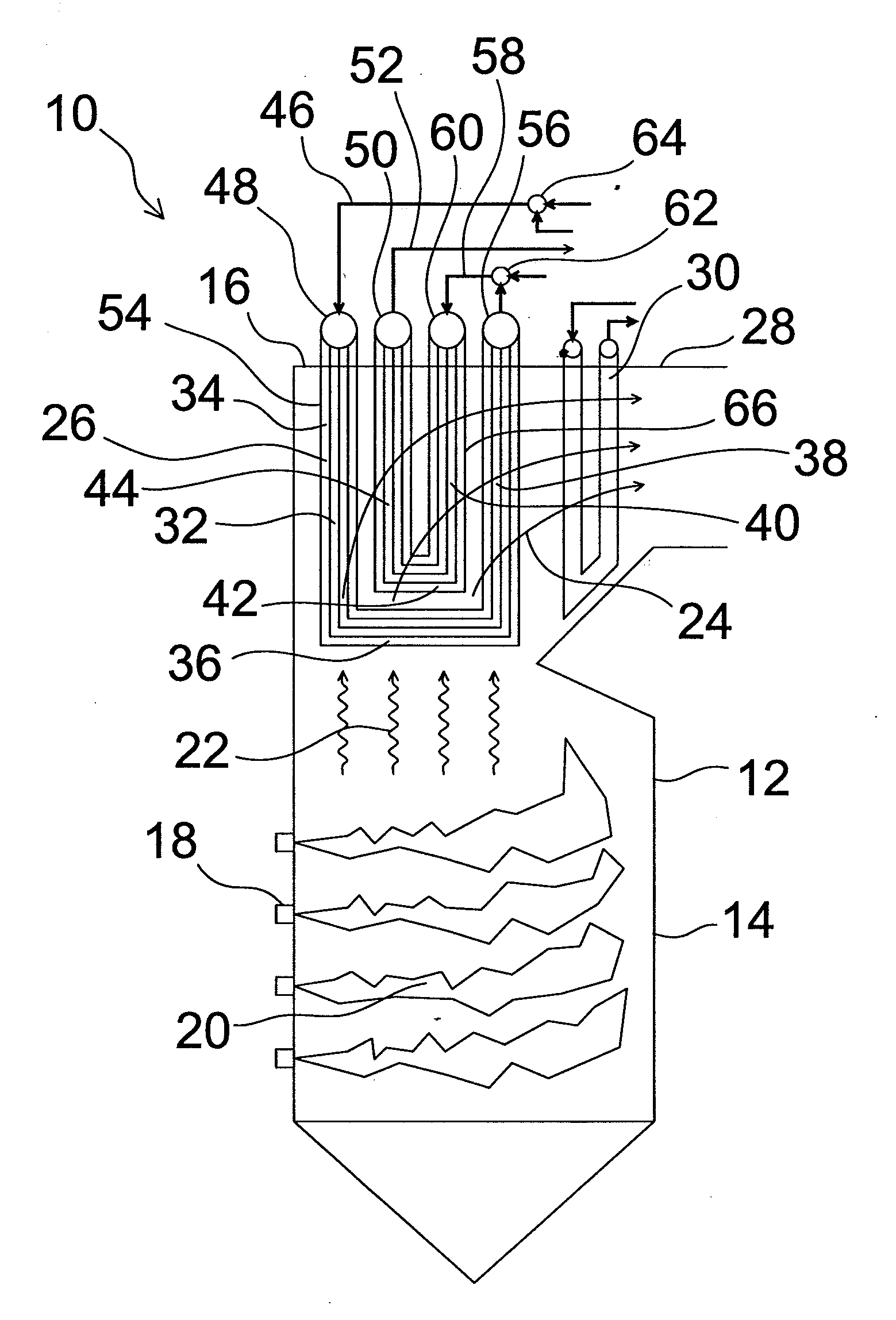

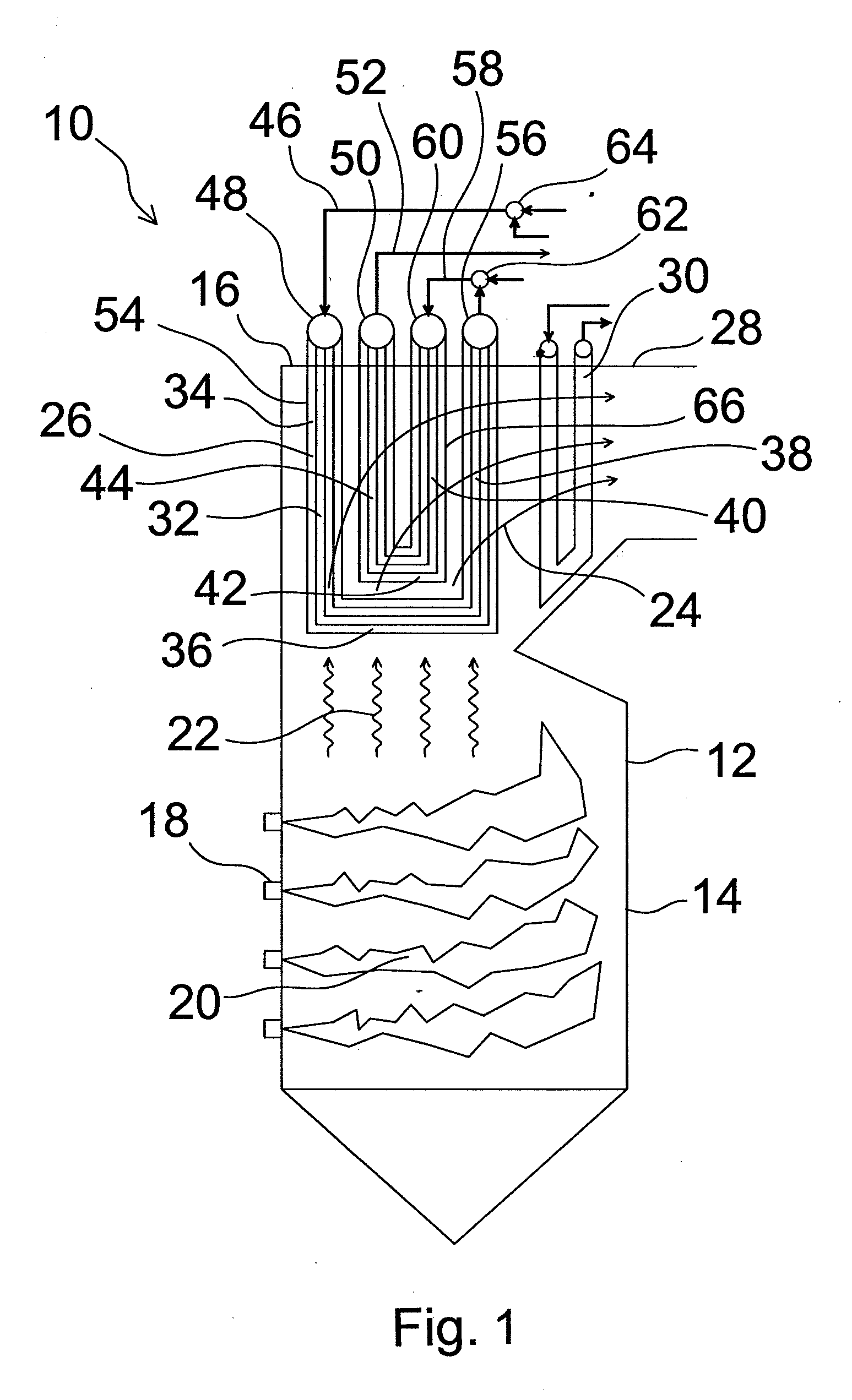

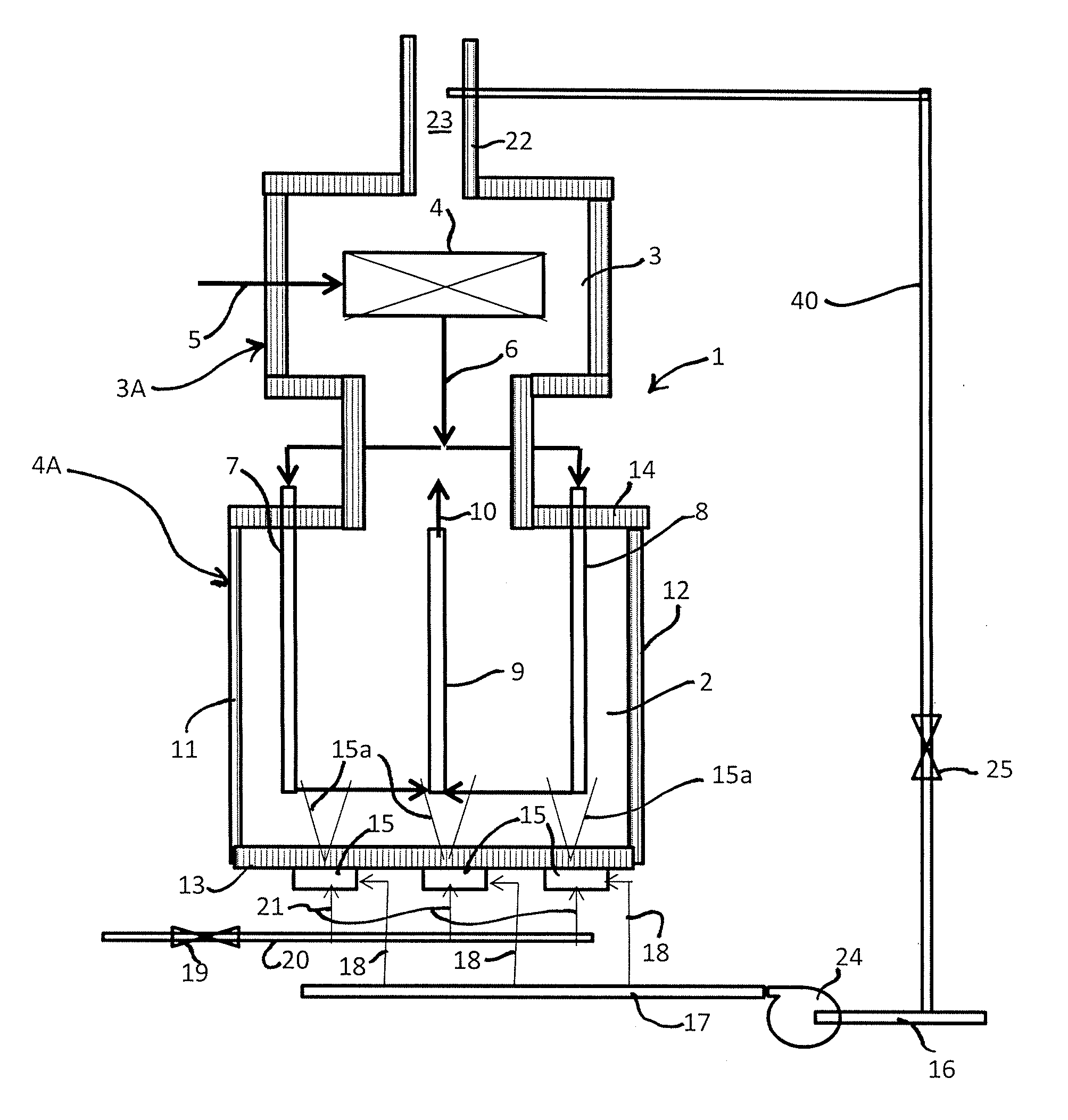

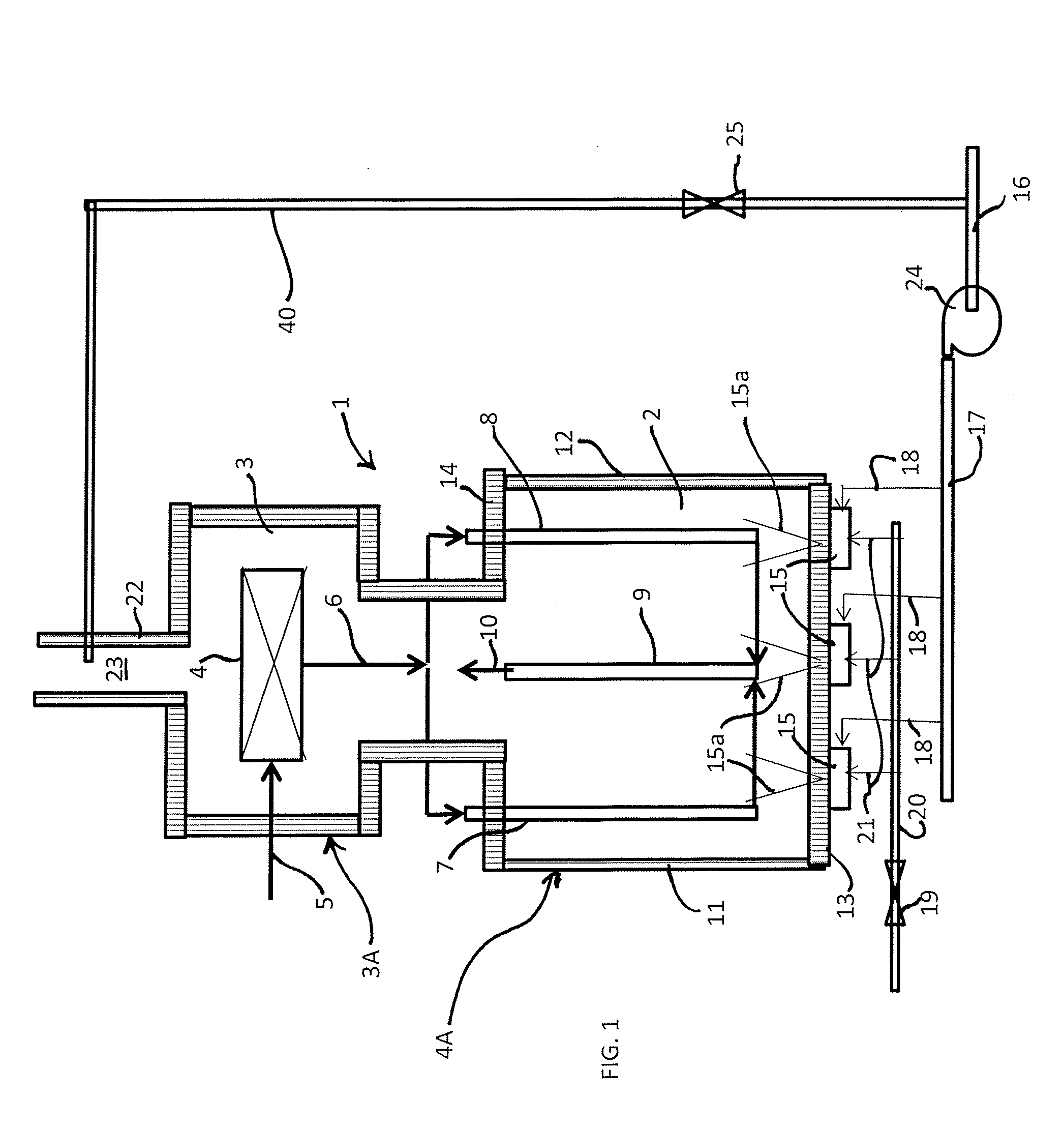

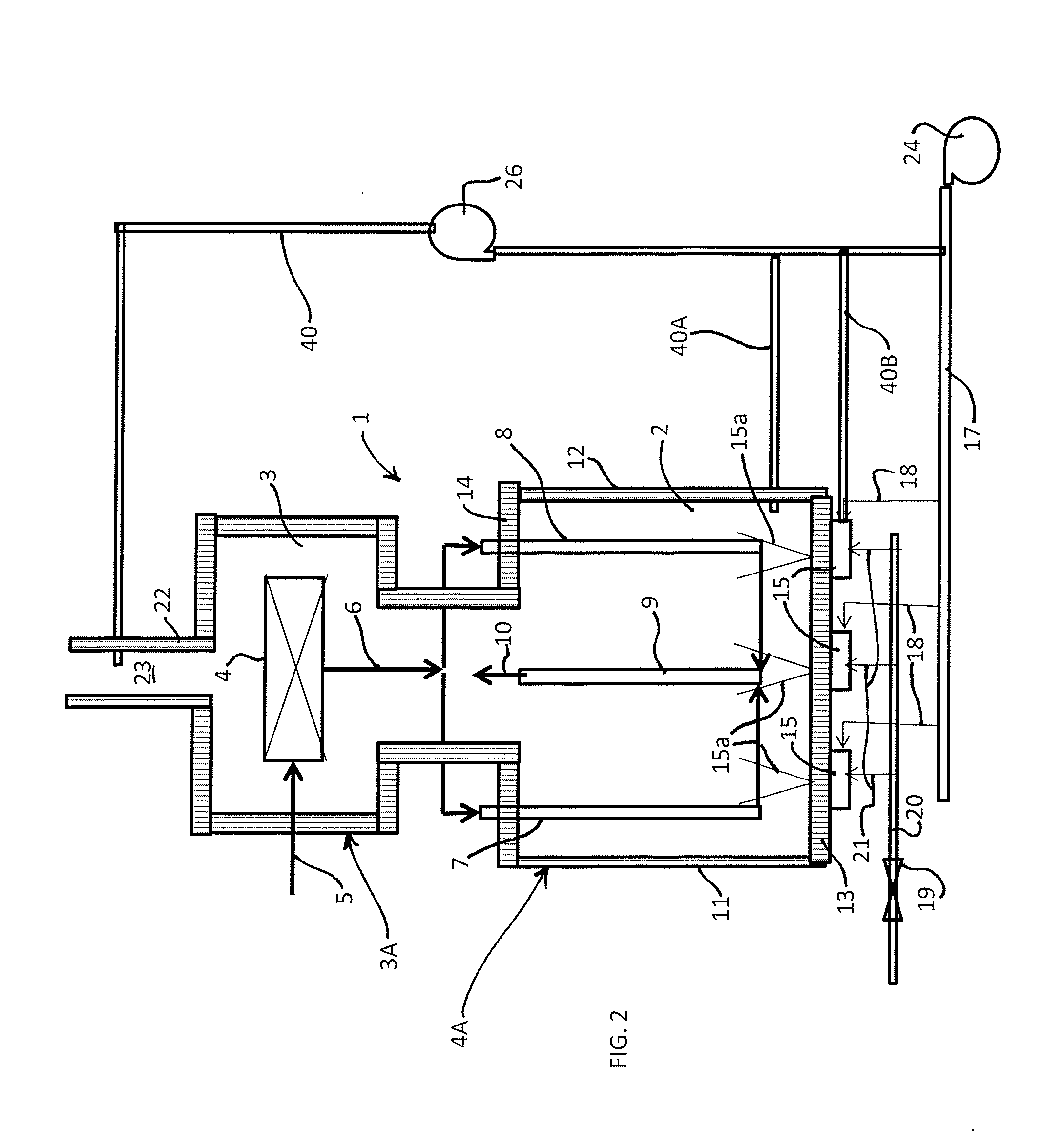

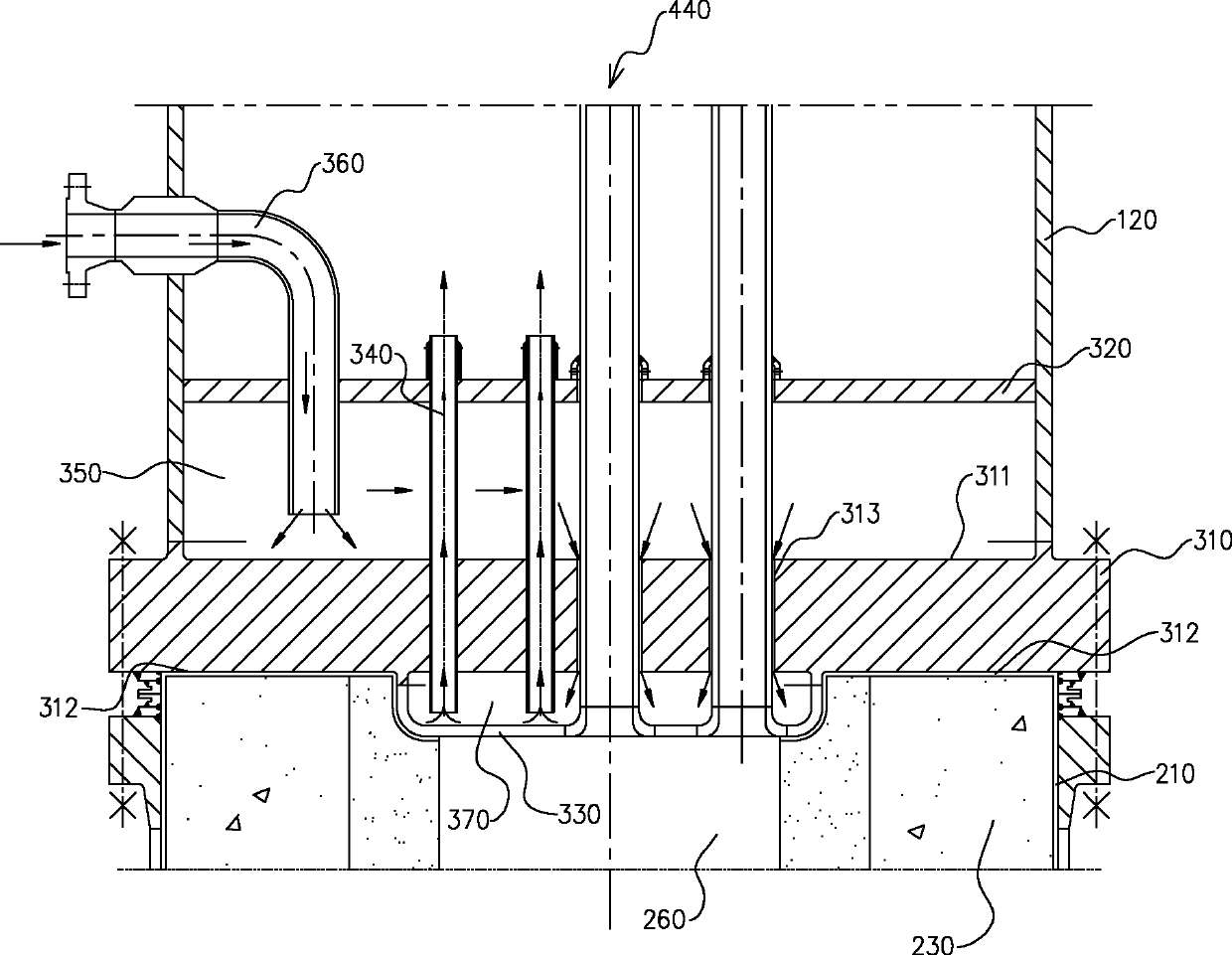

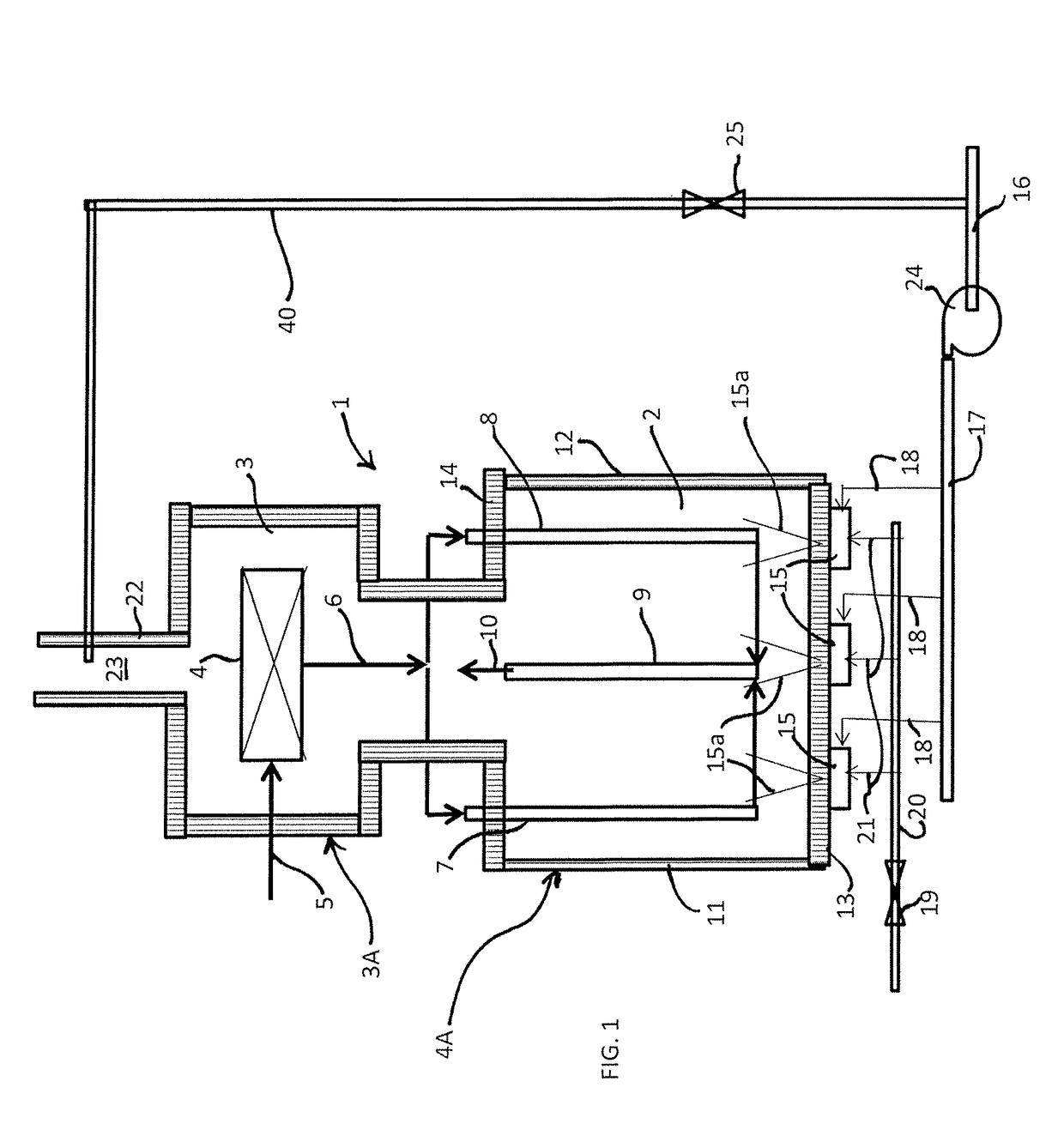

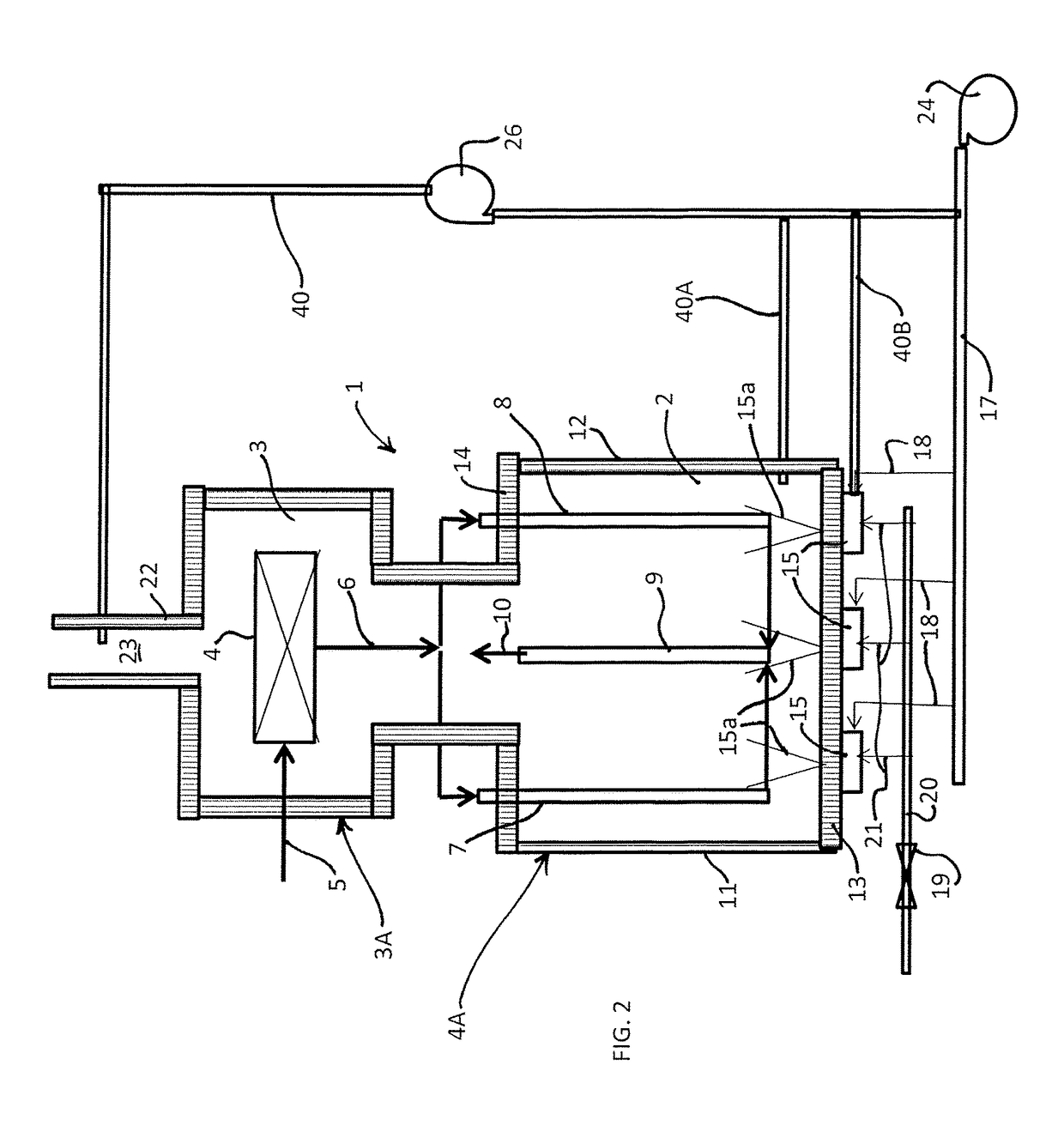

Turbocharged engine cylinder head internal cooling

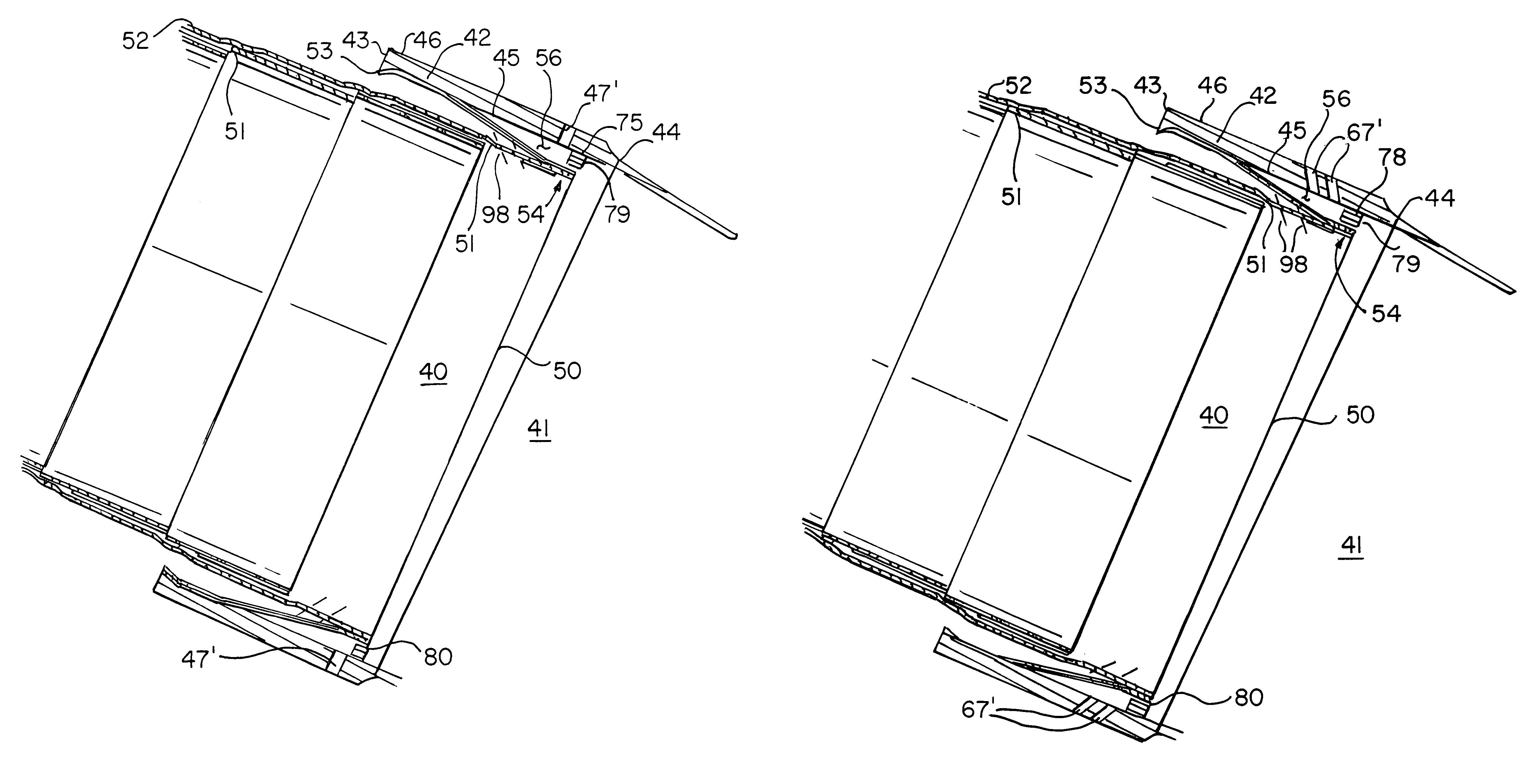

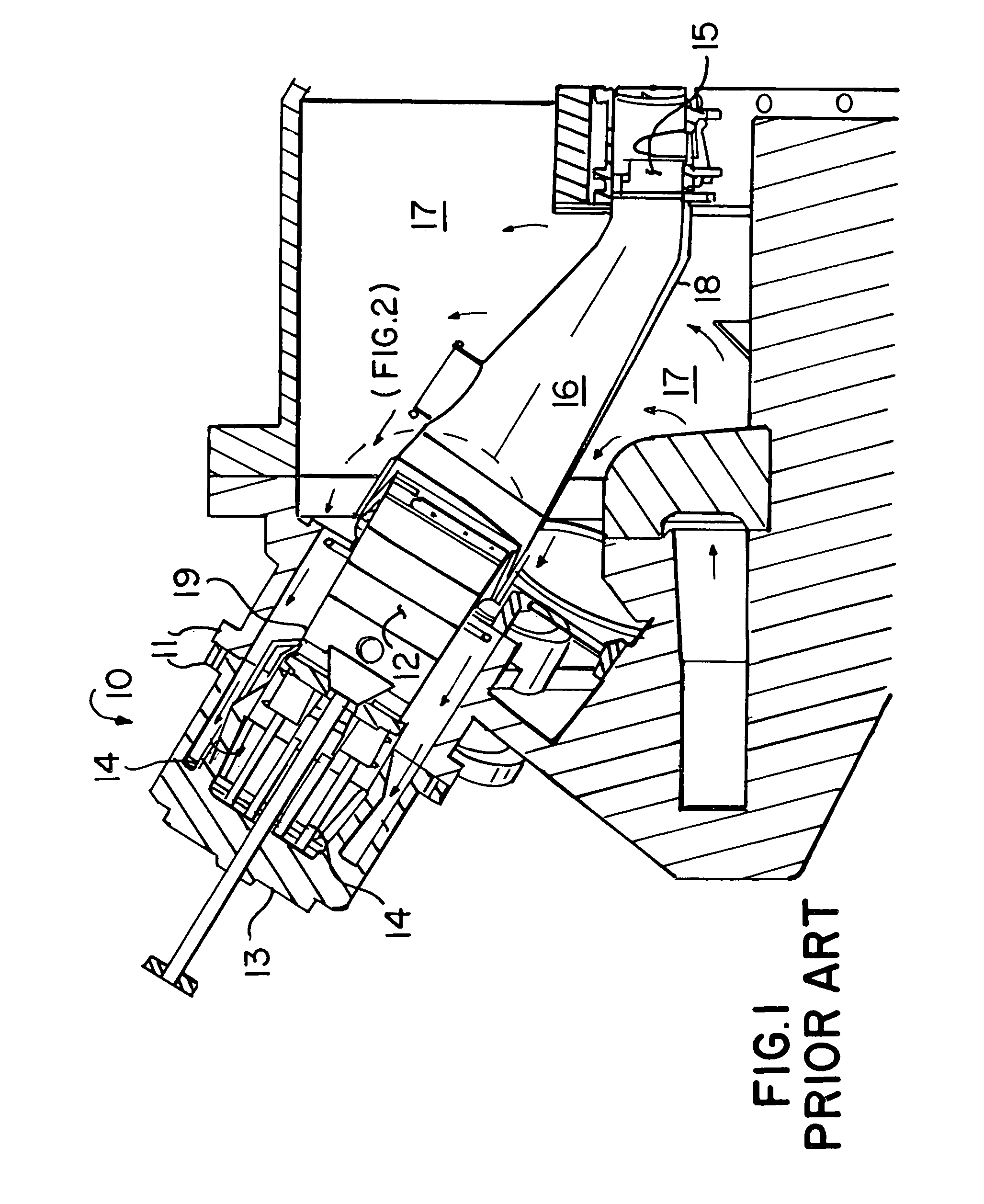

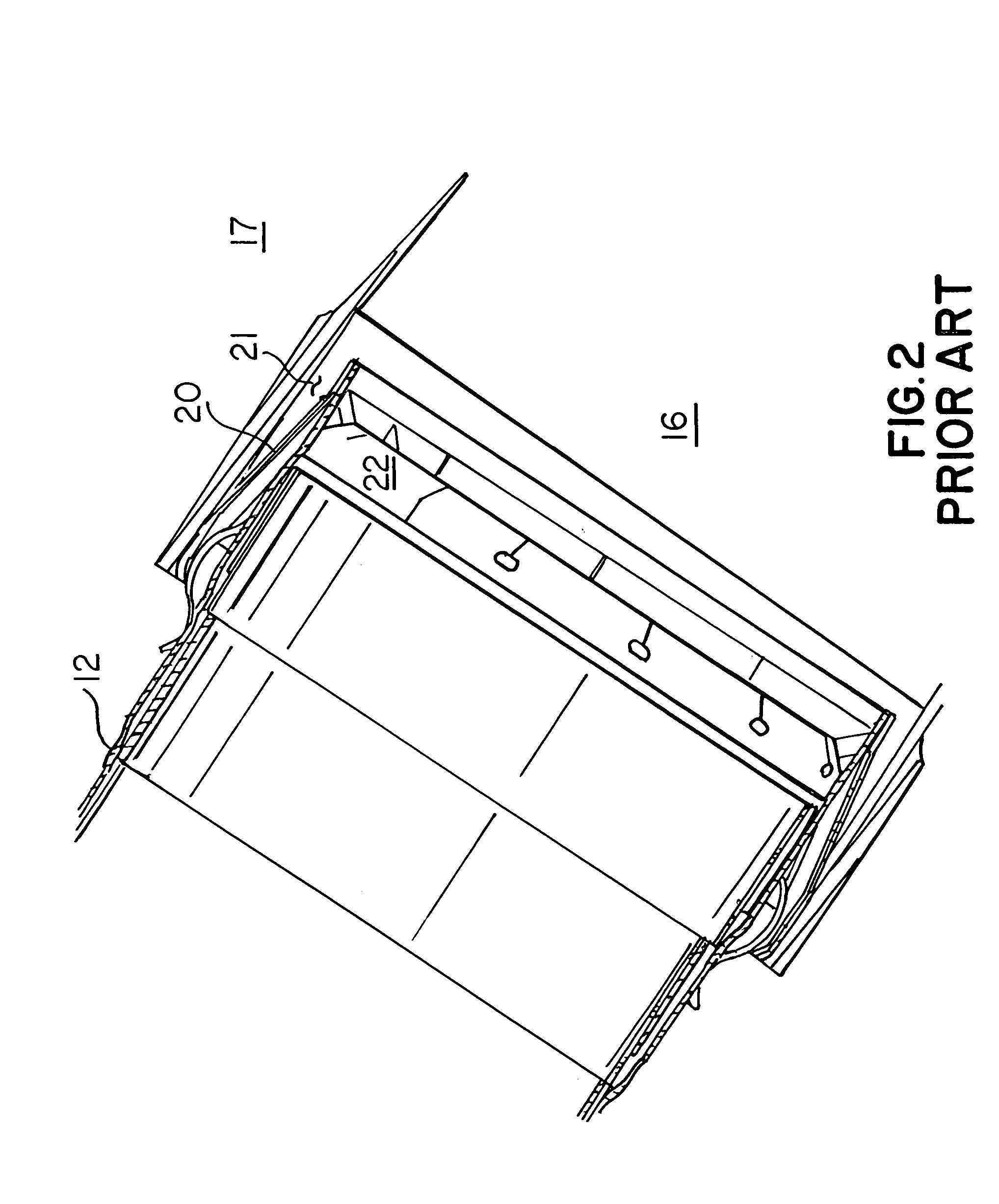

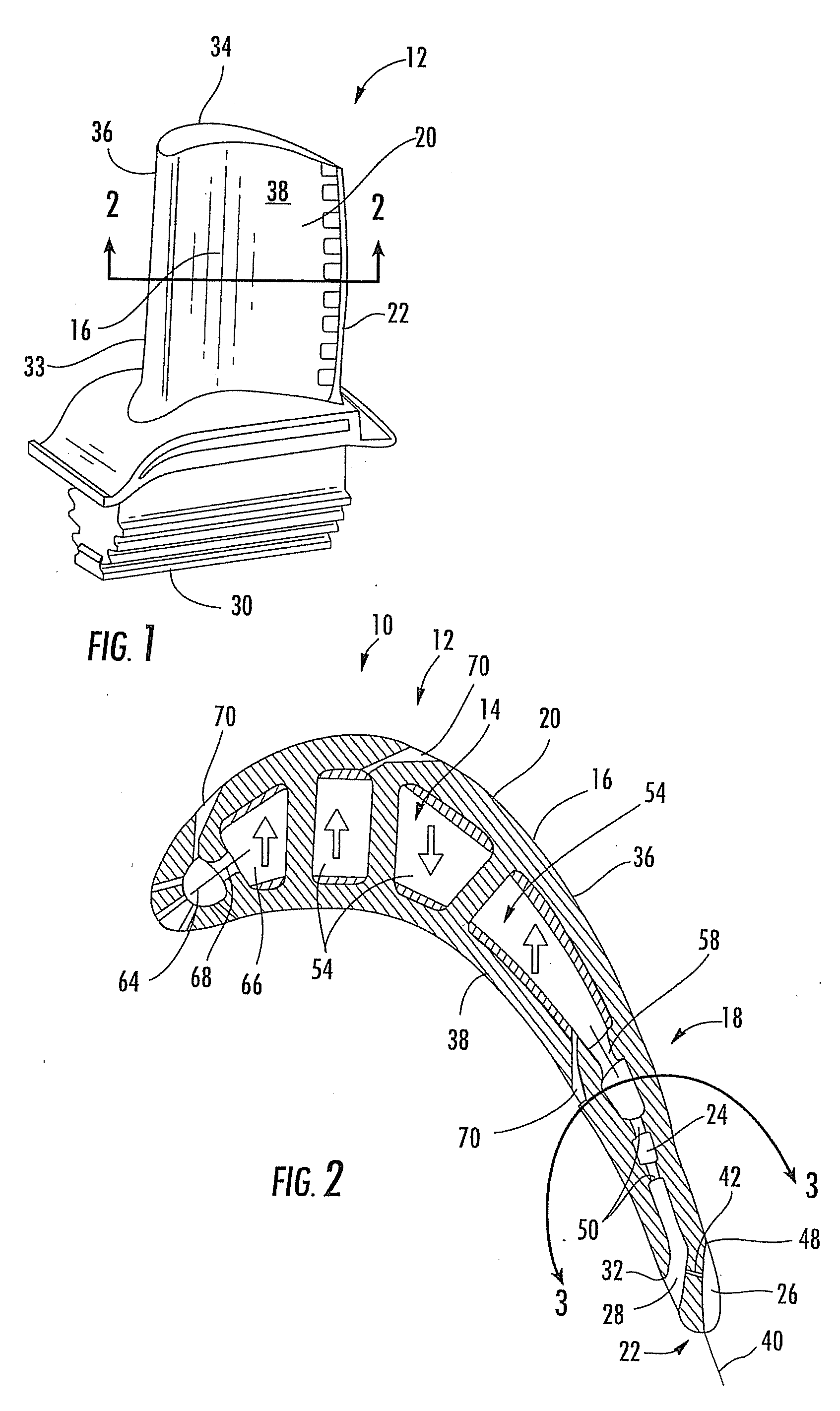

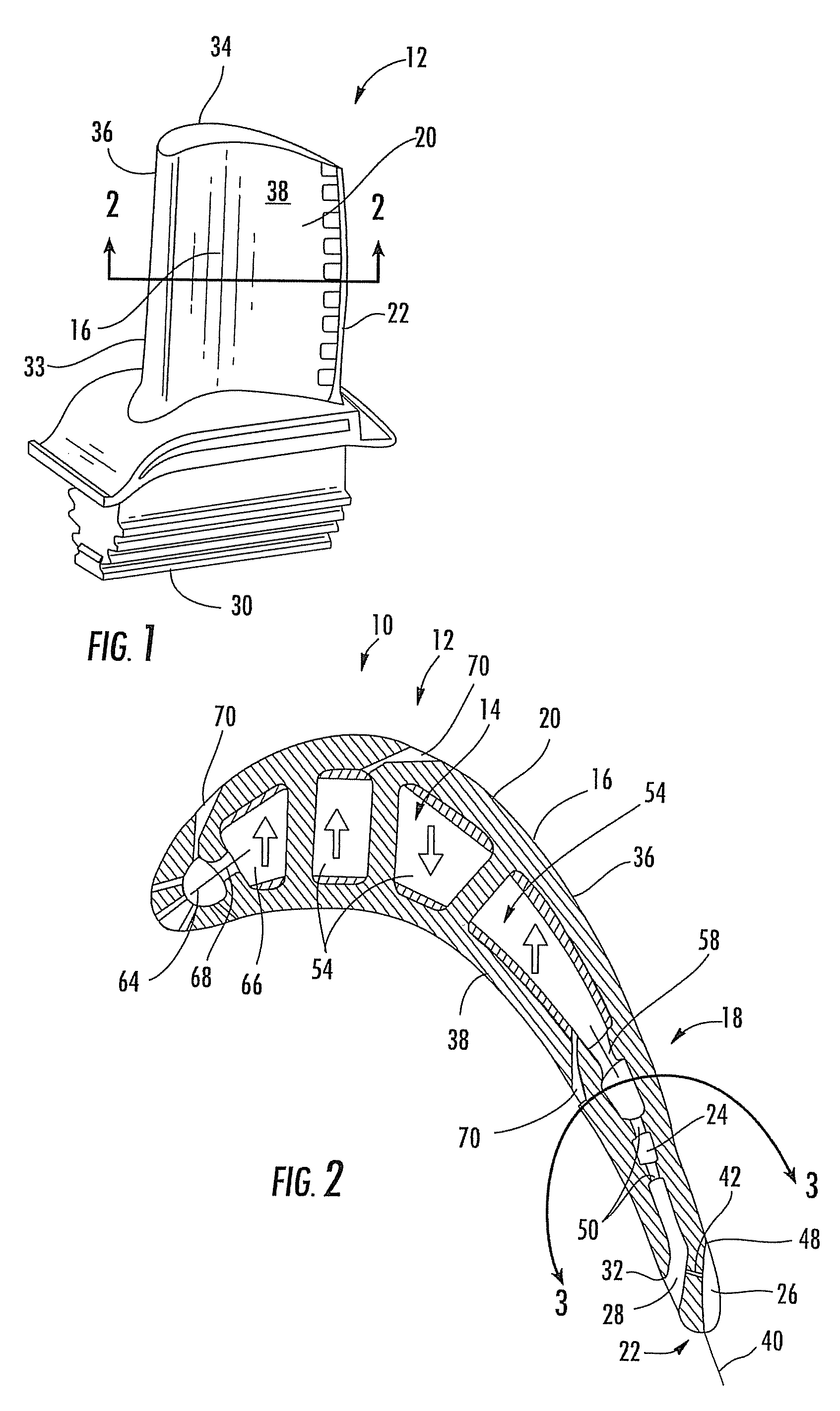

InactiveUS20090126659A1Reduce metal temperatureReduce stepsInternal combustion piston enginesAir coolingCylinder headTurbocharger

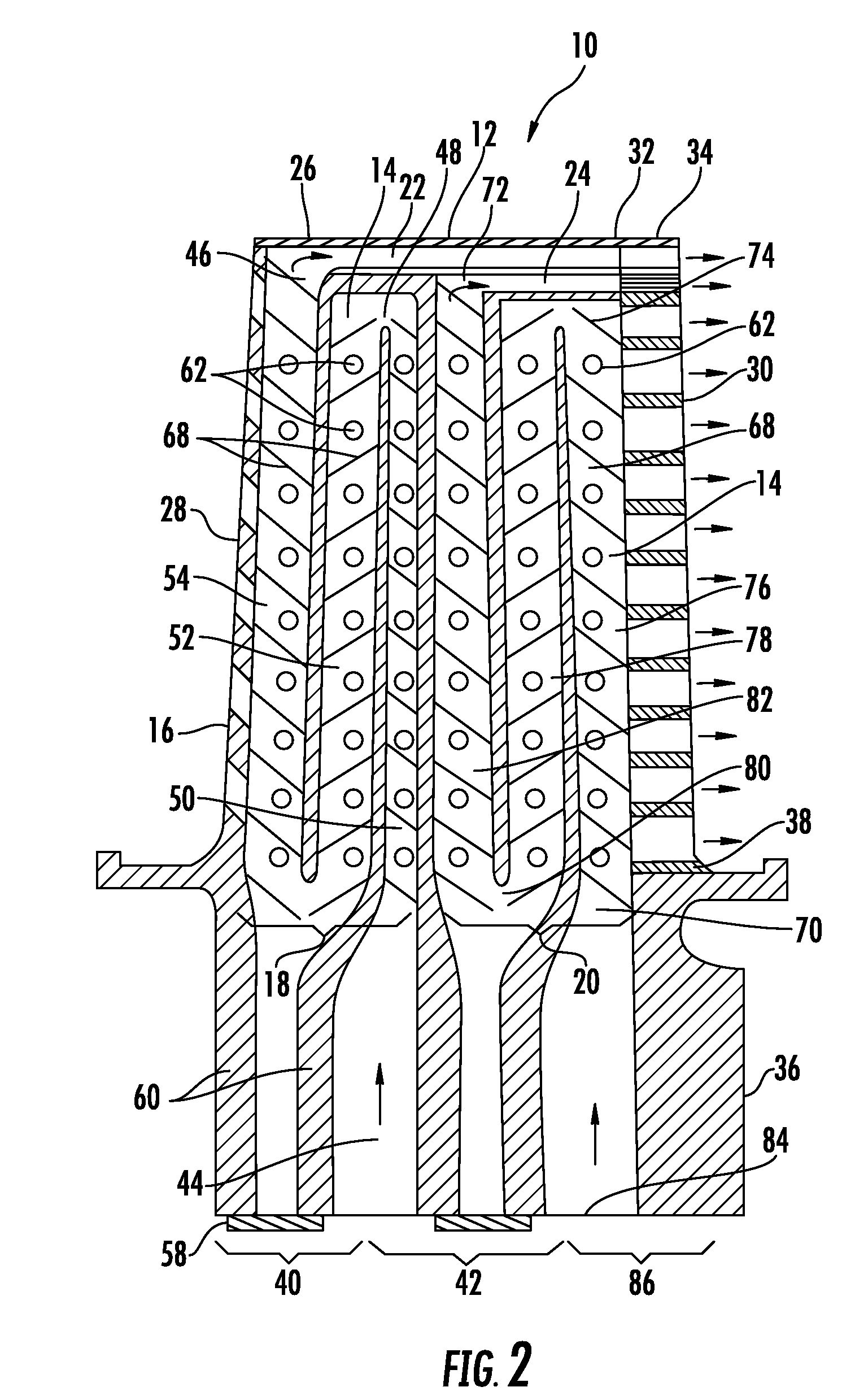

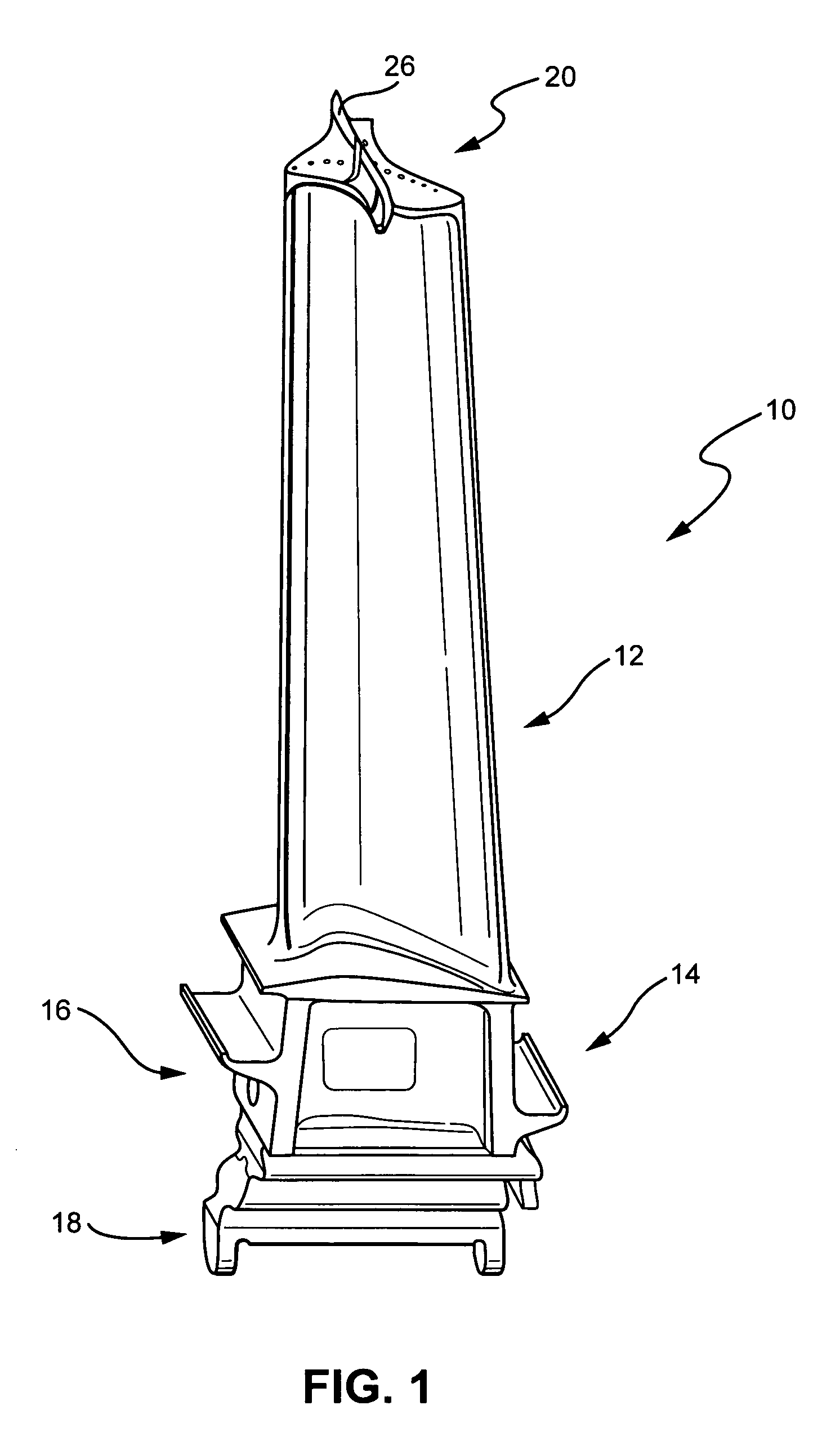

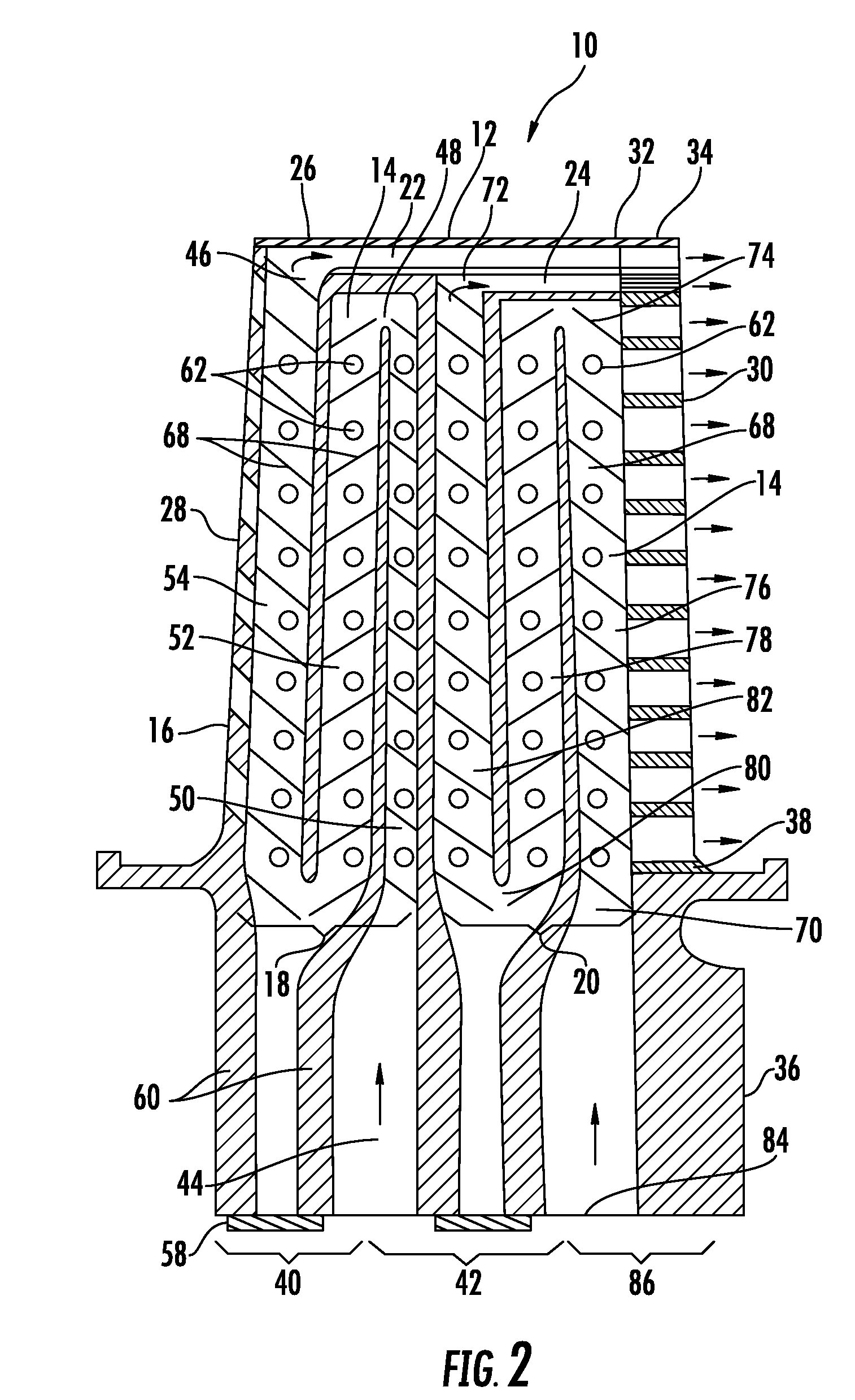

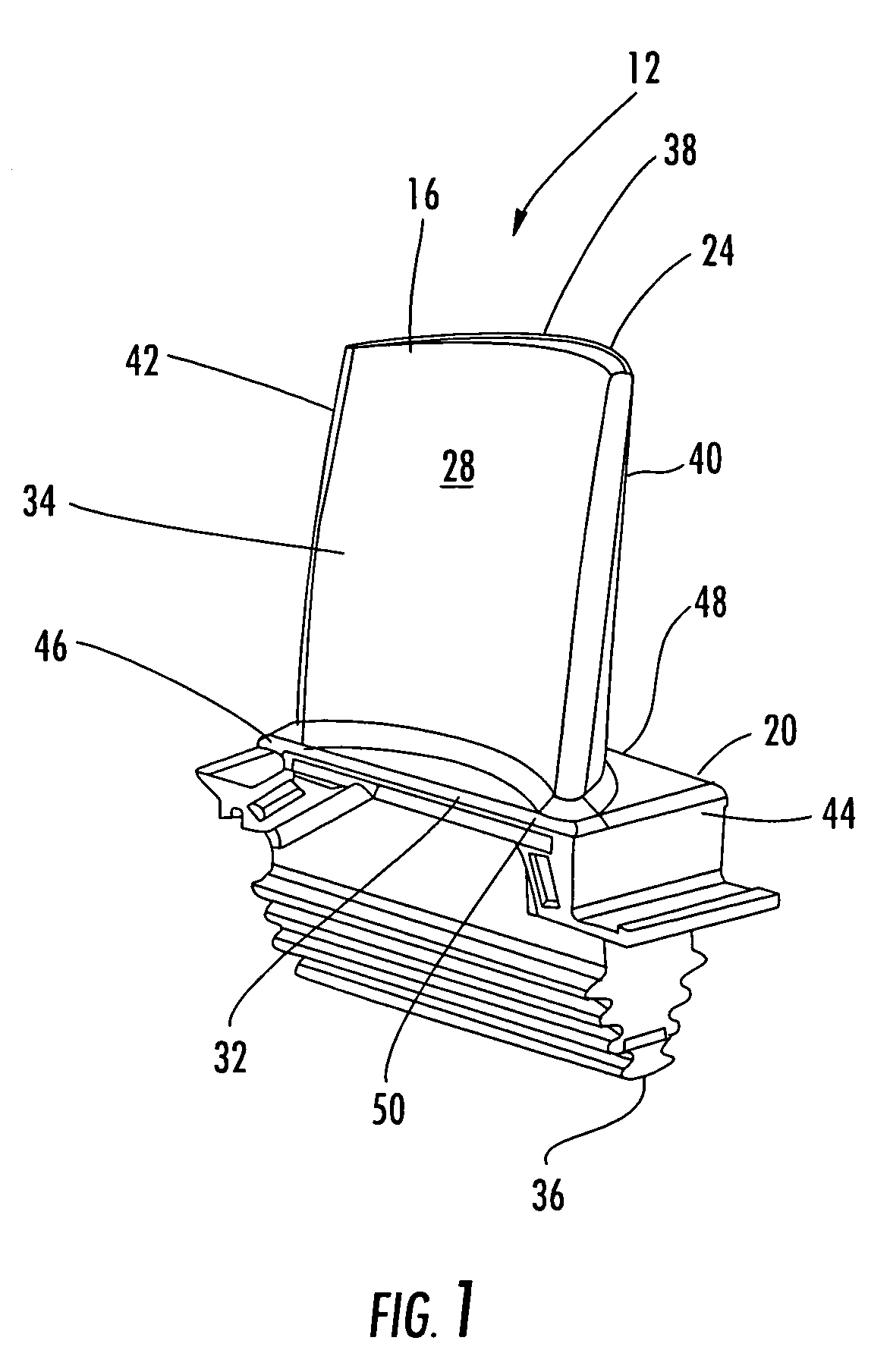

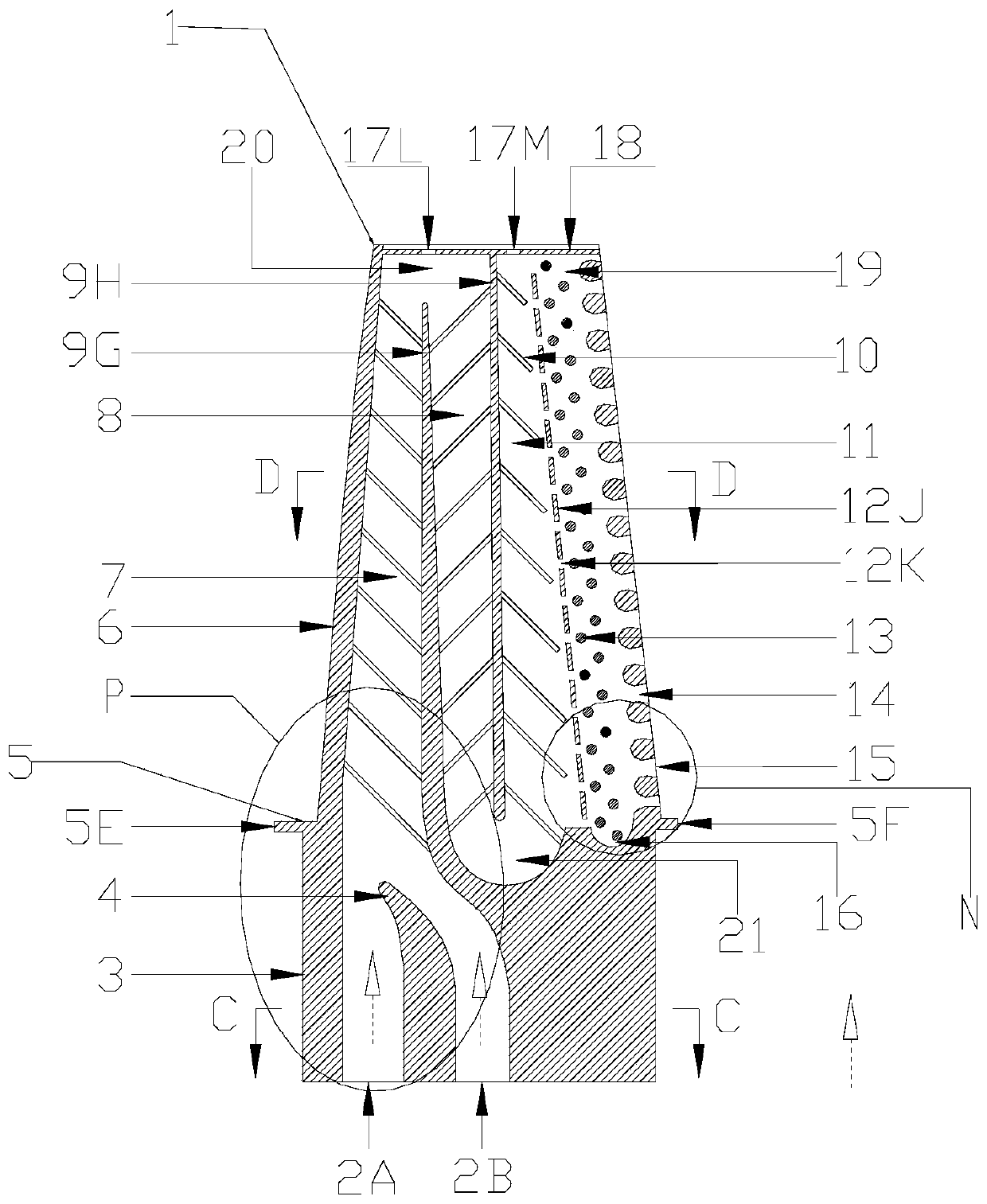

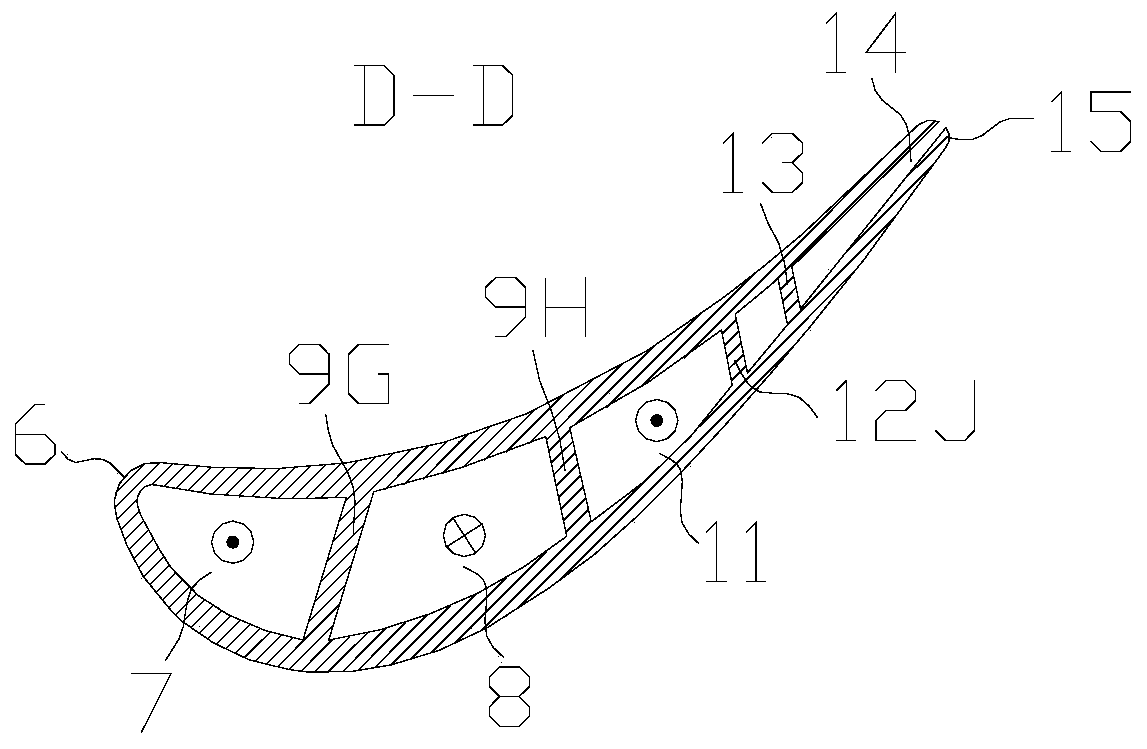

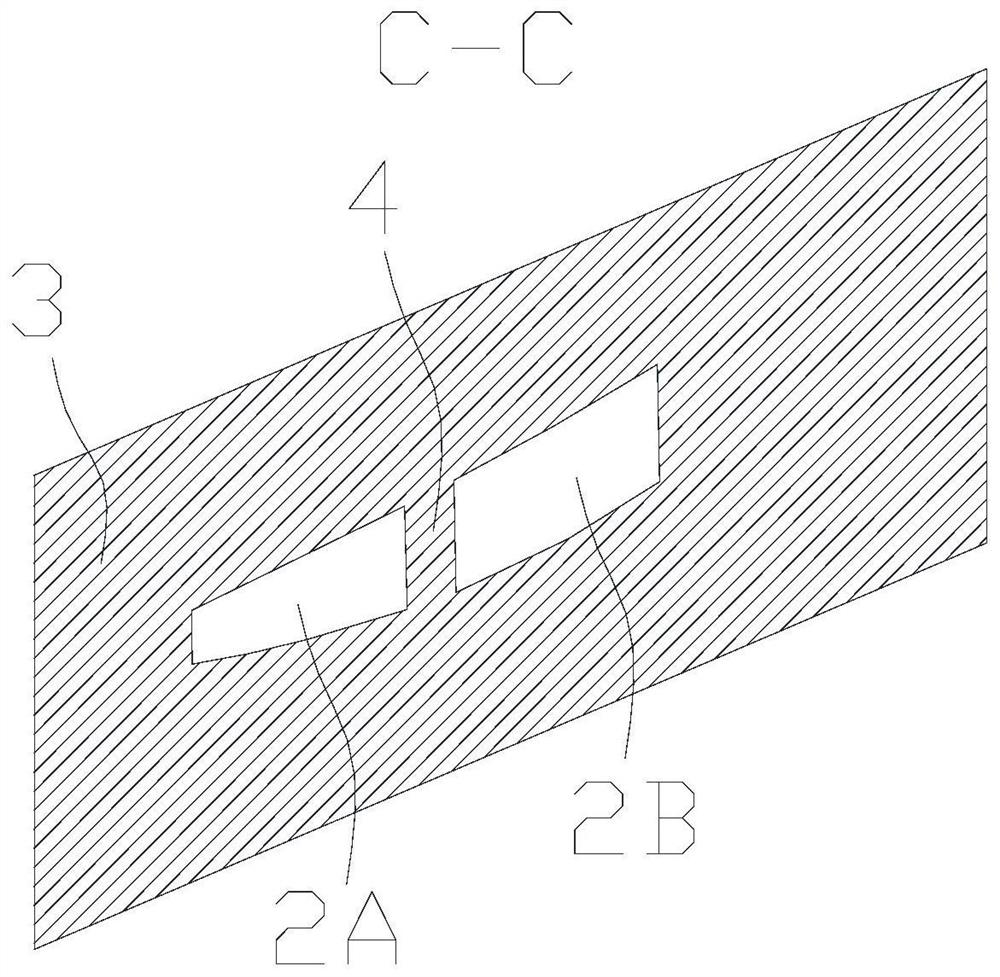

An engine cylinder head has an exhaust manifold cast in the cylinder head. A turbocharger with a turbine body is adapted to mount directly to an exhaust outlet mounting face of the exhaust manifold. A dual level water jacket within the cylinder head has separate coolant feeds for upper and lower cooling jackets. The cooling jackets extend above and below the exhaust outlet and are connected inward of the exhaust mounting face to reduce metal temperatures of the mounting face below those of the turbocharger exhaust inlet flange. Separate cores for the upper and lower jackets are connected at coolant inlet and outlet locations at opposite ends. Intermediate core print connectors form controlled flow passages between the upper and lower jackets and exhaust ports in the cylinder head and integrated manifold. The improved cooling in these areas lowers operating temperatures in the cylinder head and obviates the need for a separate exhaust manifold.

Owner:GM GLOBAL TECH OPERATIONS LLC

Turbocharged engine cylinder head internal cooling

InactiveUS7784442B2Reduce metal temperatureReduce stepsLiquid coolingInternal combustion piston enginesTurbochargerCylinder head

An engine cylinder head has an exhaust manifold cast in the cylinder head. A turbocharger with a turbine body is adapted to mount directly to an exhaust outlet mounting face of the exhaust manifold. A dual level water jacket within the cylinder head has separate coolant feeds for upper and lower cooling jackets. The cooling jackets extend above and below the exhaust outlet and are connected inward of the exhaust mounting face to reduce metal temperatures of the mounting face below those of the turbocharger exhaust inlet flange. Separate cores for the upper and lower jackets are connected at coolant inlet and outlet locations at opposite ends. Intermediate core print connectors form controlled flow passages between the upper and lower jackets and exhaust ports in the cylinder head and integrated manifold. The improved cooling in these areas lowers operating temperatures in the cylinder head and obviates the need for a separate exhaust manifold.

Owner:GM GLOBAL TECH OPERATIONS LLC

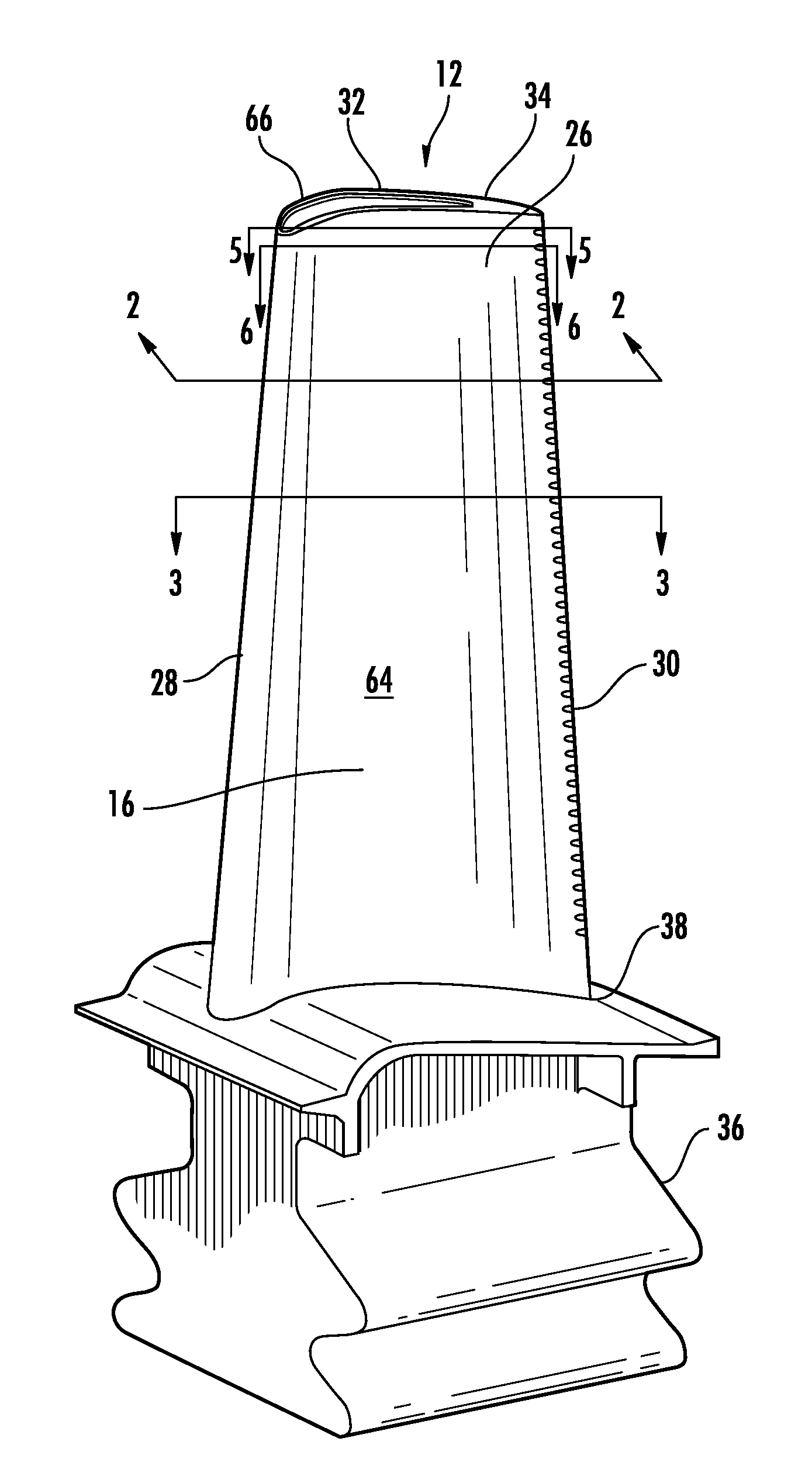

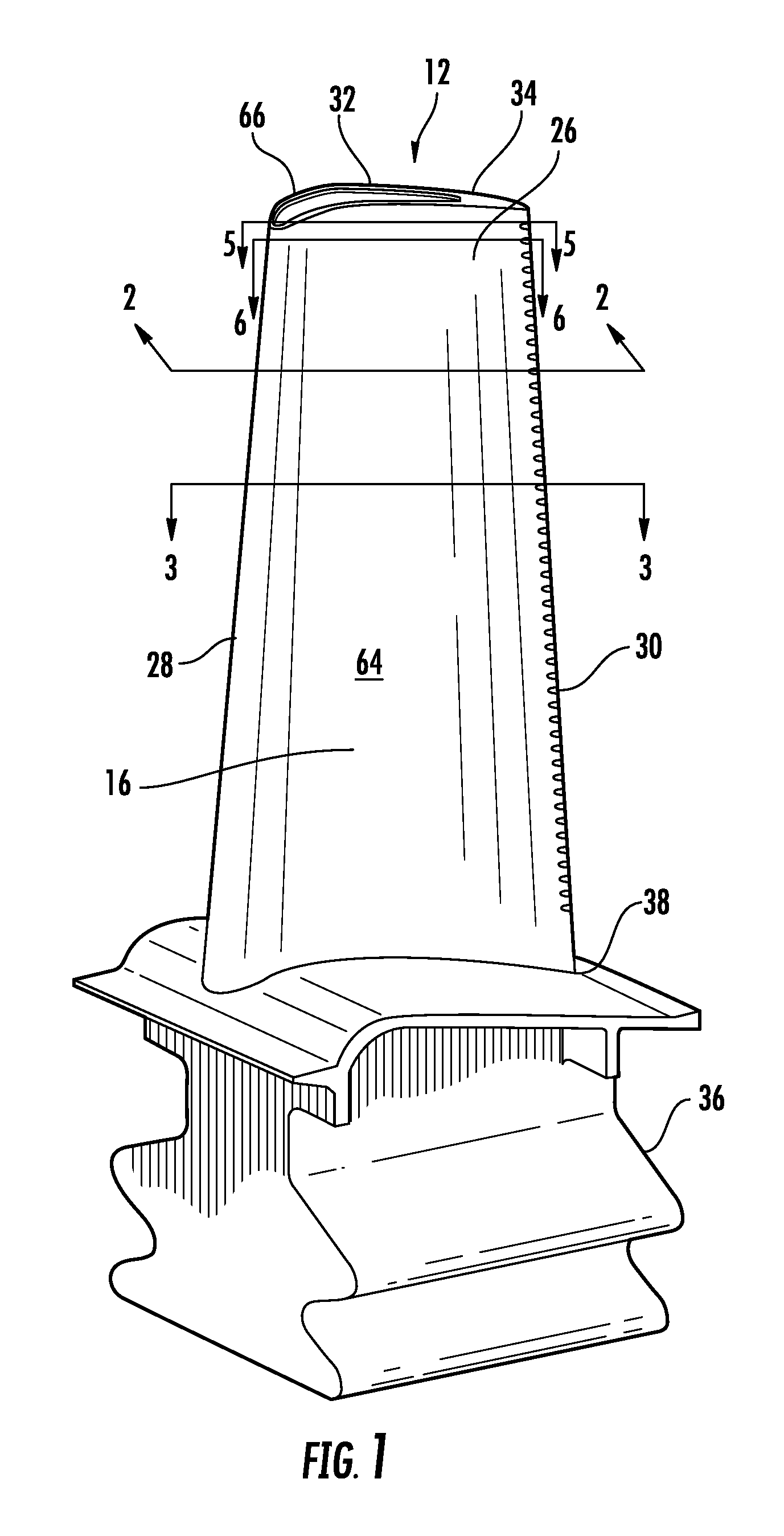

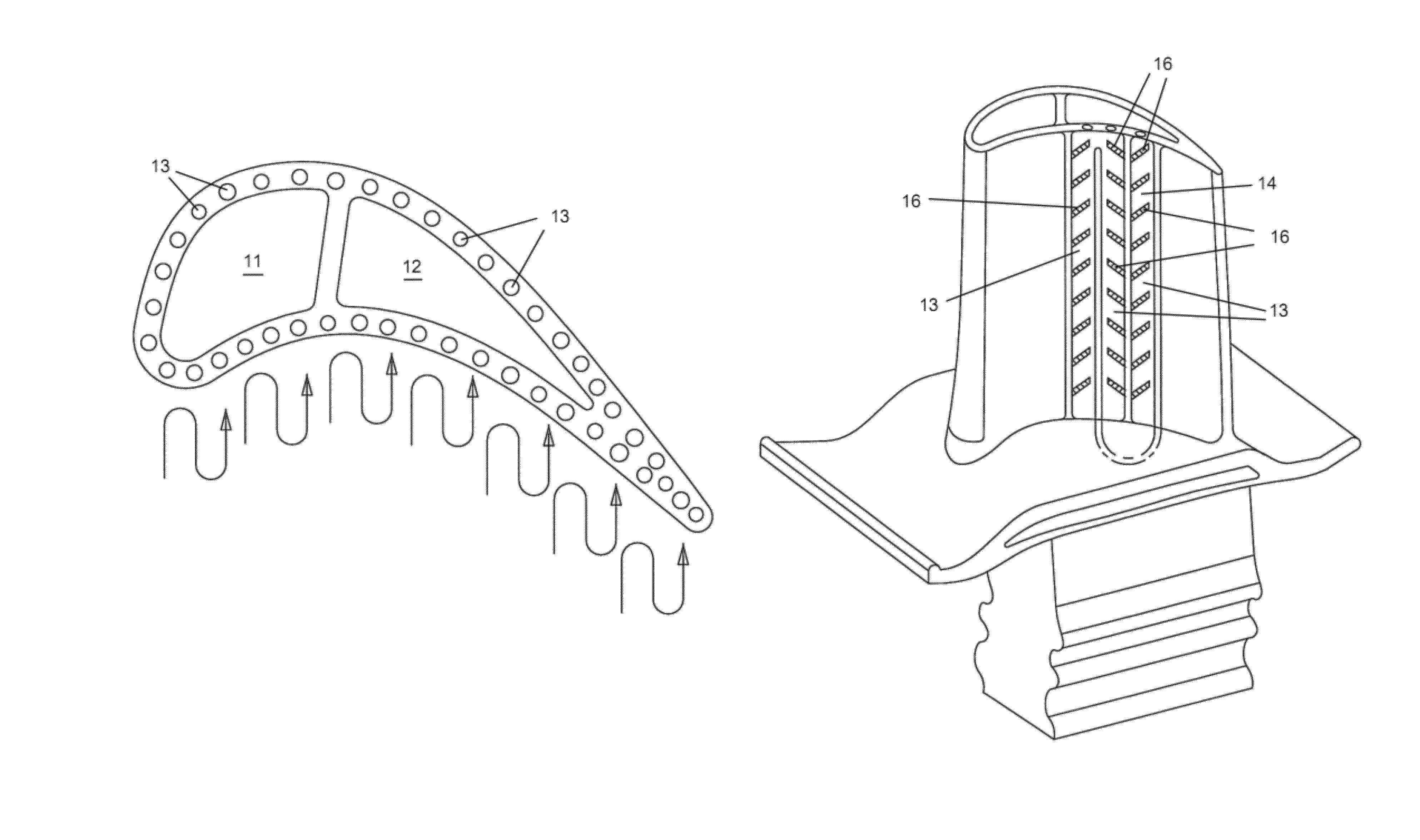

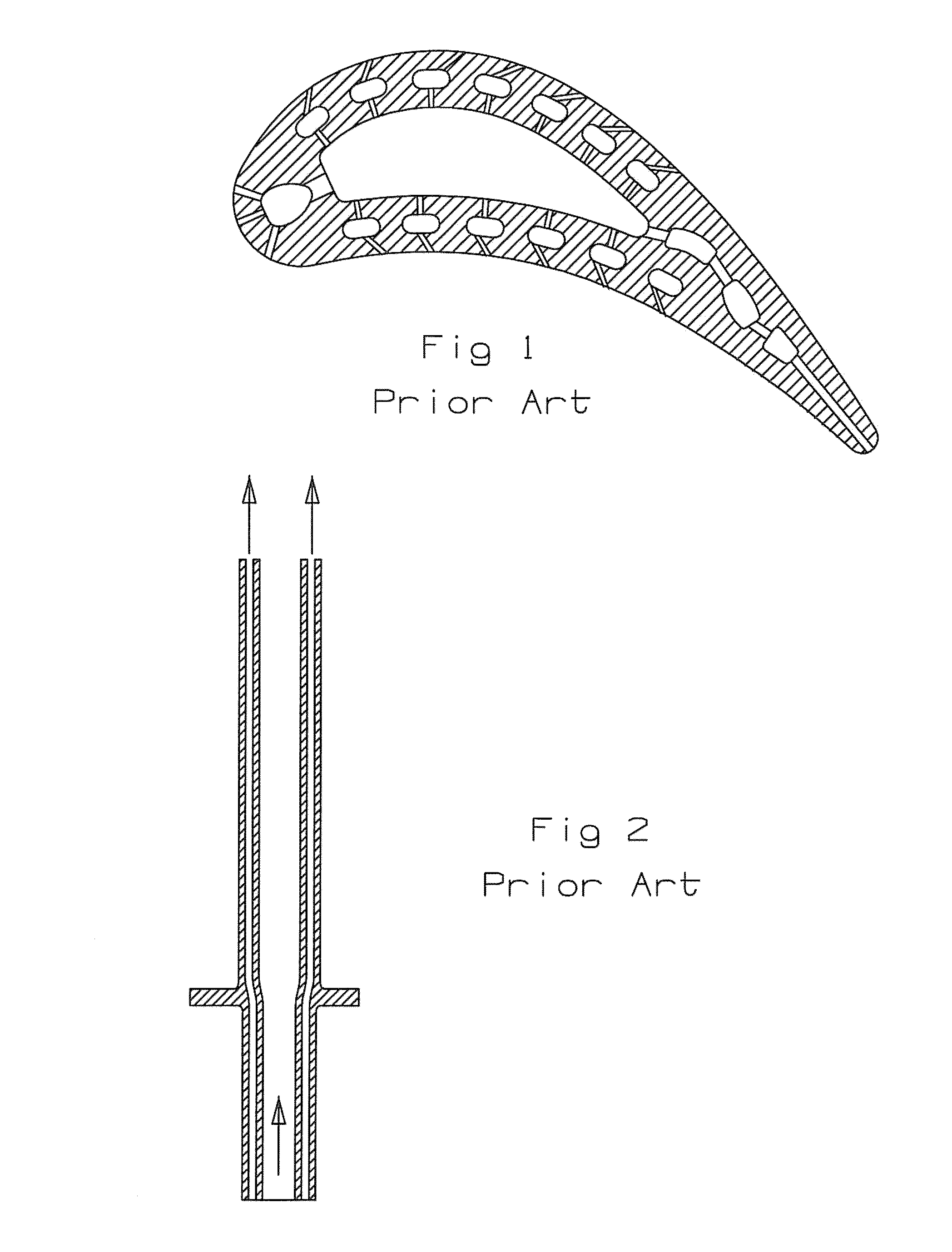

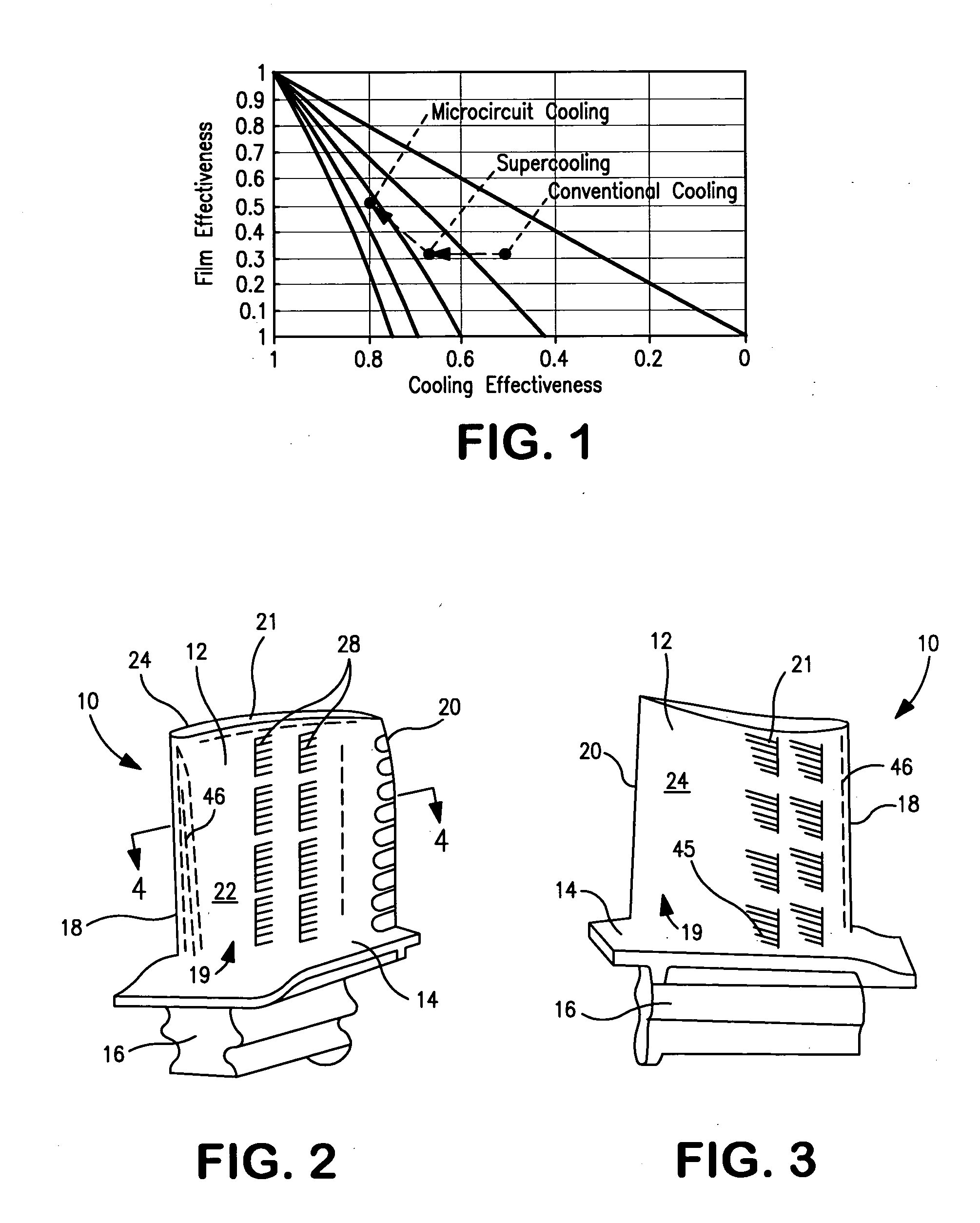

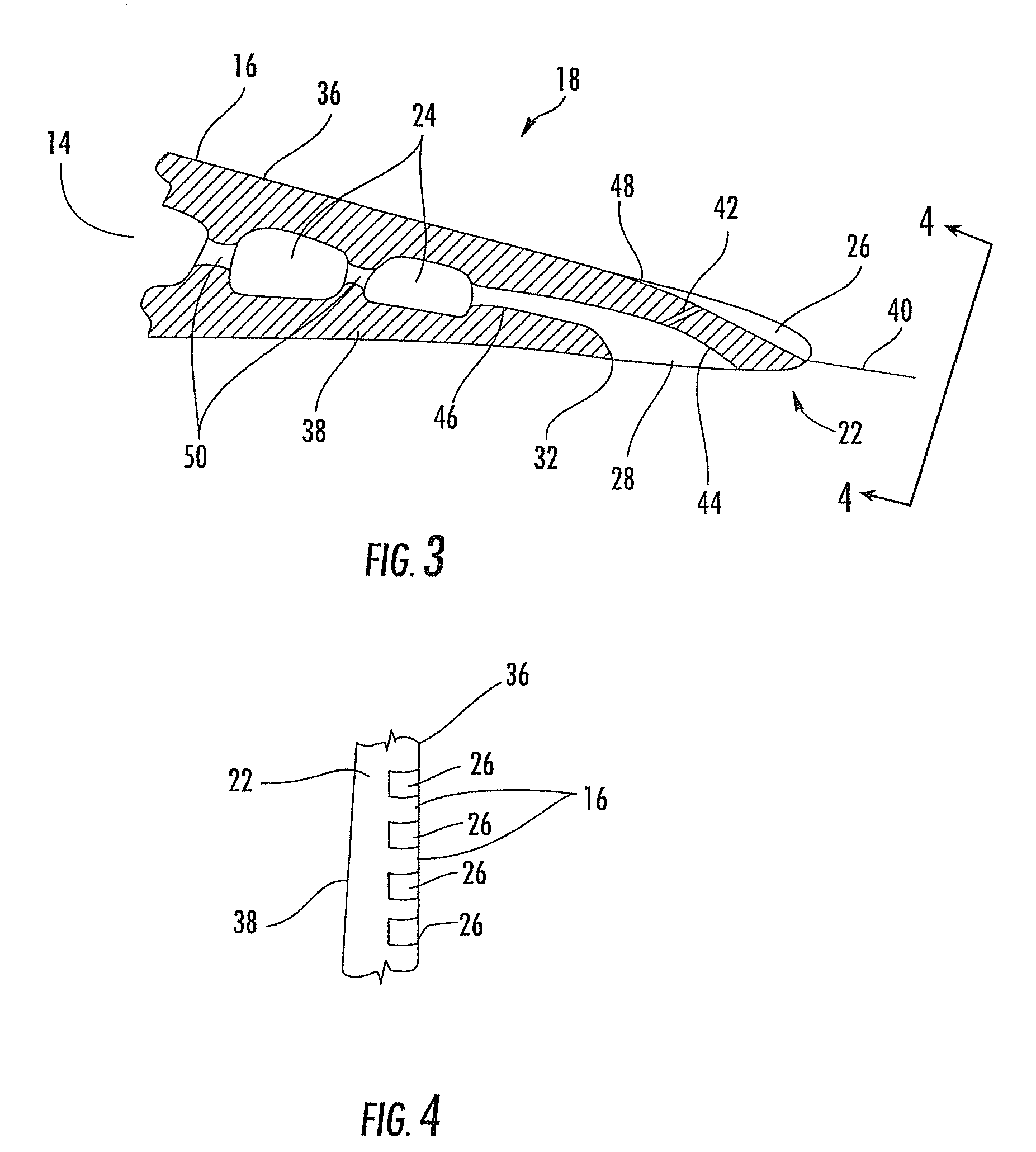

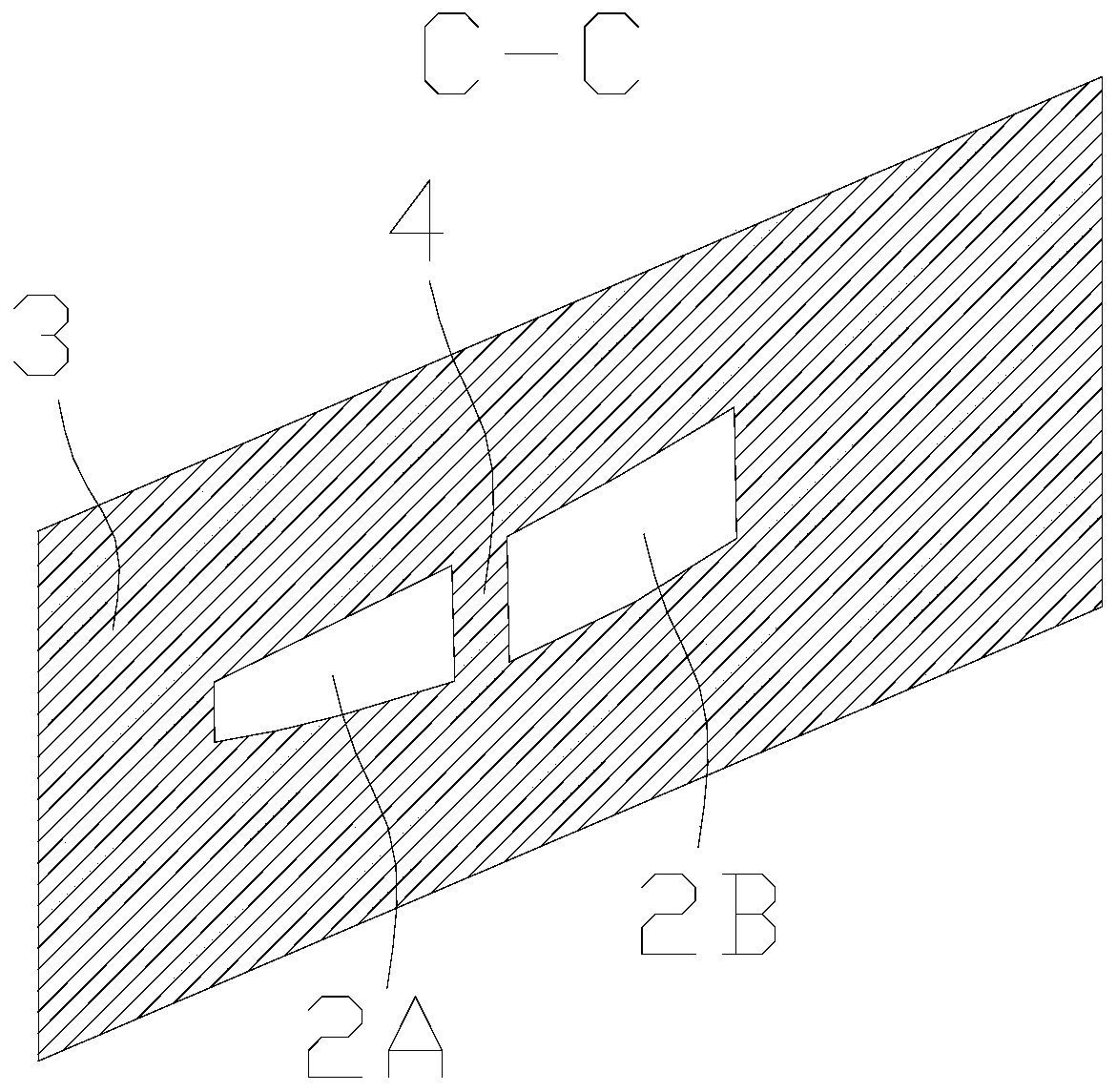

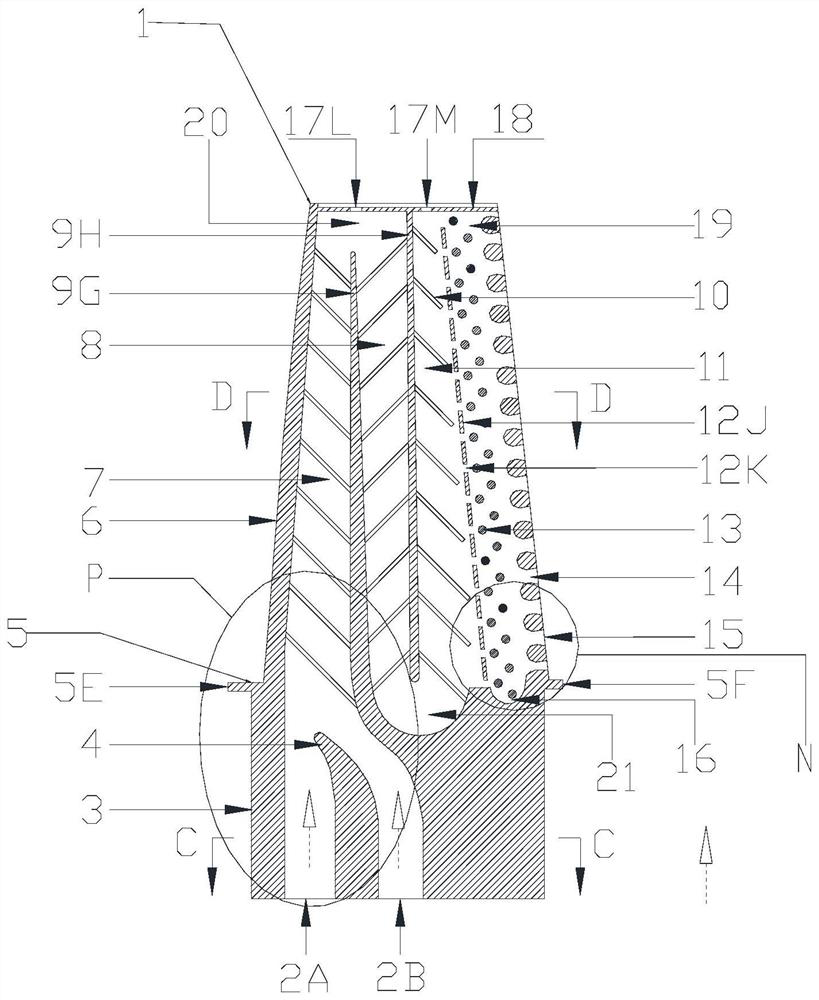

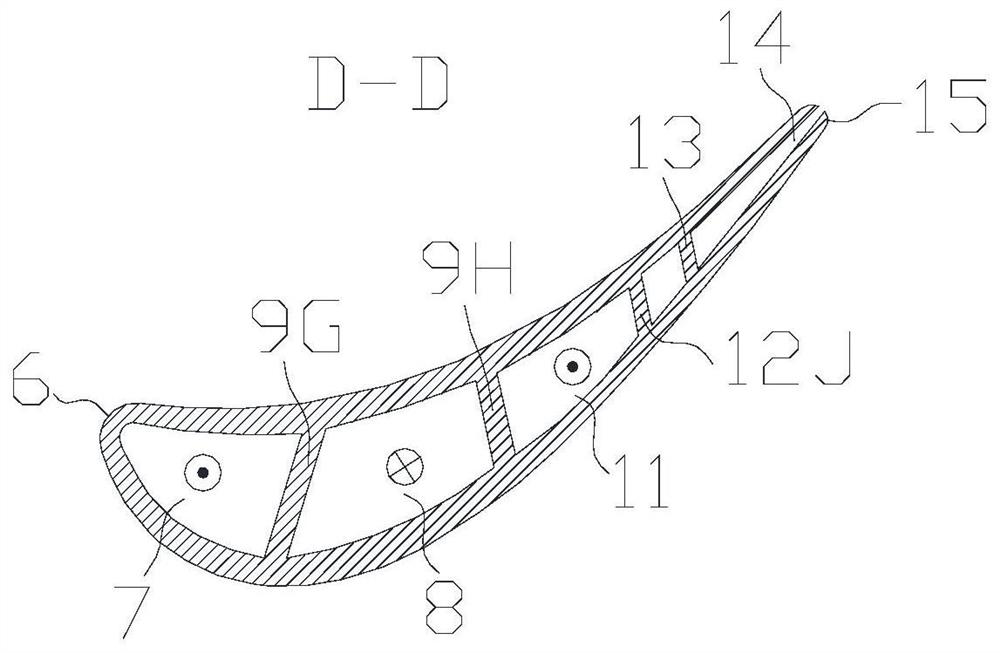

Turbine blade dual channel cooling system

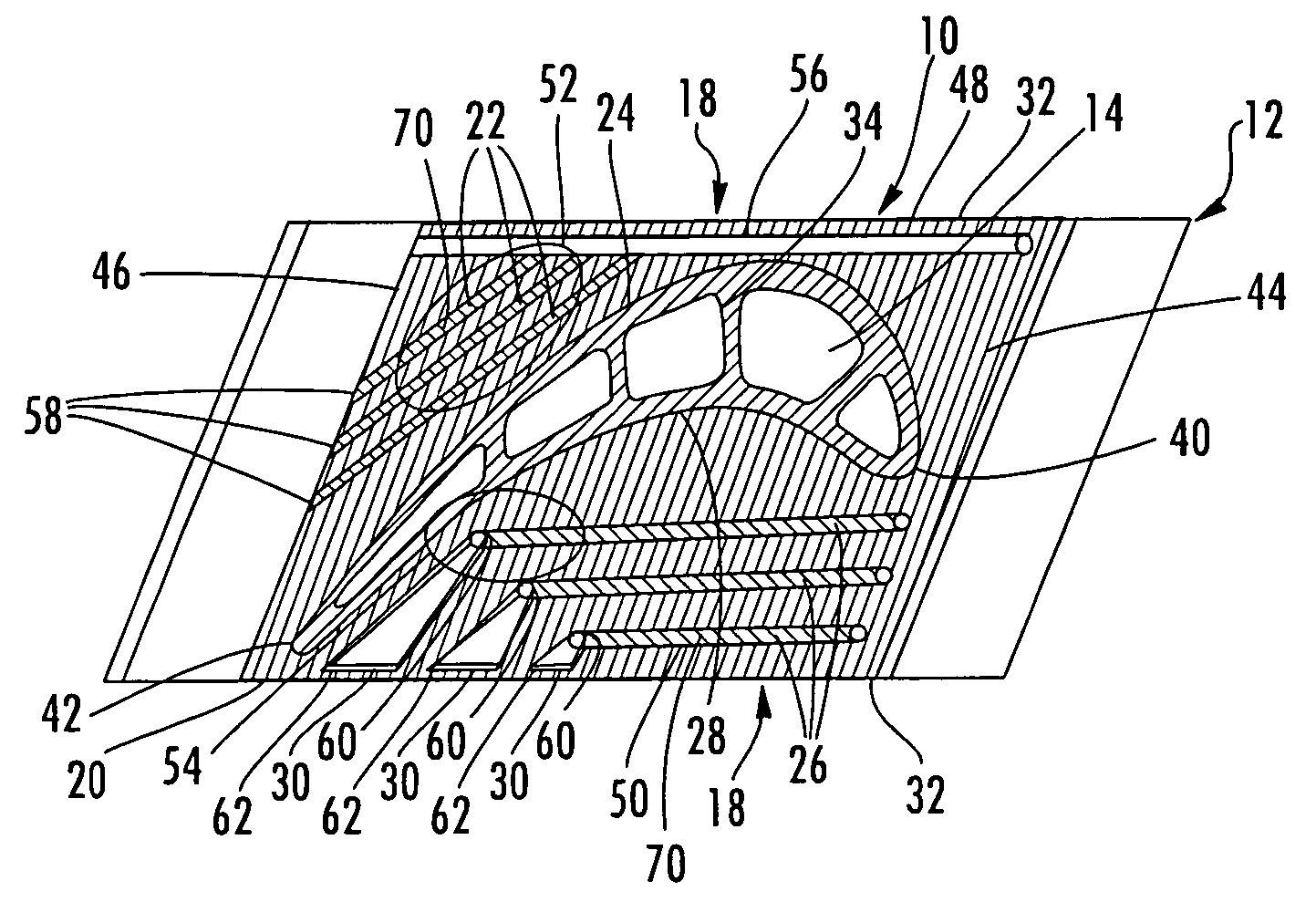

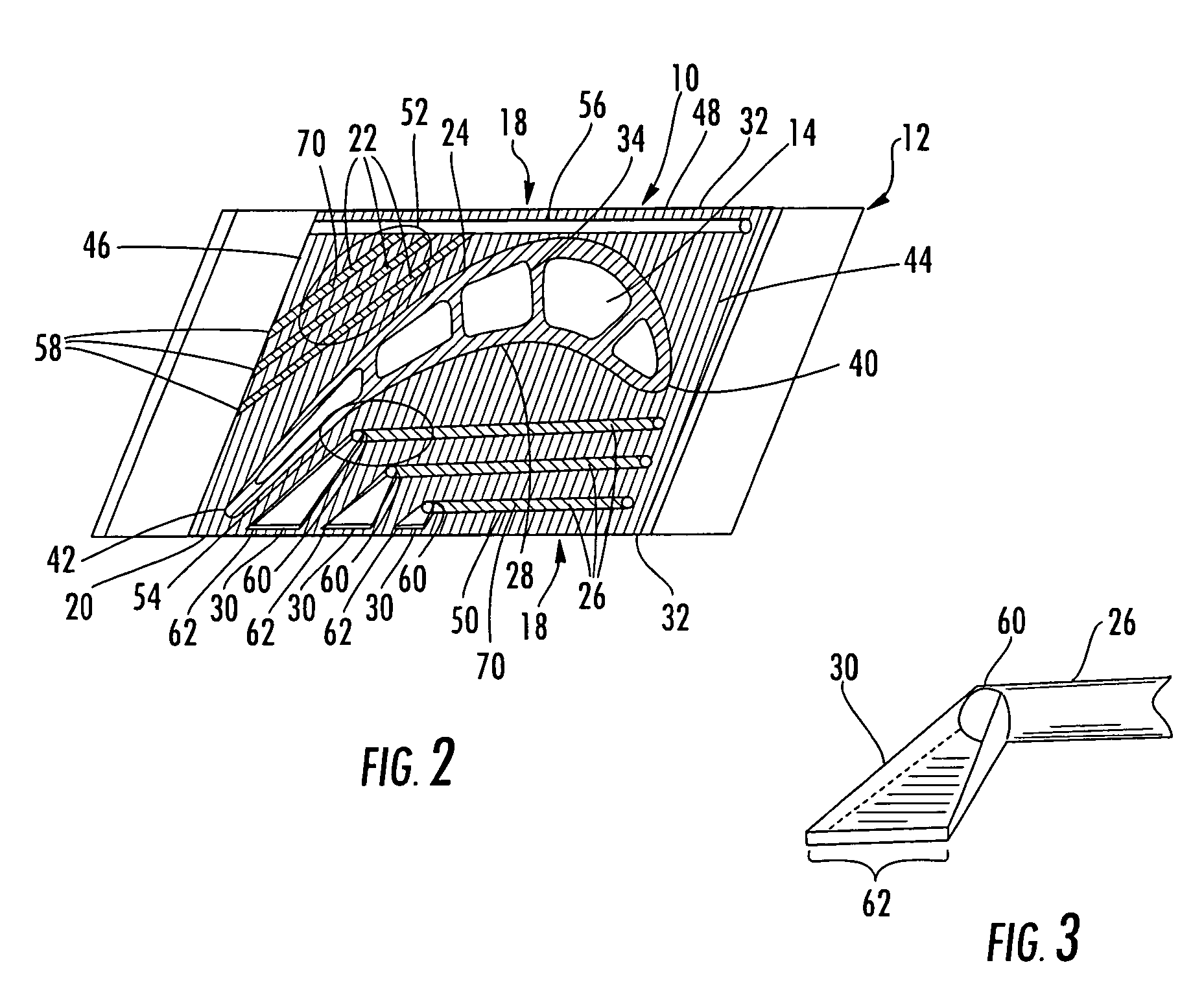

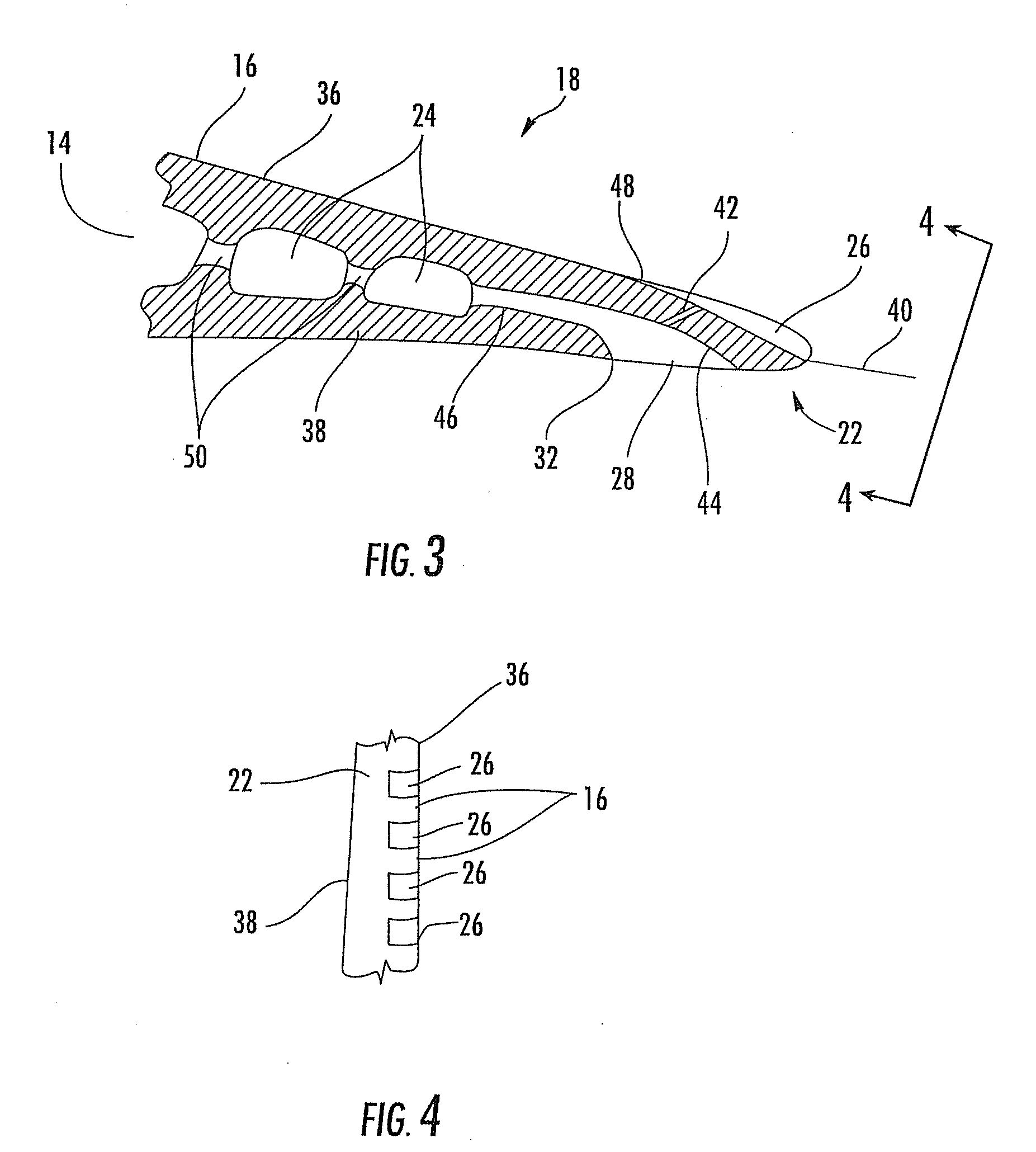

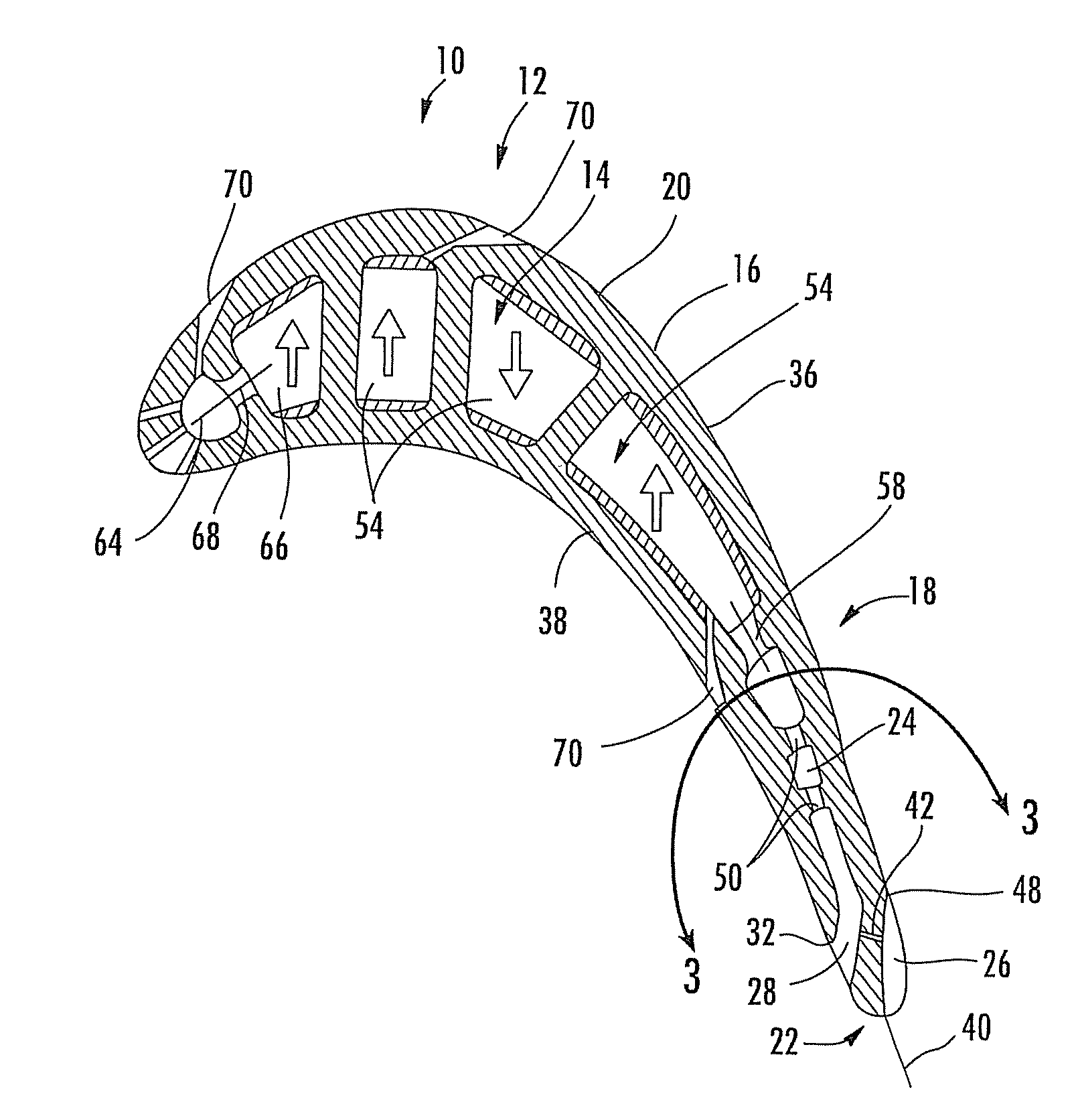

InactiveUS20100226789A1Prevent temperature overageAvoid Blade DamageEngine manufacturePump componentsLeading edgeTurbine blade

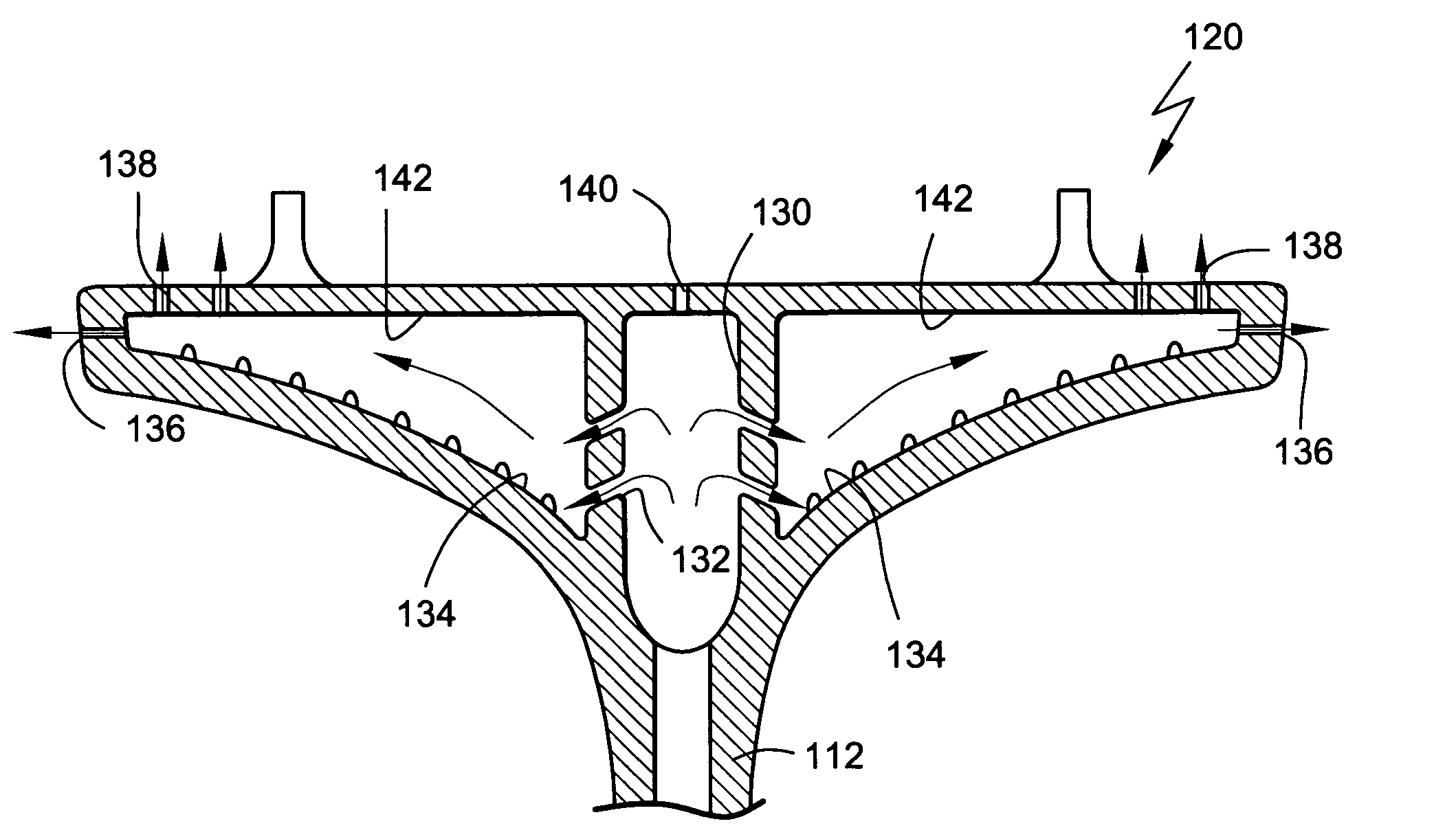

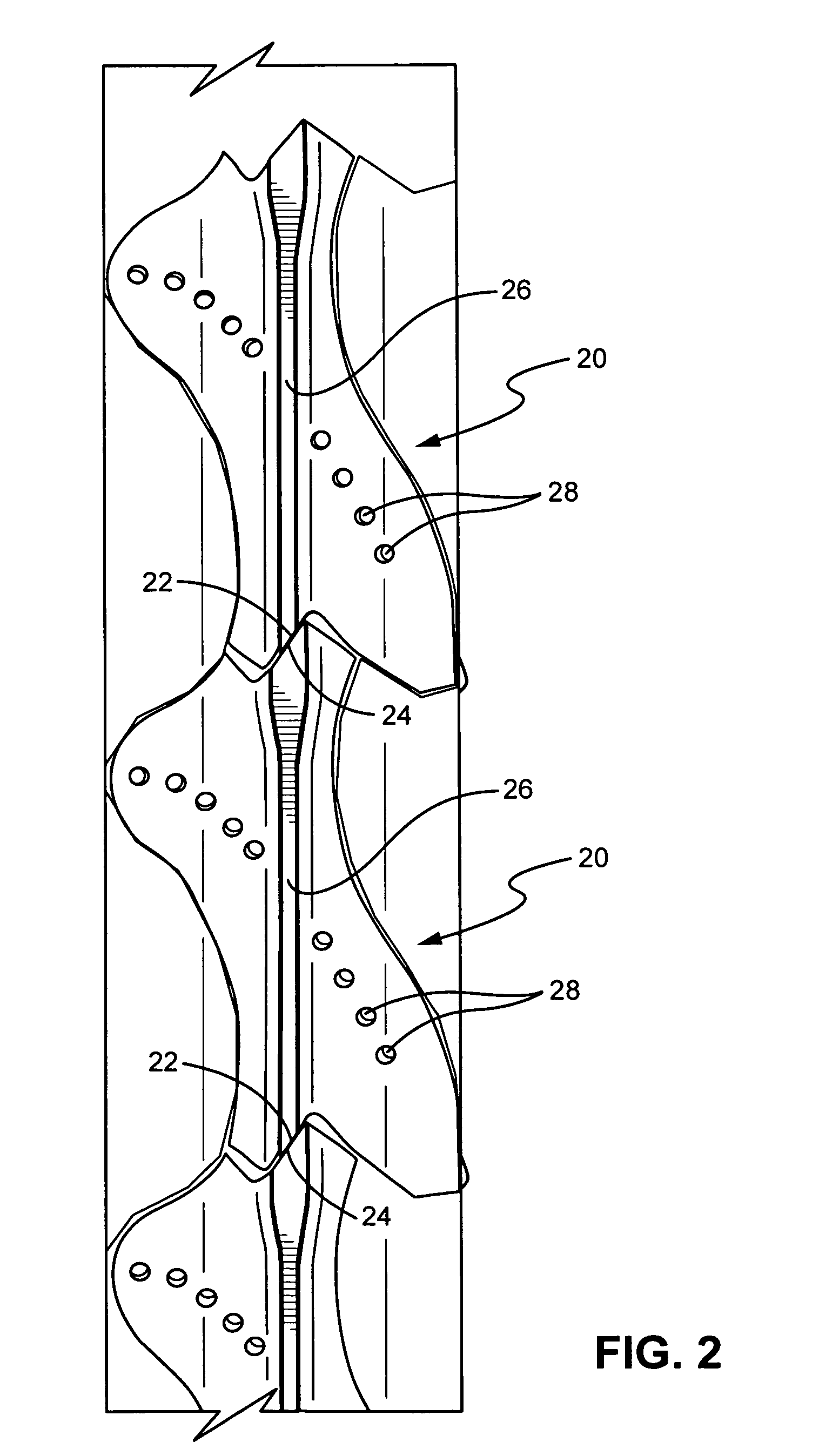

A turbine blade having an internal cooling system with dual serpentine cooling channels in communication with tip cooling channels is disclosed. In at least one embodiment, the cooling system may include first and second tip cooling channels in communication with the first and second serpentine cooling channels, respectively. The first tip cooling channel may extend from the leading edge to the trailing edge and be formed from a first suction side tip cooling channel and a first pressure side tip cooling channel. The second tip cooling channel may extend from a midchord region toward the trailing edge and may be positioned between the pressure and suction sides such that the second tip cooling channel is positioned generally between the first suction side and pressure side tip cooling channels. The first and second tip cooling channels may exhaust cooling fluids through the trailing edge.

Owner:SIEMENS ENERGY INC

Impingement cooled bucket shroud, turbine rotor incorporating the same, and cooling method

ActiveUS7568882B2Effectively cool the blade tip shroudReduce metal temperaturePump componentsEngine fuctionsEngineeringCooling methods

A localized directional impingement cooling is used to reduce the metal temperatures on highly stressed regions of the tip shroud.

Owner:GENERAL ELECTRIC CO

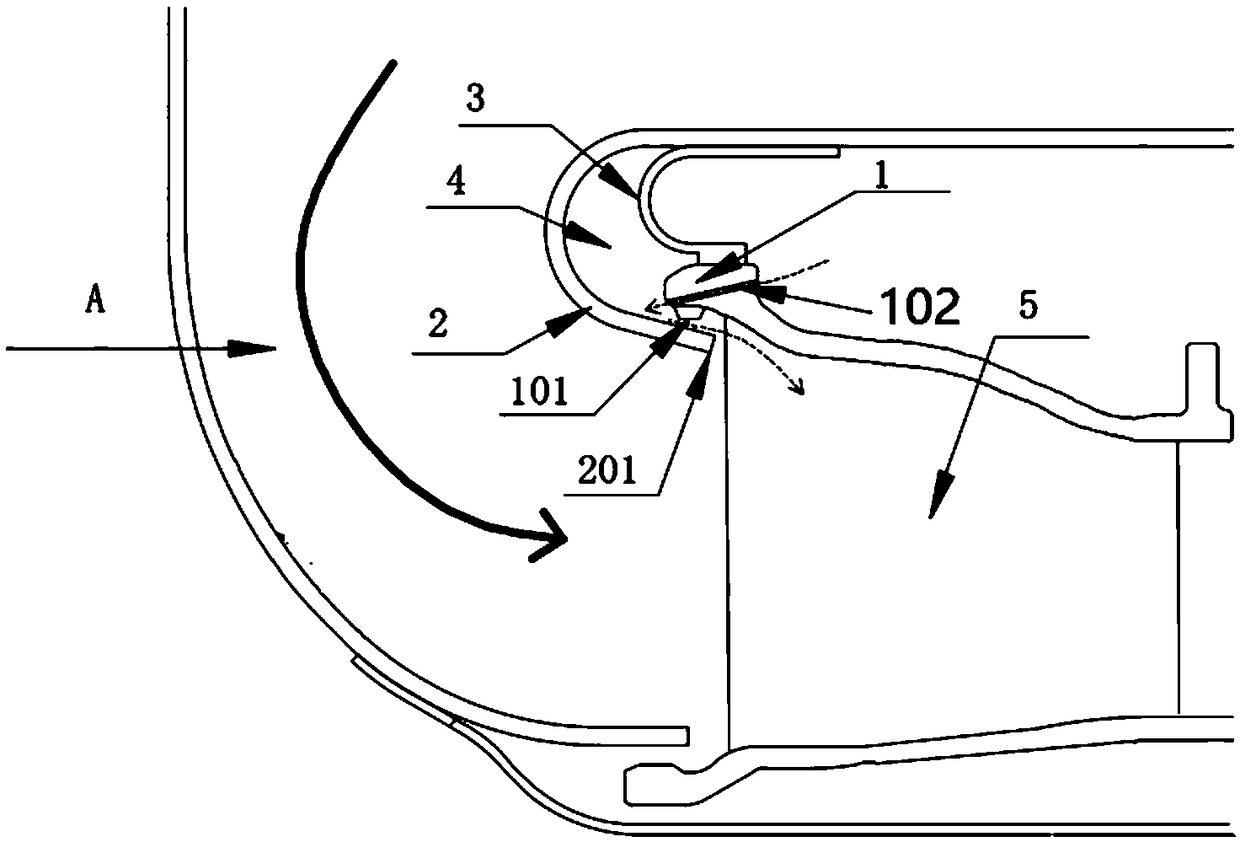

Cooling and sealing design for a gas turbine combustion system

ActiveUS7096668B2Reduce metal temperatureExtended component lifeBurnersContinuous combustion chamberCombustion systemGuide tube

An interface region between a combustion liner and a transition duct of a gas turbine combustor is disclosed having improved cooling such that component life is increased and metal temperatures are lowered. An aft end of a combustion liner is telescopically received within the transition duct such that a combustion liner seal is in contact with an inner wall of the transition duct inlet ring. Increasing the dedicated cooling air supply to the combustion liner aft end, coupled with a modified combustion liner aft end geometry, significantly reduces turbulence and flow re-circulation, thereby resulting in lower metal temperatures and increased component life. Multiple embodiments of the interface region are disclosed depending on the amount of cooling required.

Owner:H2 IP UK LTD

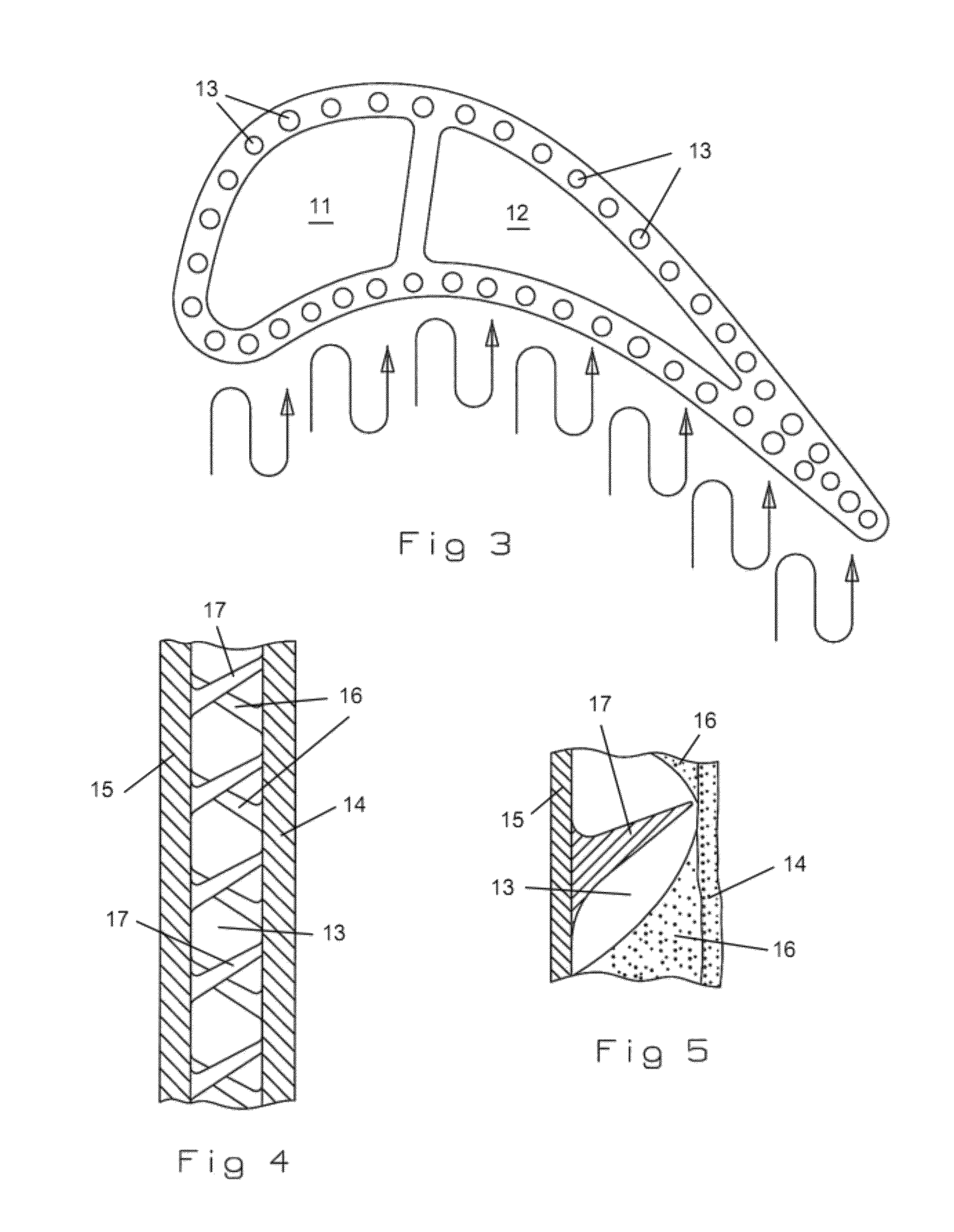

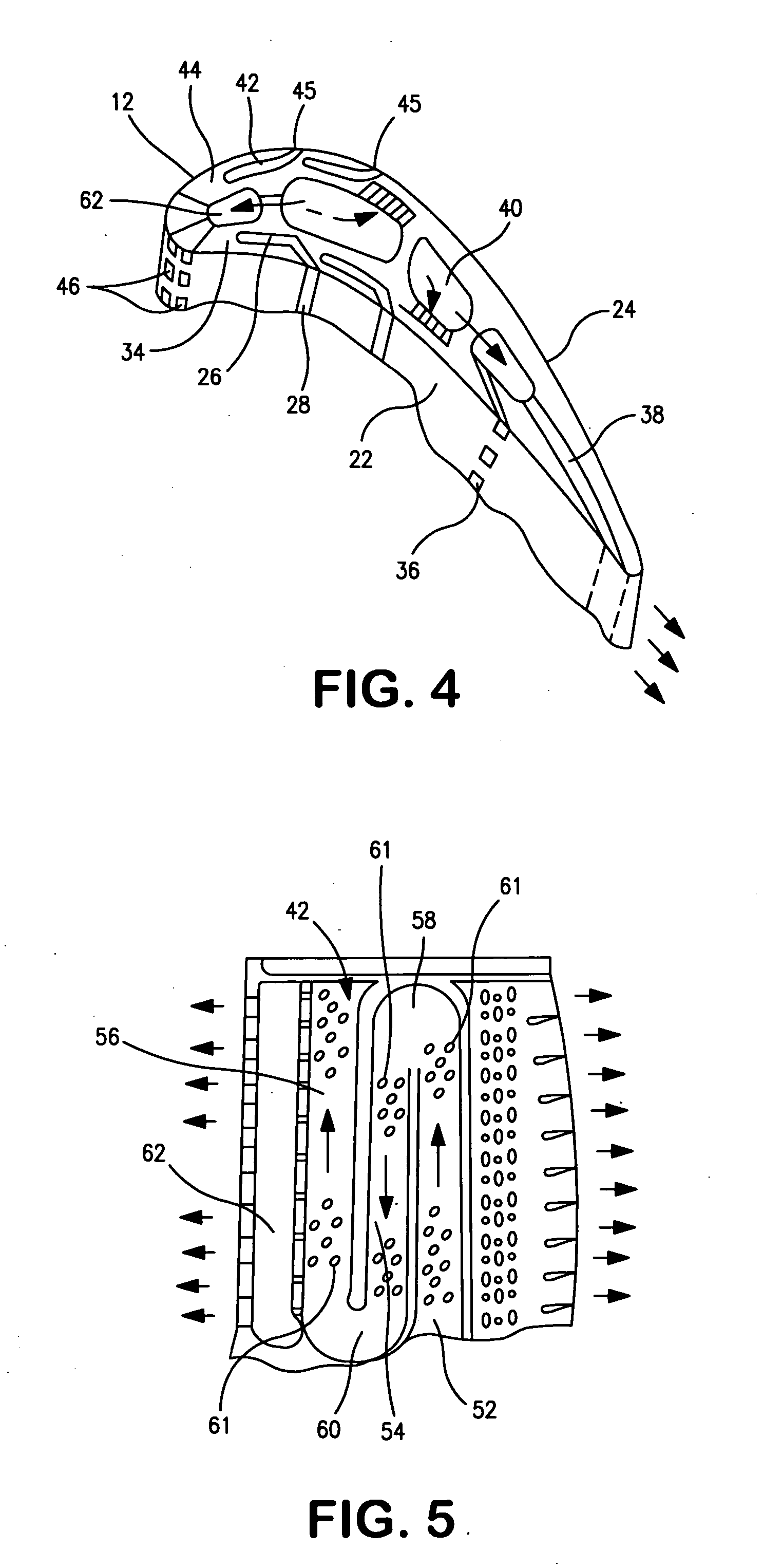

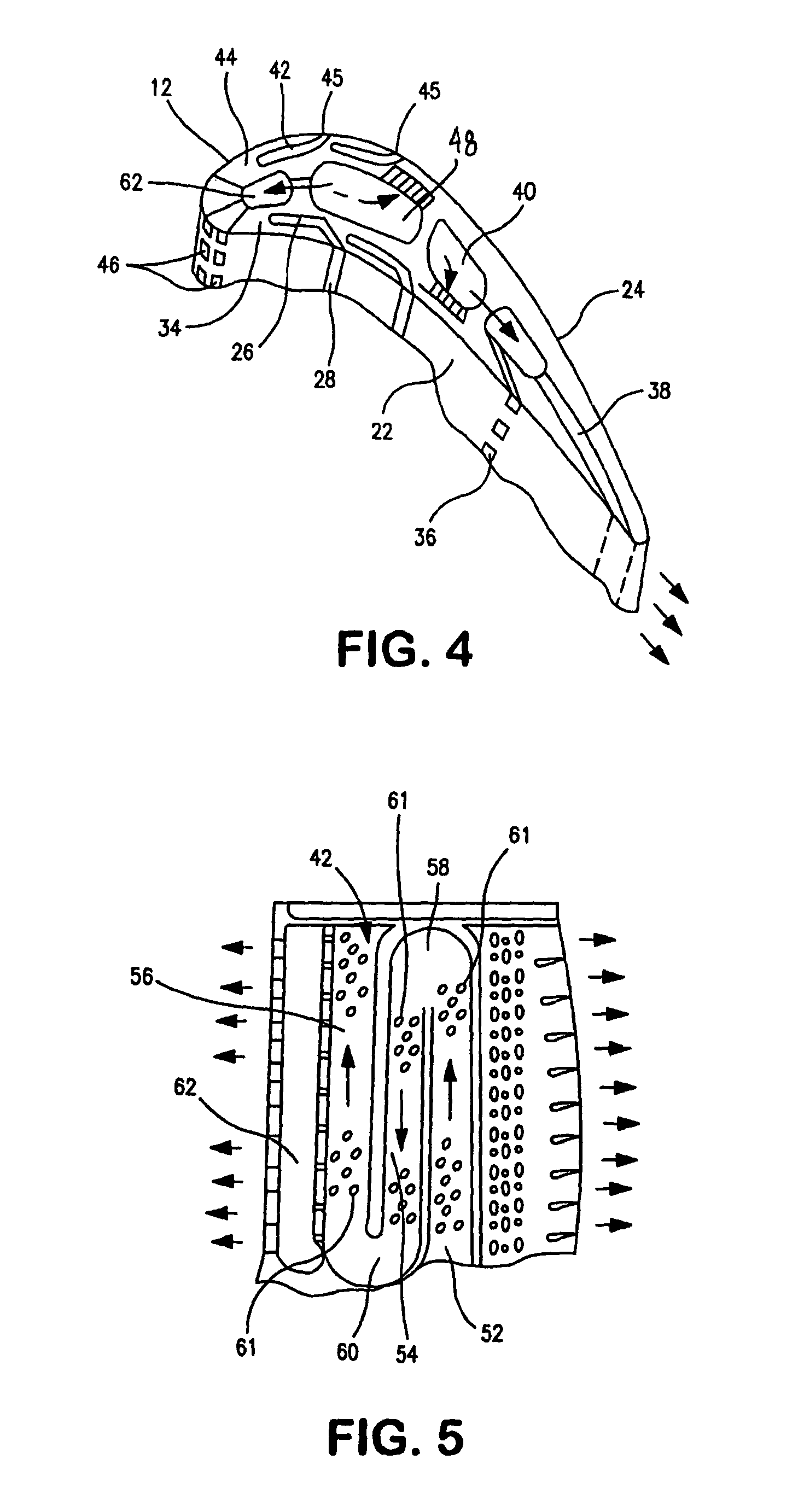

Turbine airfoil with near wall vortex cooling

InactiveUS8251660B1Reduce trafficReduce metal temperaturePropellersEngine manufactureTurbineSingle pass

A turbine airfoil having walls with radial extending near wall cooled vortex flowing channels to provide for a high cooling effectiveness with a low cooling flow requirement. A thermal skin is bonded over a main spar in which skewed ribs extend from both the spar and the thermal skin to form a vortex flowing path along the radial channels. The vortex flowing radial channels can be single pass radial channels or connected to form a 3-pass serpentine flow circuit with tip holes to discharge the cooling air from the radial channels and cool the blade tip periphery.

Owner:FLORIDA TURBINE TECH

Turbine blade dual channel cooling system

InactiveUS8192146B2Avoid damageAvoid temperaturePropellersEngine manufactureLeading edgeTurbine blade

A turbine blade having an internal cooling system with dual serpentine cooling channels in communication with tip cooling channels is disclosed. In at least one embodiment, the cooling system may include first and second tip cooling channels in communication with the first and second serpentine cooling channels, respectively. The first tip cooling channel may extend from the leading edge to the trailing edge and be formed from a first suction side tip cooling channel and a first pressure side tip cooling channel. The second tip cooling channel may extend from a midchord region toward the trailing edge and may be positioned between the pressure and suction sides such that the second tip cooling channel is positioned generally between the first suction side and pressure side tip cooling channels. The first and second tip cooling channels may exhaust cooling fluids through the trailing edge.

Owner:SIEMENS ENERGY INC

Turbine airfoil cooling system with platform cooling channels with diffusion slots

InactiveUS7766606B2Improve cooling efficiencyReduce metal temperatureEngine manufacturePump componentsTurbine bladeCooling chamber

Owner:SIEMENS ENERGY INC

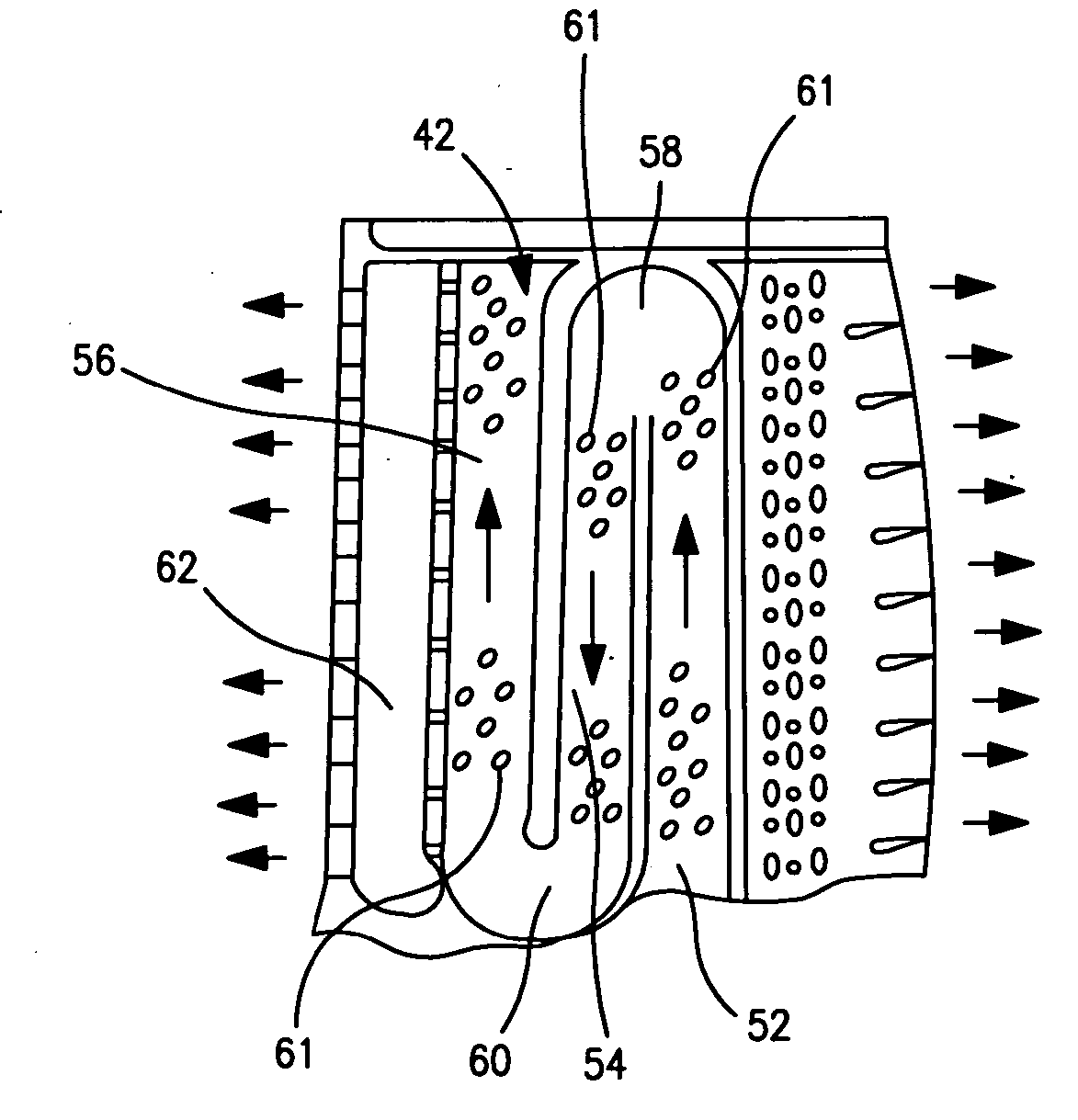

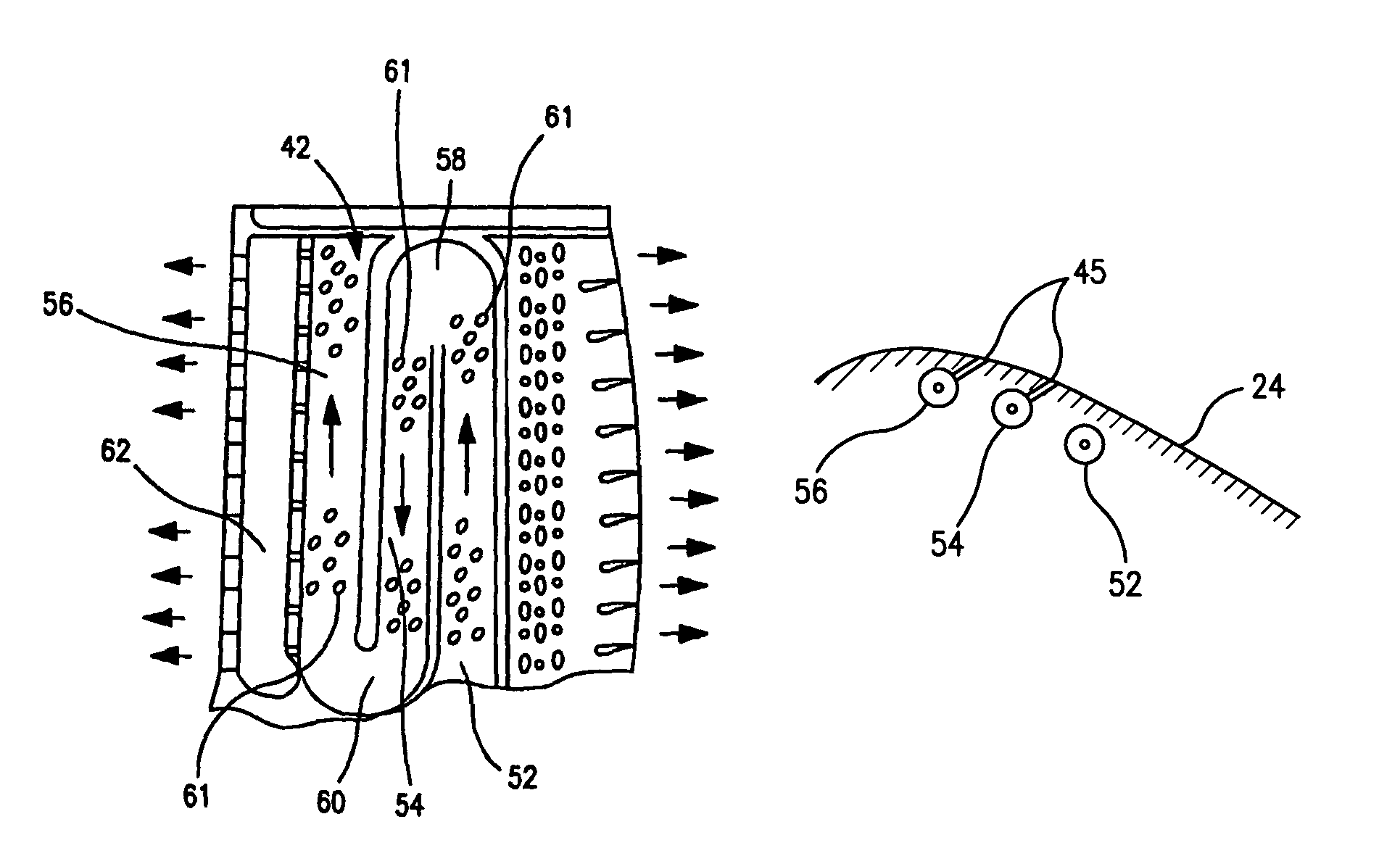

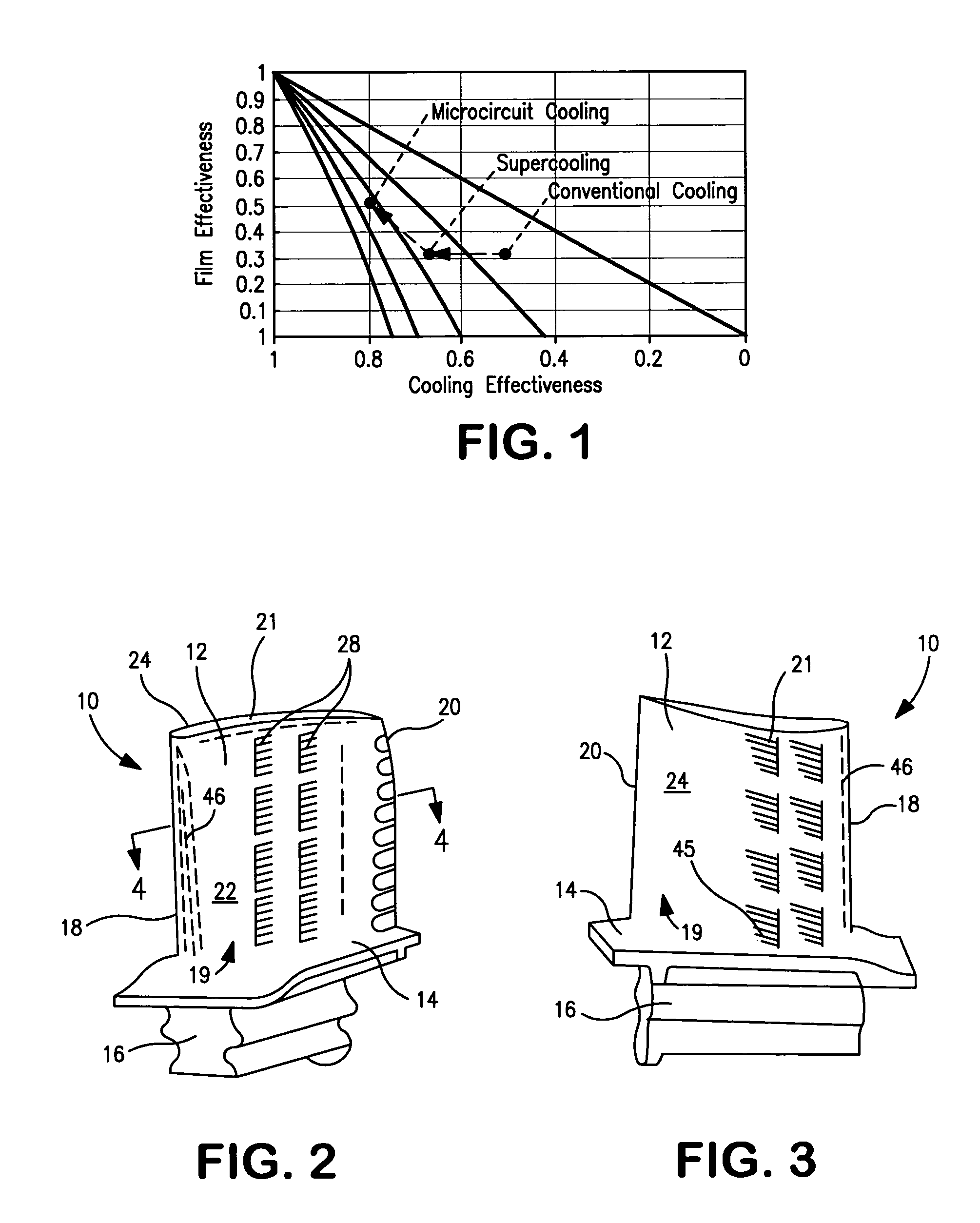

Microcircuit cooling with an aspect ratio of unity

ActiveUS20070172355A1Improve protectionReduce airfoil metal temperatureEngine manufactureEngine fuctionsTrailing edgeAspect ratio

A turbine engine component having improved cooling is provided. The turbine engine component includes an airfoil portion having a leading edge, a trailing edge, a pressure side, a suction side, a root, and a tip, and at least one cooling circuit in a wall of the airfoil portion. The at least one cooling circuit has at least one passageway extending between the root and the tip. The at least one passageway has an aspect ratio of no greater than 2:1, and preferably substantially unity.

Owner:RAYTHEON TECH CORP

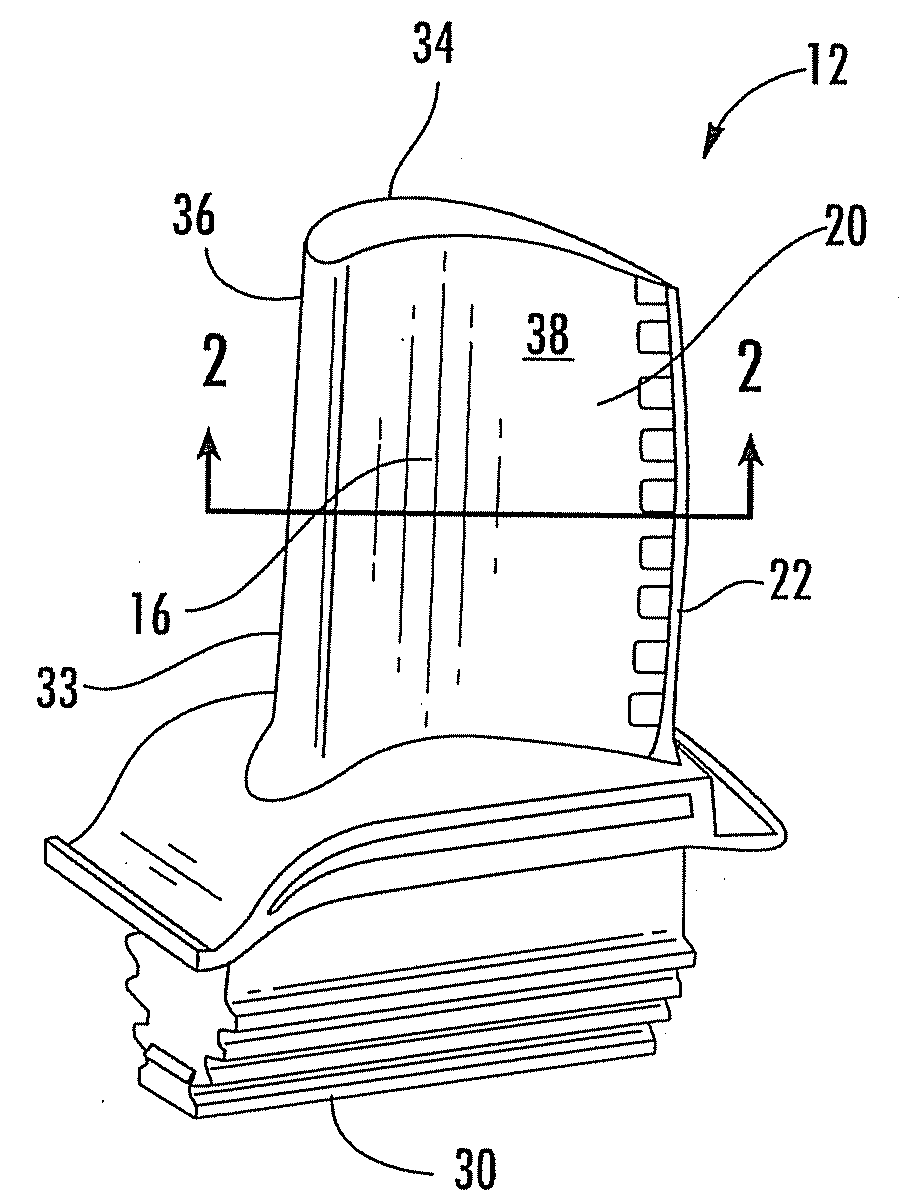

Turbine blade with multiple trailing edge cooling slots

InactiveUS20100183429A1Reduce airfoil trailing edge effective thicknessReducing base region heat loadEngine manufacturePump componentsTurbine bladeTrailing edge

A cooling system for a turbine airfoil of a turbine engine has a multiple suction side cooling slots extending from a front edge on the suction side to the center of the trailing edge or even to the pressure side of the center line and a pressure side cooling slot curving to a pressure side outlet forward of the trailing edge and having a front pressure side lip that is aligned with or forward of the front edge of the suction side cooling slots. The suction side cooling slots receive cooling flow from the pressure side cooling slots through a boundary layer bleed valve, which is also aligned with or rearward of the pressure side lip. The cooling system may also combine double impingement cooling with these features. The cooling system minimizes shear mixing, reduces hot spots and can reduce the trailing edge thickness, resulting in more efficient stage performance and extended operational life.

Owner:SIEMENS ENERGY INC

Turbine blade with multiple trailing edge cooling slots

A cooling system for a turbine airfoil of a turbine engine has a multiple suction side cooling slots extending from a front edge on the suction side to the center of the trailing edge or even to the pressure side of the center line and a pressure side cooling slot curving to a pressure side outlet forward of the trailing edge and having a front pressure side lip that is aligned with or forward of the front edge of the suction side cooling slots. The suction side cooling slots receive cooling flow from the pressure side cooling slots through a boundary layer bleed valve, which is also aligned with or rearward of the pressure side lip. The cooling system may also combine double impingement cooling with these features. The cooling system minimizes shear mixing, reduces hot spots and can reduce the trailing edge thickness, resulting in more efficient stage performance and extended operational life.

Owner:SIEMENS ENERGY INC

Microcircuit cooling with an aspect ratio of unity

ActiveUS8177506B2Improve protectionImprove heat absorptionEngine manufactureEngine fuctionsLeading edgeTrailing edge

A turbine engine component having improved cooling is provided. The turbine engine component includes an airfoil portion having a leading edge, a trailing edge, a pressure side, a suction side, a root, and a tip, and at least one cooling circuit in a wall of the airfoil portion. The at least one cooling circuit has at least one passageway extending between the root and the tip. The at least one passageway has an aspect ratio of no greater than 2:1, and preferably substantially unity.

Owner:RTX CORP

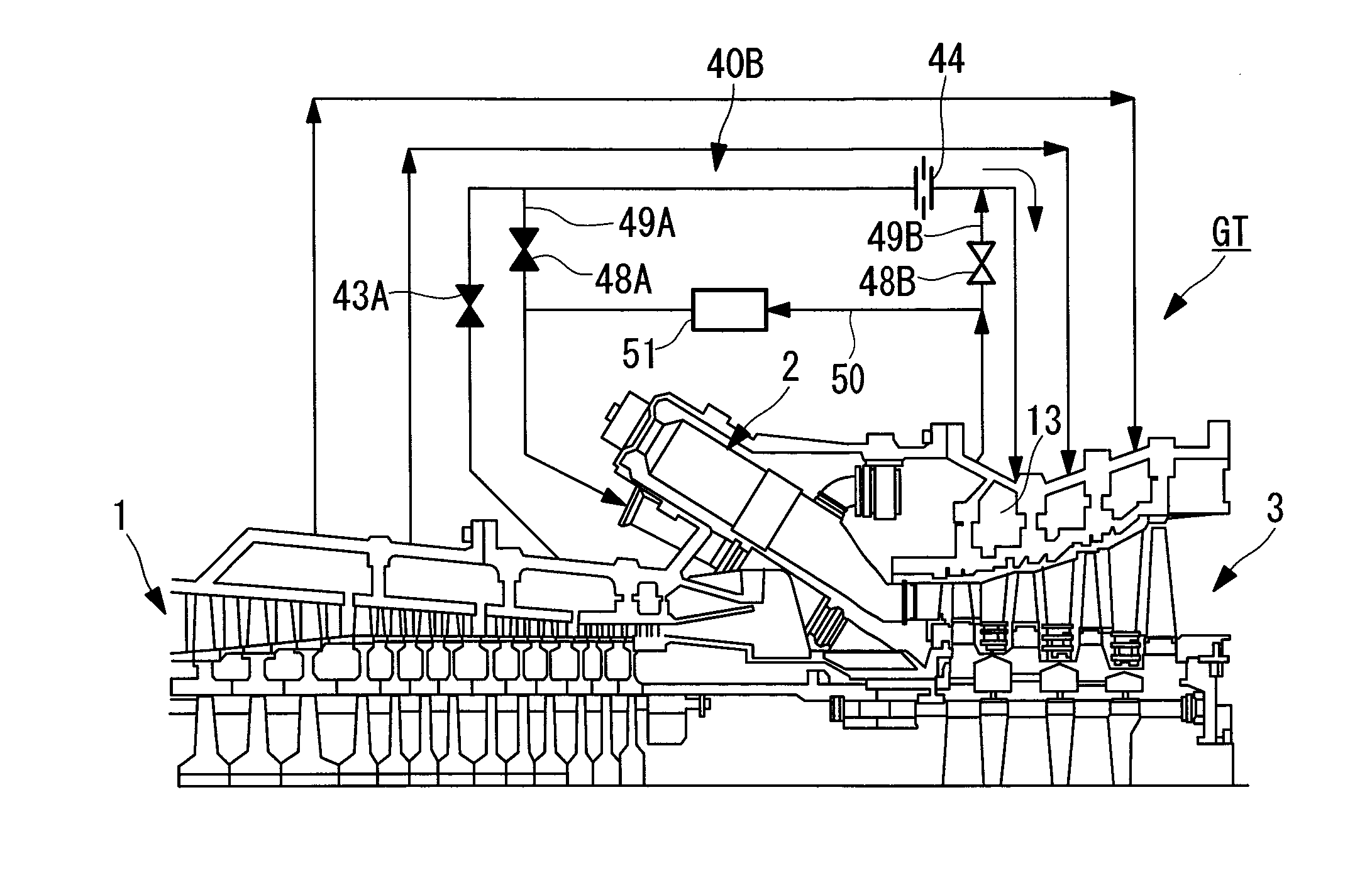

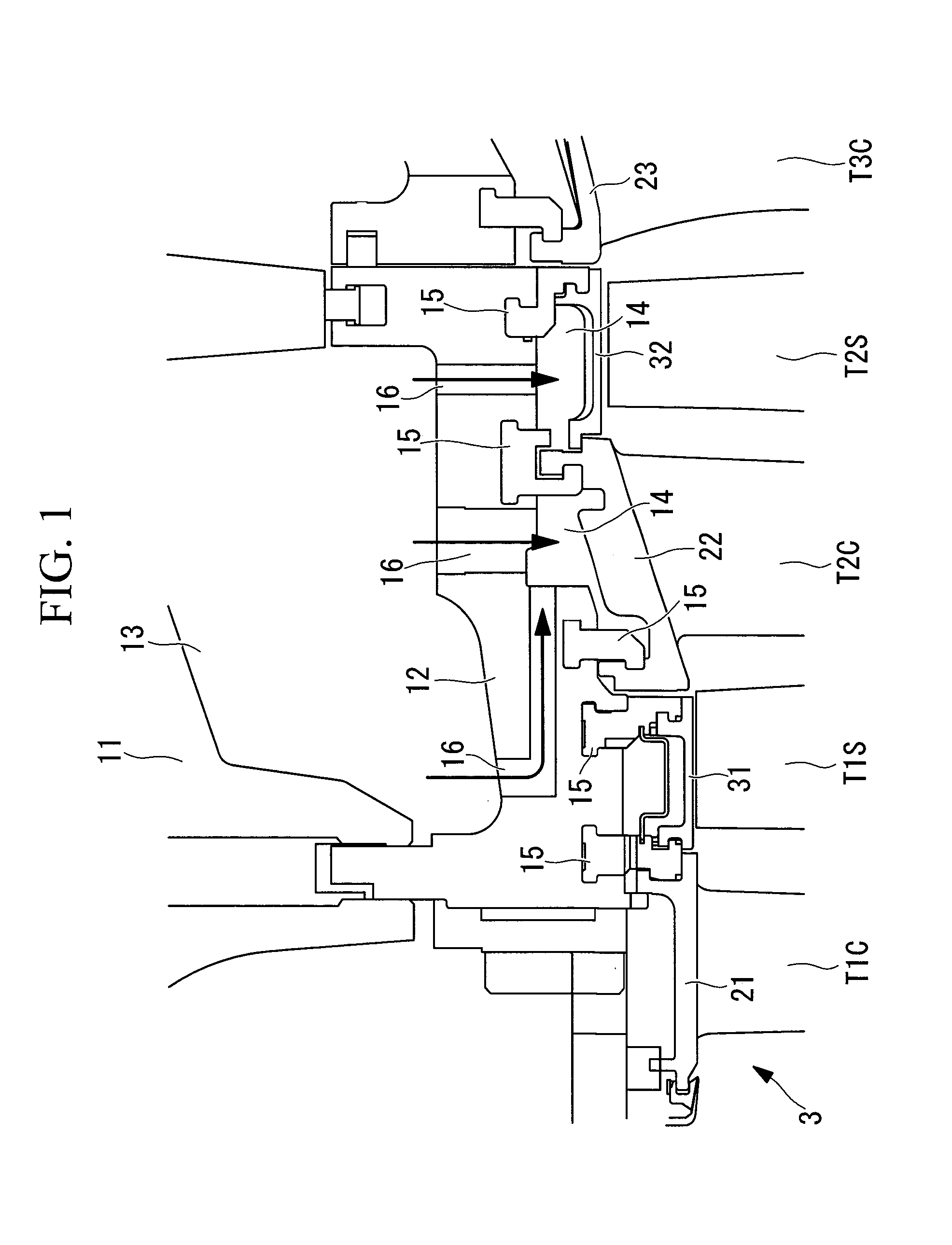

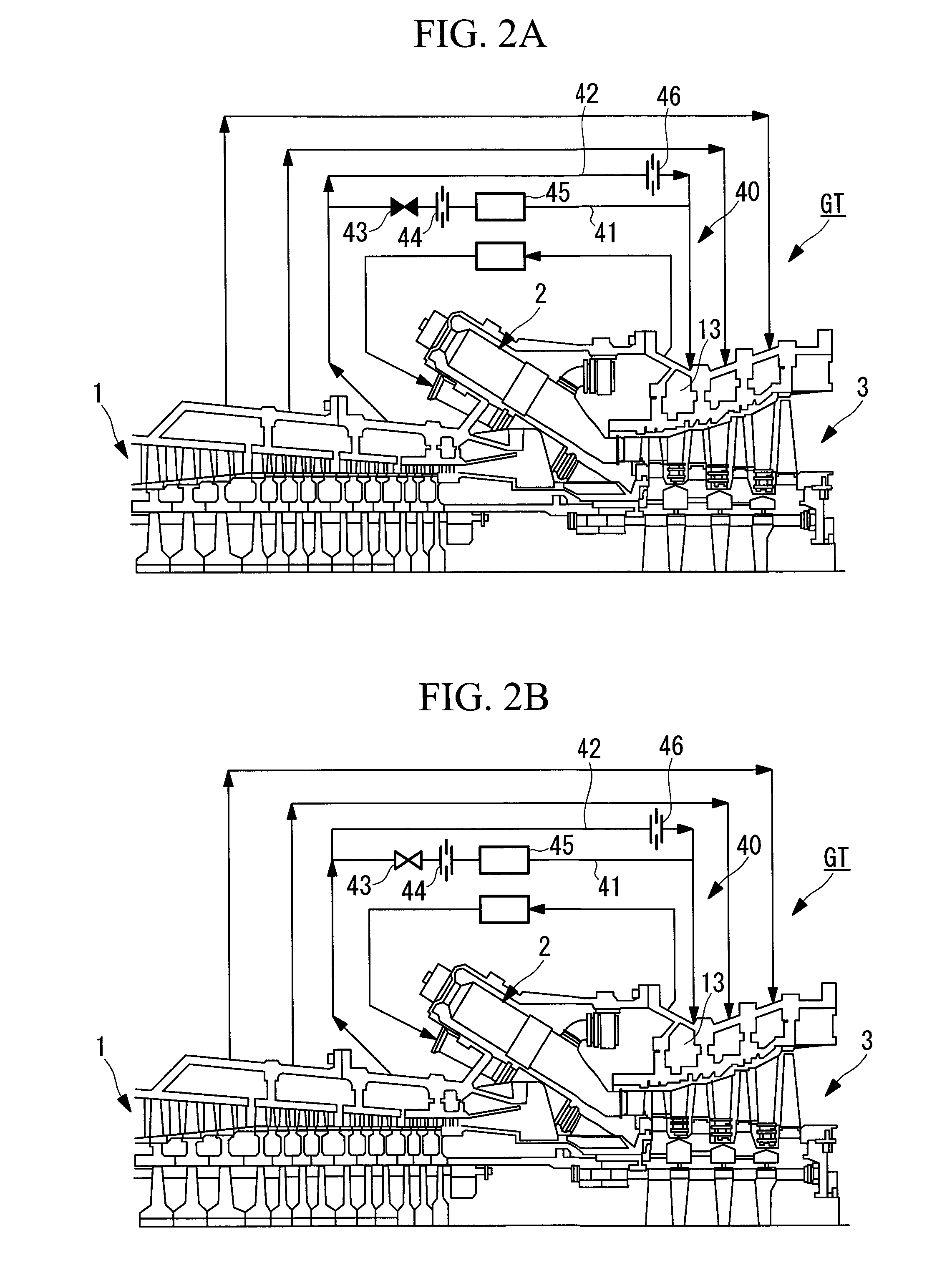

Gas turbine plant

ActiveUS8602724B2Convenience to workControl clearancePump componentsWind motor controlThermal expansionGas turbines

Provided is a gas turbine plant that enables active clearance control for ensuring tip clearance of first-stage turbine rotor blades required during start-up and for achieving the minimum tip clearance during load operation. In a gas turbine plant including a cooler in an air system used for cooling second-stage turbine stator blades, a first-stage segmented ring and a second-stage segmented ring that oppose tips of first-stage turbine rotor blades and second-stage turbine rotor blades are supported by the same blade ring member, and a cooling-air for the second-stage turbine stator blades forms a cooling air flow cooling the blade ring, to control thermal expansion of the blade ring and to control the clearance with respect to the tips.

Owner:MITSUBISHI HEAVY IND LTD

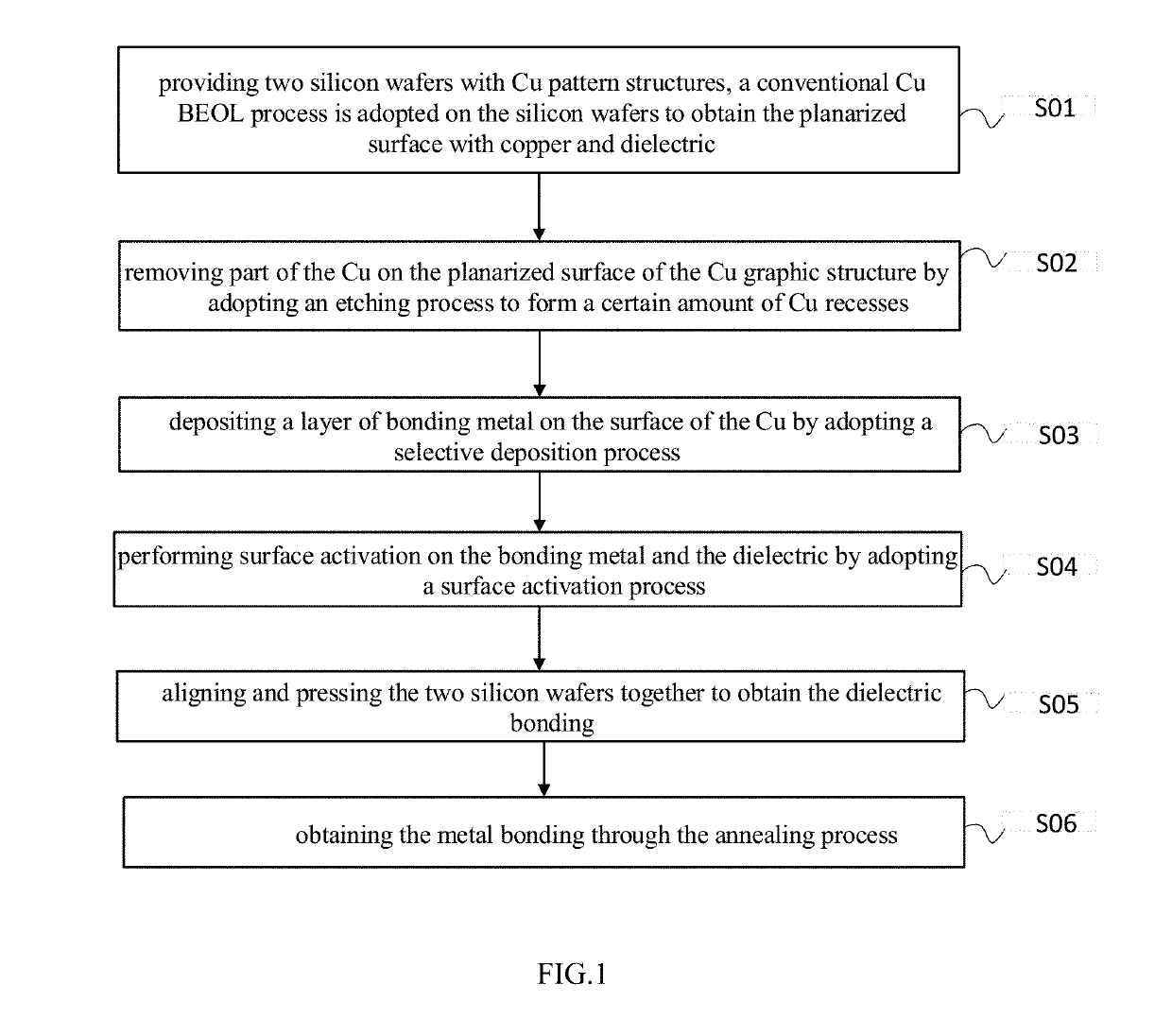

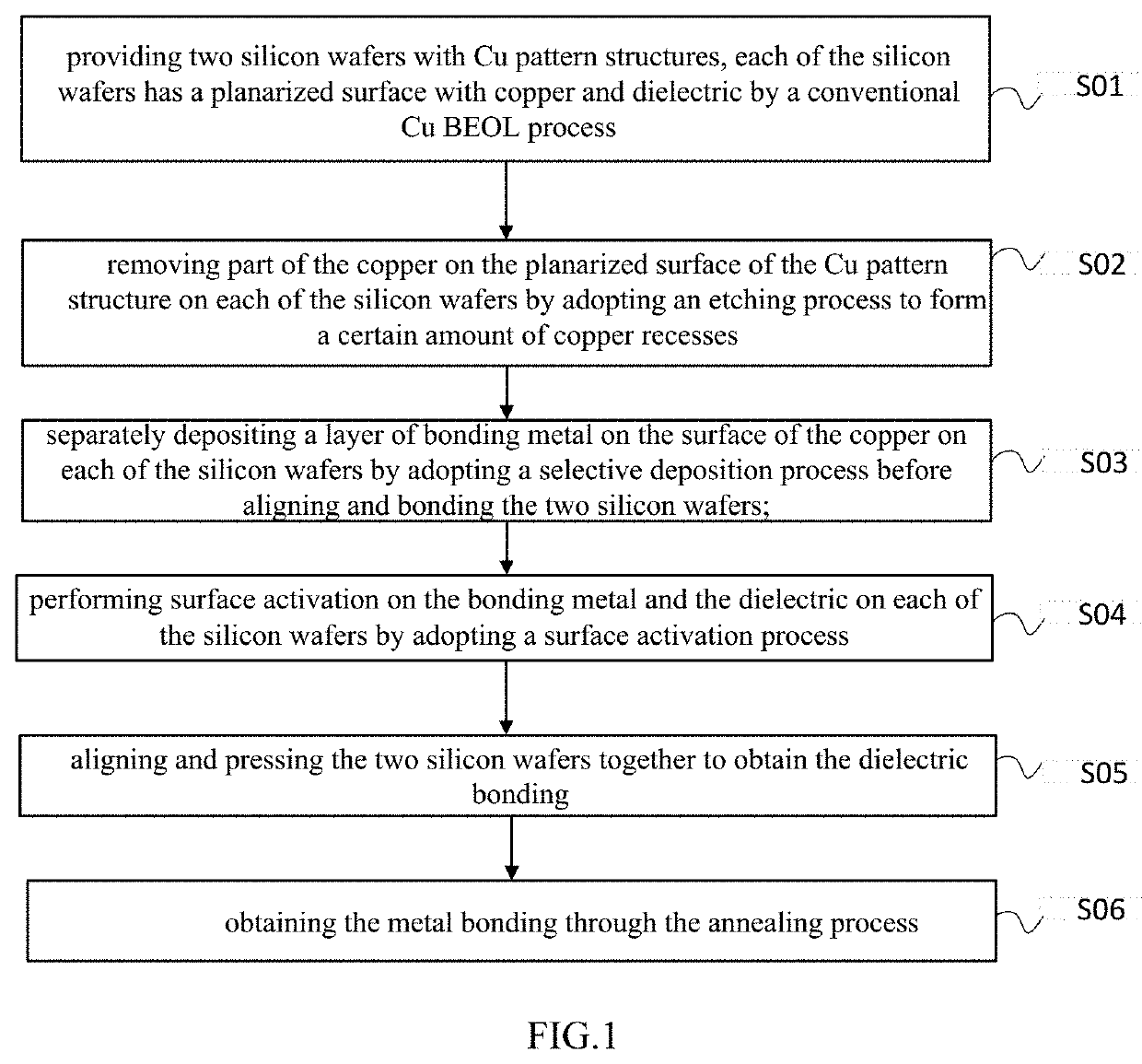

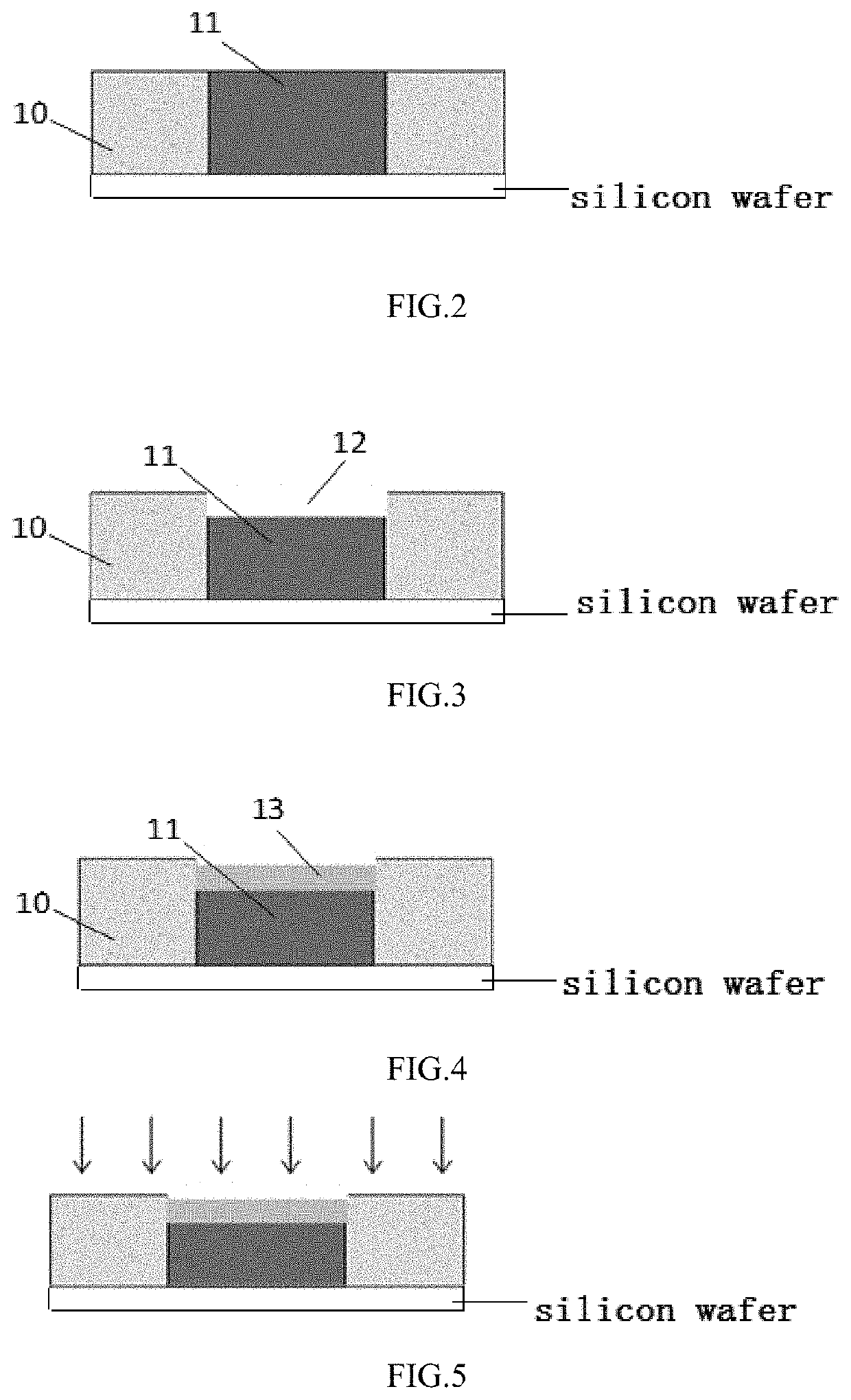

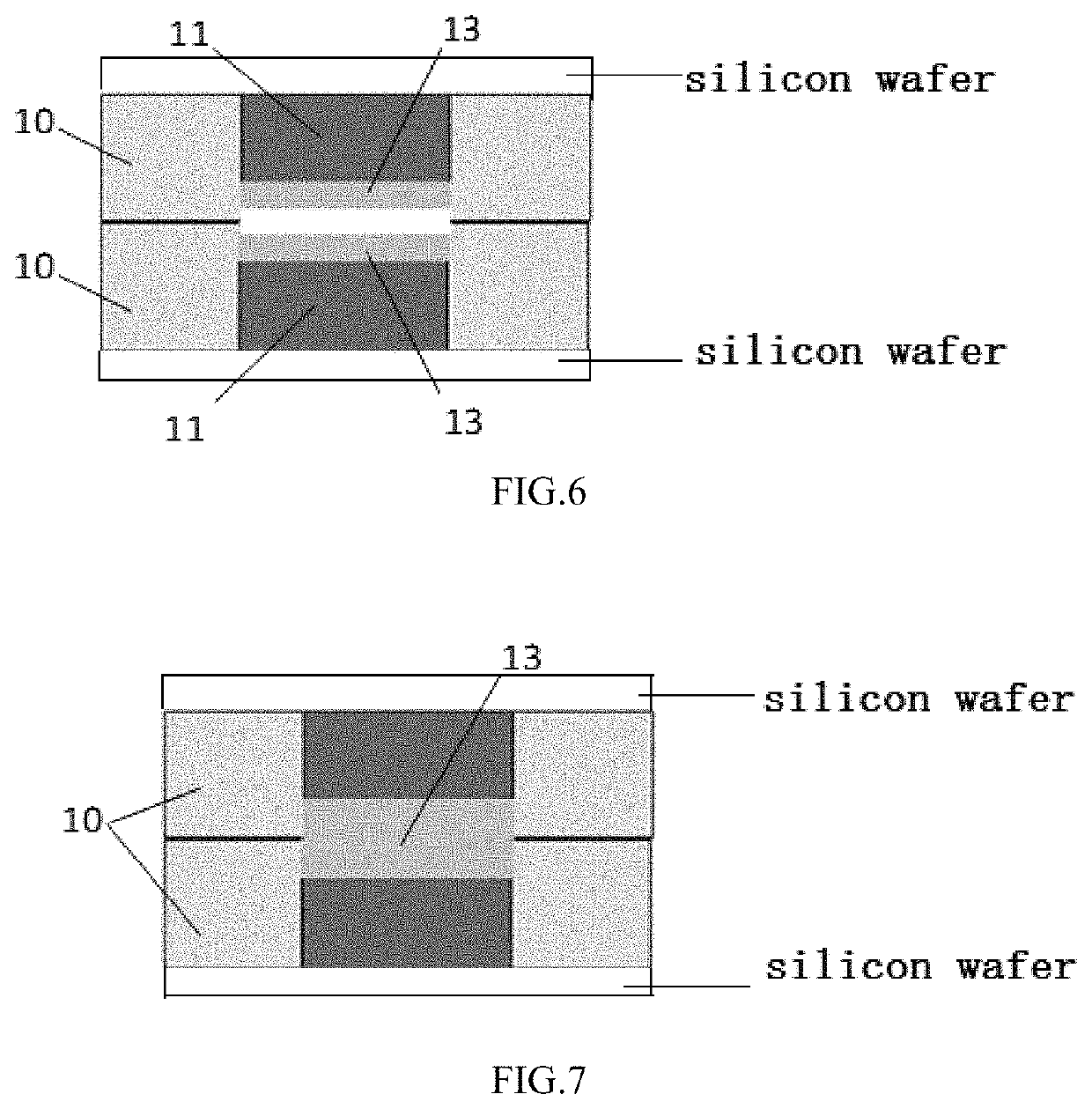

Method for hybrid wafer-to-wafer bonding

ActiveUS20190214257A1Short processing timeFully combinedSolid-state devicesSemiconductor/solid-state device manufacturingDielectricWafering

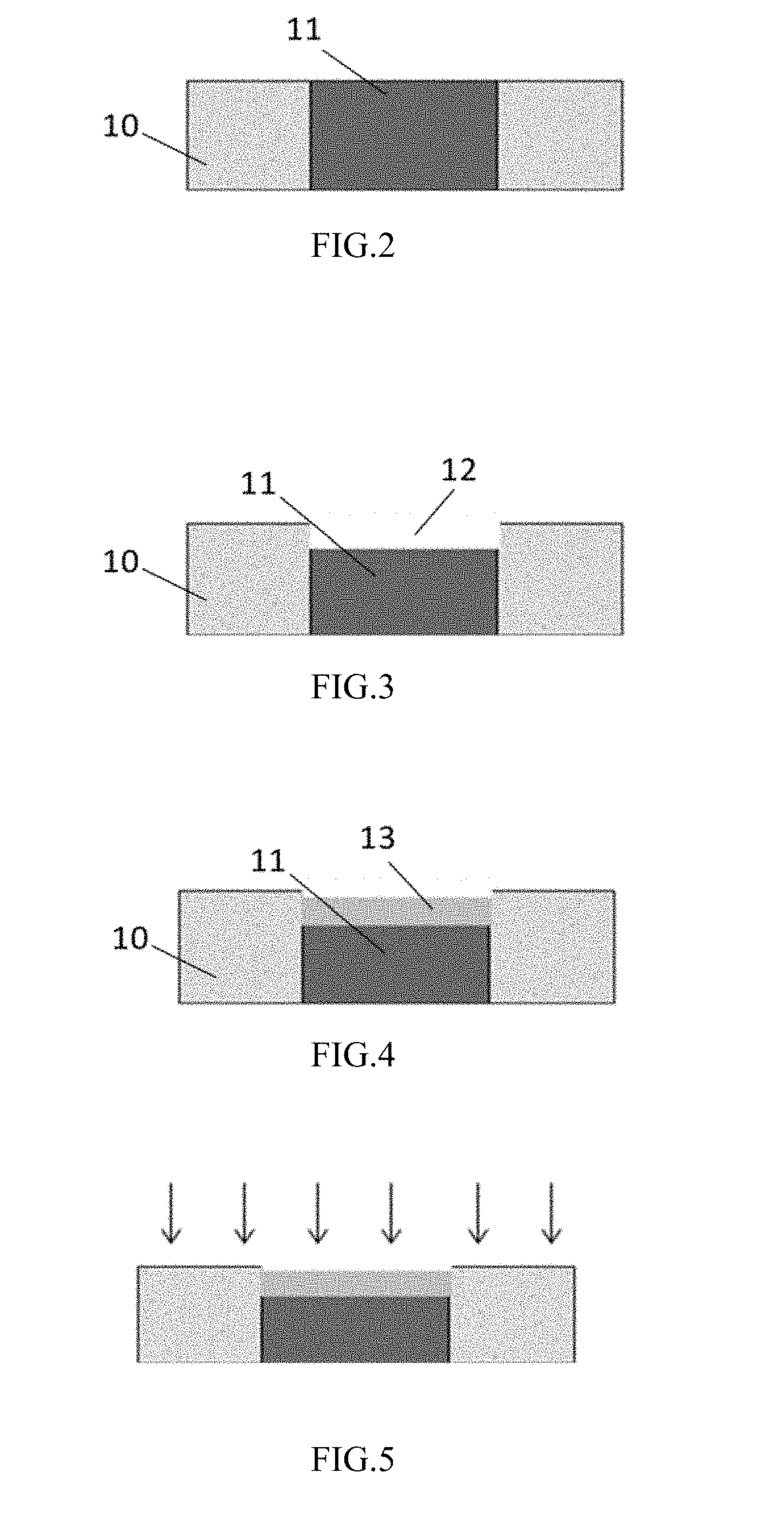

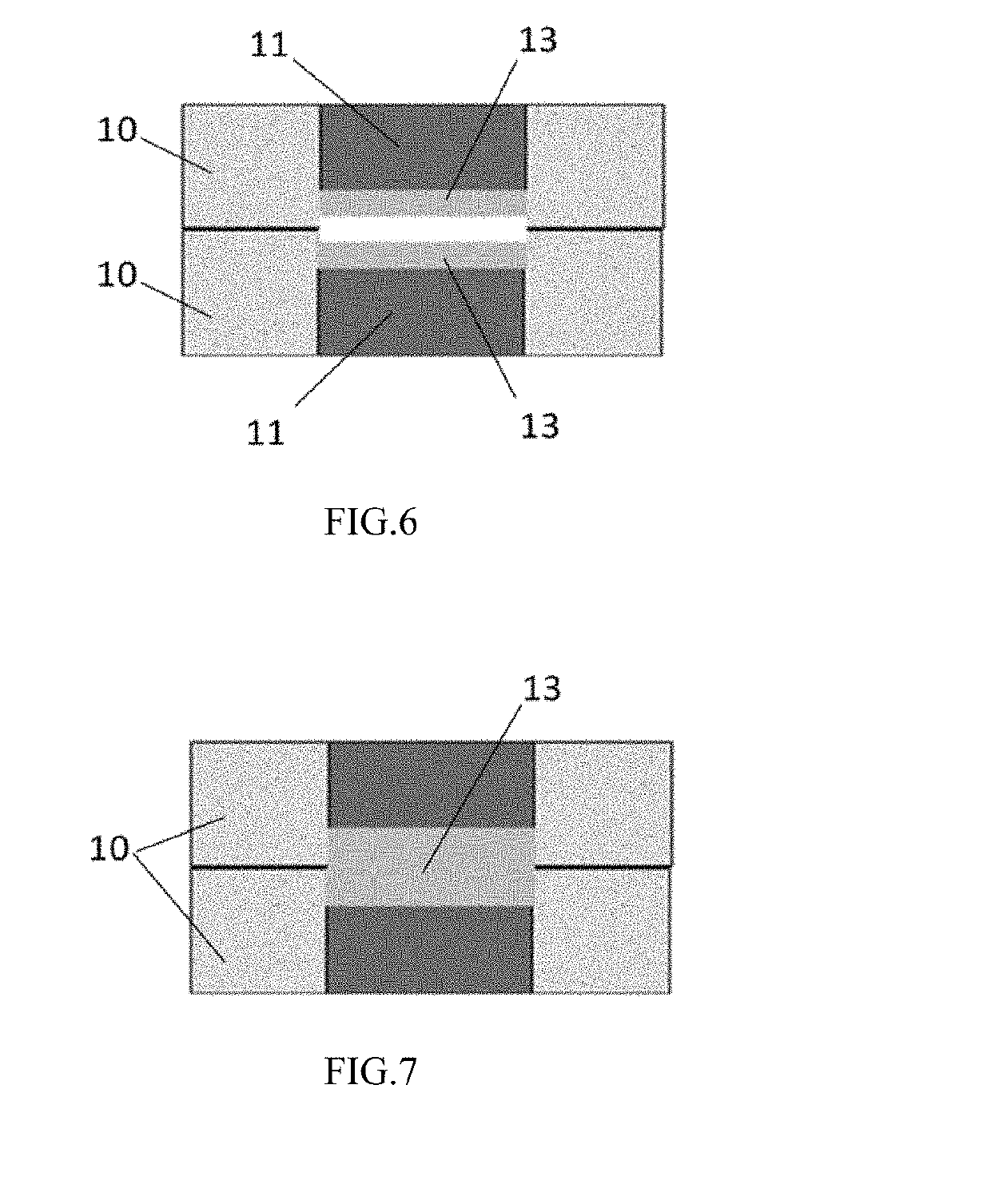

A method for hybrid wafer-to-wafer bonding, comprising: providing two silicon wafers with Cu pattern structures, a conventional Cu BEOL process is adopted on the silicon wafers to obtain the planarized surface with copper and dielectric; removing part of the Cu on the planarized surface of the Cu pattern structures by adopting an etching process to form a certain amount of Cu recesses; depositing a layer of bonding metal on the surface of the Cu by adopting a selective deposition process; performing surface activation on the bonding metal and the dielectric by adopting a surface activation process; aligning and pressing the two silicon wafers together to obtain the dielectric bonding; and obtaining the metal bonding through the annealing process. The sufficient metal bonding can be obtained at low annealing temperature according to the present invent, thereby the risk of dielectric delaminating caused by thermal expansion mismatch is reduced, which is conducive to reduce the difficulty of process integration, save process time and improve product yield.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Turbine rotor blade of gas turbine

ActiveCN110410158AImprove heat transfer effectEnhanced convective heat transferBlade accessoriesMachines/enginesBlade plateLeading edge

The invention relates to a turbine rotor blade of a gas turbine. The turbine rotor blade of the gas turbine comprises a blade profile, a blade platform, a blade top and a blade root, wherein a coolingair channel loop is arranged in the blade, a cooling air channel and a cooling air channel inlet are arranged in the loop, and ribs are arranged in the cooling air channel; and the blade surface is divided into a blade leading edge and a blade trail edge by a pressure surface and a suction surface. The blade tail edge is provided with a tail edge exhaust slot, a tail edge channel is provided witha guide groove structure, and at least one turbulence column is arranged in the guide groove structure; and the blade root cooling air channel is divided into at least two channels by a partition plate, and the partition plate is gradually bent towards the front edge side of the blade in the airflow direction. According to the turbine rotor blade of the gas turbine, the heat exchange effect of aleading edge channel, the tail edge exhaust slot and cooling air in the blade can be improved, and the leading edge metal temperature close to the blade platform and the metal temperature of the tailedge, the blade platform close to the tail edge and the blade root can be reduced.

Owner:HANGZHOU TURBINE POWER GRP

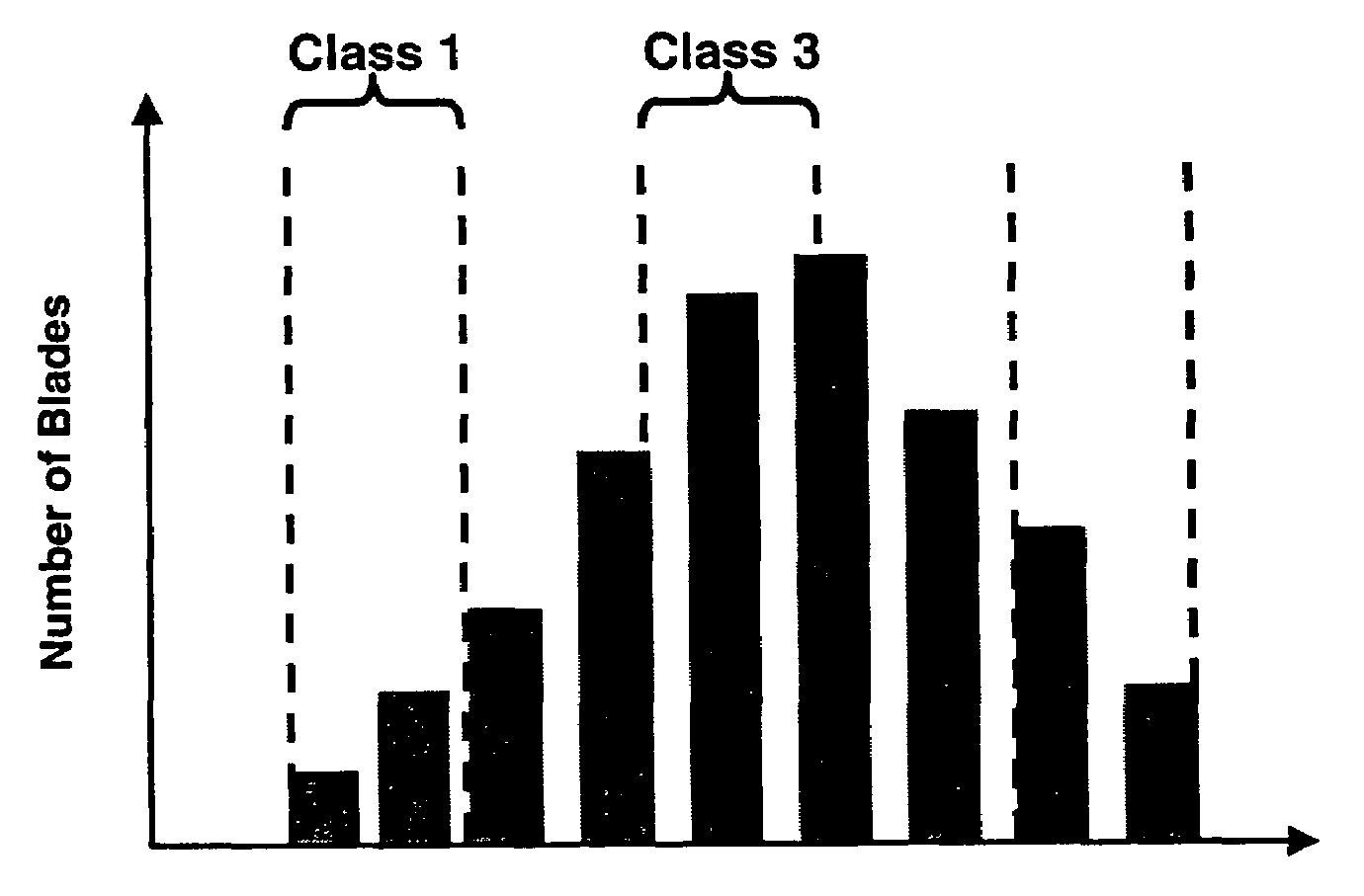

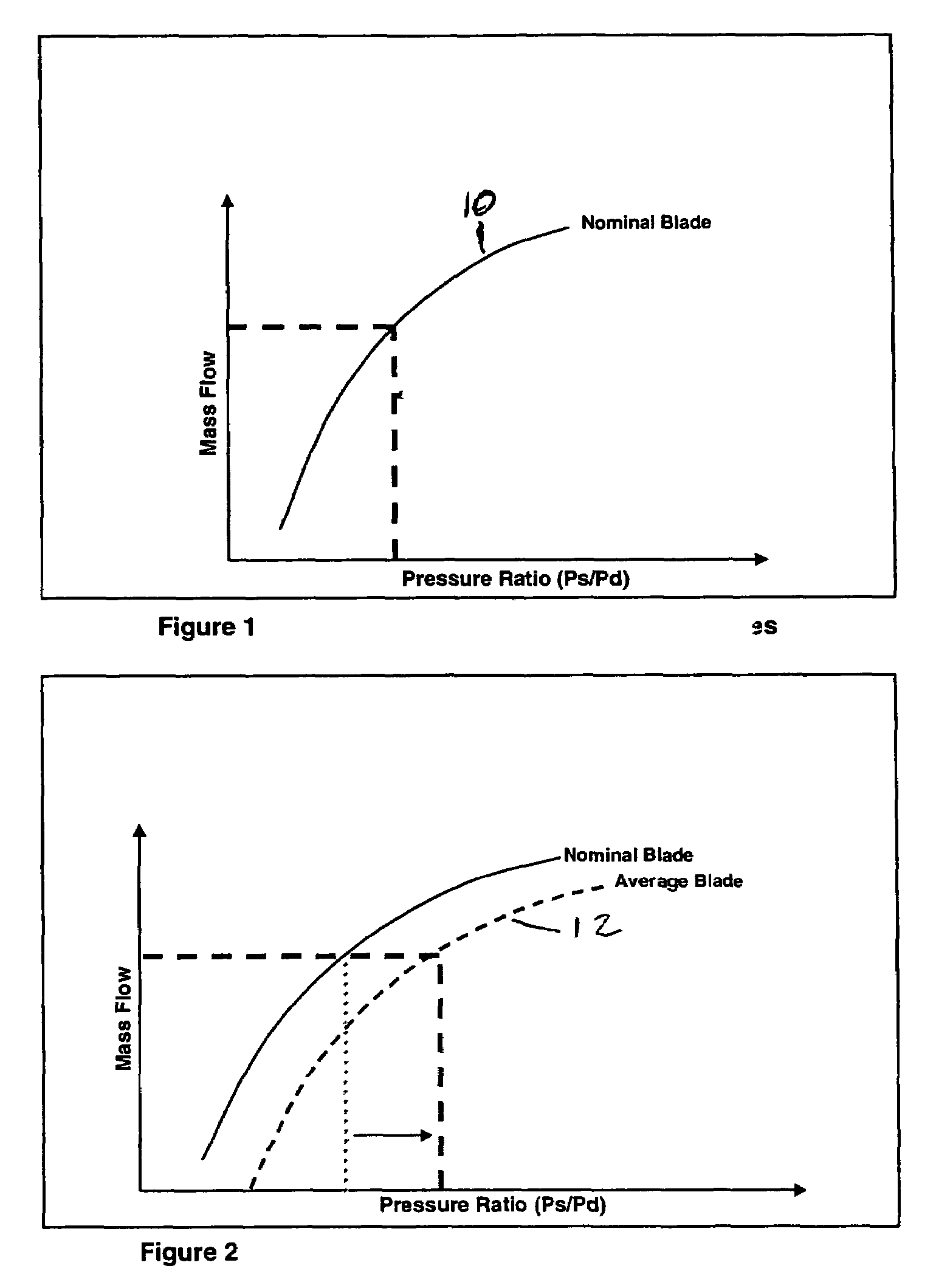

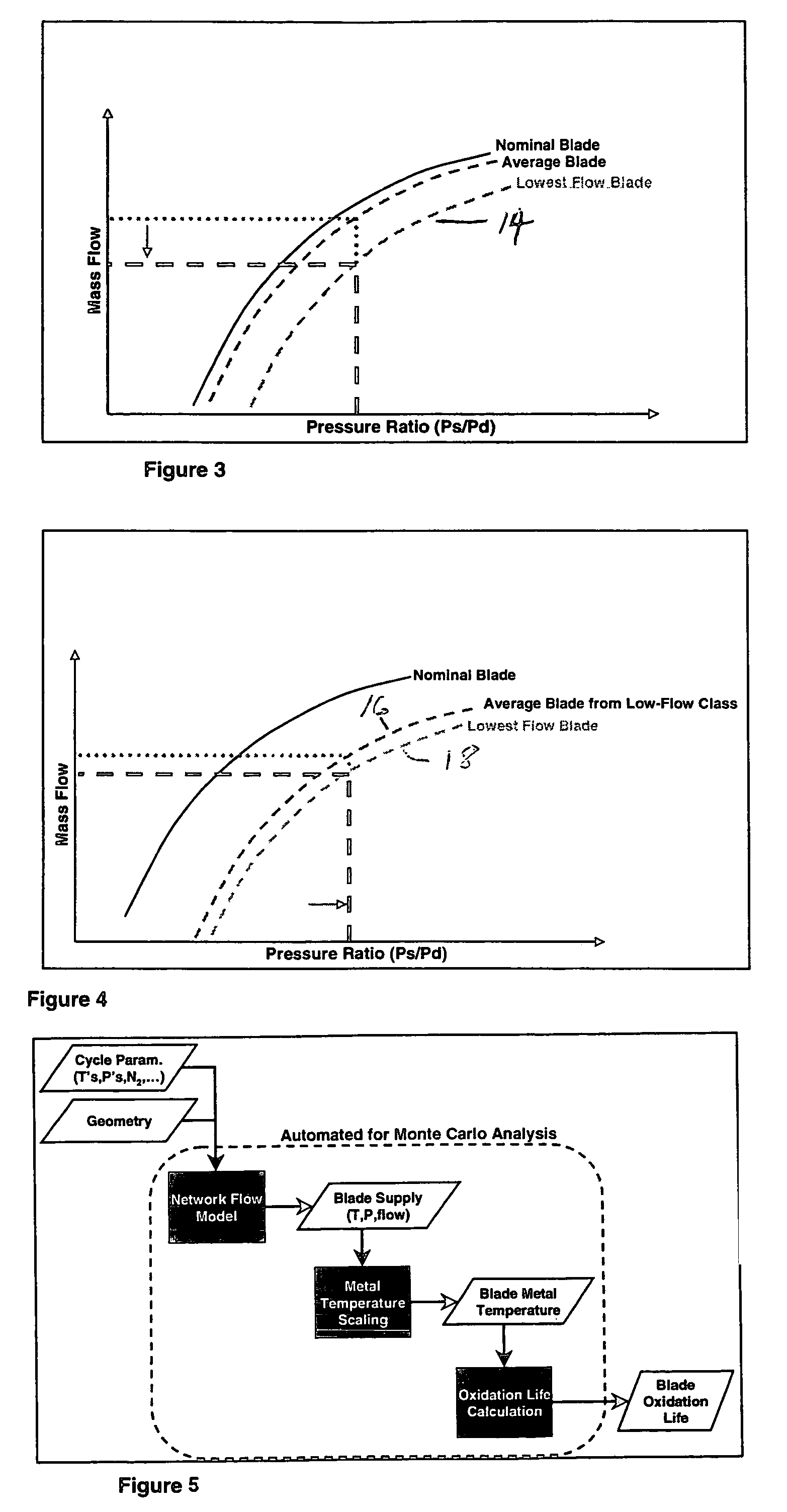

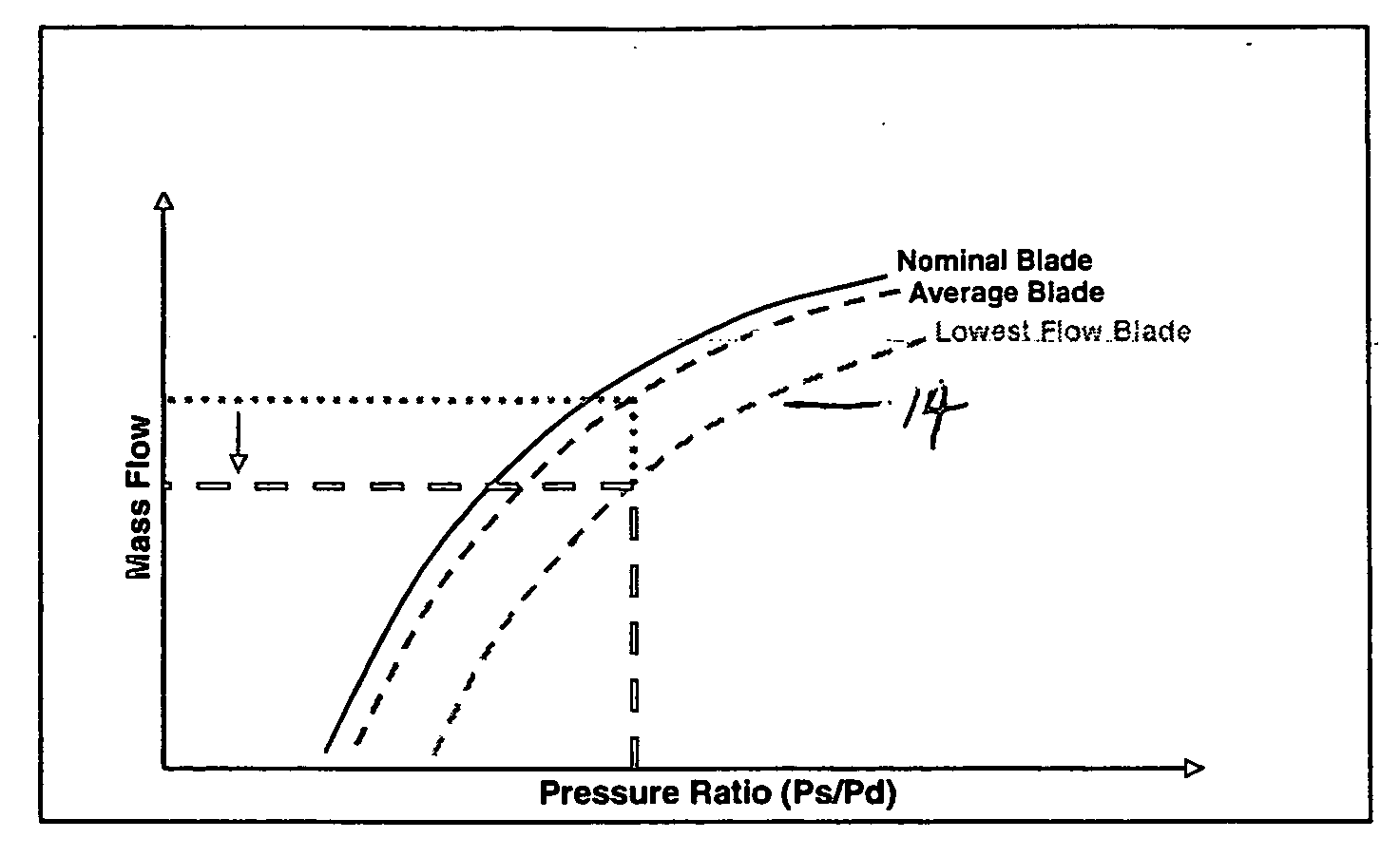

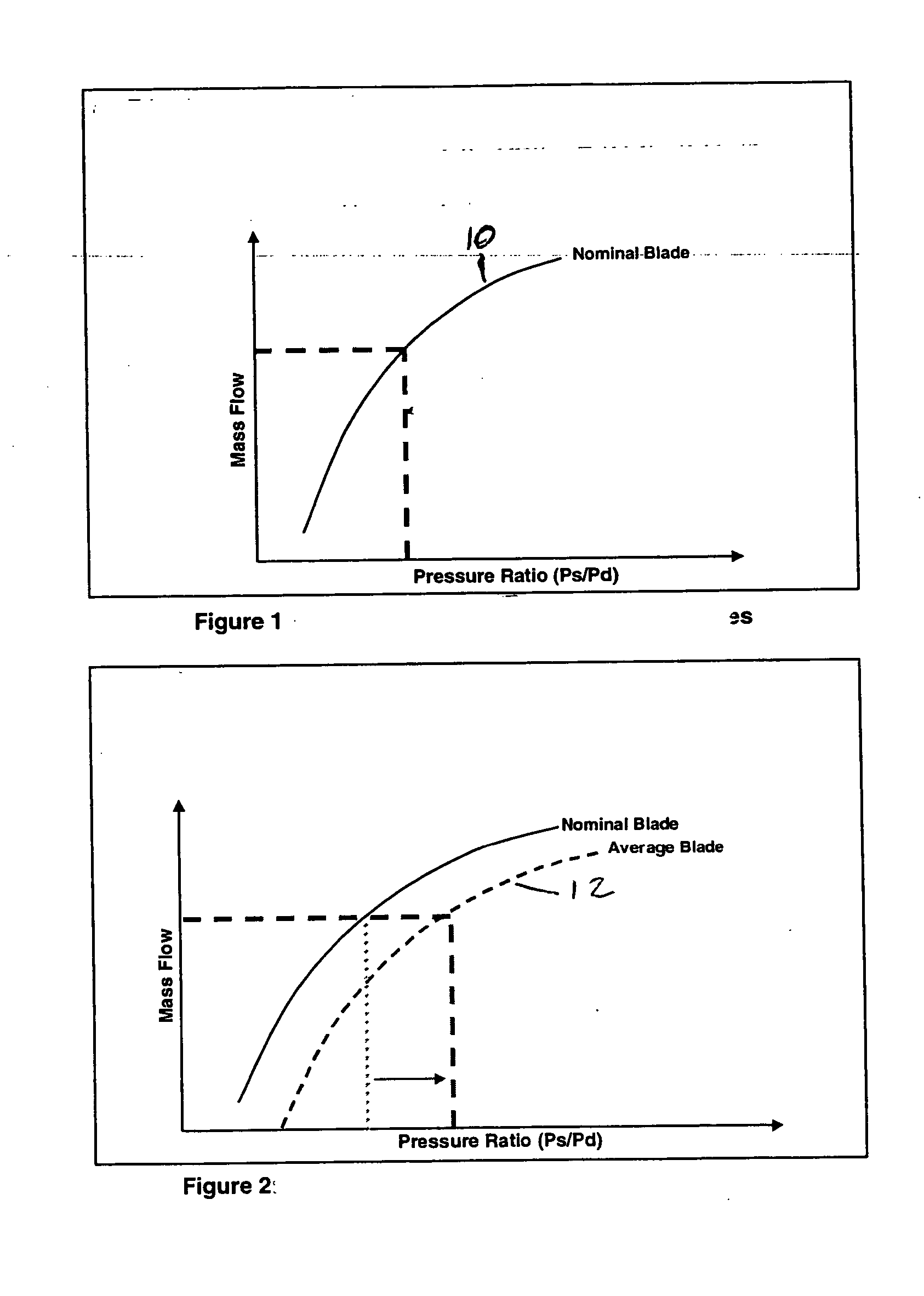

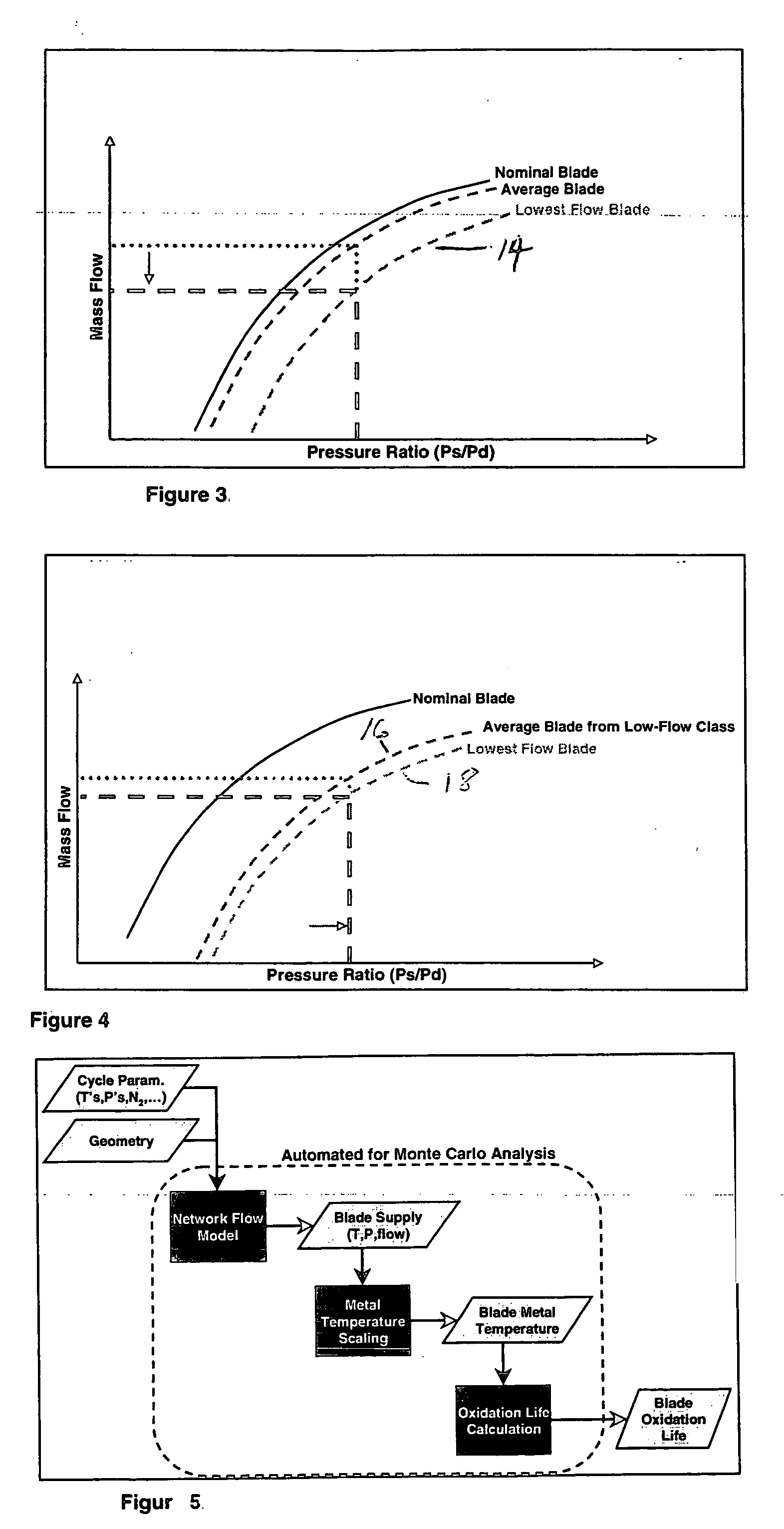

Method for assembling gas turbine engine components

ActiveUS7021892B2Increase pressure ratioReduce metal temperaturePump componentsBlade accessoriesTurbineGas turbines

Owner:MASSACHUSETTS INST OF TECH +1

Method for assembling gas turbine engine components

ActiveUS20050111975A1Reduce metal temperatureConvenient lifePropellersRotary propellersTurbineGas turbines

Method for assembling into turbine sets turbine components having internal cooling passages. The turbine components are classified according to flow capability through the internal cooling passages and turbine sets are assembled in which the turbine components have the same flow capability classification.

Owner:MASSACHUSETTS INST OF TECH +1

Method for hybrid wafer-to-wafer bonding

ActiveUS10796913B2Reduce riskReduce metal temperatureSolid-state devicesSemiconductor/solid-state device manufacturingDielectricThermal dilatation

A method for hybrid wafer-to-wafer bonding, comprising: providing two silicon wafers with Cu pattern structures, a conventional Cu BEOL process is adopted on the silicon wafers to obtain the planarized surface with copper and dielectric; removing part of the Cu on the planarized surface of the Cu pattern structures by adopting an etching process to form a certain amount of Cu recesses; depositing a layer of bonding metal on the surface of the Cu by adopting a selective deposition process; performing surface activation on the bonding metal and the dielectric by adopting a surface activation process; aligning and pressing the two silicon wafers together to obtain the dielectric bonding; and obtaining the metal bonding through the annealing process. The sufficient metal bonding can be obtained at low annealing temperature according to the present invent, thereby the risk of dielectric delaminating caused by thermal expansion mismatch is reduced, which is conducive to reduce the difficulty of process integration, save process time and improve product yield.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

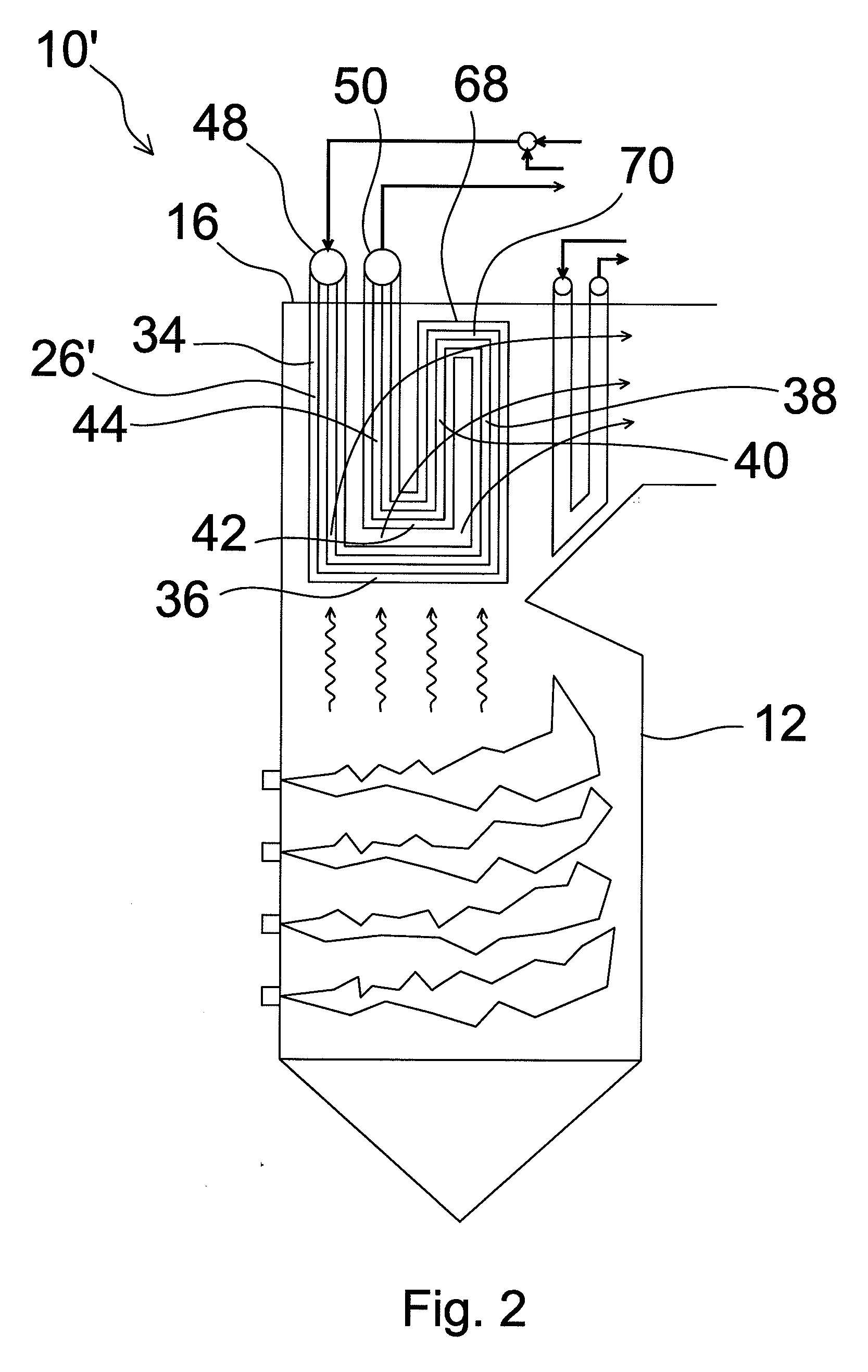

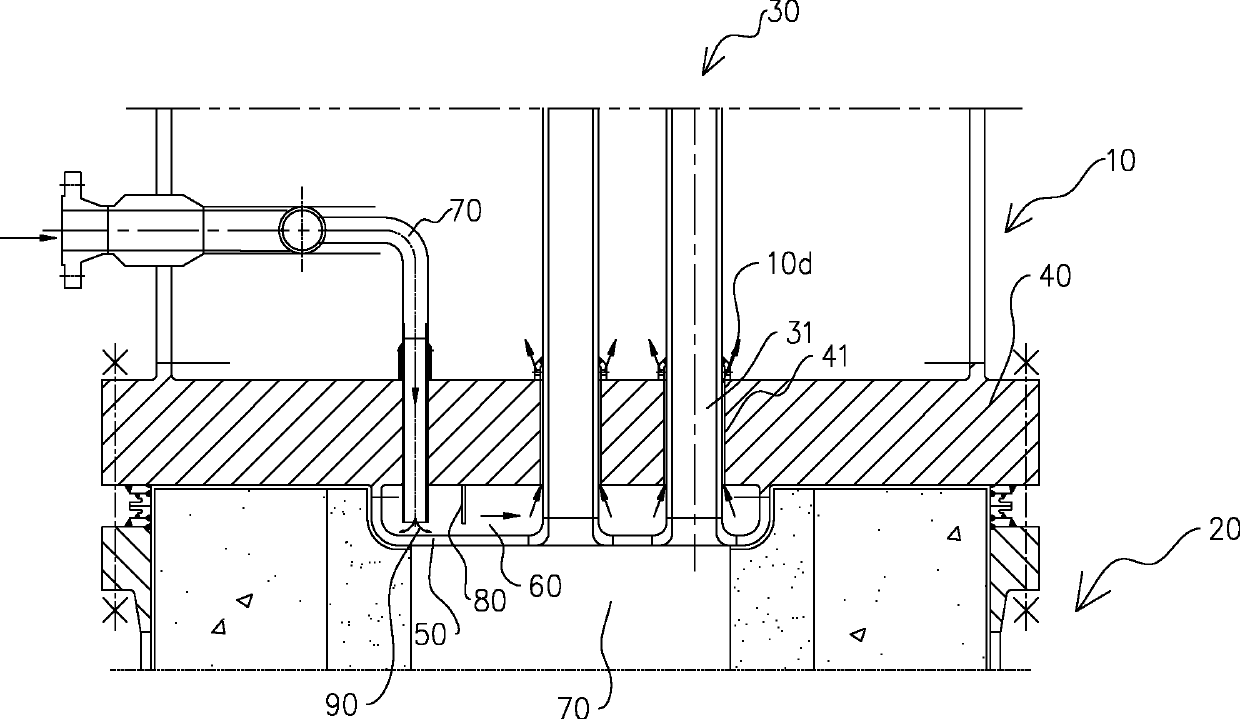

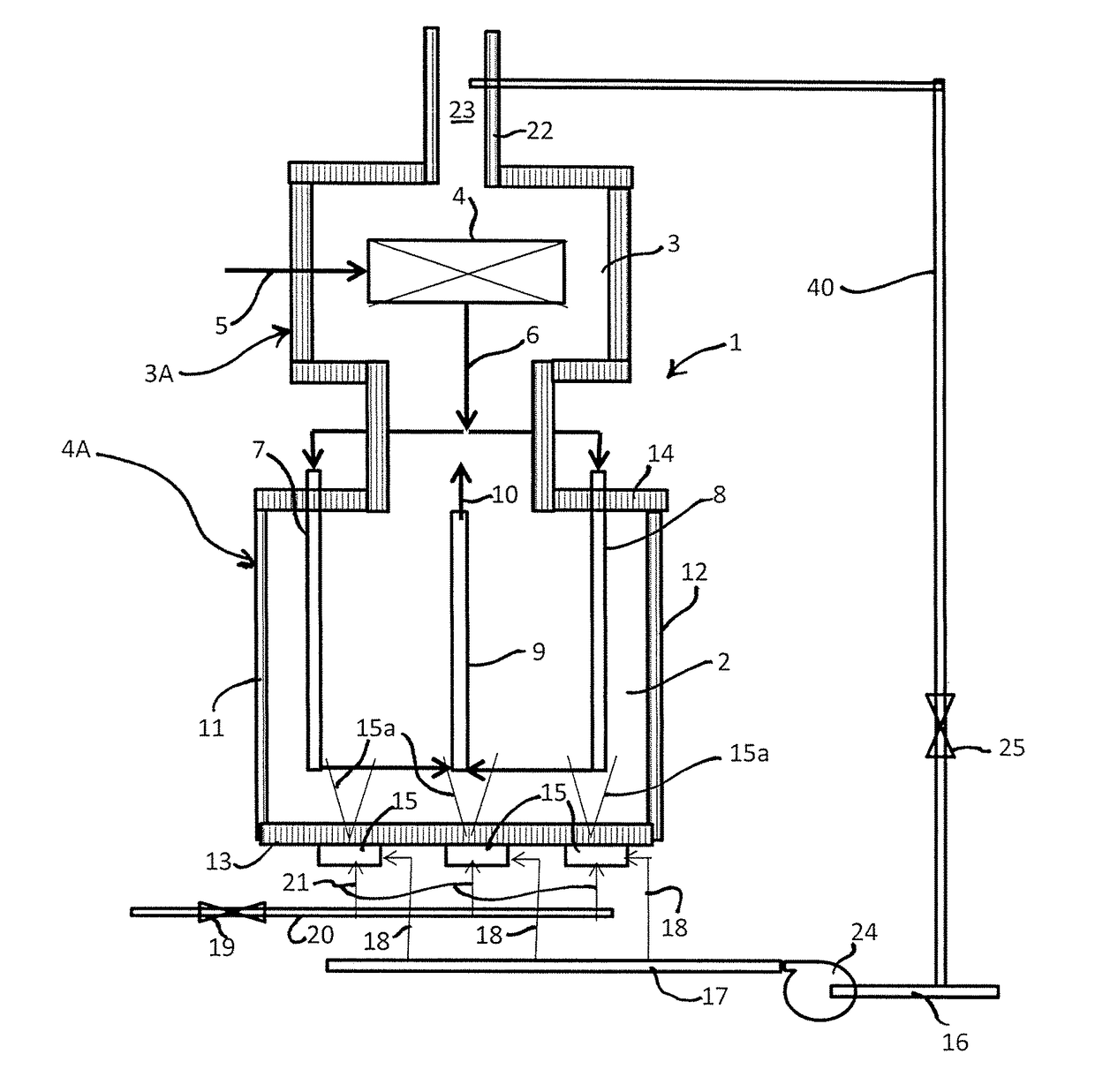

Radiant Superheater

InactiveUS20130008394A1Minimizes problemAcceptable levelMachines/enginesSteam superheatersMarine engineeringSuperheater

A radiant superheater arranged to hang at the upper portion of a furnace of a boiler. The radiant superheater is substantially planar and includes a first vertical pass, a first connection pass, a second vertical pass, a third vertical pass, a second connection pass, and a fourth vertical pass. Each vertical pass includes an upper end and a lower end. The vertical passes are connected in series, so that steam to be superheated enters at the upper end of the first vertical pass and flows through the first vertical pass and from the lower end of the first vertical pass via the first connection pass to the lower end of the second vertical pass and through the second vertical pass and from the upper end of the second vertical pass to the upper end of the third vertical pass and through the third vertical pass and from the lower end of the third vertical pass via the second connection pass to the lower end of the fourth vertical pass and through the fourth vertical pass, to be discharged from the upper end of the fourth vertical pass. The first connection pass is arranged below the second connection pass so as to shield the second connection pass from radiation from the lower portion of the furnace.

Owner:FOSTER WHEELER NORTH AMERICA CORP

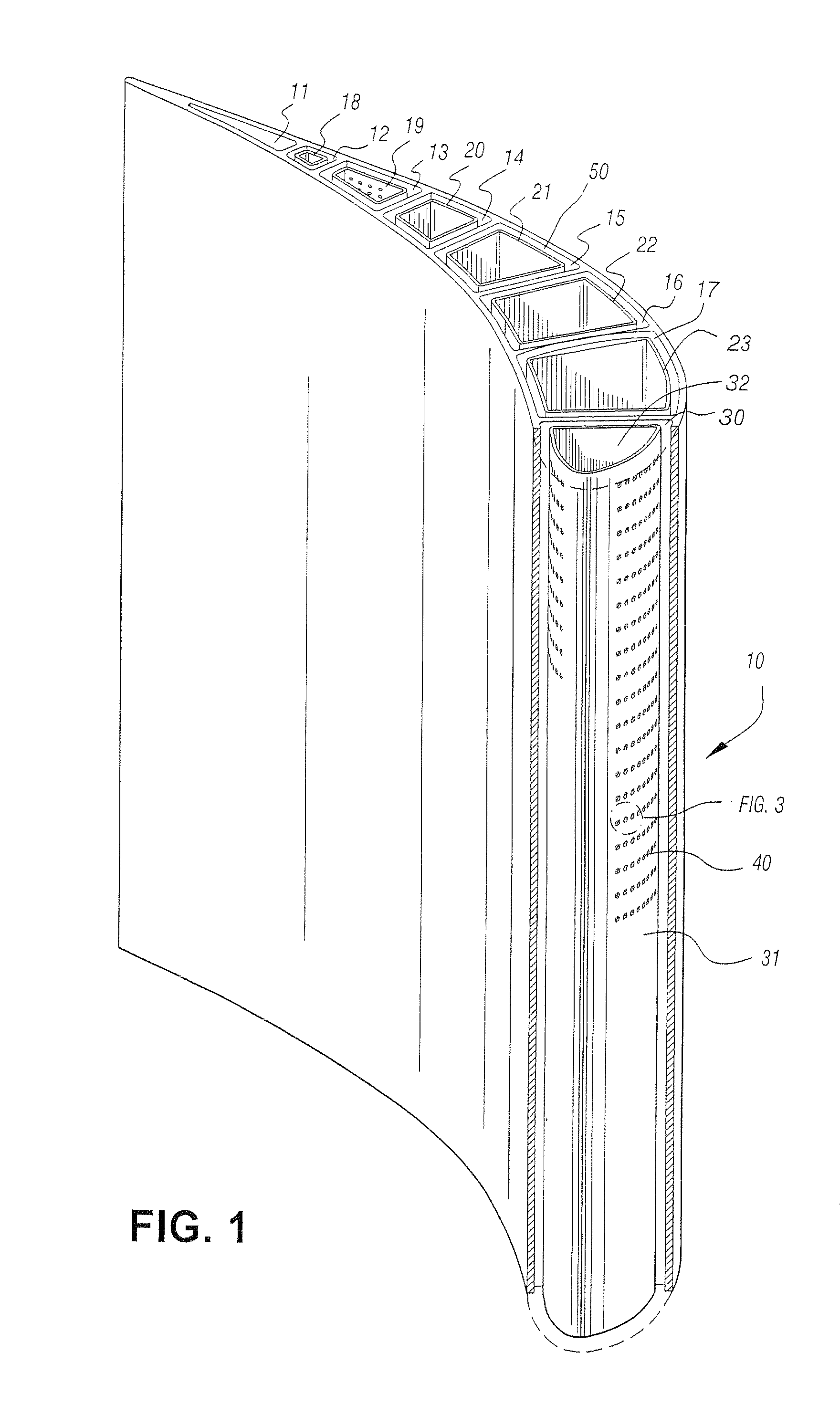

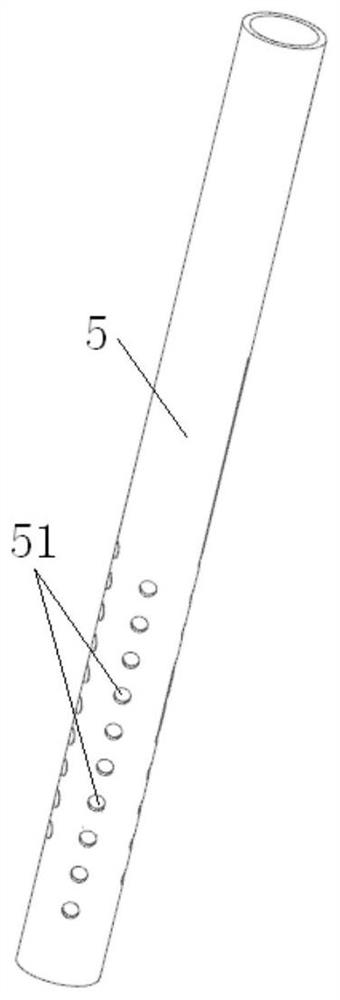

Use of multi-faceted impingement openings for increasing heat transfer characteristics on gas turbine components

InactiveUS9151173B2Improve heat transfer performanceIncrease fluid velocityEngine manufacturePump componentsGas turbinesCooling medium

An improved nozzle vane for a gas turbine engine, comprising a vane wall having inner and outer wall surfaces, the wall surfaces being spaced from one another to define a plurality of fluid passageways for a cooling medium; discreet cavities formed by interior wall members disposed between the inner and outer wall surfaces and within the fluid passageway for the cooling medium; a plurality of impingement cooling sleeves disposed in the discreet cavities defined by the inner and outer wall surfaces and by interior wall members; and a plurality of non-round, e.g., serrated, openings in each of the impingement cooling sleeves, with the openings being sufficient in size and number to accommodate the flow of a cooling media.

Owner:GENERAL ELECTRIC CO

Furnaces and methods of reducing heat degrading of metal heating coils of furnaces

InactiveUS20160076761A1Reduced combustibilityReduce soot formationFluegas recirculationAir/fuel supply for combustionCombustorMetallurgy

A method includes providing a furnace including a radiant heating zone having metal heating coils and burners, concurrently applying a combustion media, having a combustibility, and a diluent to the burners, the burners burning the combustion media producing flames heating the radiant heating zone, and the diluent reducing the combustibility of the combustion media for reducing heat generated by the flames for reducing heat degradation of the metal heating coils.

Owner:ATD COMBUSTORS

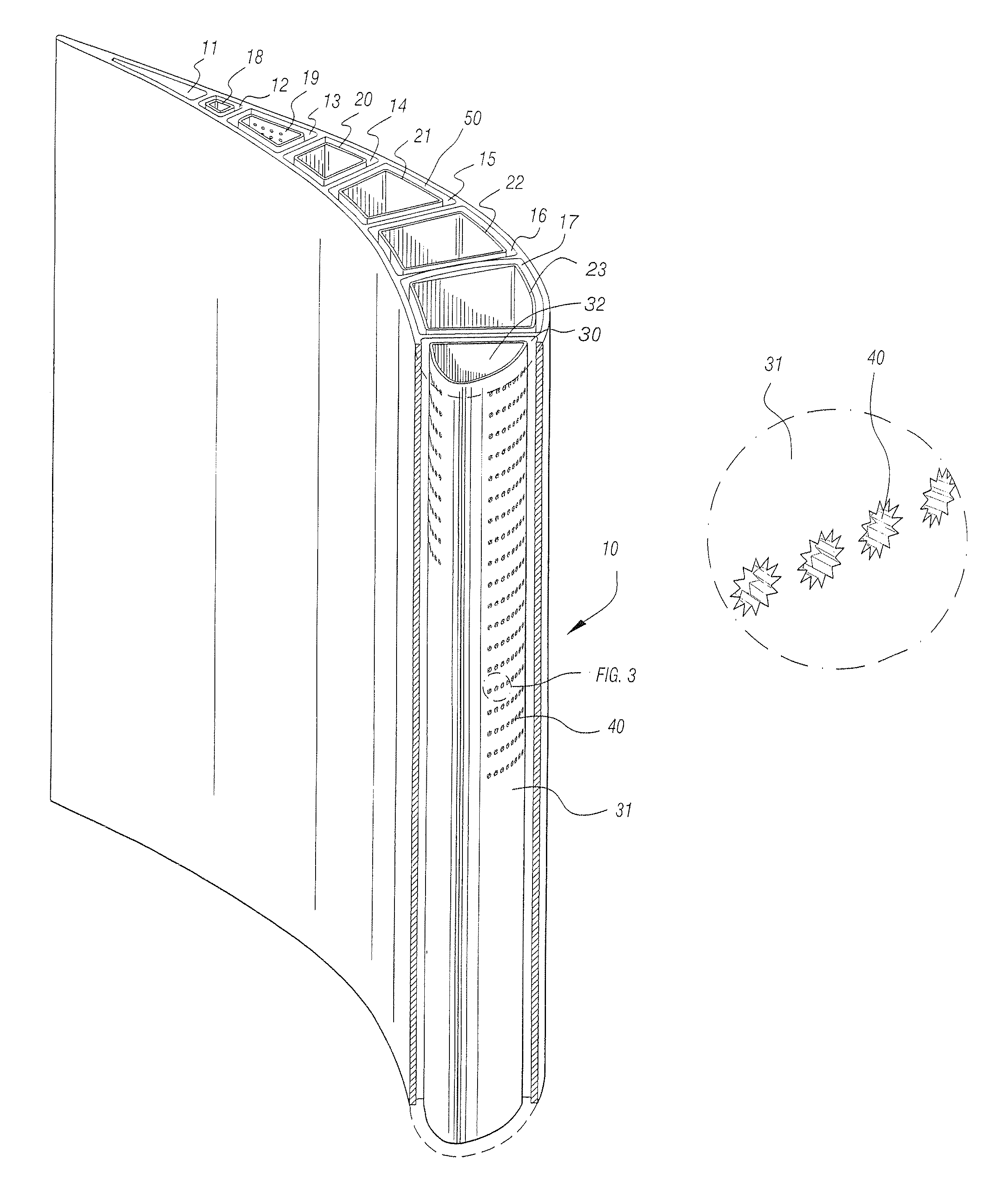

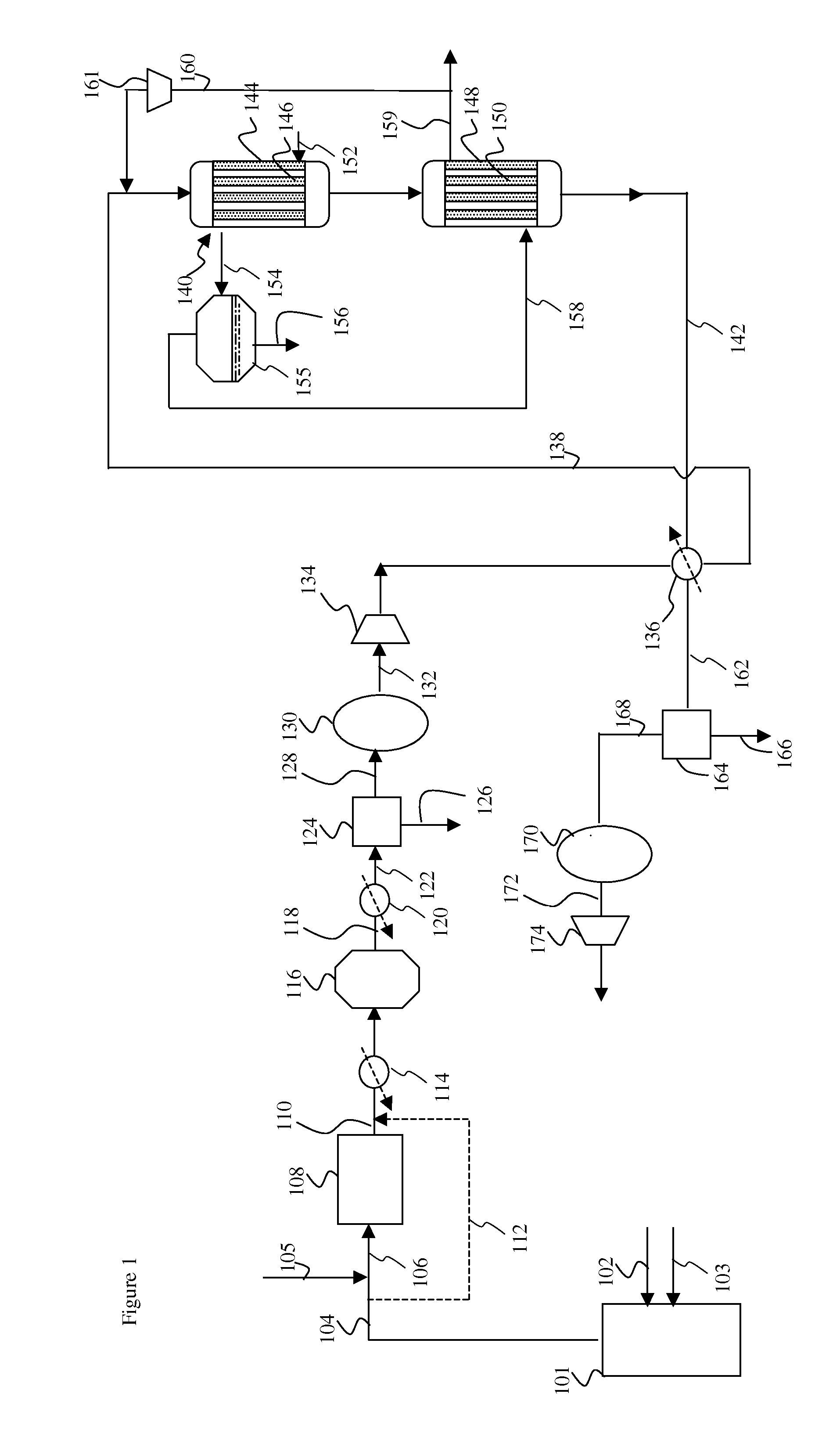

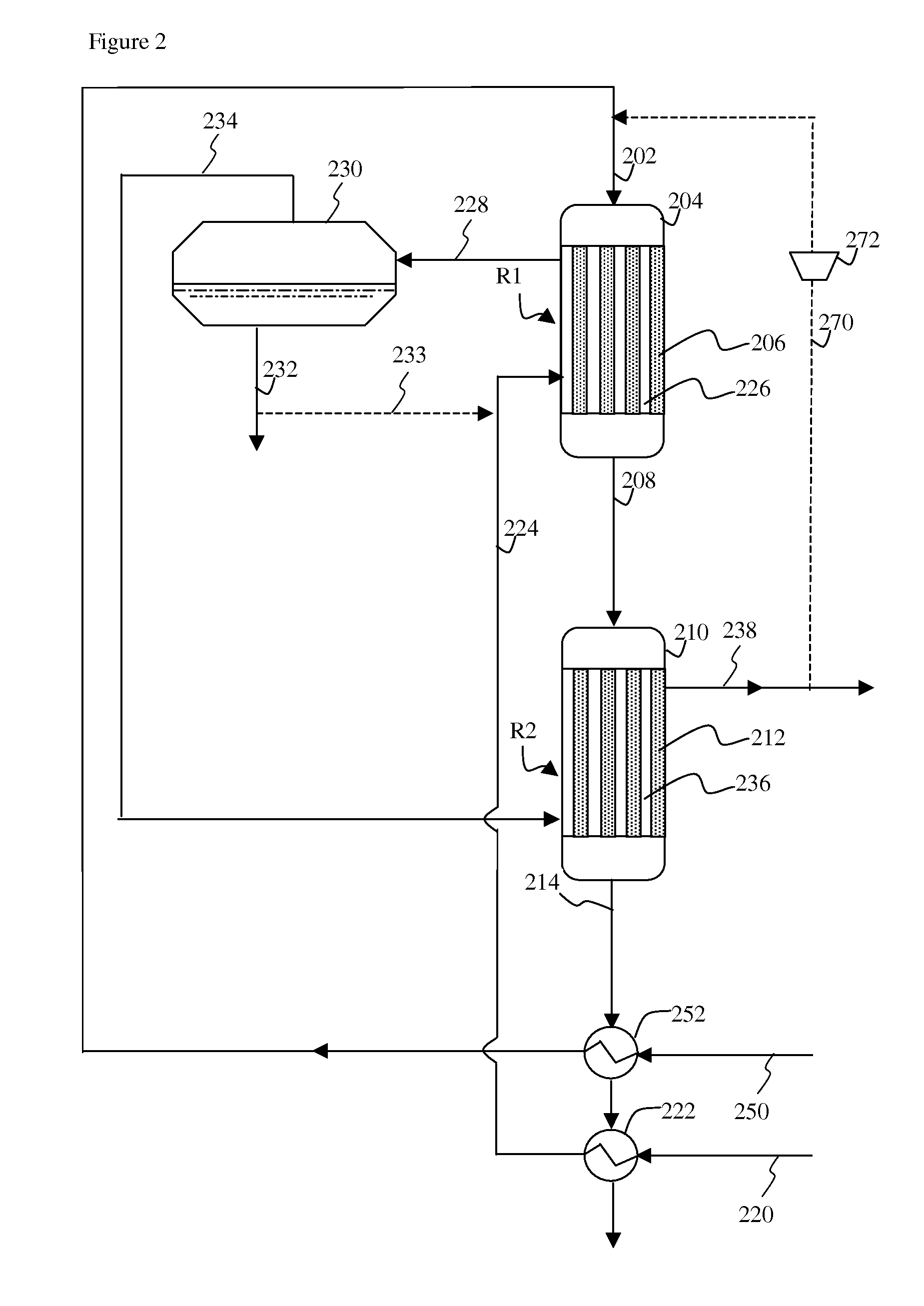

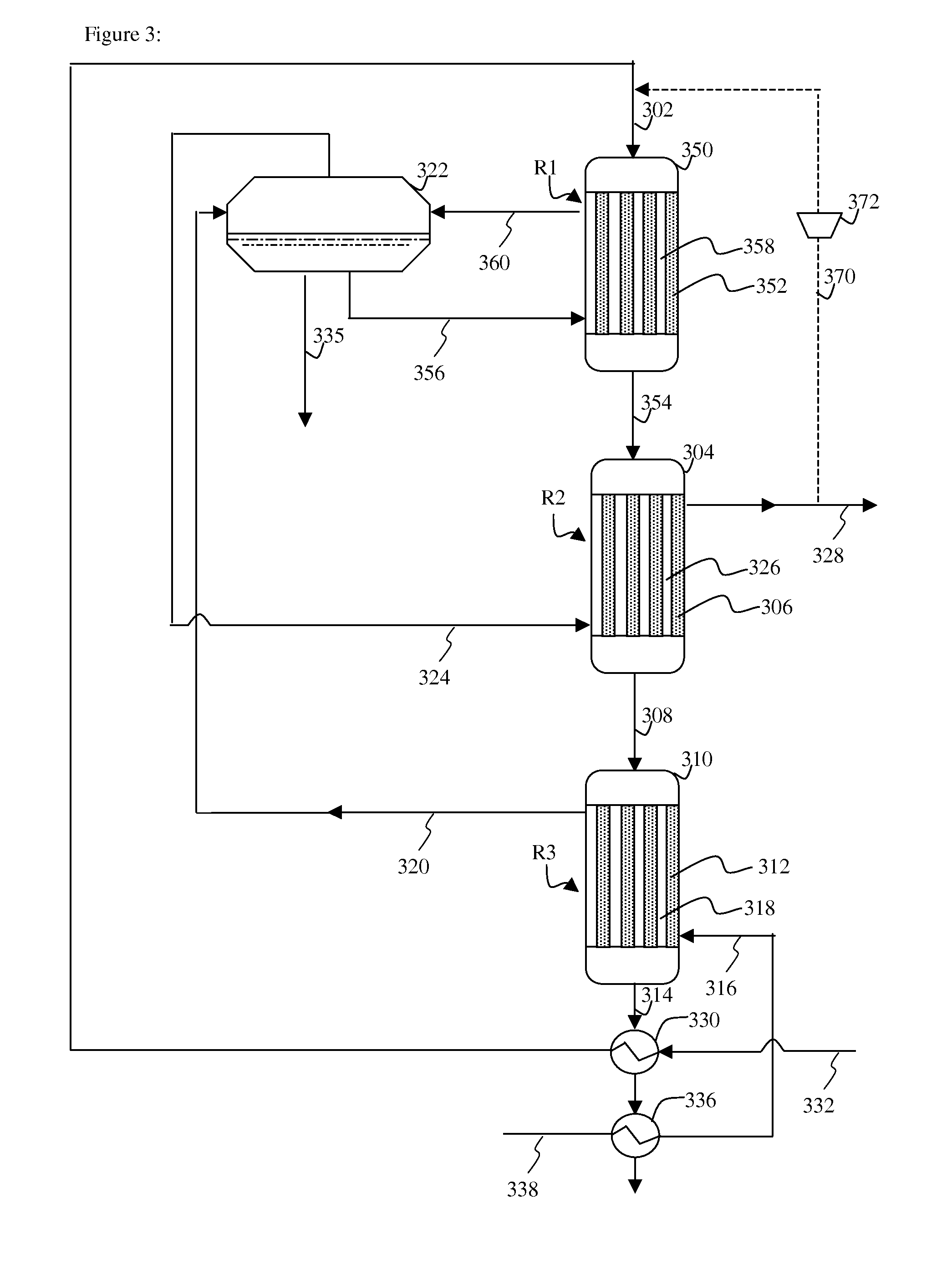

Process for the co-production of superheated steam and methane

ActiveUS8461216B2Low costReduce metal temperatureOrganic compound preparationOxygen compounds preparation by reductionMethanationWater flow

A process for the co-production of superheated steam and methane includes reacting a gas containing carbon monoxide and hydrogen in a series of methanation regions to produce a product gas containing methane The gas containing carbon monoxide and hydrogen flows, in passing through the series of methanation regions, successively through at least a first internally cooled methanation region and a second internally cooled methanation region, cooling the first and second internally cooled methanation region with water, which water is vaporized in the first internally cooled methanation region to produce steam and which steam is subsequently superheated in the second internally cooled methanation region to produce superheated steam The internally cooled methanation regions include tubes filled with a methanation catalyst and a space surrounding the tubes The gas containing carbon monoxide and hydrogen and / or product gas flows through the tubes and the water flows through the space surrounding the tubes.

Owner:SHELL USA INC

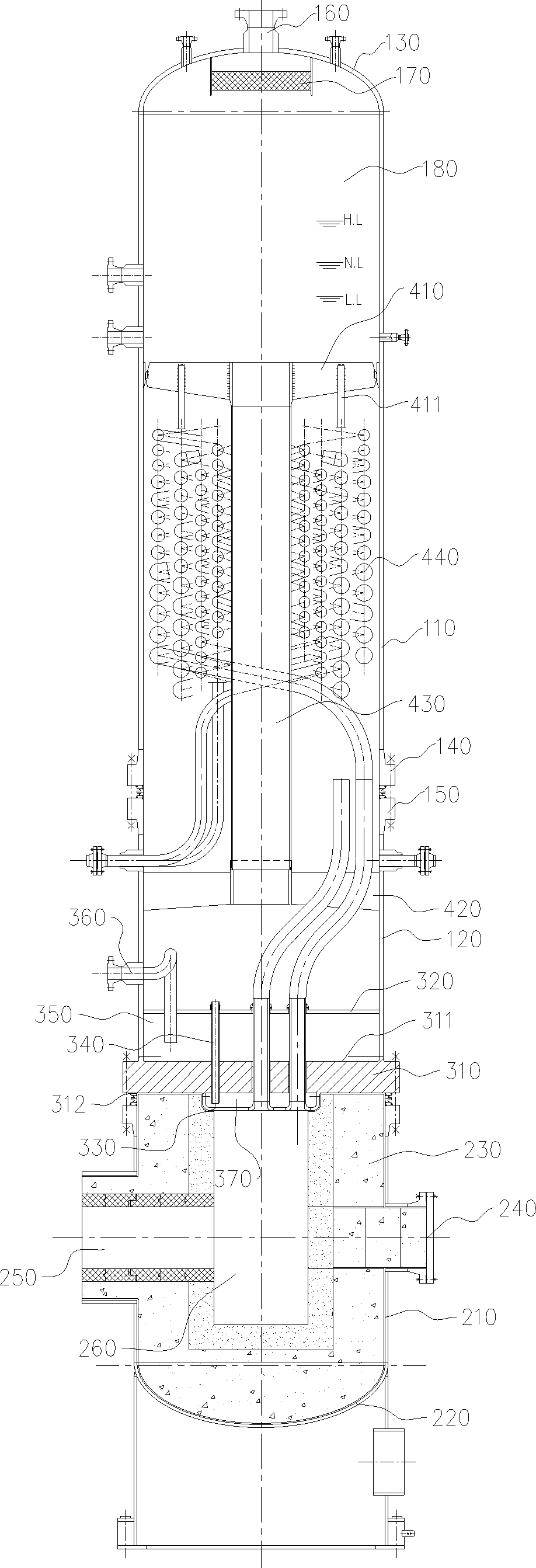

High-temperature vertical waste heat boiler with coil pipes

ActiveCN102705801BWide range of applicable parametersSolving Recycling ProblemsHeat exchanger casingsSteam boilersDraining tubeWater source

Owner:SHANGHAI INT ENG CONSULTING

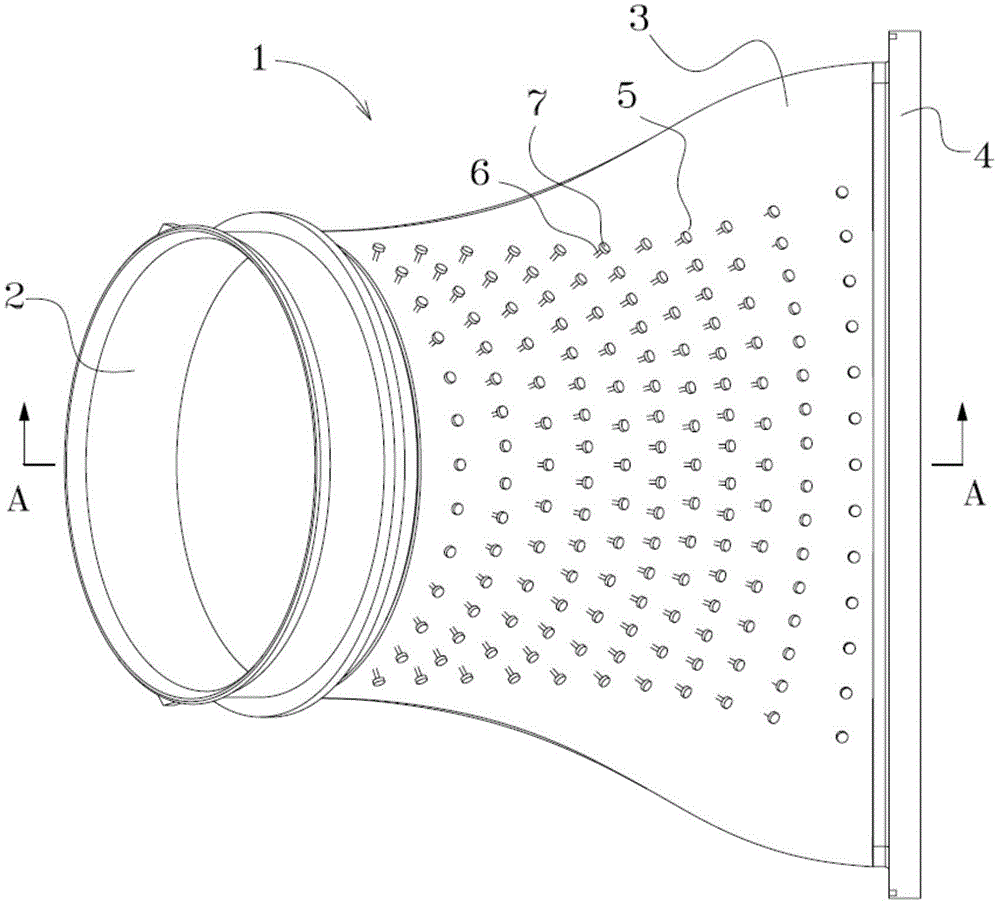

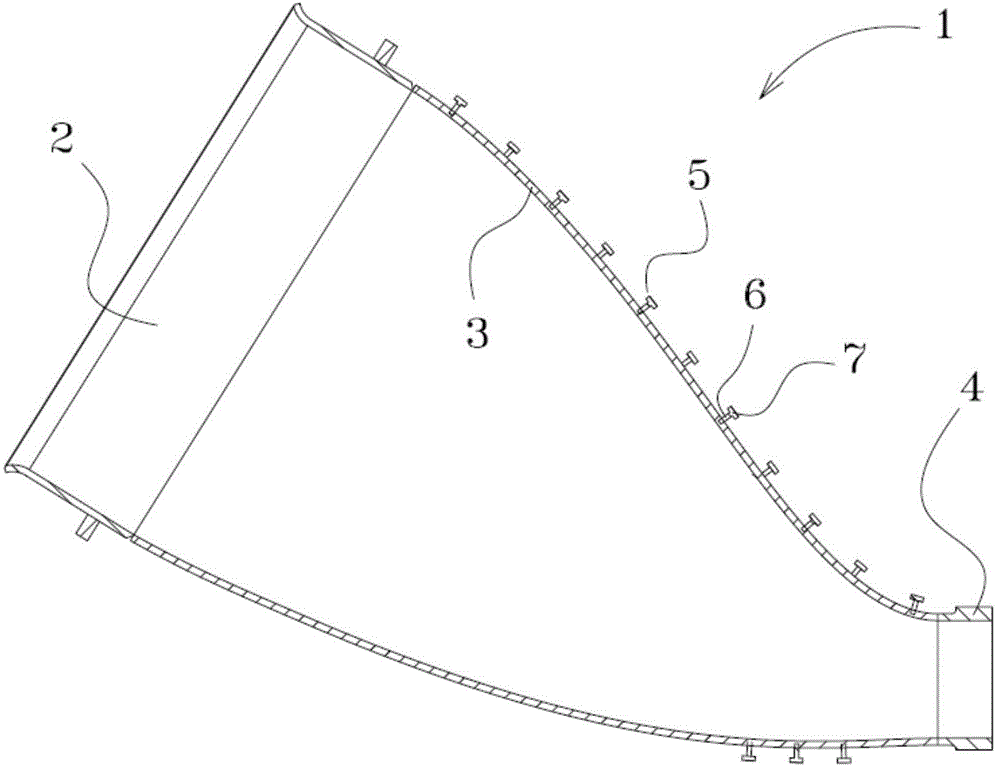

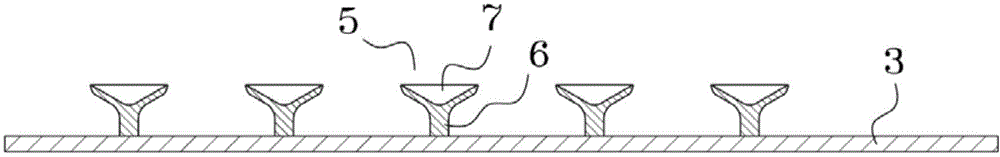

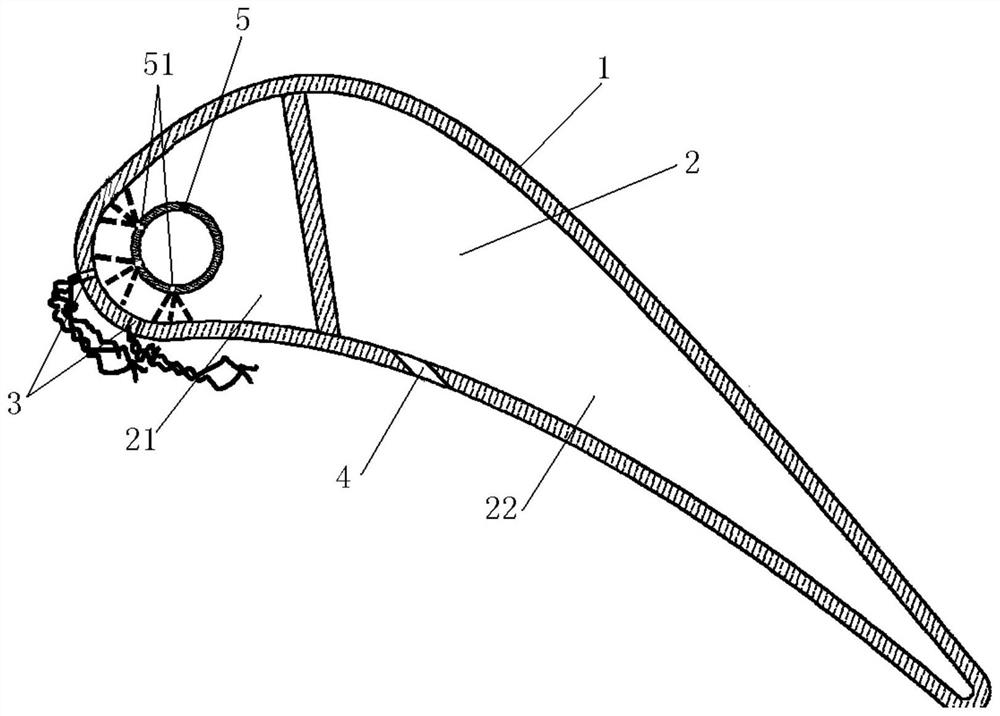

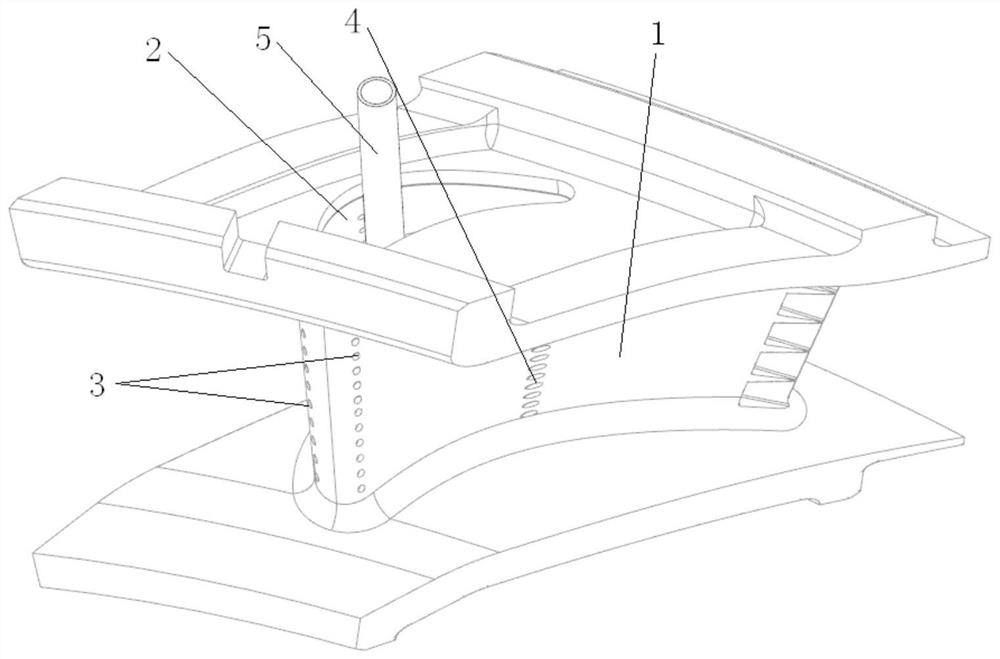

Gas turbine combustor transition section with cooling structure

InactiveCN104566458AIncrease the heat exchange areaReduce metal temperatureContinuous combustion chamberThermal insulationGas turbines

The invention discloses a gas turbine combustor transition section with a cooling structure, and belongs to the technical field of a gas turbine. The outer surface of a transition section body is provided with a plurality of cooling components; each cooling component comprises a connecting piece and a heat dissipation part; the cooling components are distributed in an array, and every two adjacent cooling members are distributed in a staggered manner; each heat dissipation part is in the shape of a bowl or is spiral or dendritic or is in other shapes that not only can surface area be increased but also flow resistance is smaller. According to the gas turbine combustor transition section disclosed by the invention, the temperature of the transition section can be lowered and the service life of the transition section can be prolonged by increasing the heat exchange area of the outer surface of the transition section; meanwhile, the integrity of the transition section body cannot be broken, the reliability of a thermal barrier coating cannot be influenced and the thermal insulation effect of the can be helped to be enhanced by the cooling structure; pressure loss brought by the cooling structure is low, so that the efficiency of the gas turbine can be helped to be improved.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

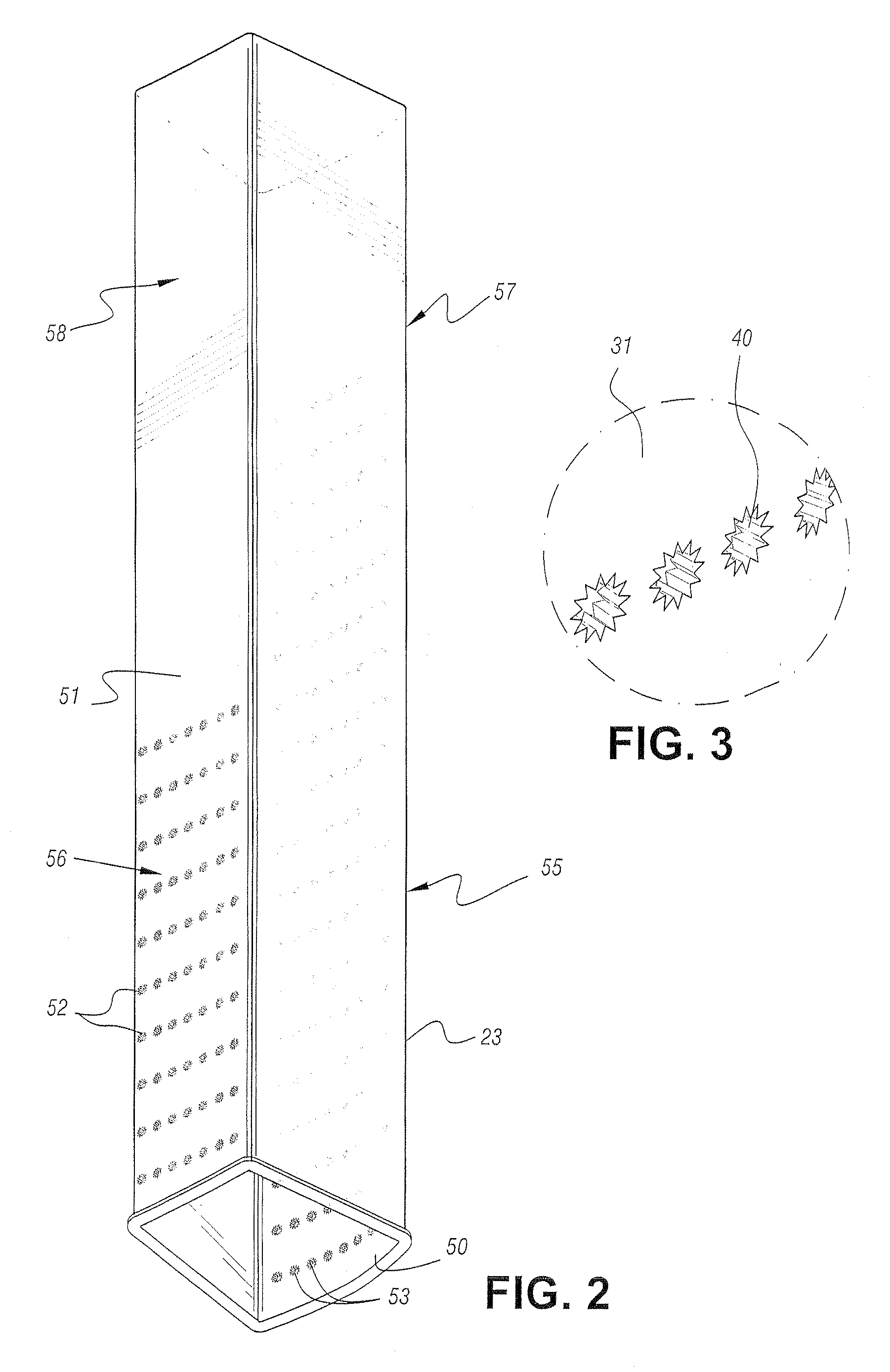

High-power tower receiver configuration

InactiveUS20140150428A1Reduce metal temperatureReduce trafficSolar heating energyFrom solar energyPower stationEngineering

A receiver with a configuration of saturated and superheated steam solar modules in a tower solar concentration power plant. The configuration allows the incidence of radiation on both sides of the superheated steam module, providing significant benefits for its durability and global control of the power plant.

Owner:ABENGOA SOLAR NEW TECH SA

Furnaces and methods of reducing heat degrading of metal heating coils of furnaces

InactiveUS9989246B2Reduced combustibilityDecreased emissivityFluegas recirculationAir/fuel supply for combustionCombustorDiluent

A method includes providing a furnace including a radiant heating zone having metal heating coils and burners, concurrently applying a combustion media, having a combustibility, and a diluent to the burners, the burners burning the combustion media producing flames heating the radiant heating zone, and the diluent reducing the combustibility of the combustion media for reducing heat generated by the flames for reducing heat degradation of the metal heating coils.

Owner:ATD COMBUSTORS

Turbine rotor blade of a gas turbine

ActiveCN110410158BImprove heat transfer effectEnhanced convective heat transferBlade accessoriesMachines/enginesThermodynamicsSuction force

The invention relates to a turbine rotor blade of a gas turbine, which includes a blade profile, a blade platform, a blade top and a blade root. There is a cooling air passage loop inside the blade, and a cooling air passage and a cooling air passage inlet are installed in the cooling air passage. Ribbed; blade surface is divided into blade leading edge and blade trailing edge by pressure surface and suction surface. The trailing edge of the blade has a trailing edge exhaust slot, and the trailing edge channel has a diversion groove structure, and there is at least one spoiler column in the diversion groove structure; the cooling air passage of the blade root is divided into at least two passages by a partition plate, The partition plate is gradually bent toward the leading edge side of the blade along the airflow direction. The invention can improve the heat exchange effect between the internal leading edge channel, the trailing edge exhaust slot and the cooling air, and reduce the metal temperature of the leading edge near the blade platform and the metal temperature of the trailing edge and the platform and blade root near the trailing edge.

Owner:HANGZHOU TURBINE POWER GRP

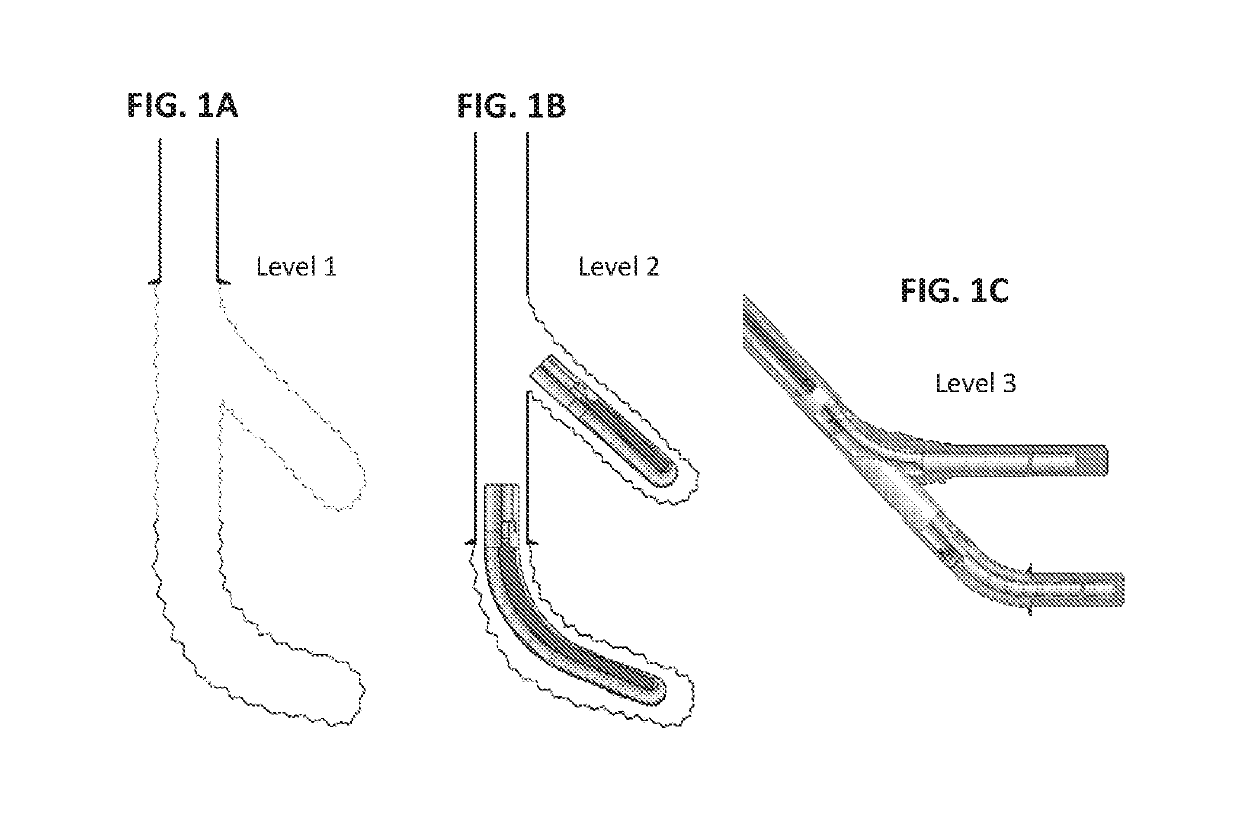

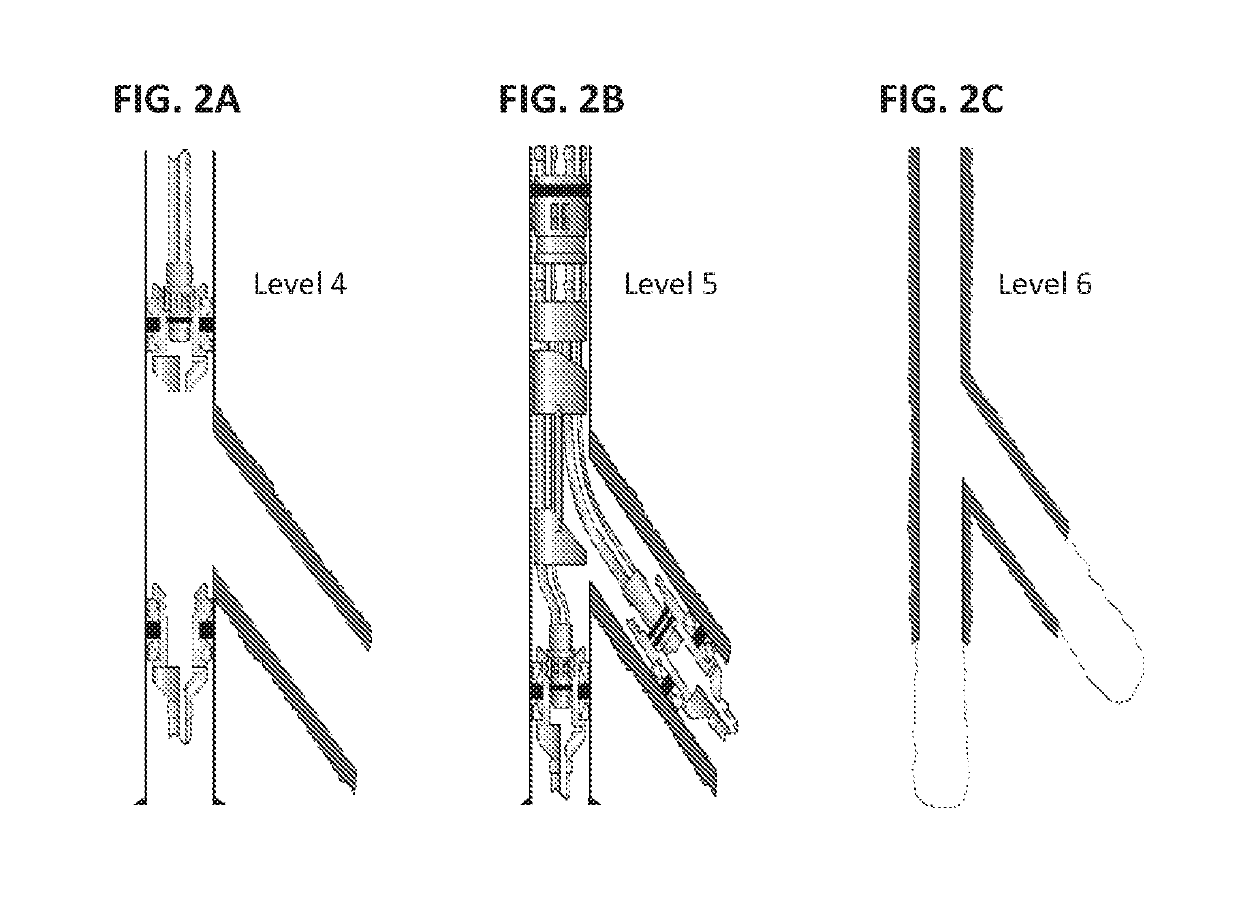

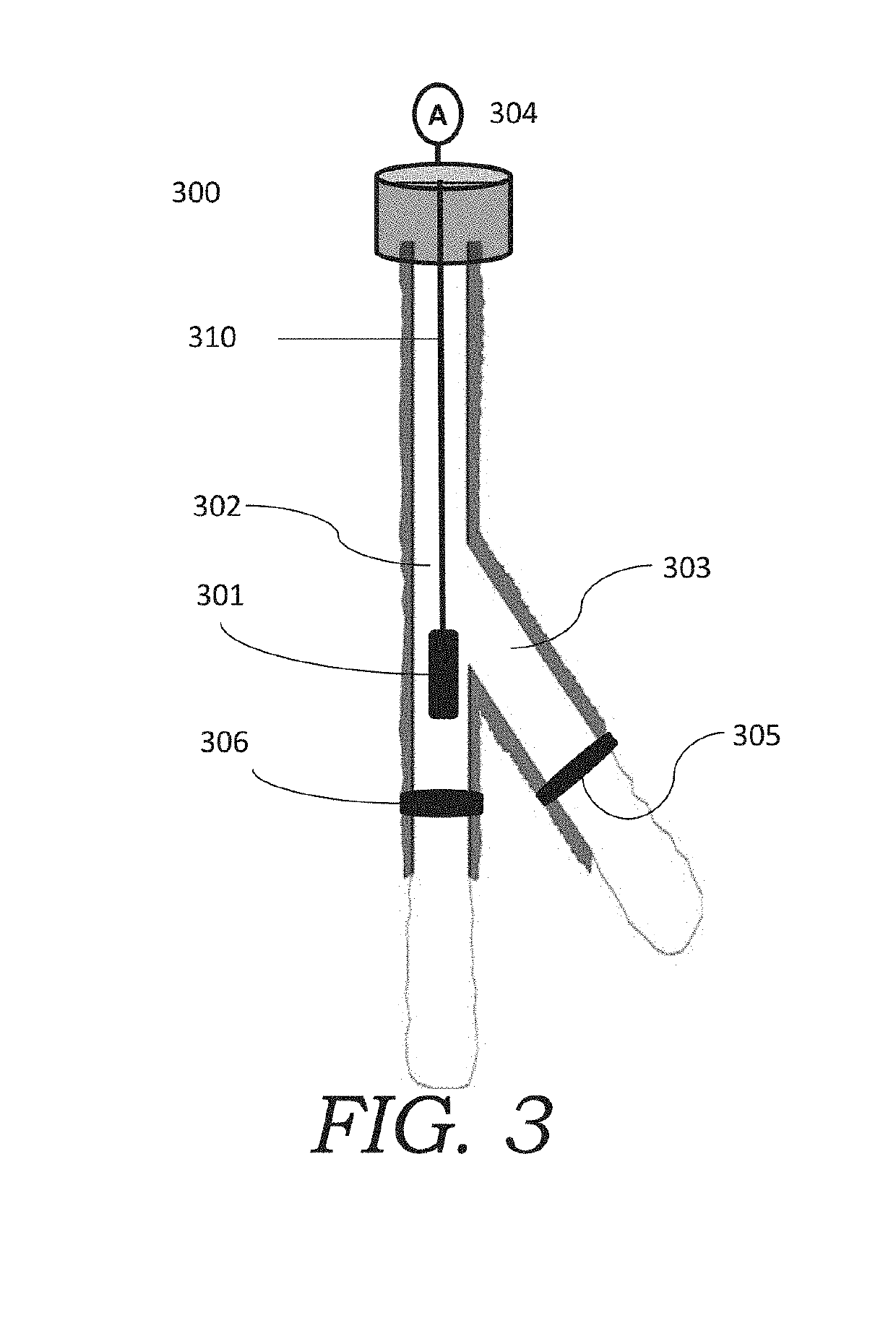

System and method for sealing multilateral junctions

ActiveUS10385654B2Above the melting point of the metalReduce metal temperatureConstructionsInsulationAlloyCooling down

A system and method for sealing a multilateral junction in an oil well is described. Molten material, such as a eutectic or non-eutectic alloy, flows into the junction area and forms a durable seal upon cooling. An expanding alloy may be utilized, which expands upon solidification and which has a melting temperature that is higher than the maximum anticipated well temperature. The alloy is placed within a cavity in the well and held at a temperature above the melting point of the alloy, after which the alloy is cooled down to the ambient well temperature and solidifies and expands within the cavity.

Owner:CONOCOPHILLIPS CO

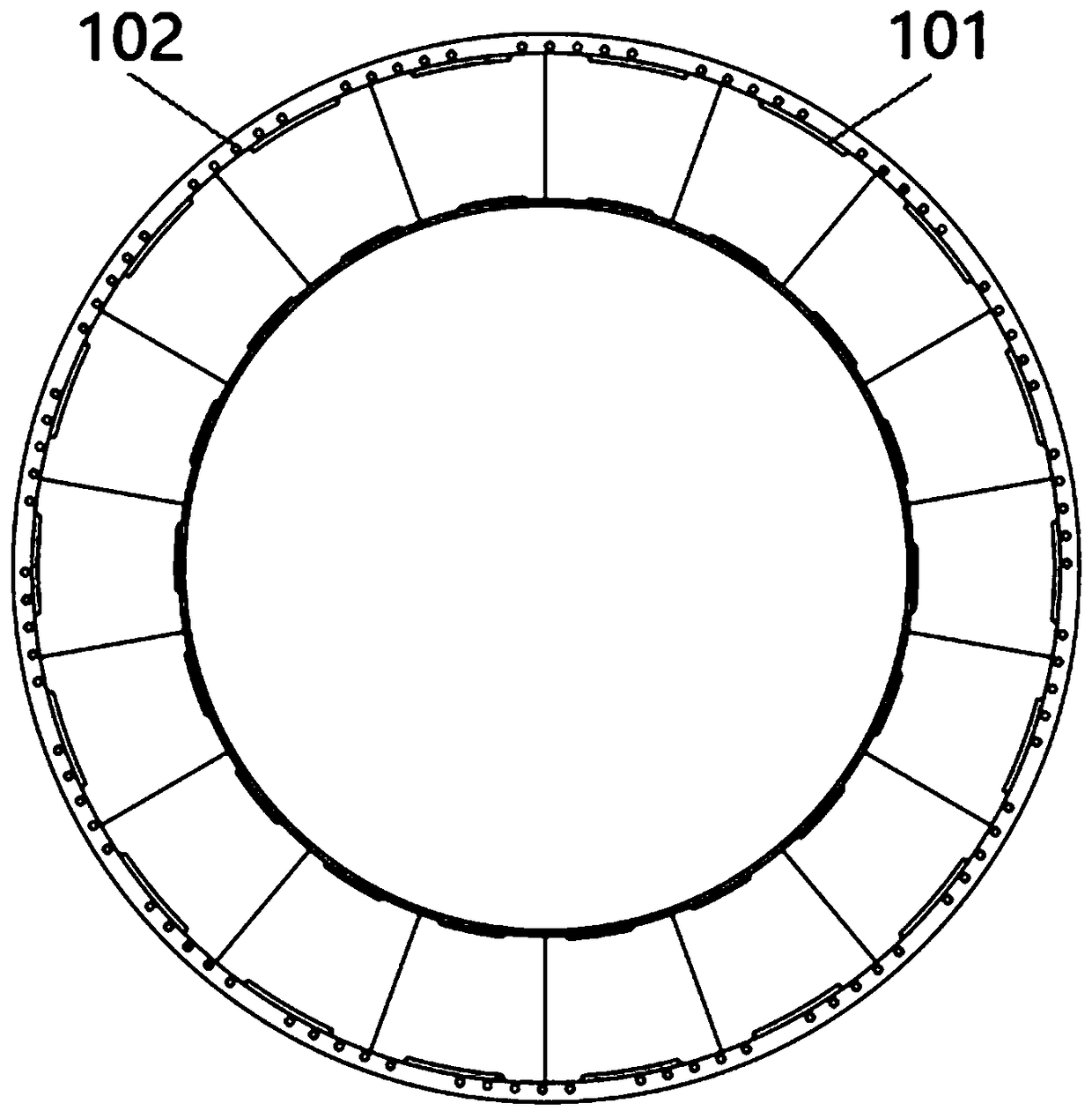

A gas turbine guide leading edge mounting edge structure and a gas turbine having the same

ActiveCN107143385BImprove cooling effectReduce metal temperatureEngine fuctionsTurbine/propulsion engine coolingCombustion chamberLap joint

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Turbine guide vane and gas turbine engine

ActiveCN113202566AReduce metal temperatureProtection from burnsTurbine/propulsion fuel heatingStatorsCold airSuction force

The invention discloses a turbine guide vane and a gas turbine engine. A cooling cavity is arranged in the turbine guide vane; the turbine guide vane comprises a front edge, a tail edge, a pressure surface and a suction surface; premixed gas injection holes communicating with the cooling cavity are formed in the turbine guide vane; and fuel is injected to the inner wall face of the cooling cavity from the cooling cavity, so that the fuel absorbs heat and is gasified on the inner wall face of the cooling cavity and then mixed with cold air in the cooling cavity to form premixed gas, and the premixed gas is injected to high-temperature high-pressure fuel gas around the turbine guide vane via the premixed gas injection holes to be combusted. According to the turbine guide vane, the energy added by the fuel combustion is increased through the supplementary combustion in the turbine guide vane, so that the temperature margin of a subsequent stage of turbine is fully utilized, the output power of the whole machine is greatly increased, and the power-to-weight ratio of the gas turbine engine is increased.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com