Patents

Literature

48results about How to "Reduce traffic requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

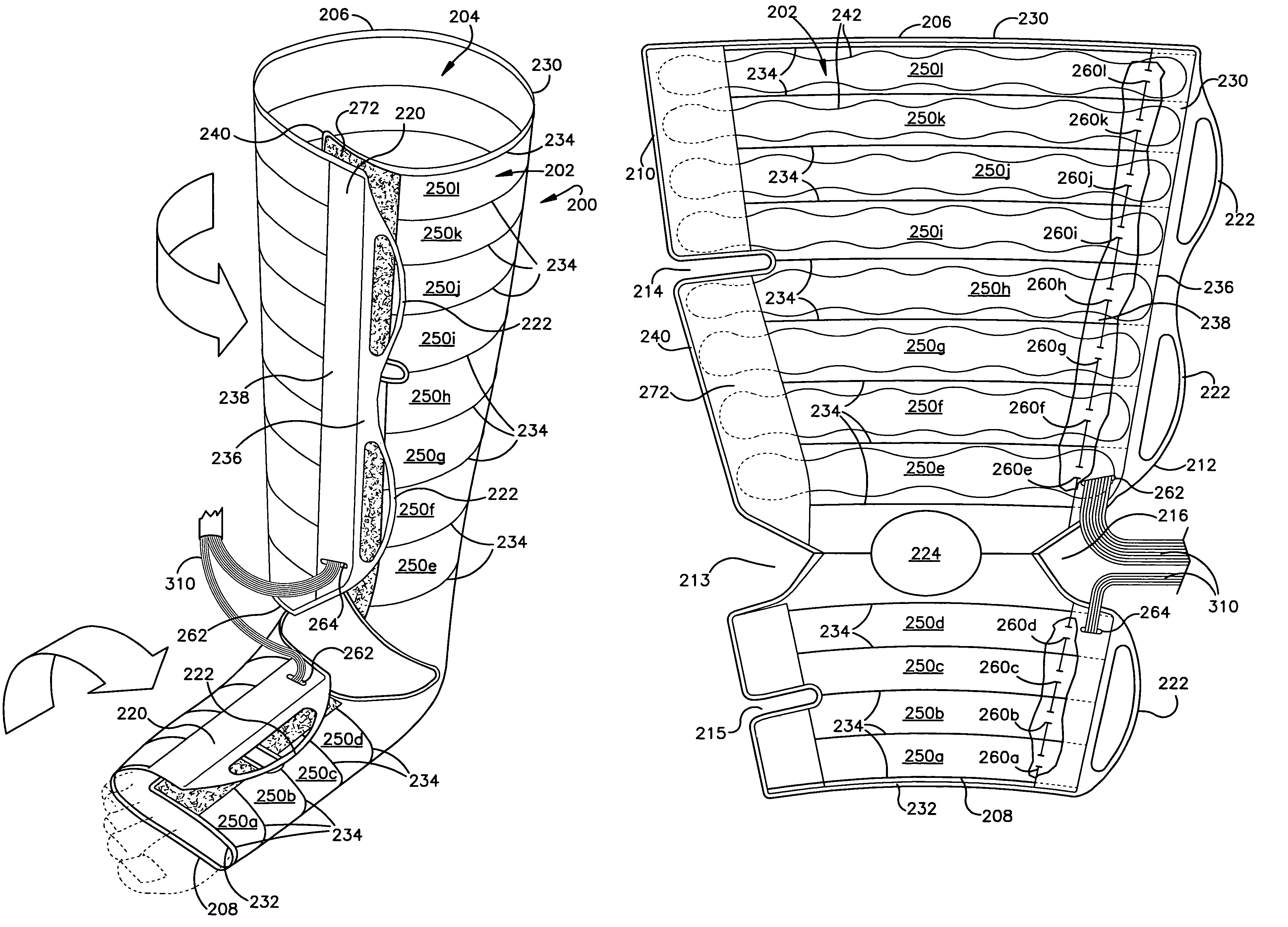

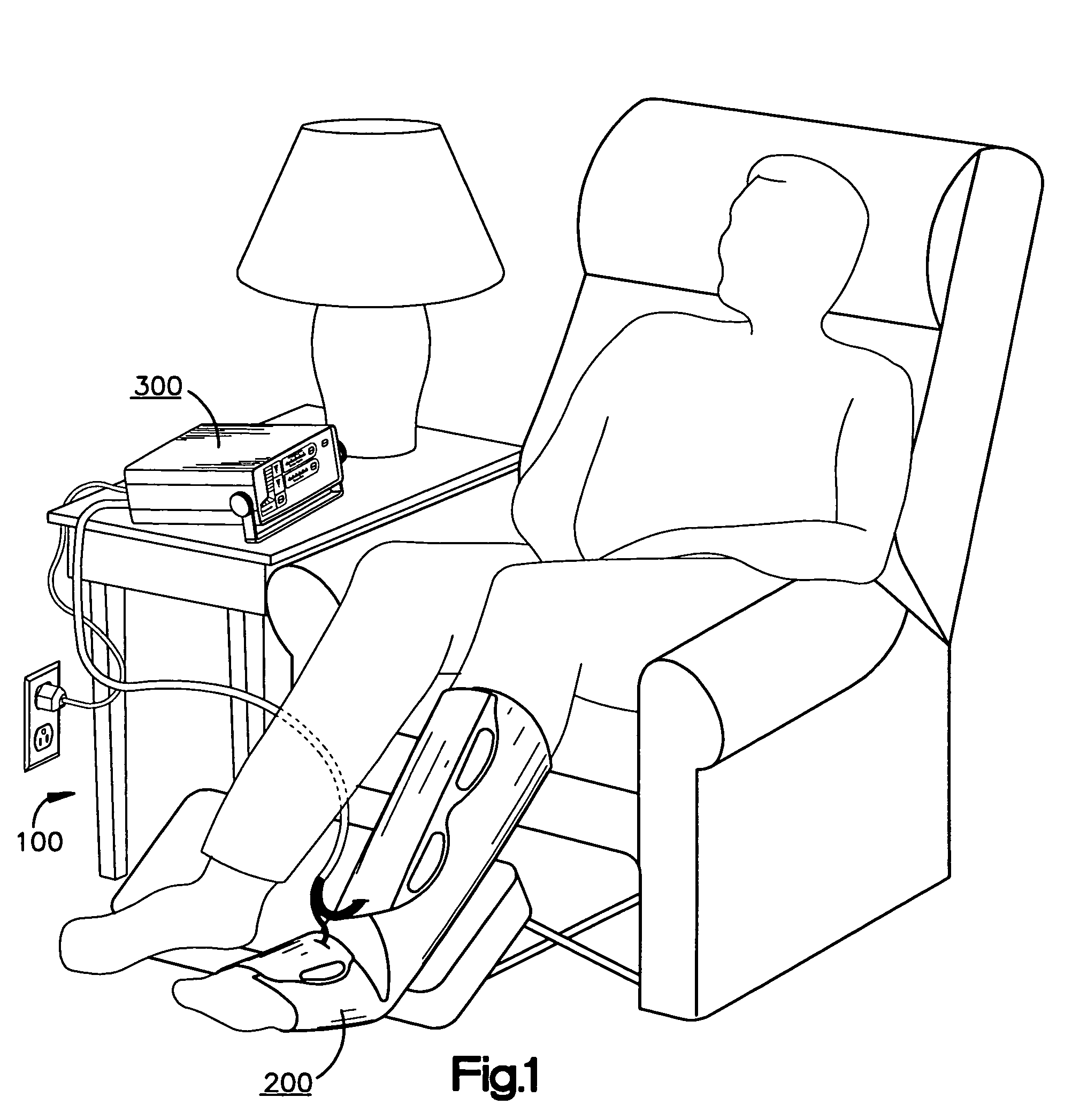

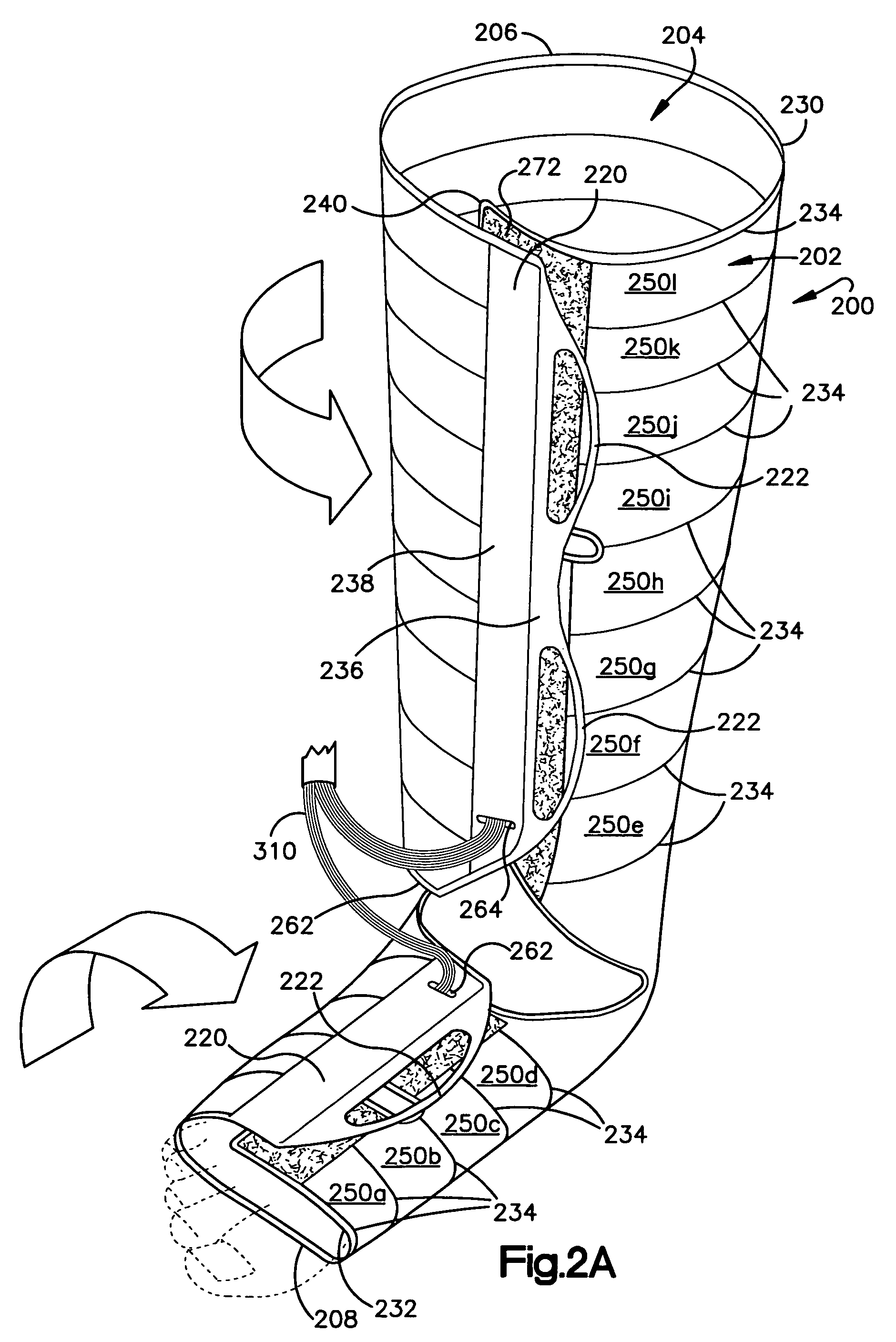

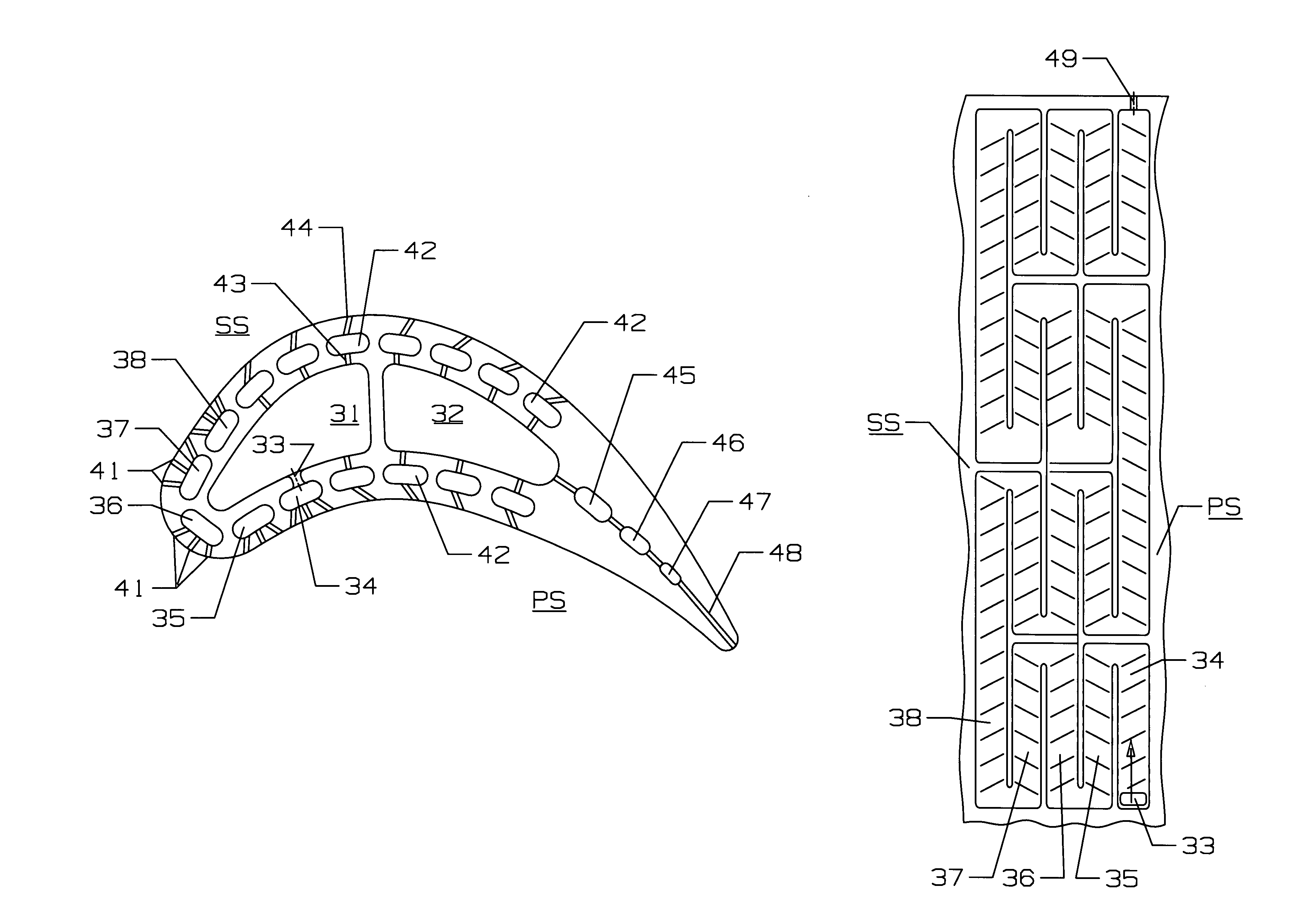

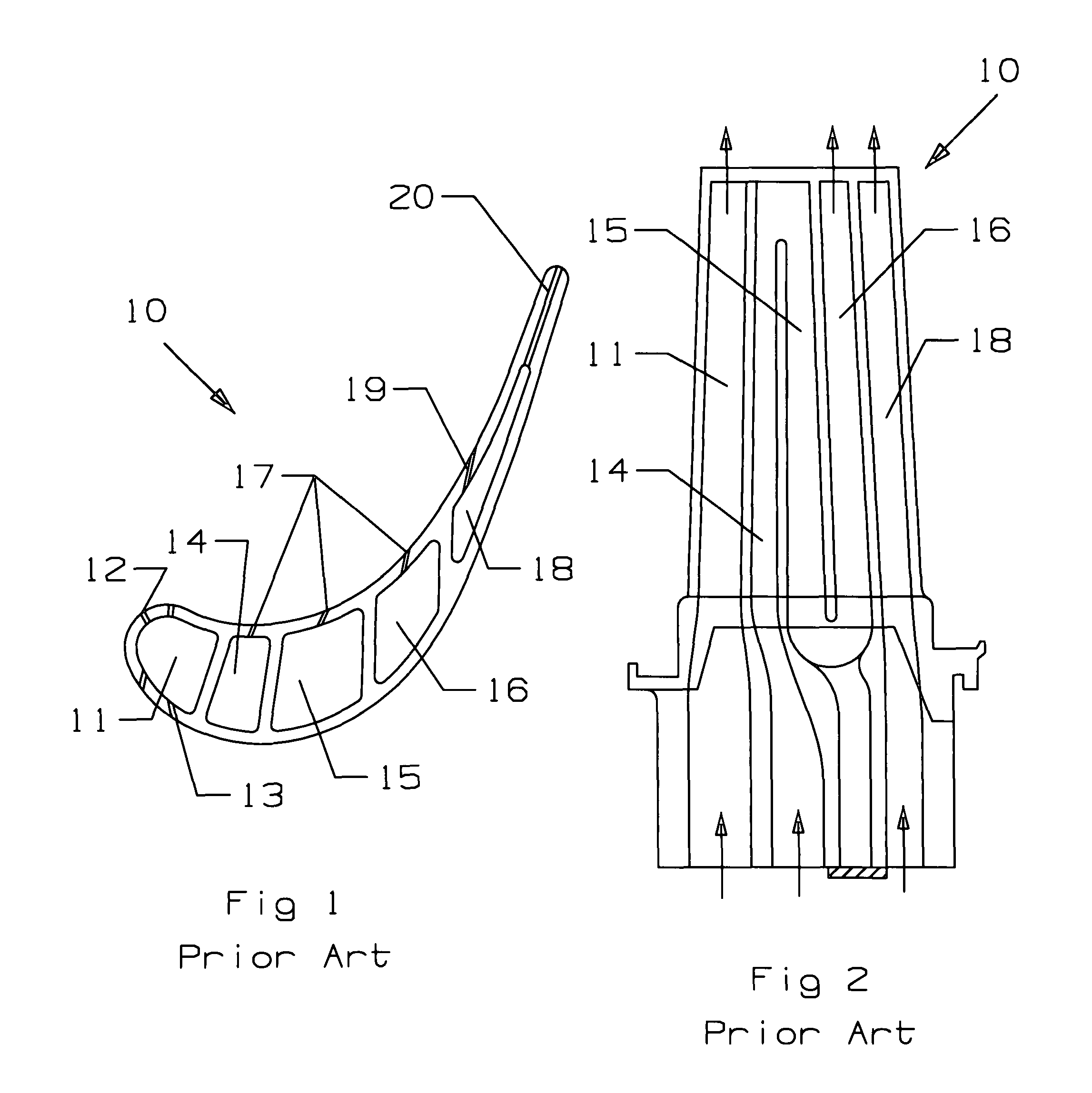

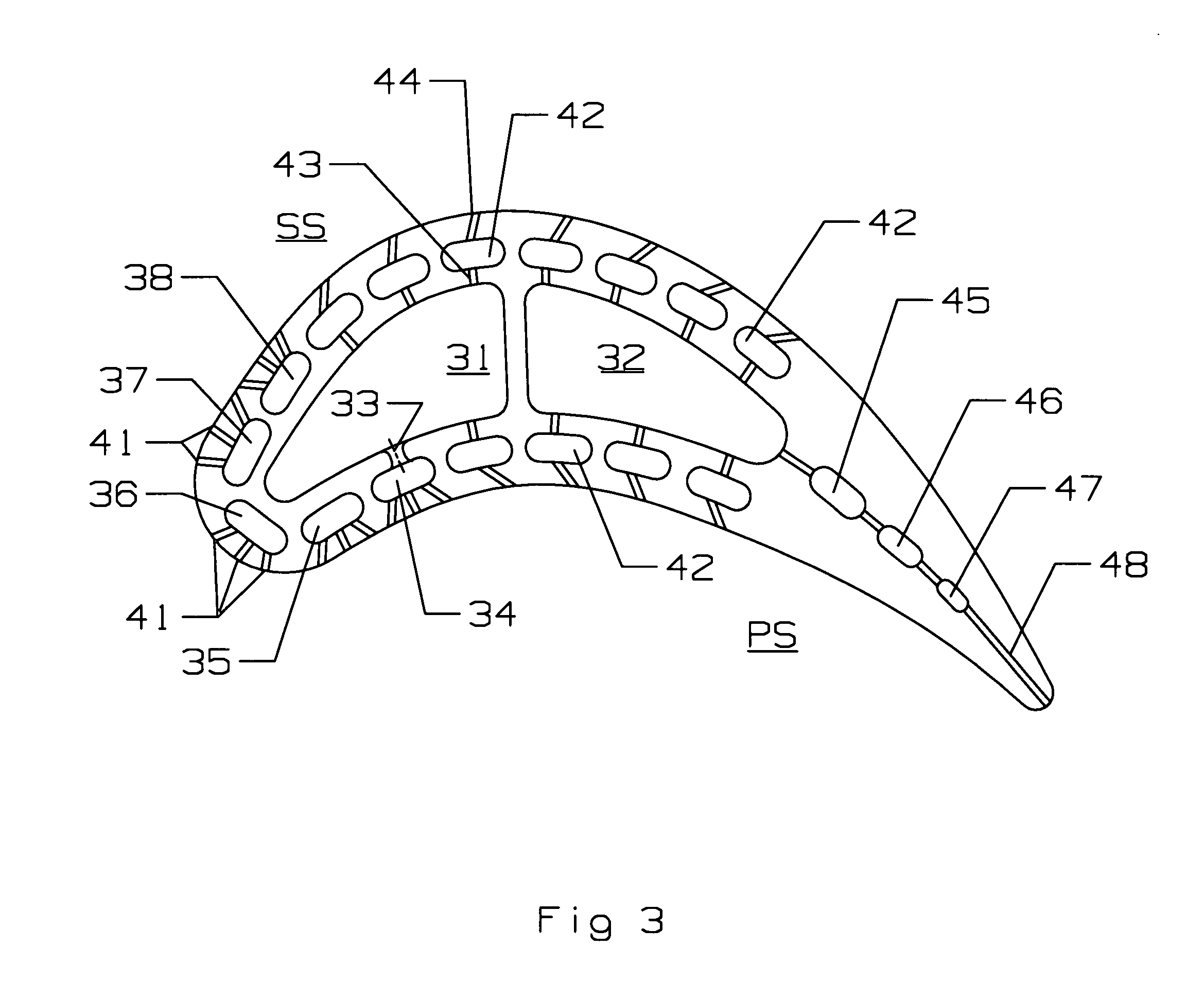

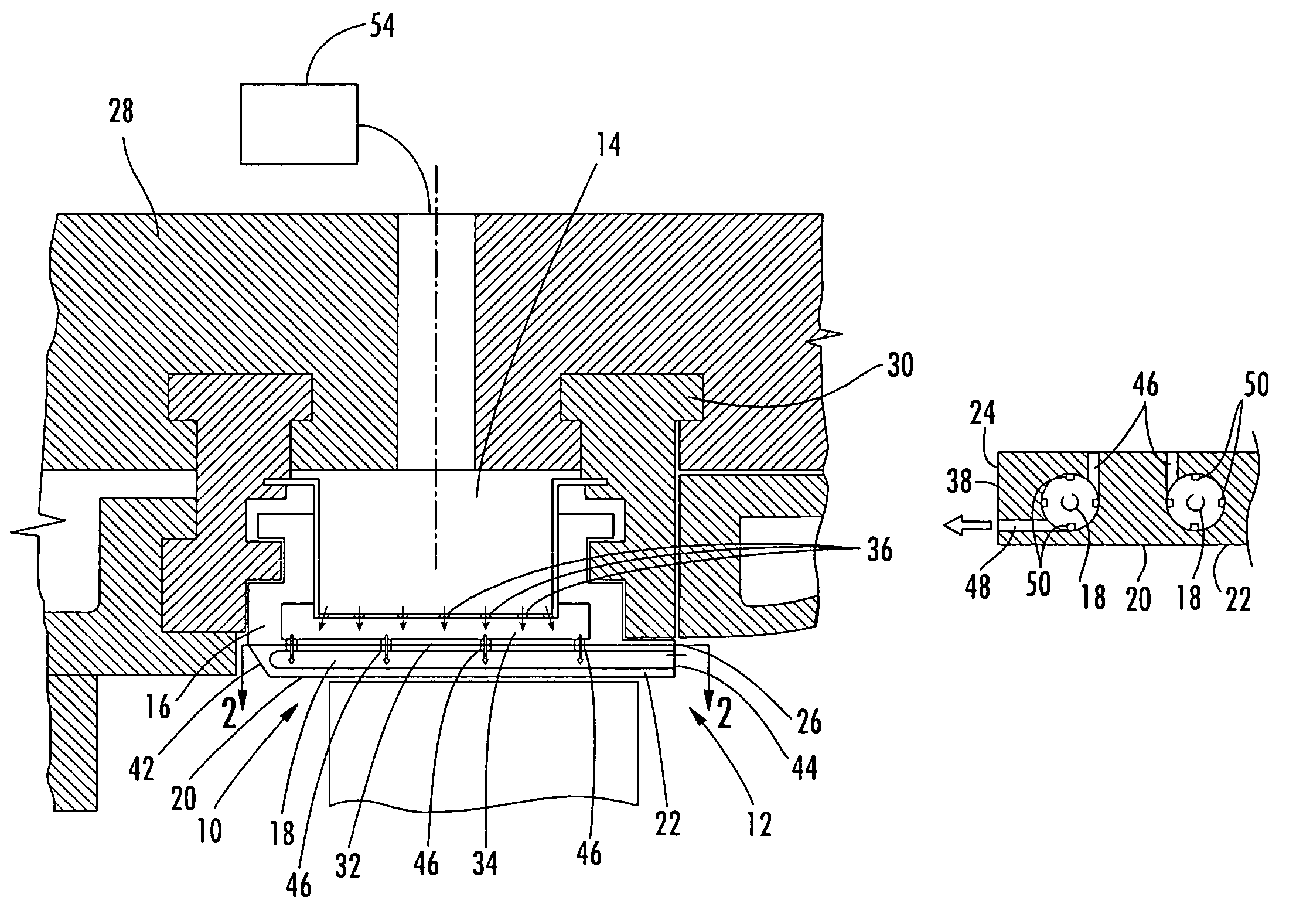

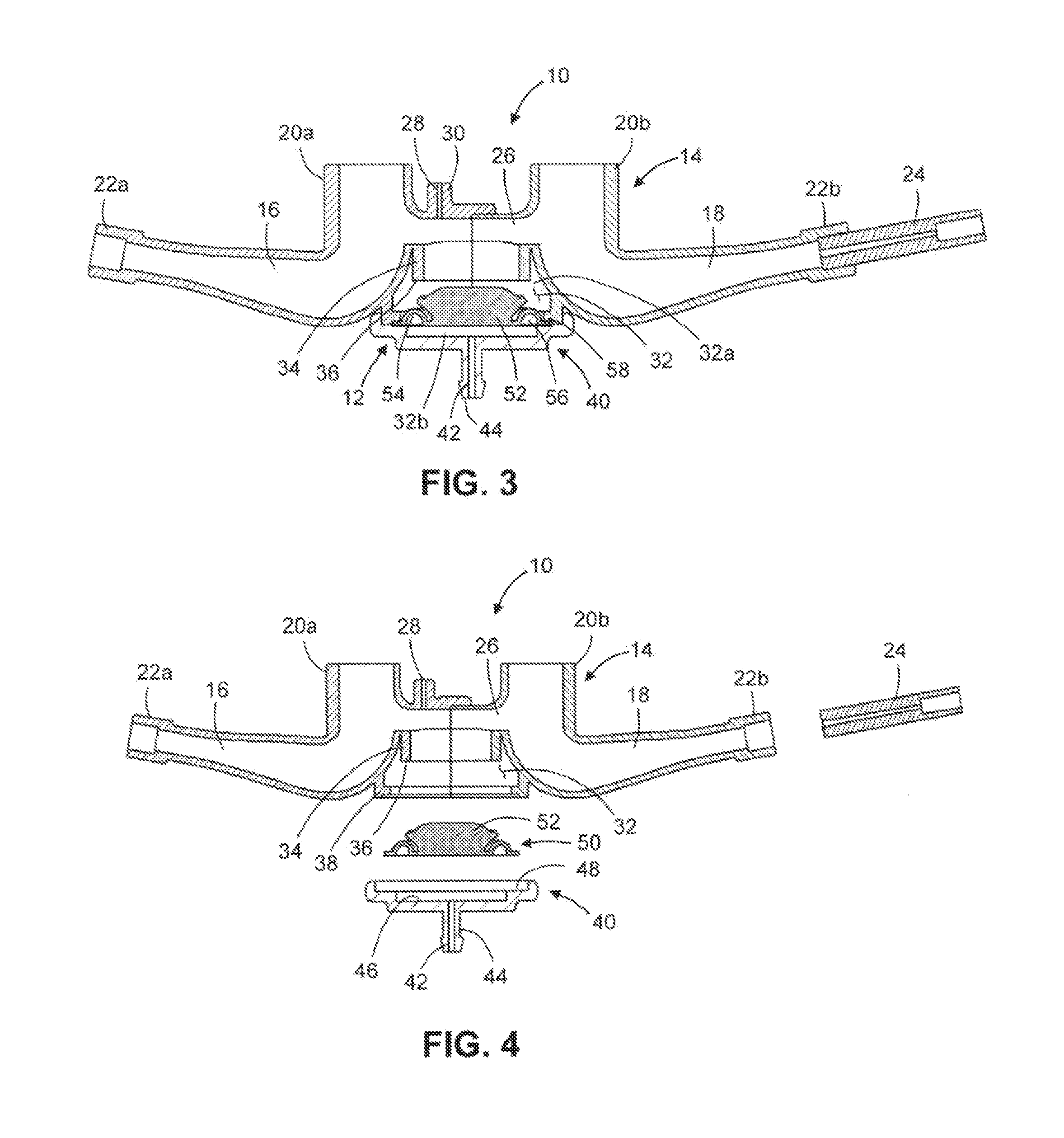

Massage device

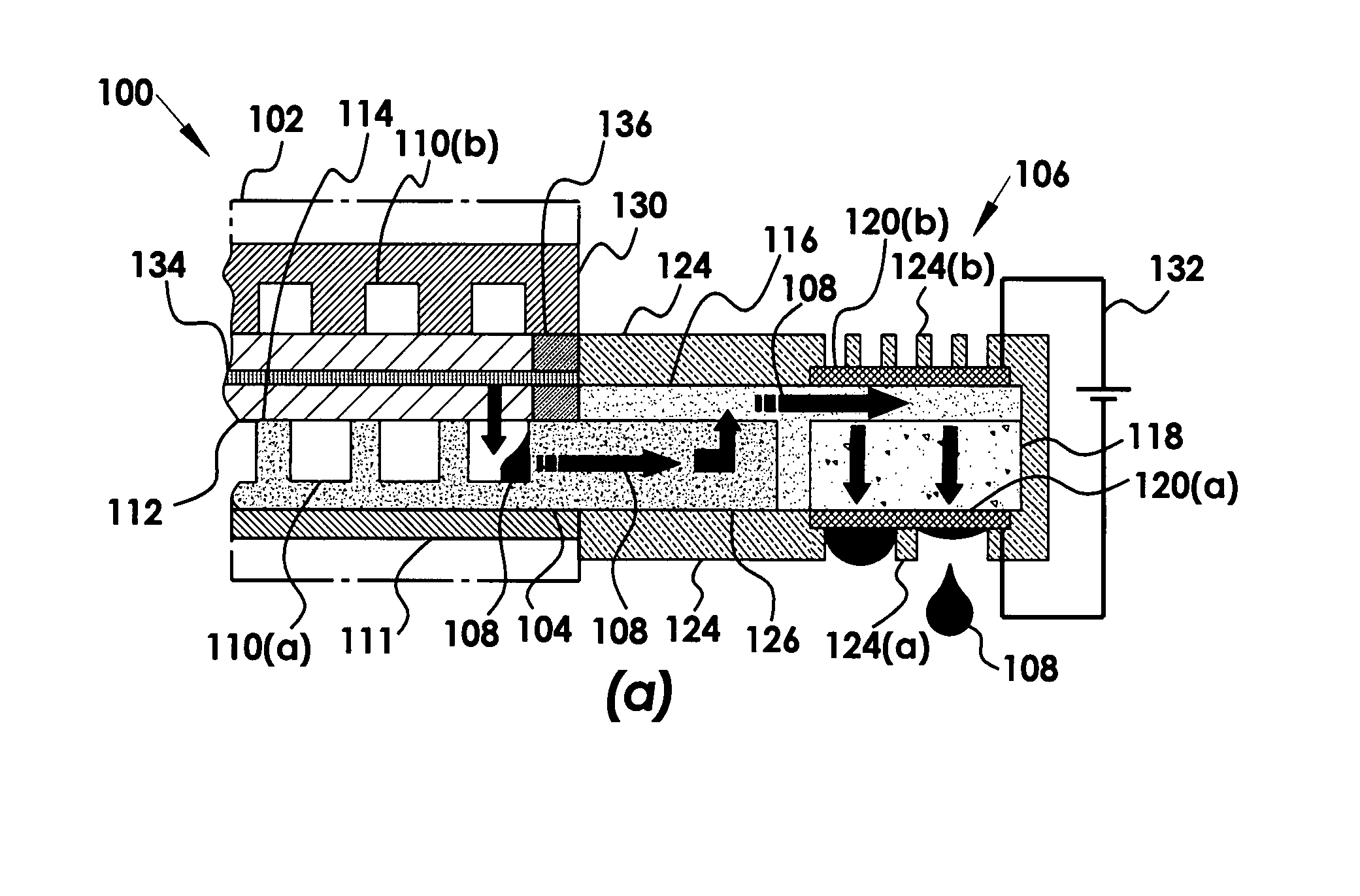

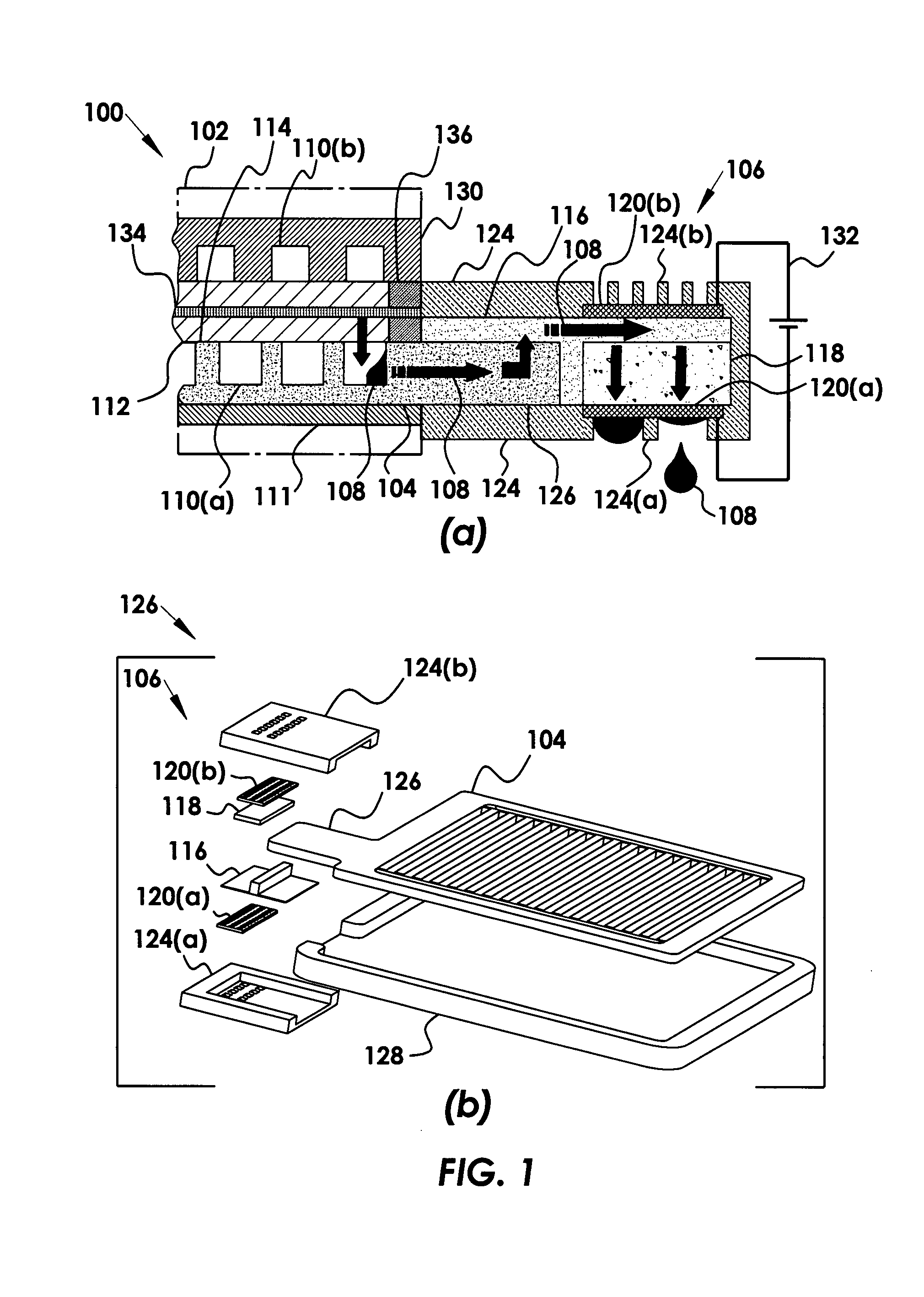

InactiveUS7044924B1Improve overall senseQuicker inflation dynamicPneumatic massageGarmentsFluid controlMassage

A massage device for massaging a body part of a person in an unsupervised and unattended setting. The massage device includes a garment, shaped to provide a snug fit and having a plurality of bladders arranged along the garment to massage the body part. An inflation assembly supplies fluid pressure to each of the bladders to inflate the respective bladders. The bladders may have approximately the same inflated volume thereby equalizing the inflation volume of the respective bladders whereby substantially even inflation timing, with substantially even applied pressure, and, thus, overall smooth massage dynamics may be provided without overly complicated inflation fluid control (e.g., an inflation assembly which supplies a substantially constant inflation capacity to each of the bladders). The garment may include a pocket having an opening communicating with the respective bladders and tubing from the inflation assembly extends into this pocket. The inflation assembly may provide throttled deflation flow, tapered inflation / deflation patterns, and / or a zone selector which allows a user to select a certain zone of the garment.

Owner:MIDTOWN TECH

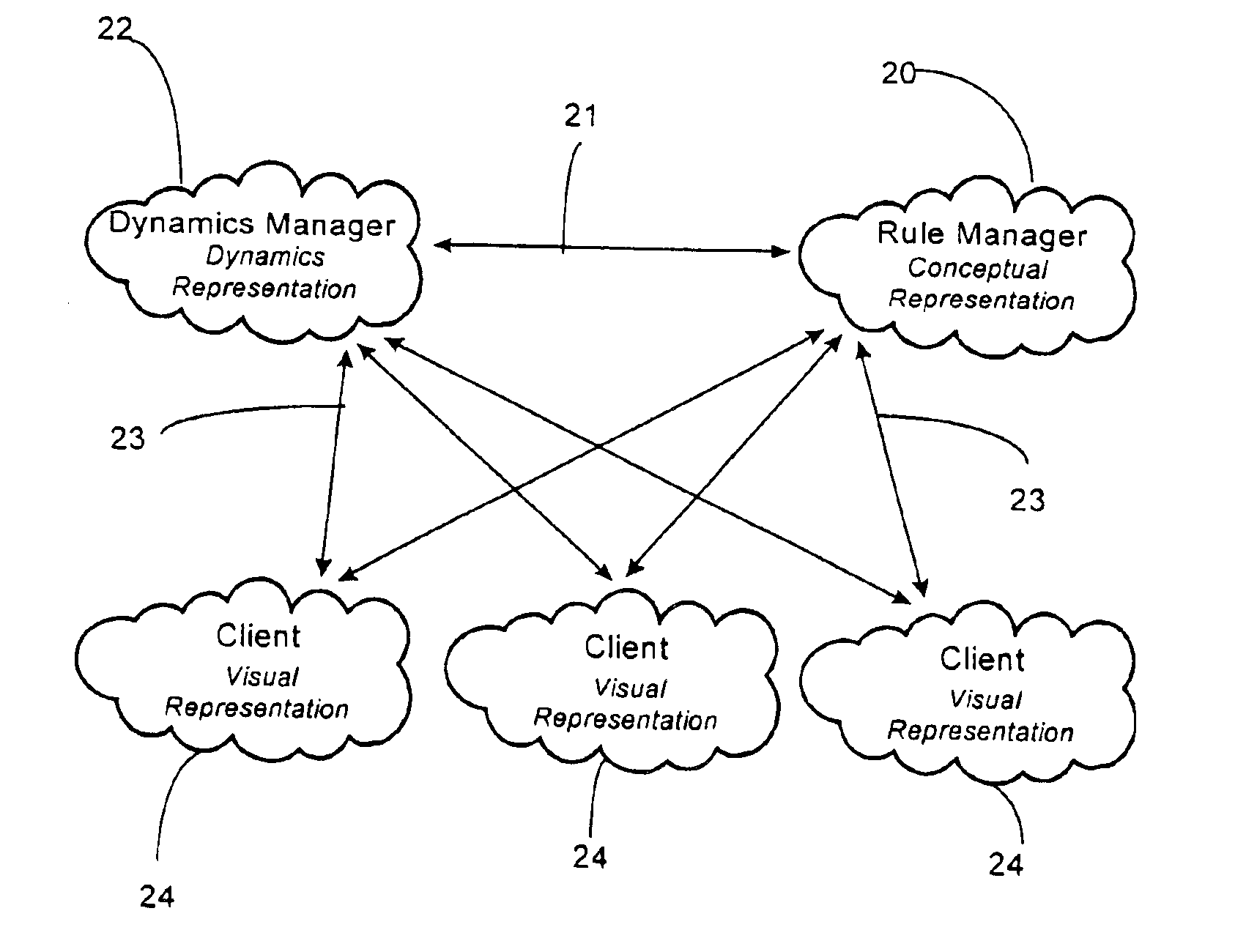

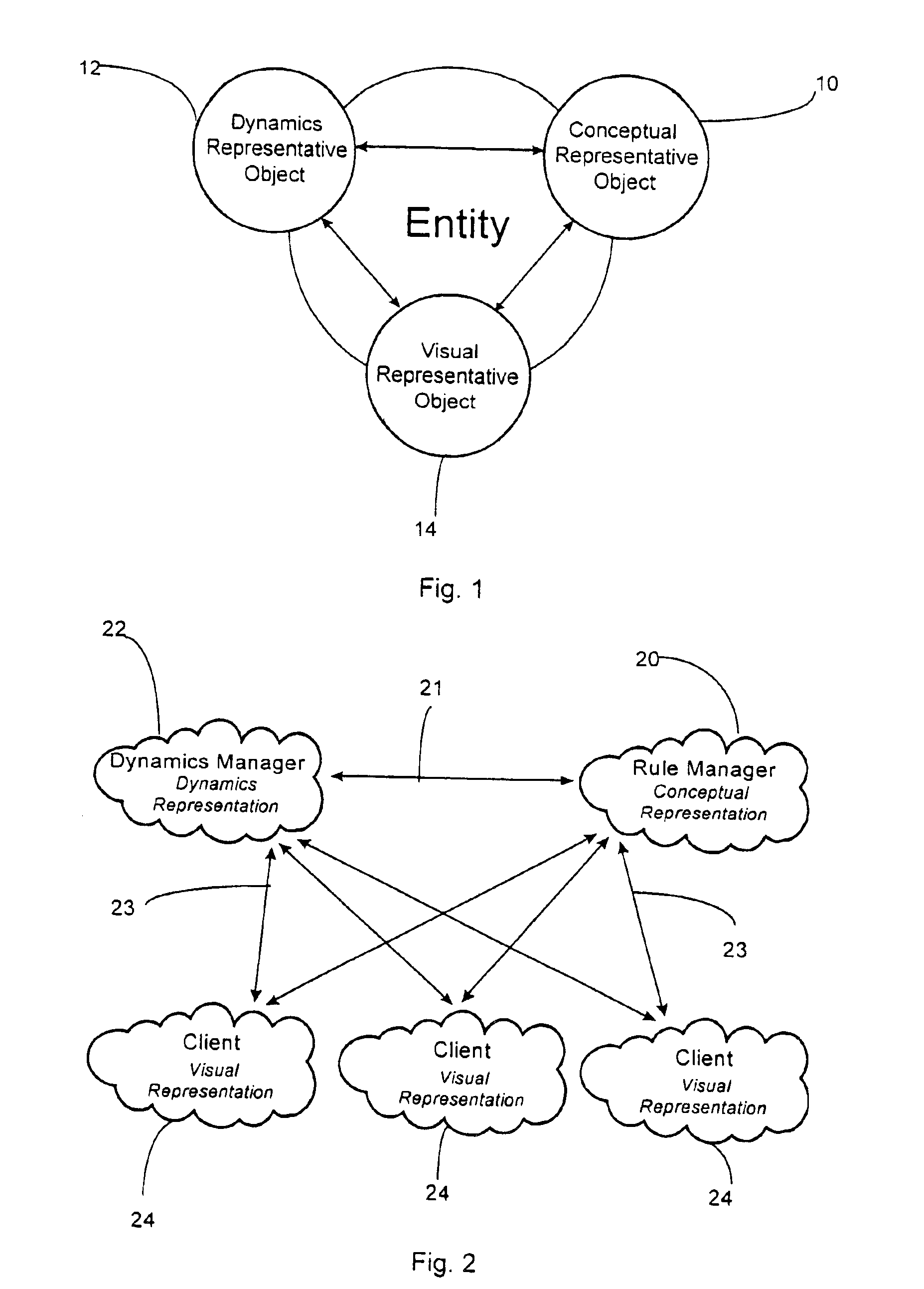

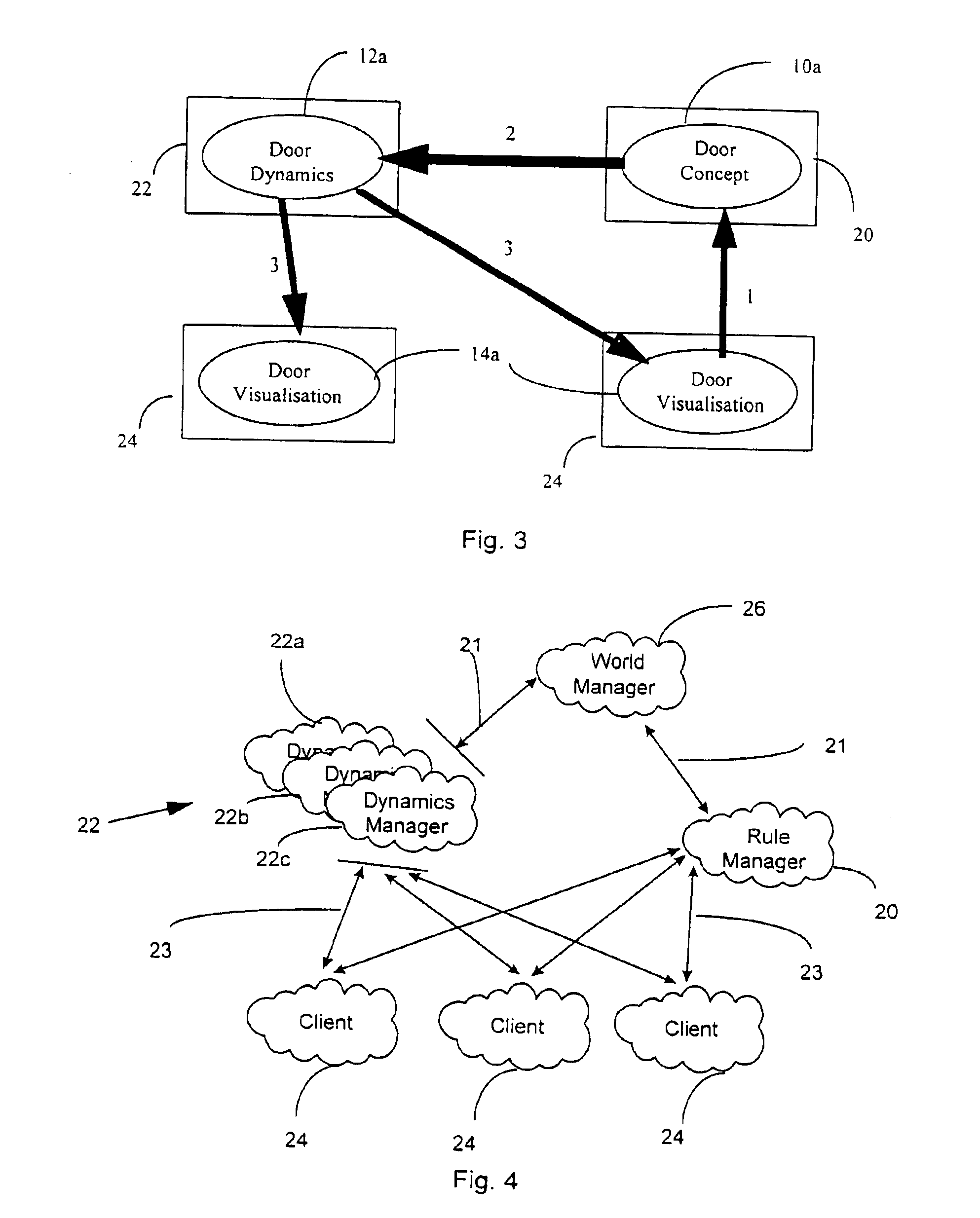

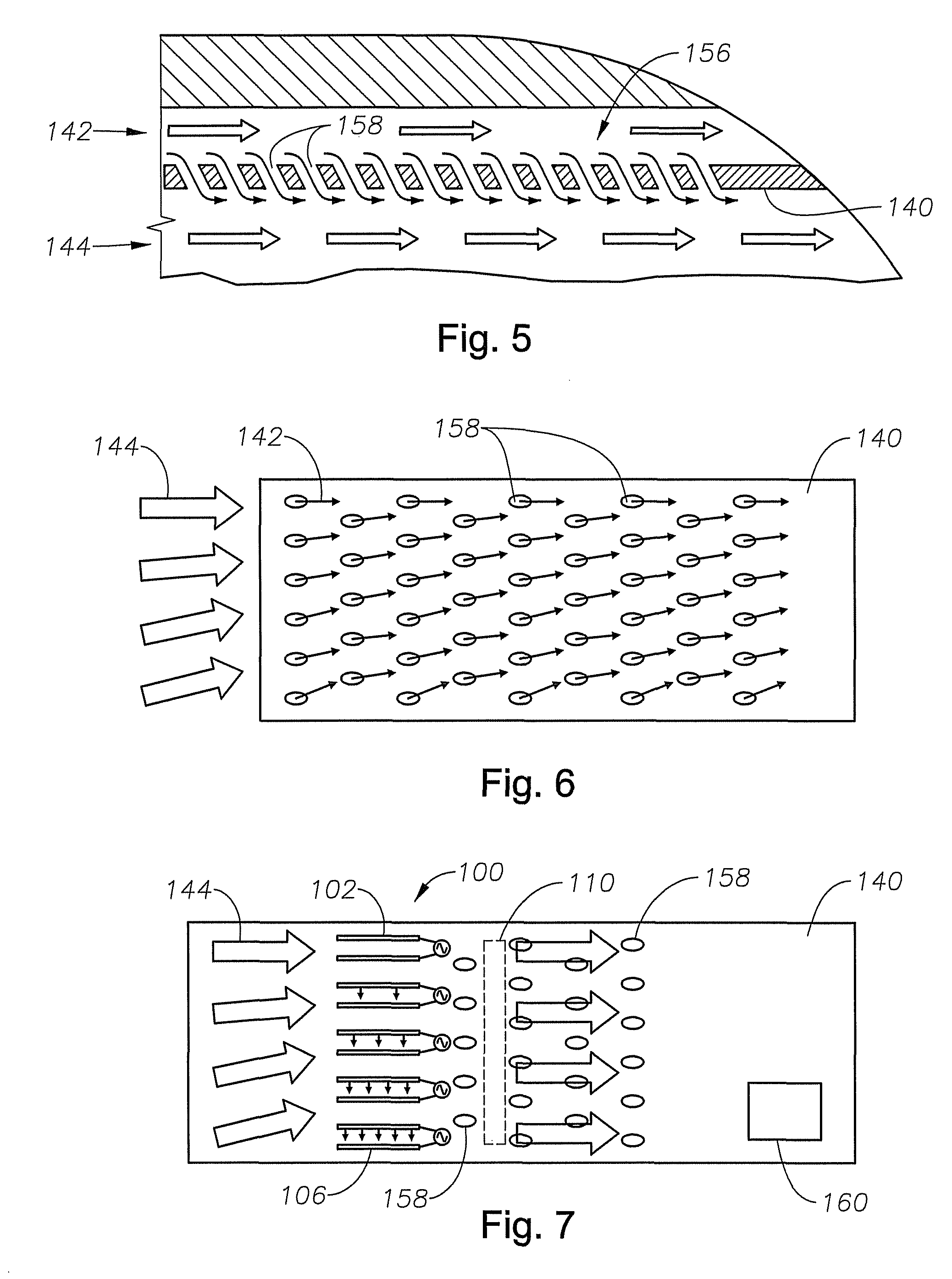

Distributed virtual environment

InactiveUS6912565B1Reduce upstream traffic requirementEnsure consistencyMultiple digital computer combinationsVideo gamesDynamic modelsClient-side

A distributed virtual environment includes one or more entities represented in the virtual environment by at least a conceptual entity-model, a dynamic entity-model and a visual entity-model each of the entity models being mutually independent. A server provides a conceptual-model manager, arranged to provide conceptual entity-models, one or more dynamic-model managers arranged to provide dynamic entity-models, and one or more client apparatuses arranged to provide a visual-model manager arranged to provide visual entity-models. Communications is arranged to allow transmission of messages between the conceptual-model manager, one or more dynamic-model managers and one or more visual-model managers.

Owner:BRITISH TELECOMM PLC

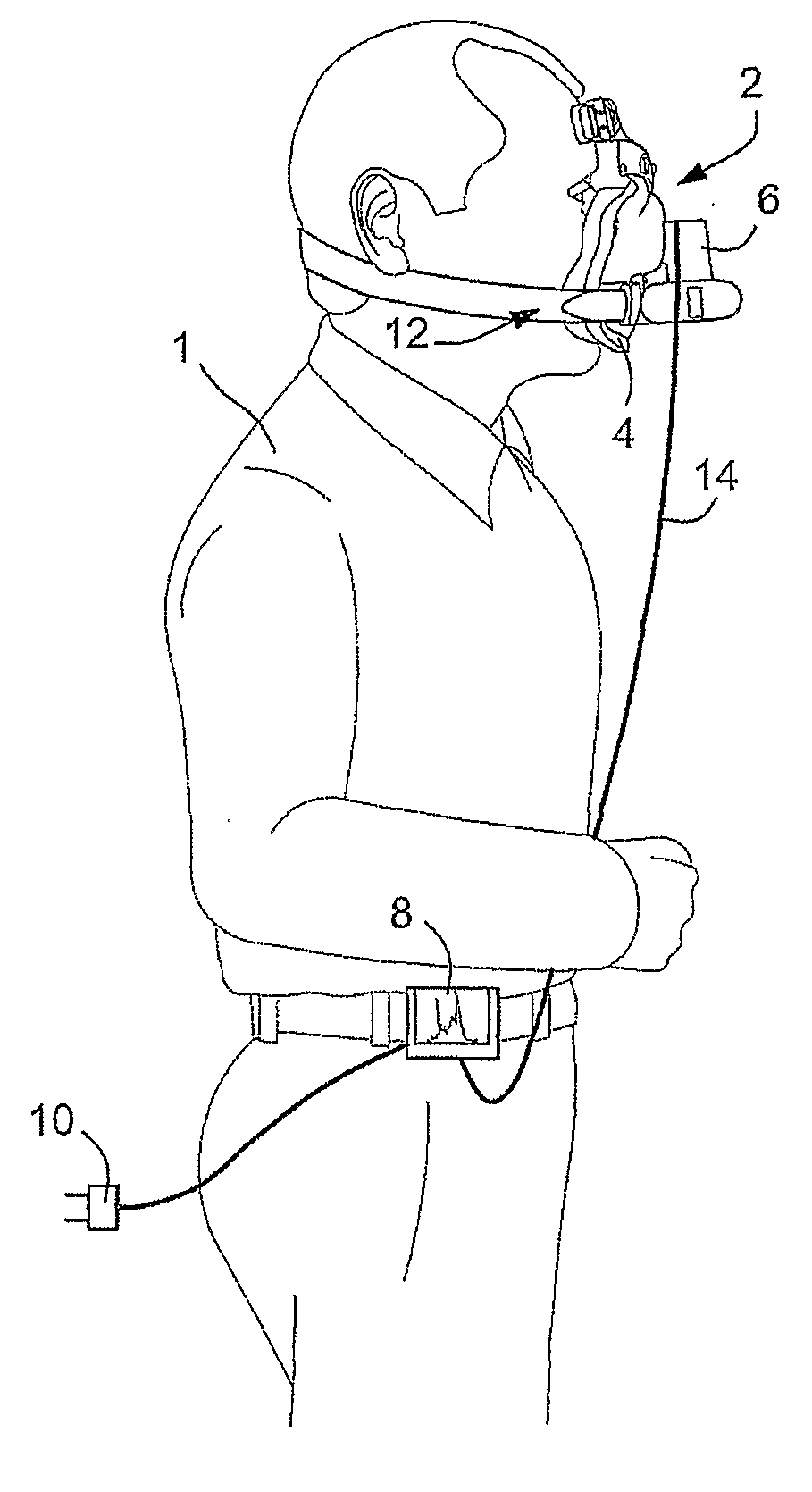

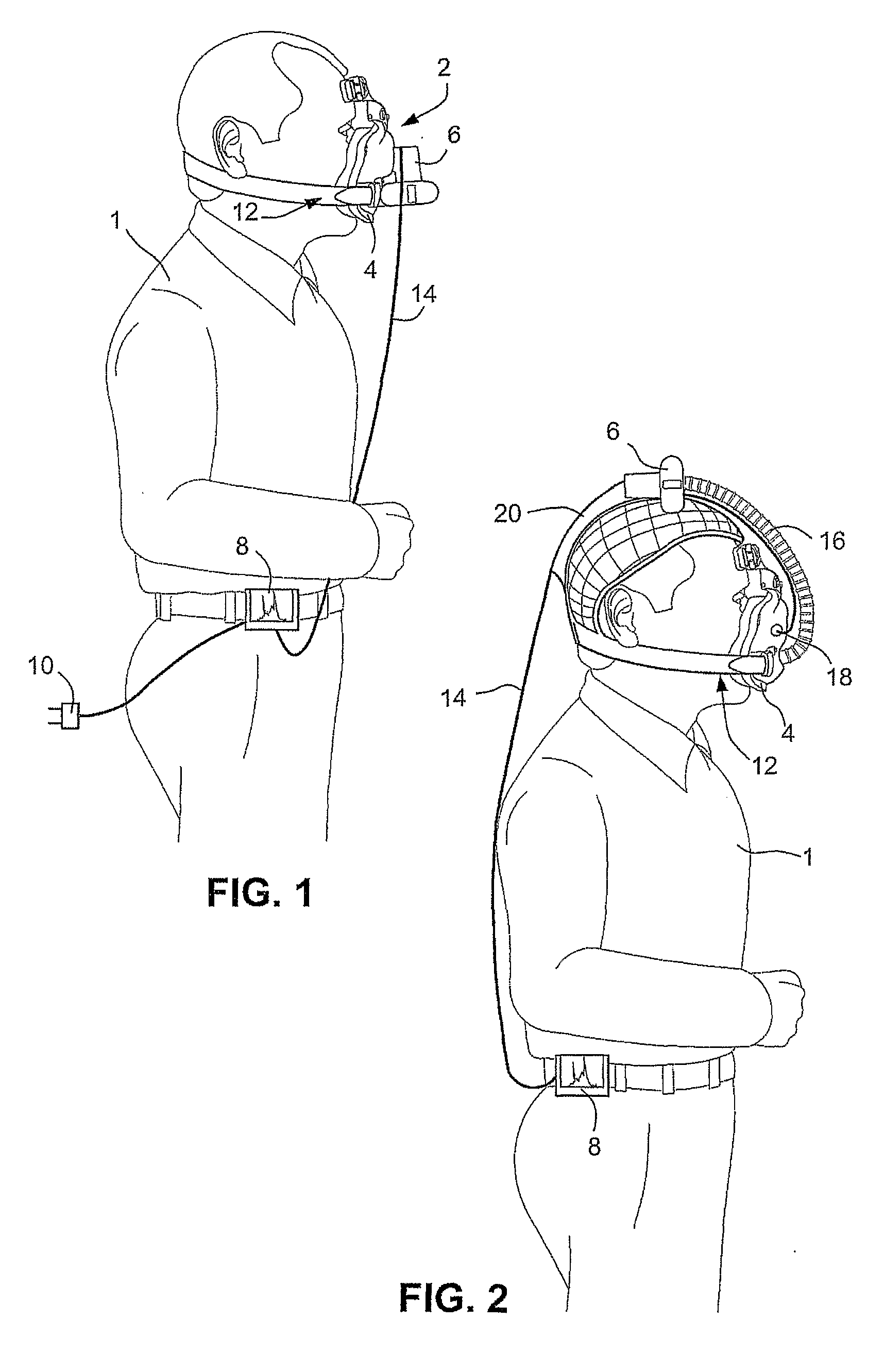

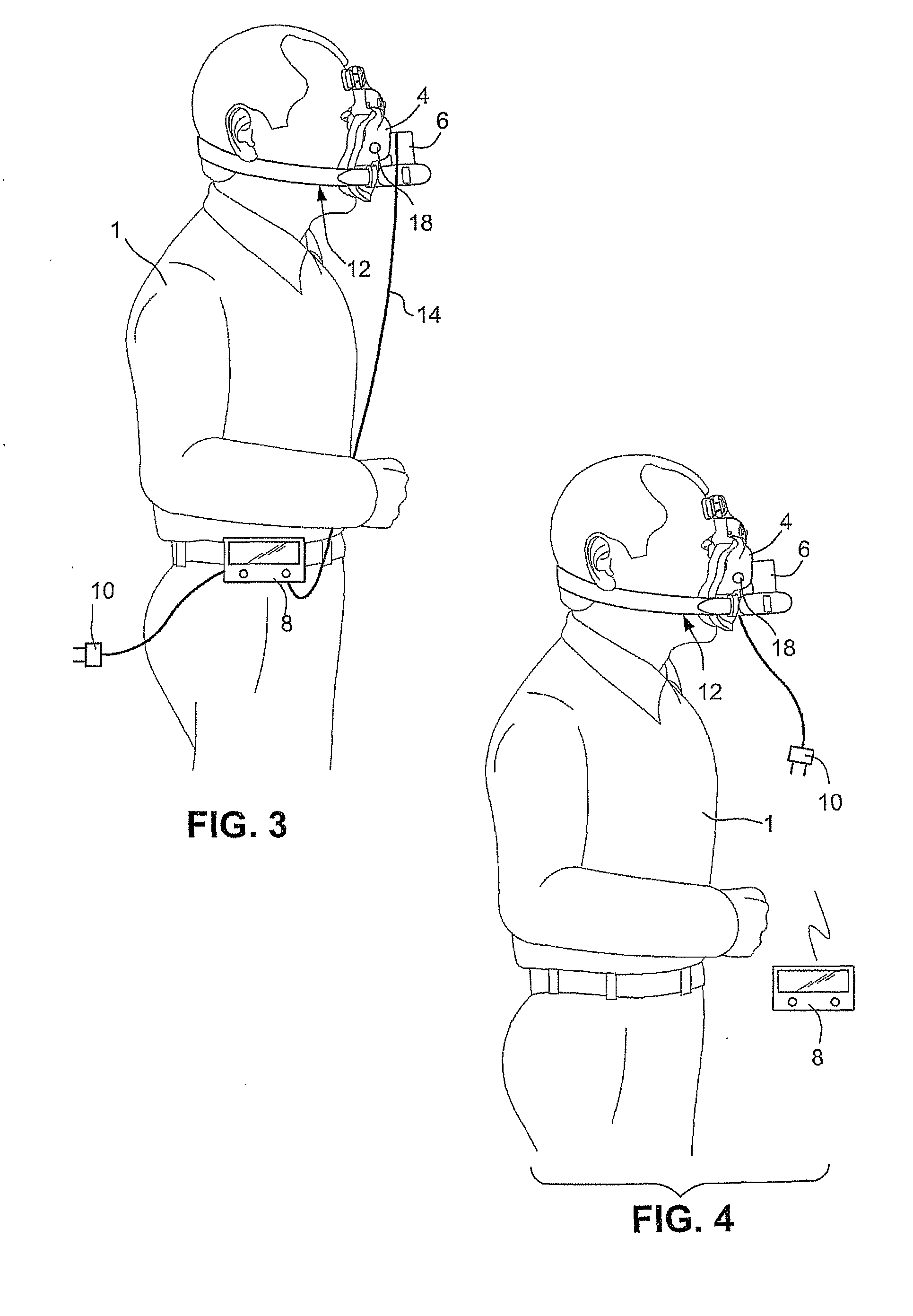

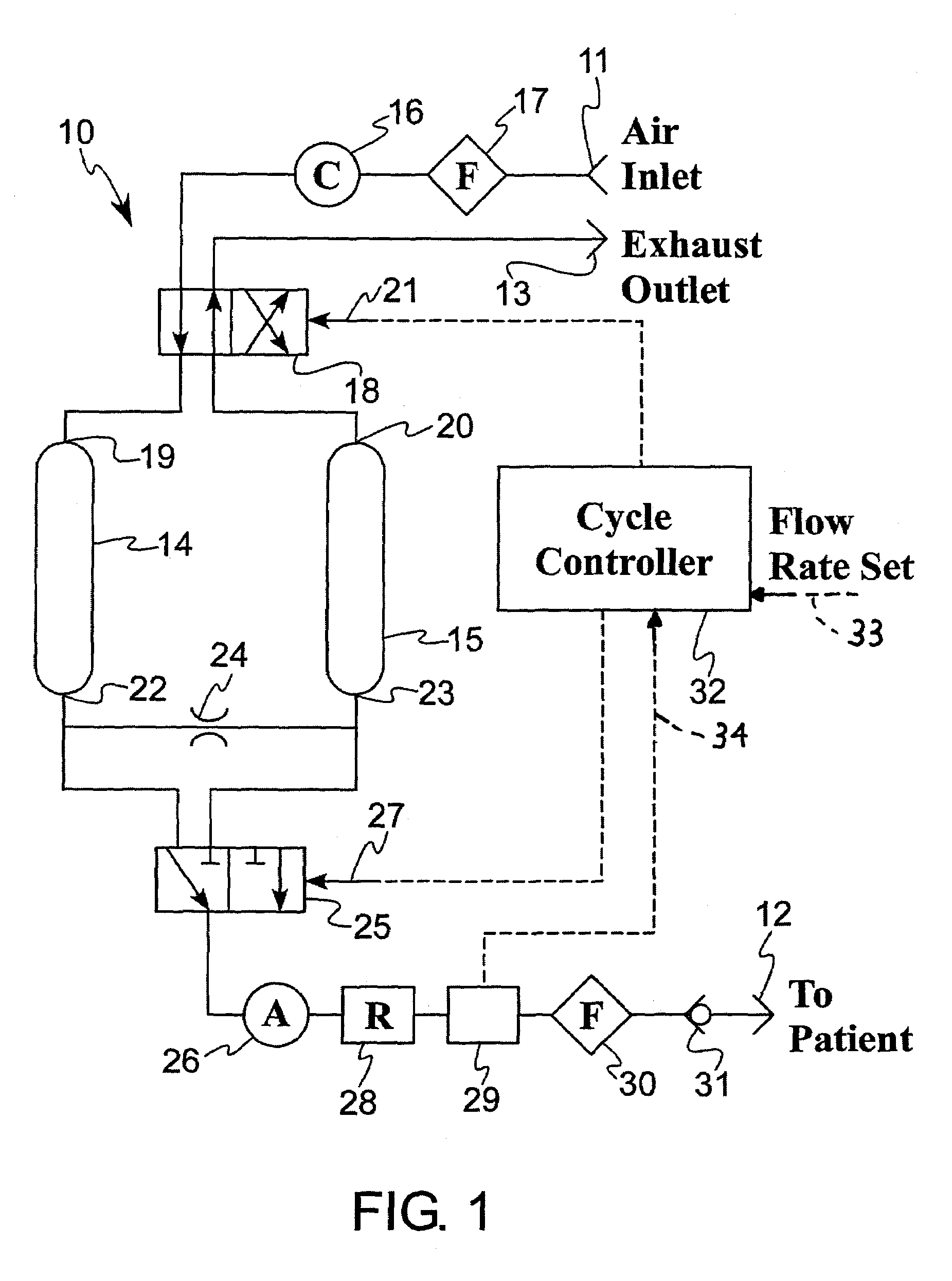

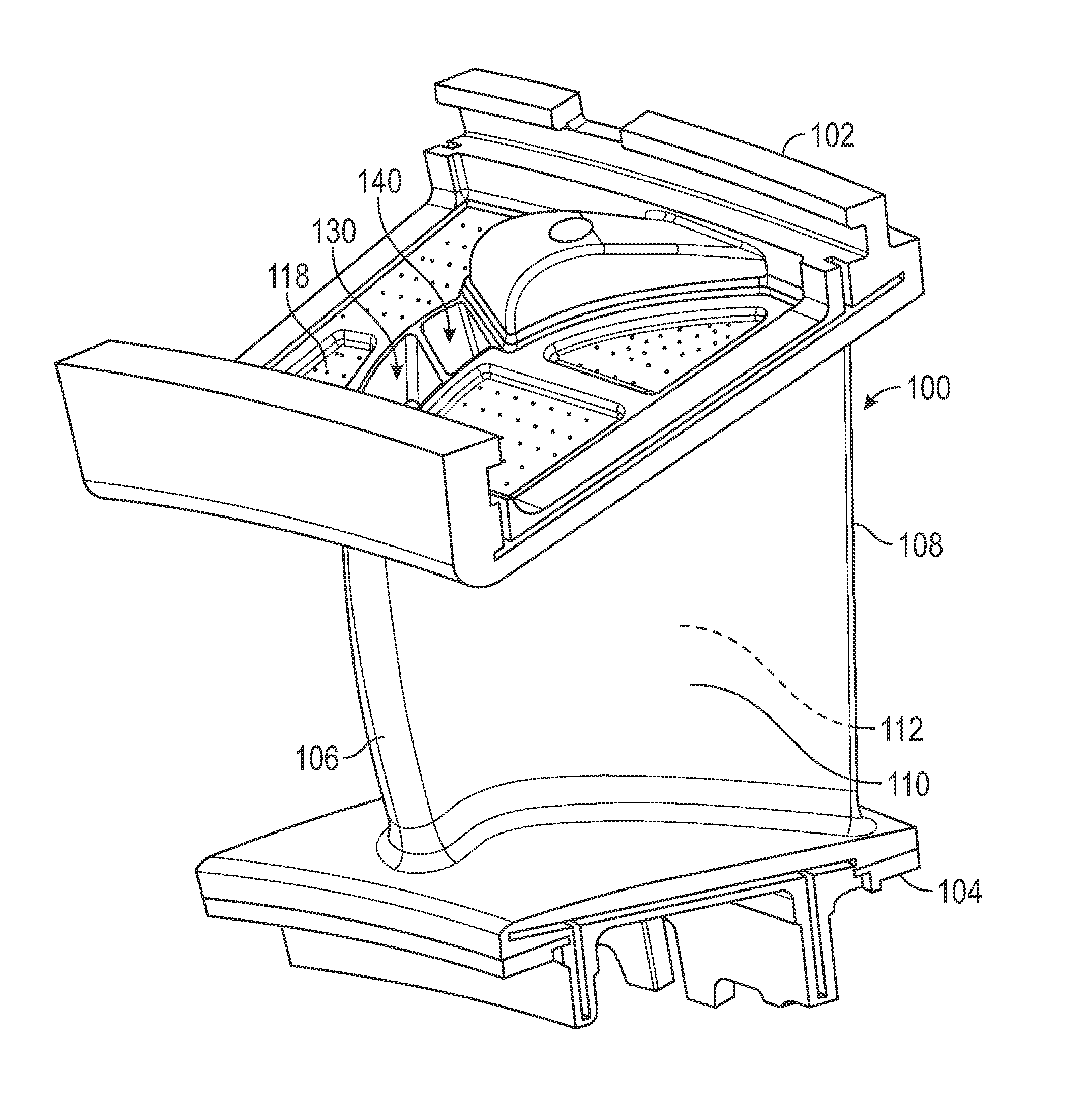

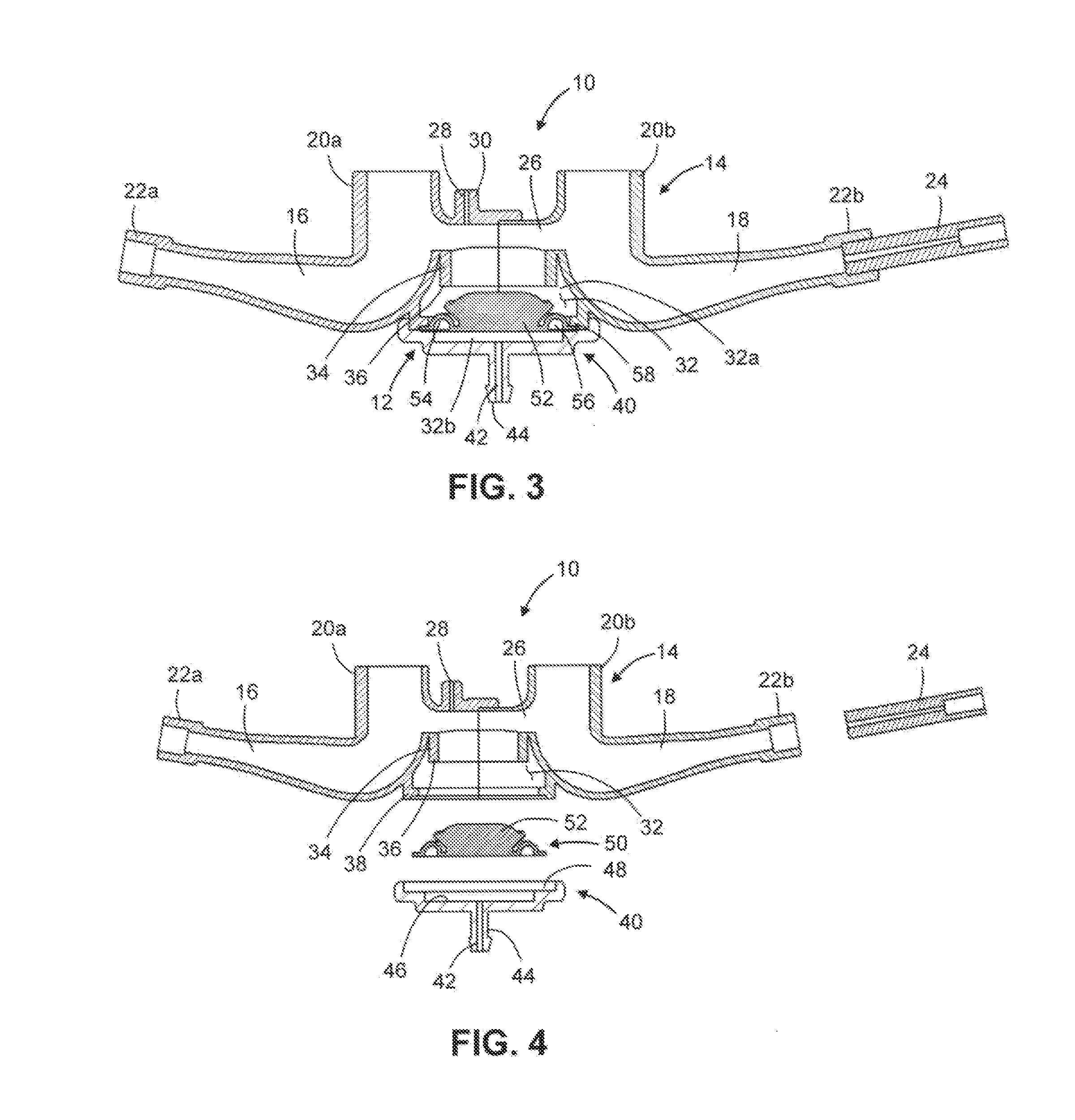

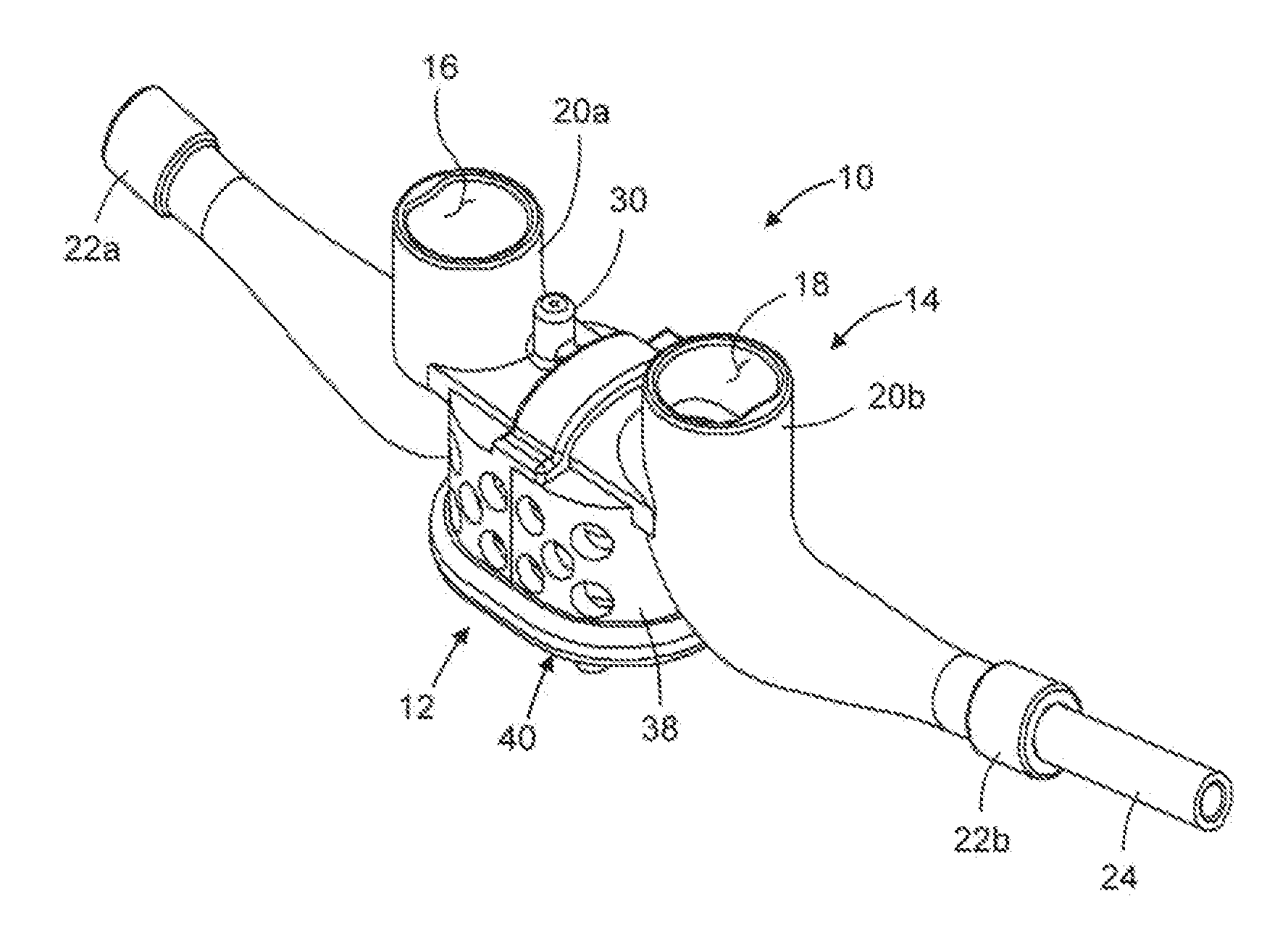

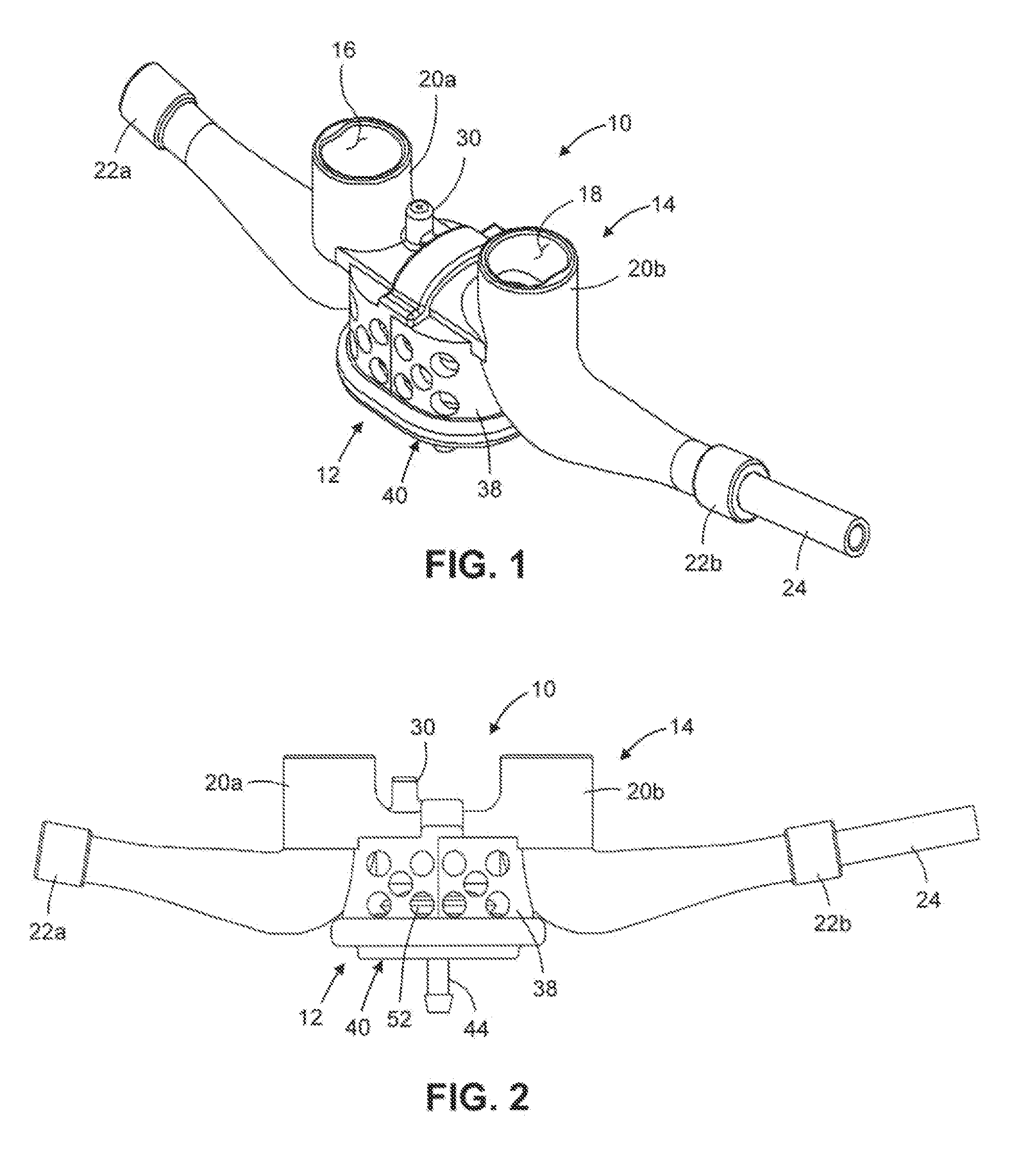

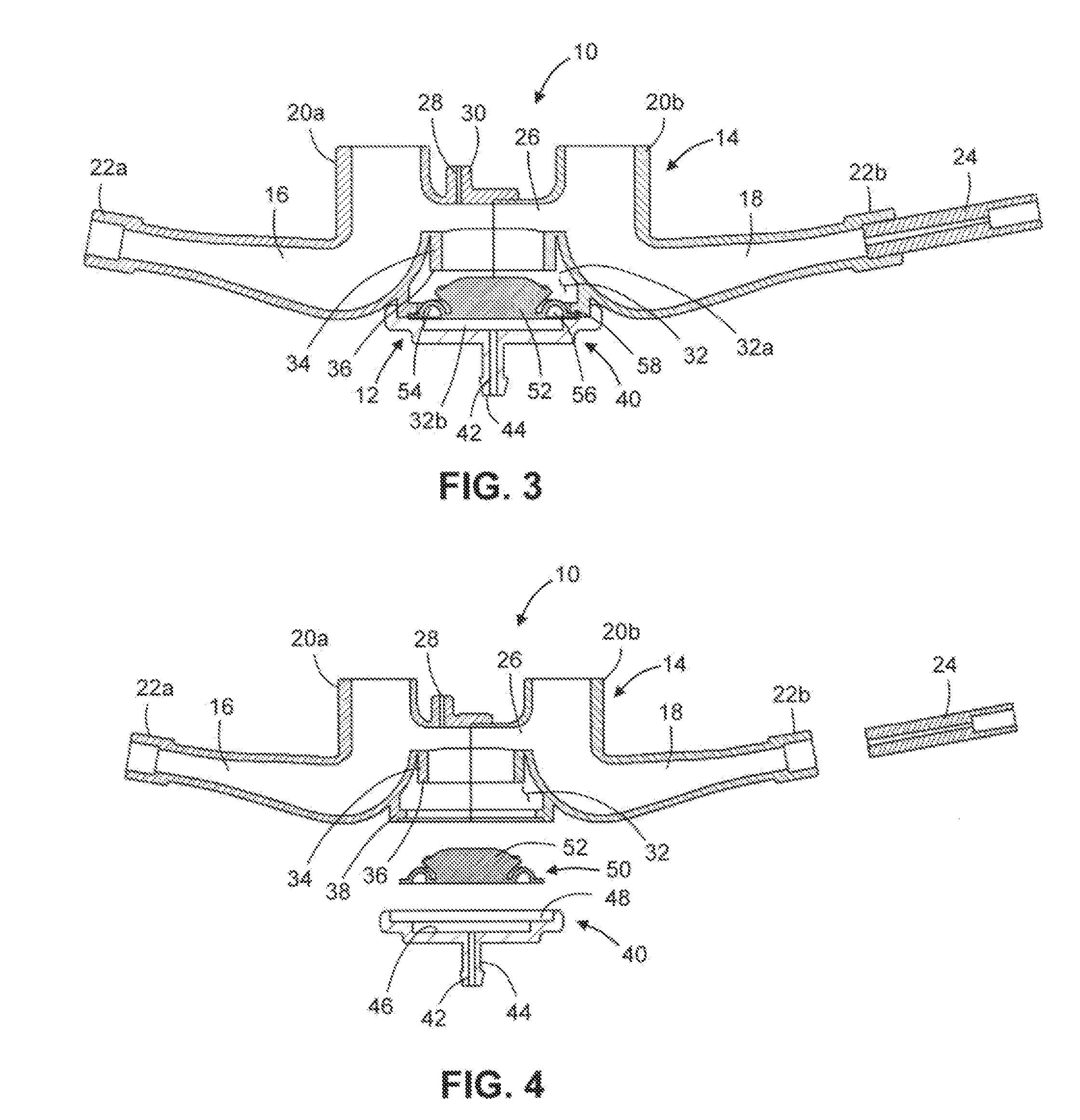

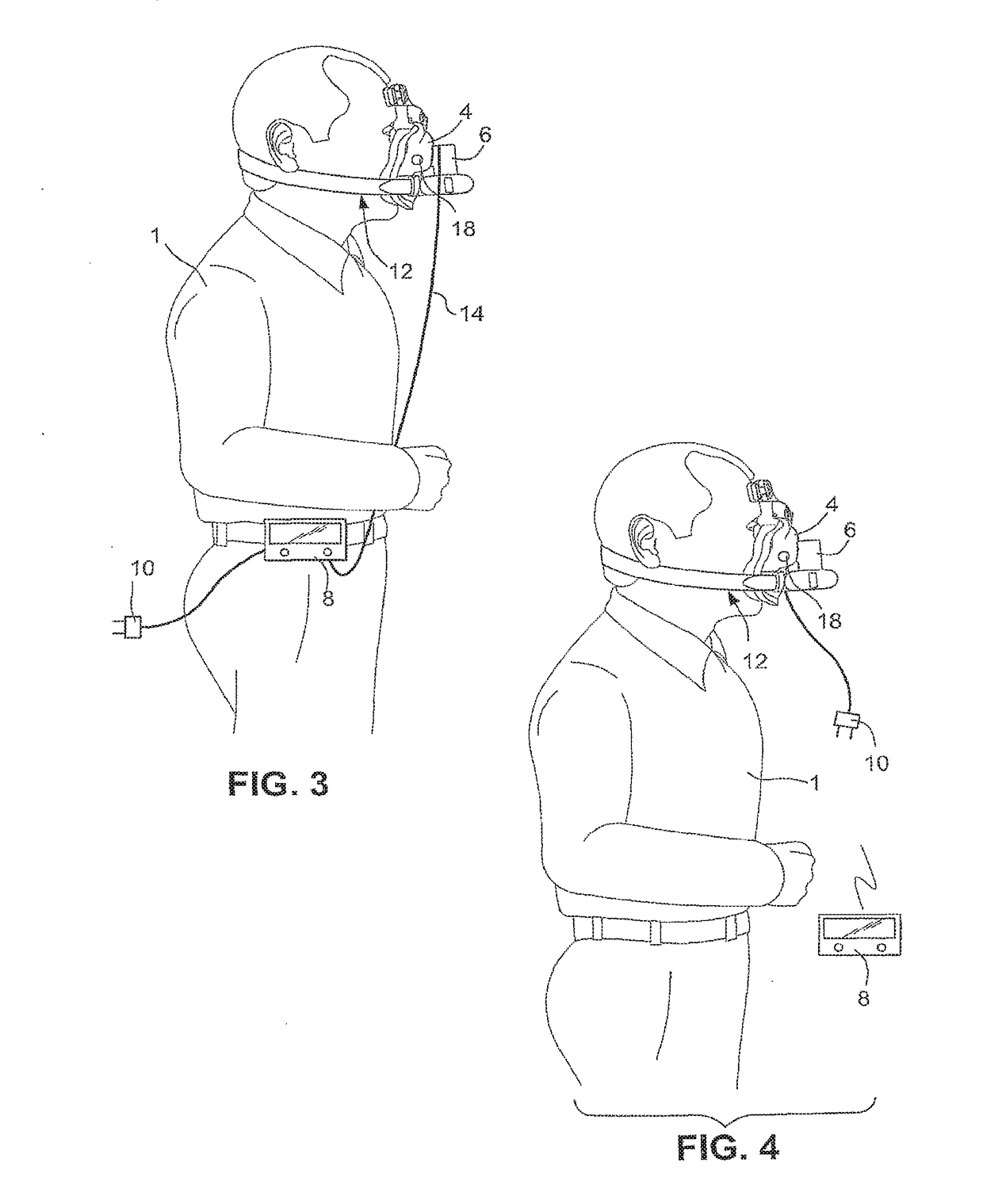

Mask and flow generator system

InactiveUS20090320842A1Reduction in functional dead spaceReduce functional dead spaceOperating means/releasing devices for valvesRespiratory masksBreathing gasEngineering

A system for delivering a pressurized flow of breathable gas to a patient includes a patient interface configured to contact the patient's head. The patient interface includes a frame, a cushion supported by the frame and configured to sealingly connect the patient interface to the patient's face and form a chamber between the frame and the wearer's face, and an inlet port in the frame to receive the pressurized flow of breathable gas. A flow generator is configured to generate the pressurized flow and is capable of creating a pressure of about 2-40 cm H20 in the chamber. A flow generator housing is provided to house the flow generator. The flow generator housing is mounted on the patient interface and configured to reduce the transmission of vibration and / or noise generated by the flow generator to the patient interface.

Owner:RESMED LTD

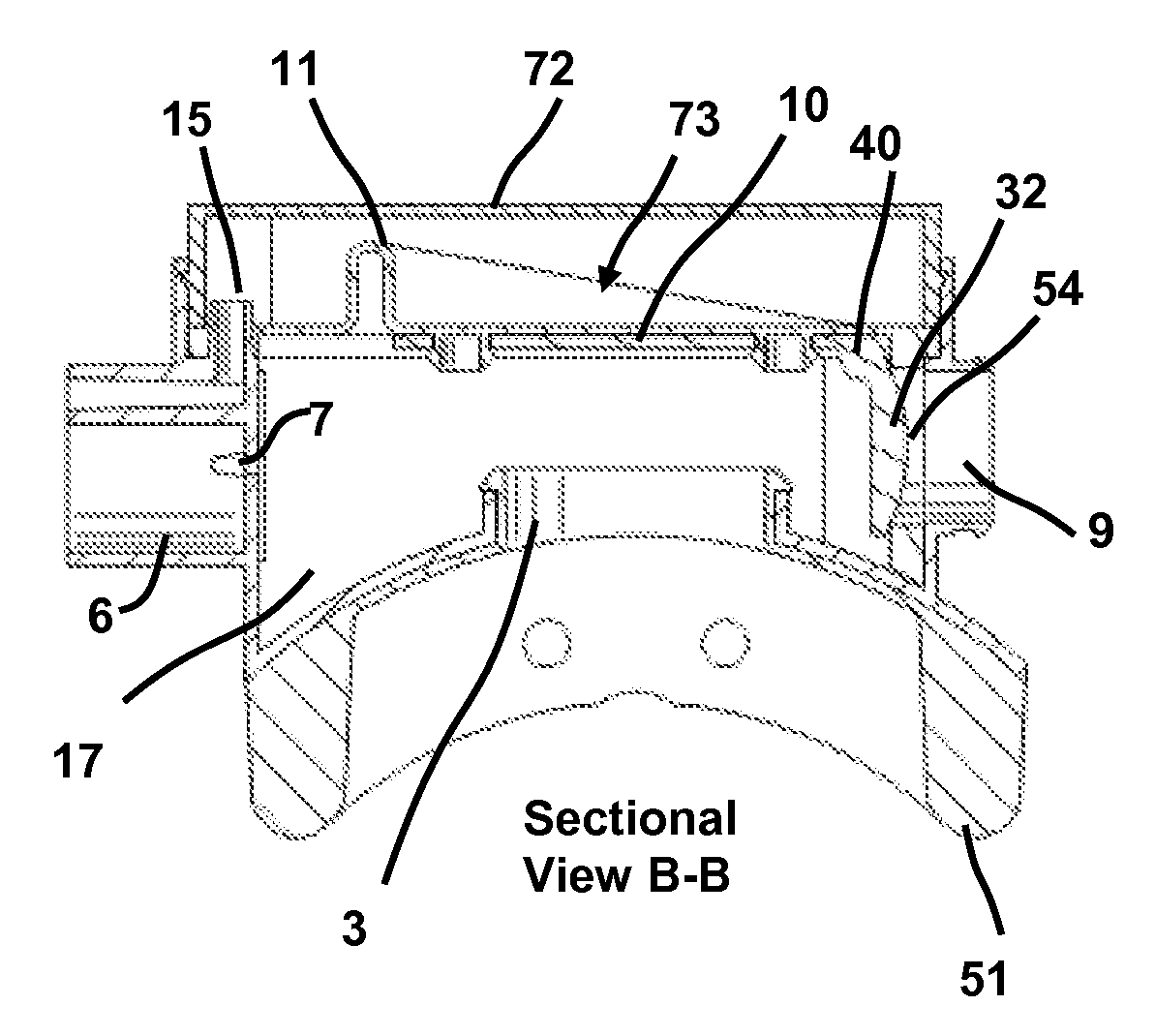

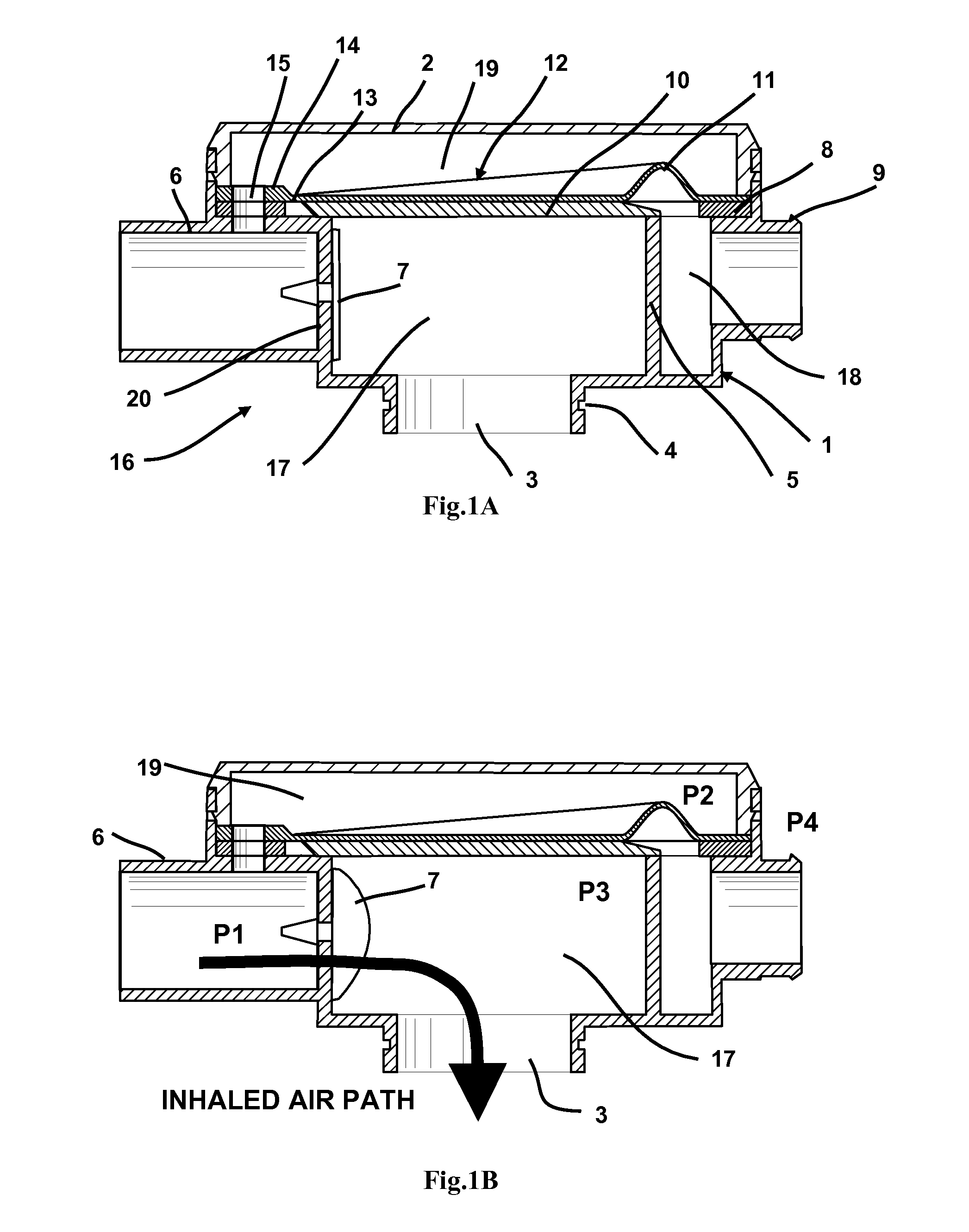

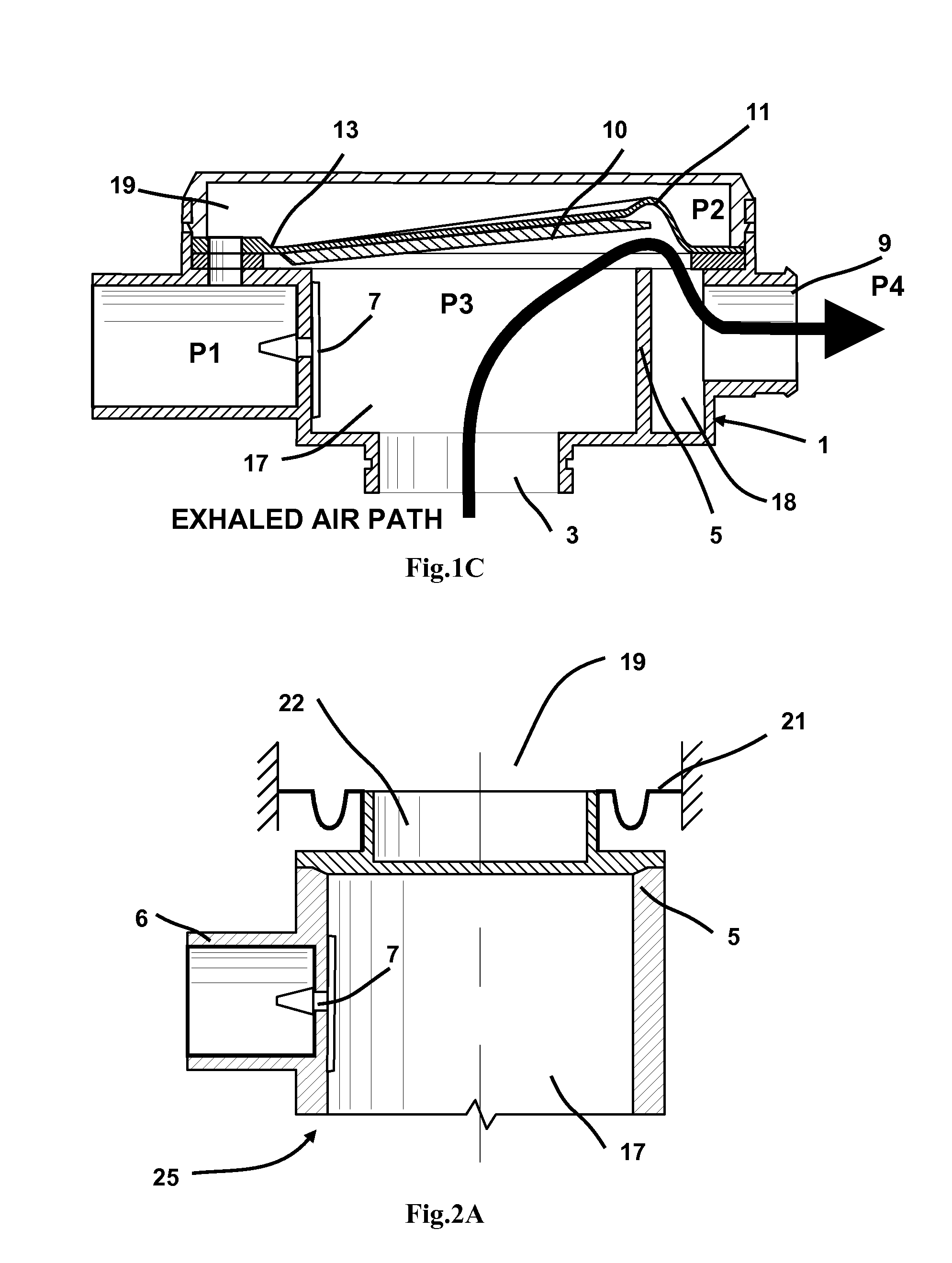

Exhaust Apparatus For Use in Administering Positive Pressure Therapy Through the Nose or Mouth

InactiveUS20080142013A1Superior CO removalReduce traffic requirementsRespiratory masksMedical devicesNasal cavityPositive pressure

We describe the use of a flow directing apparatus for incorporation into a patient mask or adjacent to it and for use with a source of pressurized breathable gas such as electronically or electronically controlled fan blower or positive displacement ventilator to provide nasal or oro-nasally administered continuous positive airway pressure or bi level therapies. Such therapies are commonly used to treat sleep disordered breathing including sleep apnea and other syndromes, as well as ventilatory insufficiency. The valve apparatus includes means to direct expired air to atmosphere and inspired air from a pressure source to a user's airway. In this way advantage is provided compared to alternative means as described in the prior art which vent a user's expired gas to atmosphere through a fixed open vent.

Owner:HALLETT MICHAEL DAVID +1

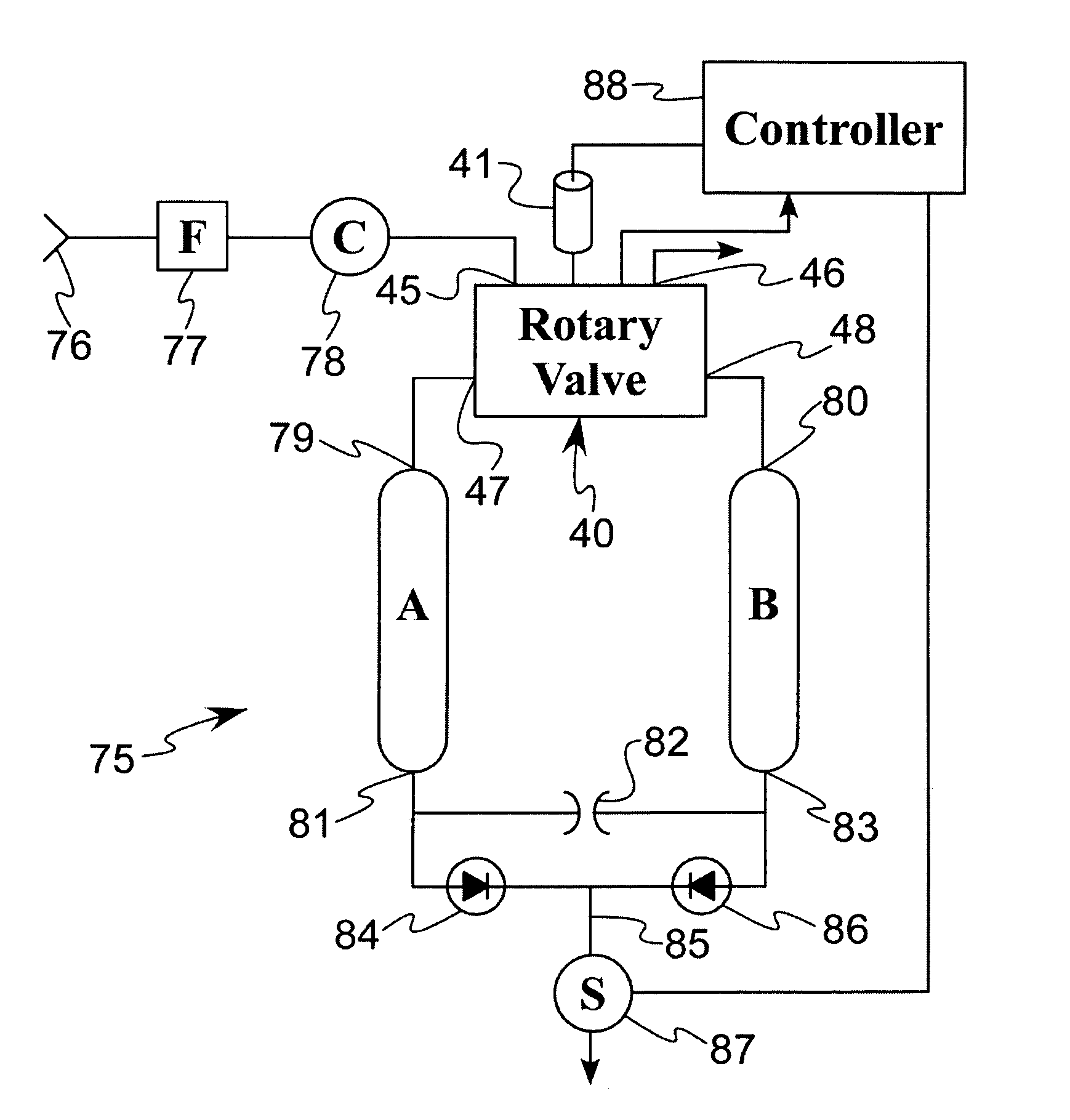

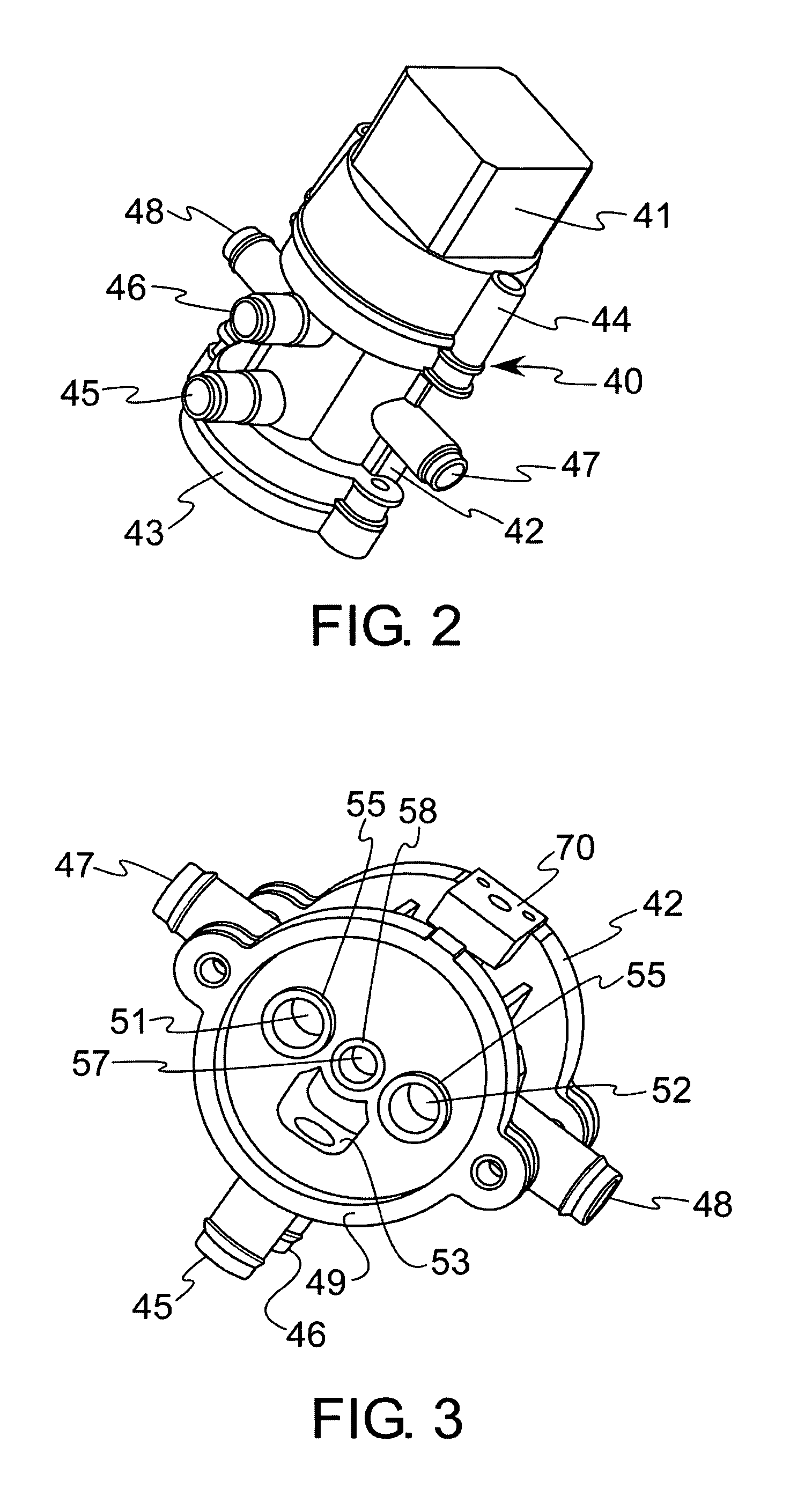

Energy efficient oxygen concentrator

InactiveUS7445663B1Improve energy efficiencyOxygen flow requirementRespiratorsGas treatmentNitrogenProcess engineering

An energy efficient oxygen concentrator in which a compressor applies pressurized air to at least two gas separating elements which will pass a flow of oxygen while blocking a flow of nitrogen. The gas separating elements are alternately cycled between a gas separating mode for producing oxygen enriched gas and a purge mode for purging nitrogen from the elements. According to the invention, the speed of the cycle time is increased as the oxygen enriched gas flow requirement is decreased below the maximum concentrator output. The higher cycle speed reduces the maximum compressor pressure to reduce energy consumption.

Owner:DEVILBISS HEALTHCARE

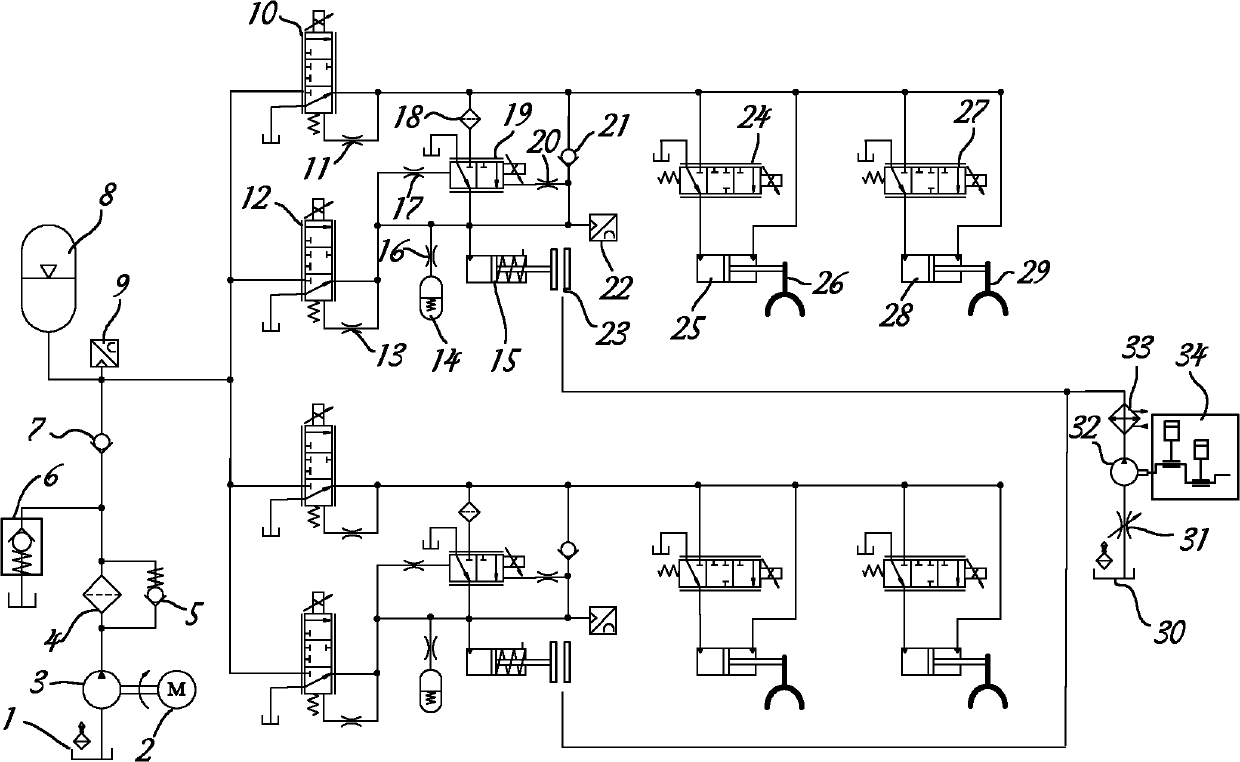

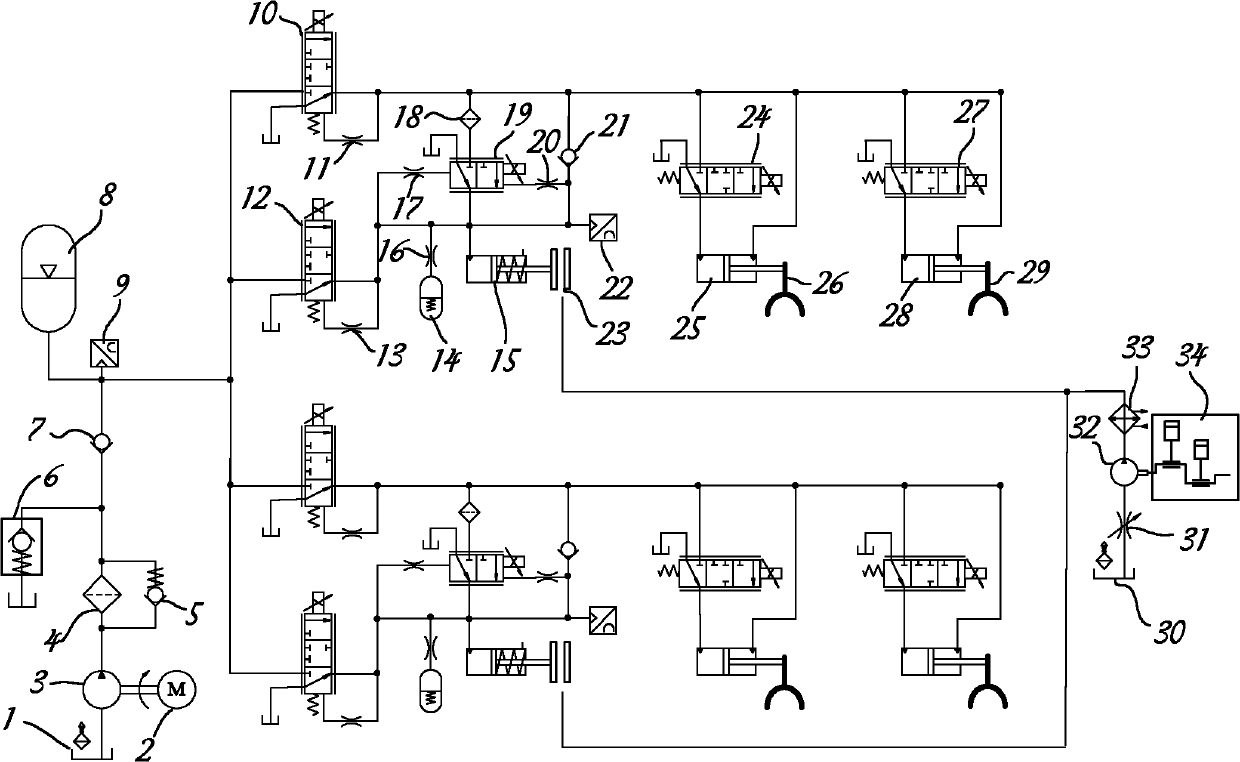

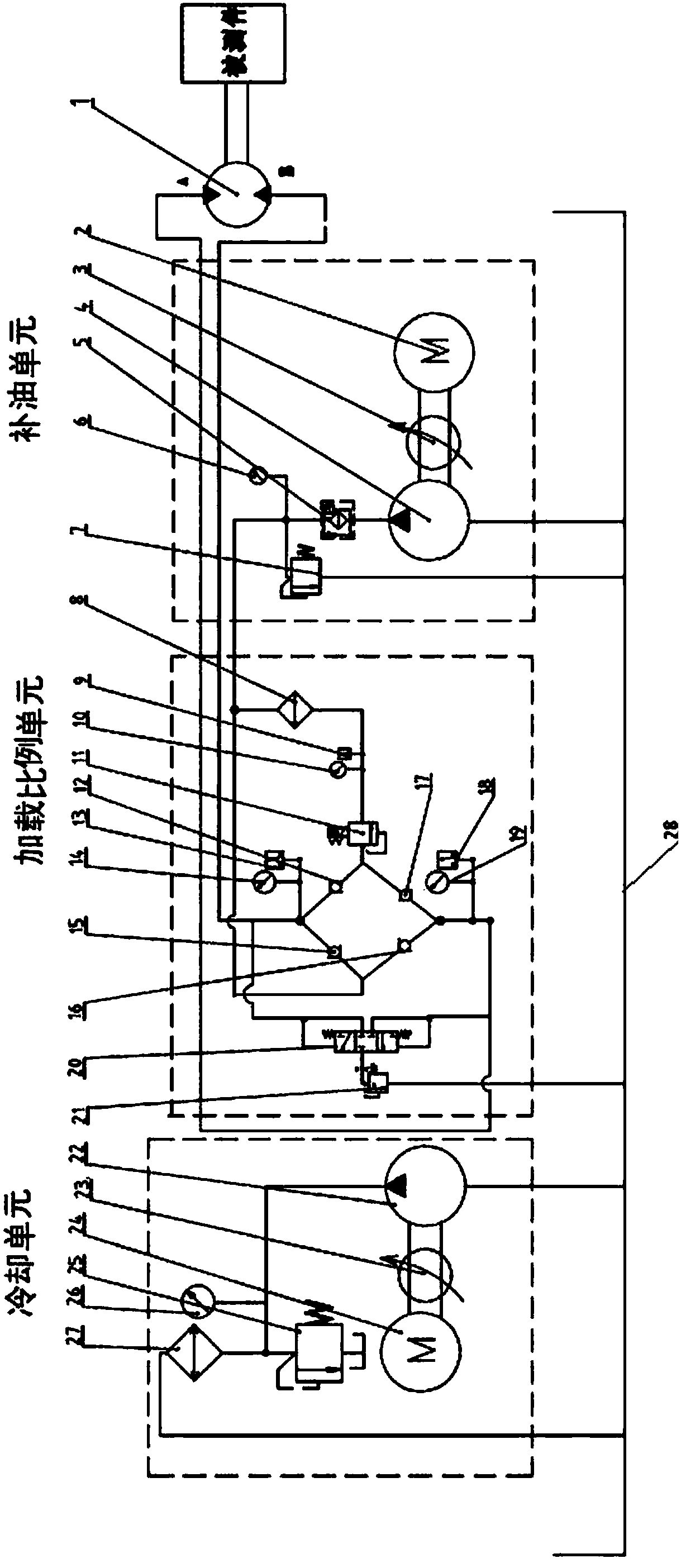

Hydraulic control system for wet-type double-clutch automatic transmission

ActiveCN102168754AReduce displacementLow powerClutchesGear lubrication/coolingAutomatic transmissionControl signal

The invention belongs to automobile transmissions, in particular to a hydraulic control system for a wet-type double-clutch automatic transmission. The hydraulic control system consists of two separate subsystems, wherein one subsystem is a clutch and gearshift mechanism hydraulic control subsystem which is mainly used for operating an odd number gear clutch and an even number gear clutch to separate and combine according to a control signal transmitted by an electronic control unit as well as operating a gear-shift mechanism control oil cylinder to finish switching of each gear synchronizer; and the other subsystem is a clutch cooling and lubricating subsystem. By adopting a more scientific and reasonable hydraulic control system, the efficiency of the hydraulic control system for the wet-type double-clutch automatic transmission is improved, the fuel consumption is reduced, the effects of saving energy and reducing emission are achieved, and the reliability of the system work and the compactness of the structure are enhanced.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

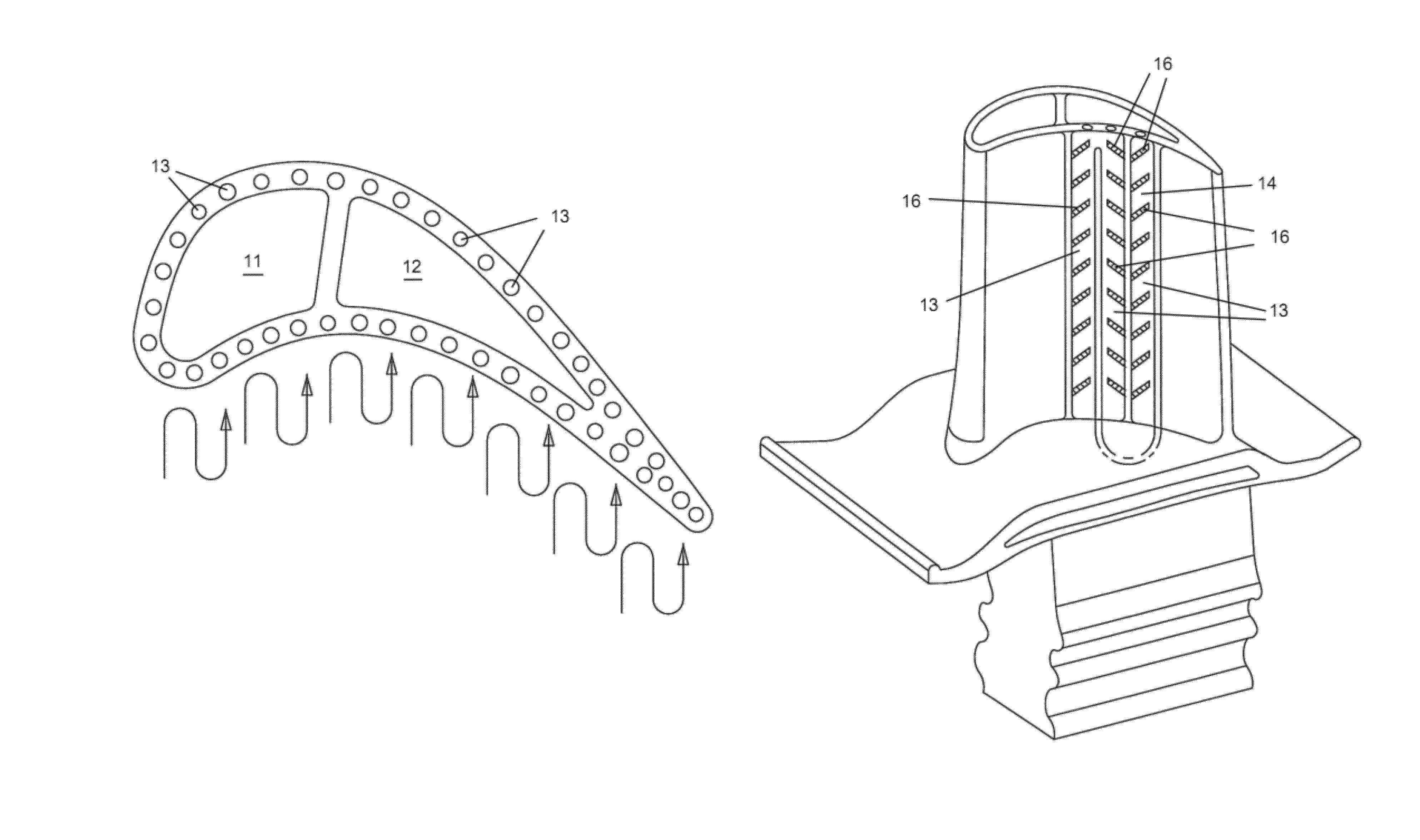

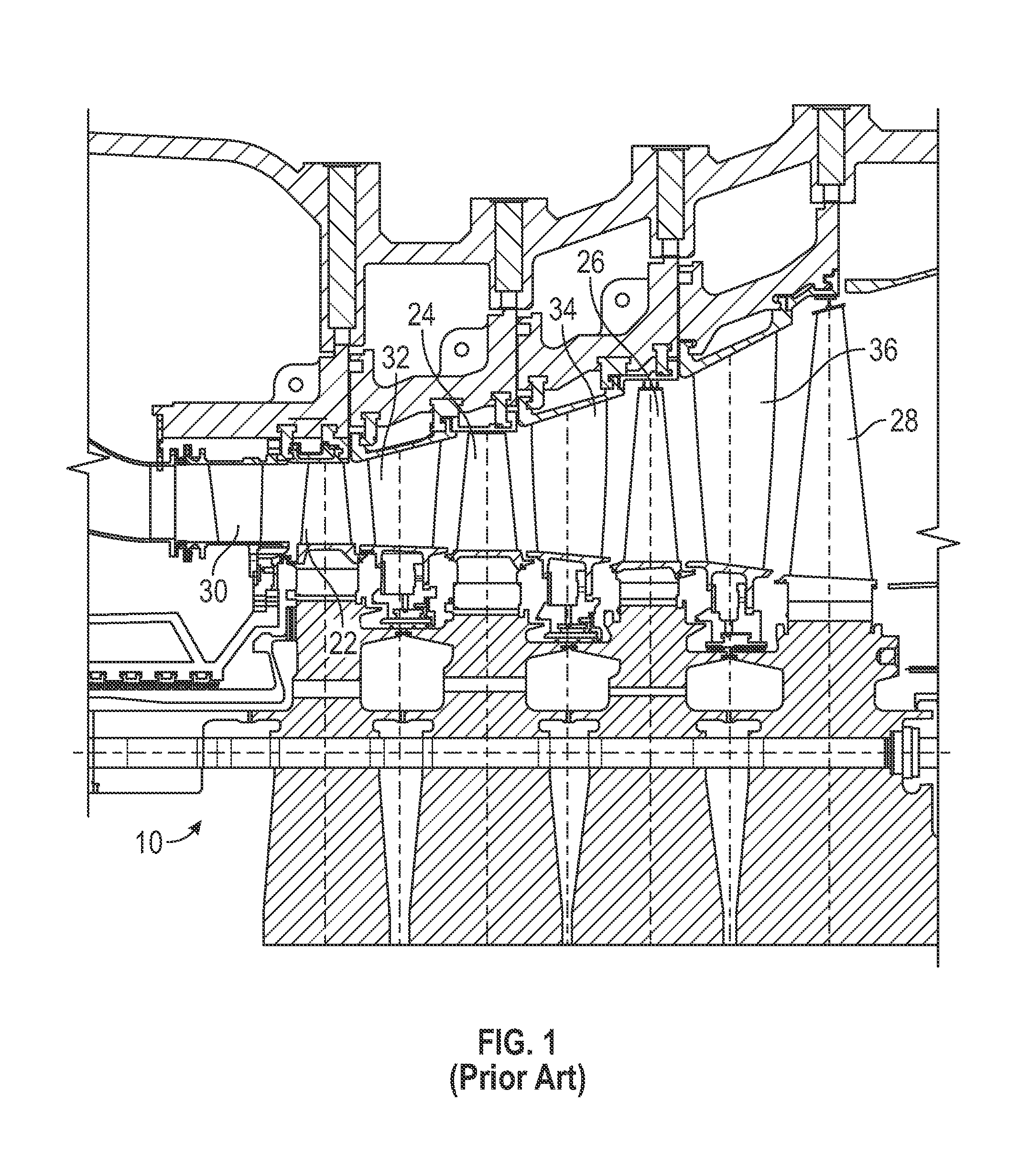

Turbine airfoil with near wall vortex cooling

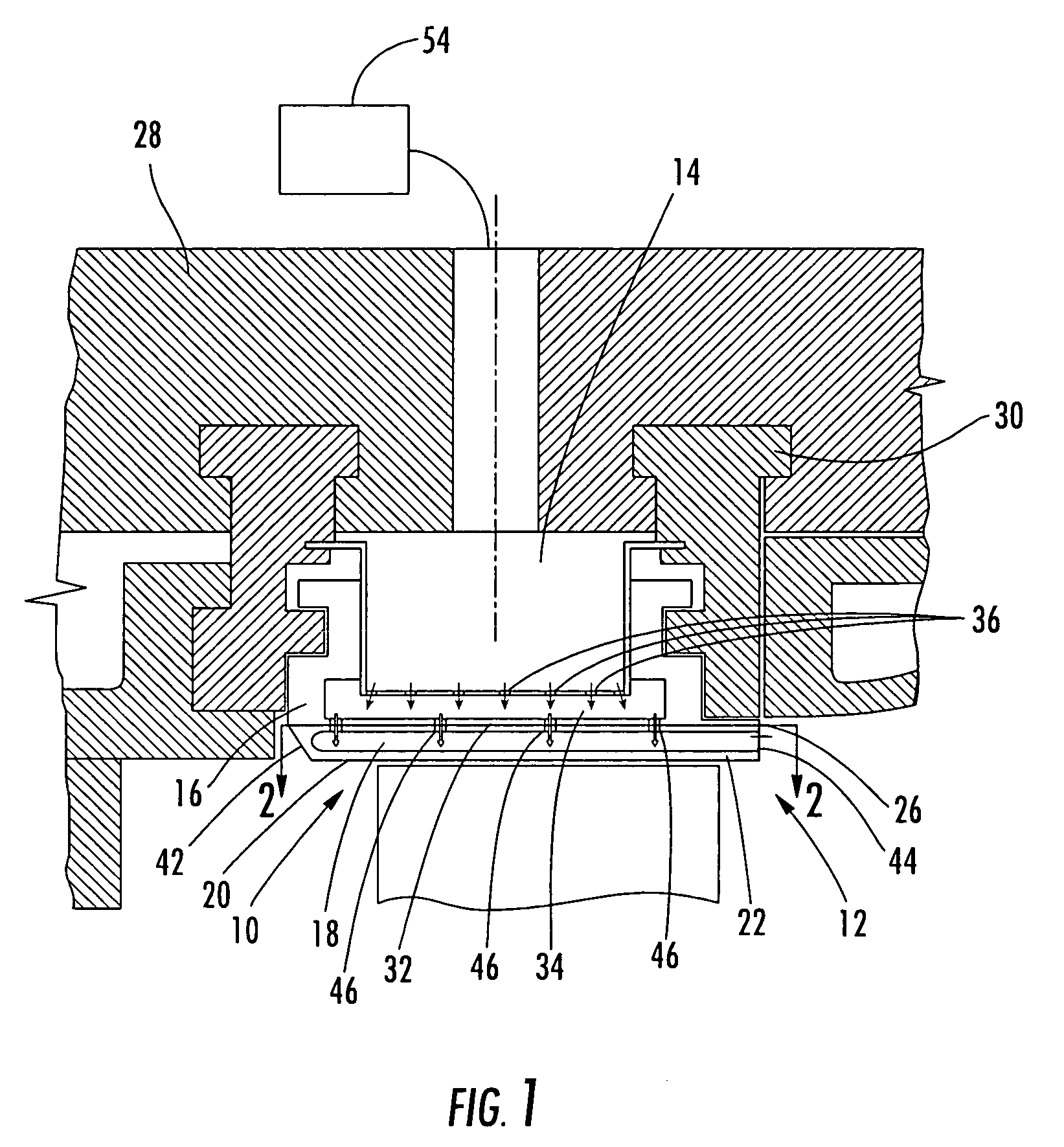

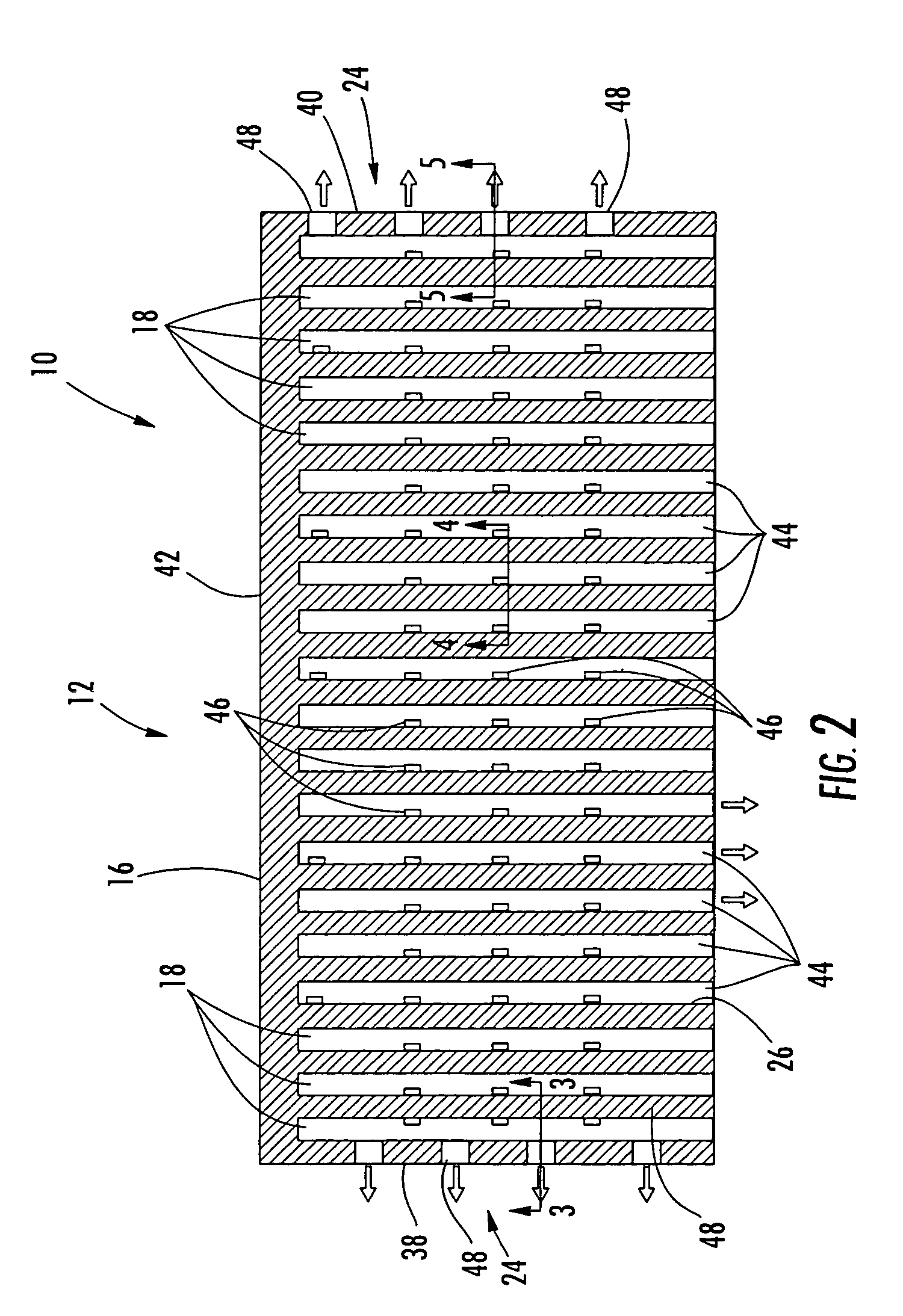

InactiveUS8251660B1Reduce trafficReduce metal temperaturePropellersEngine manufactureTurbineSingle pass

A turbine airfoil having walls with radial extending near wall cooled vortex flowing channels to provide for a high cooling effectiveness with a low cooling flow requirement. A thermal skin is bonded over a main spar in which skewed ribs extend from both the spar and the thermal skin to form a vortex flowing path along the radial channels. The vortex flowing radial channels can be single pass radial channels or connected to form a 3-pass serpentine flow circuit with tip holes to discharge the cooling air from the radial channels and cool the blade tip periphery.

Owner:FLORIDA TURBINE TECH

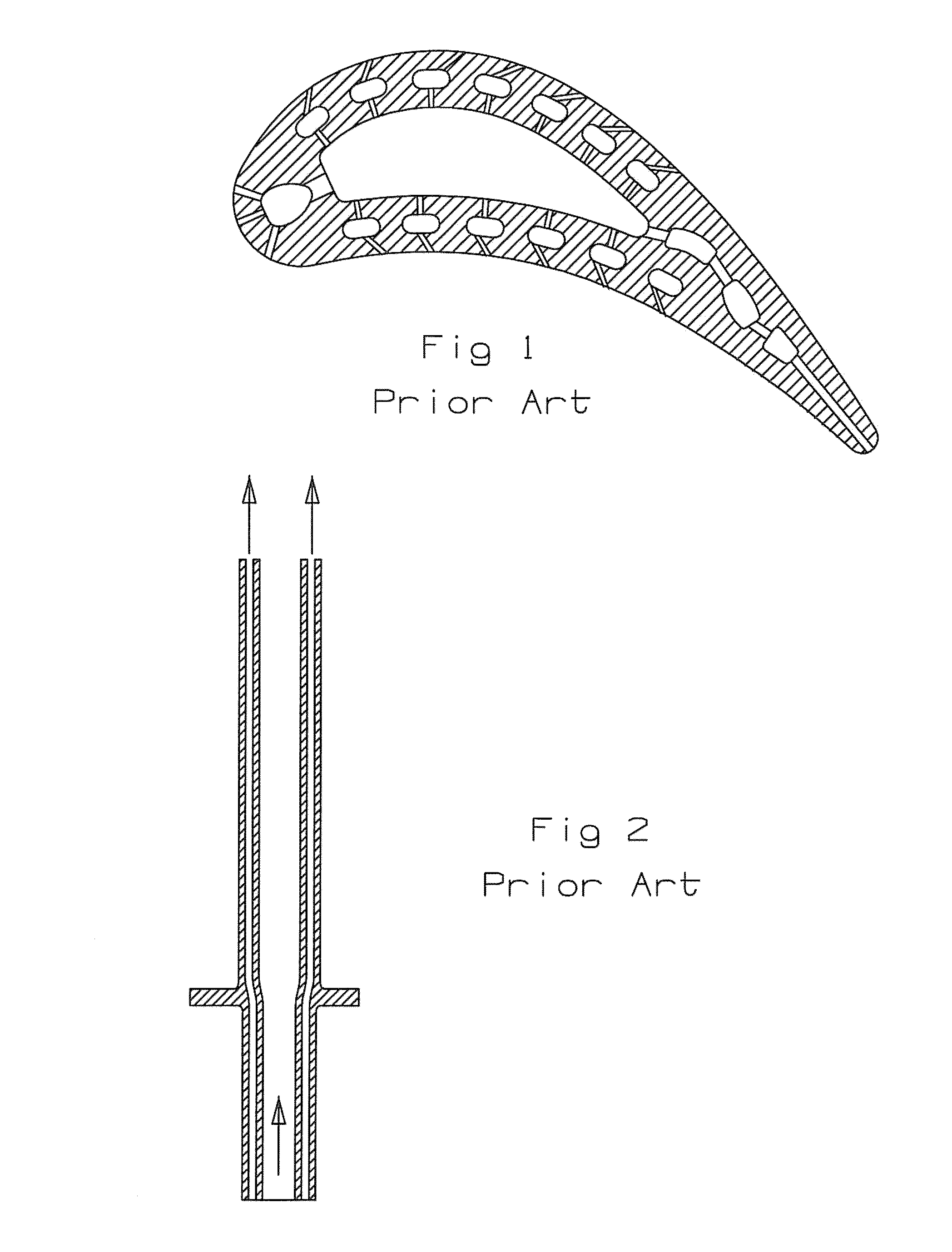

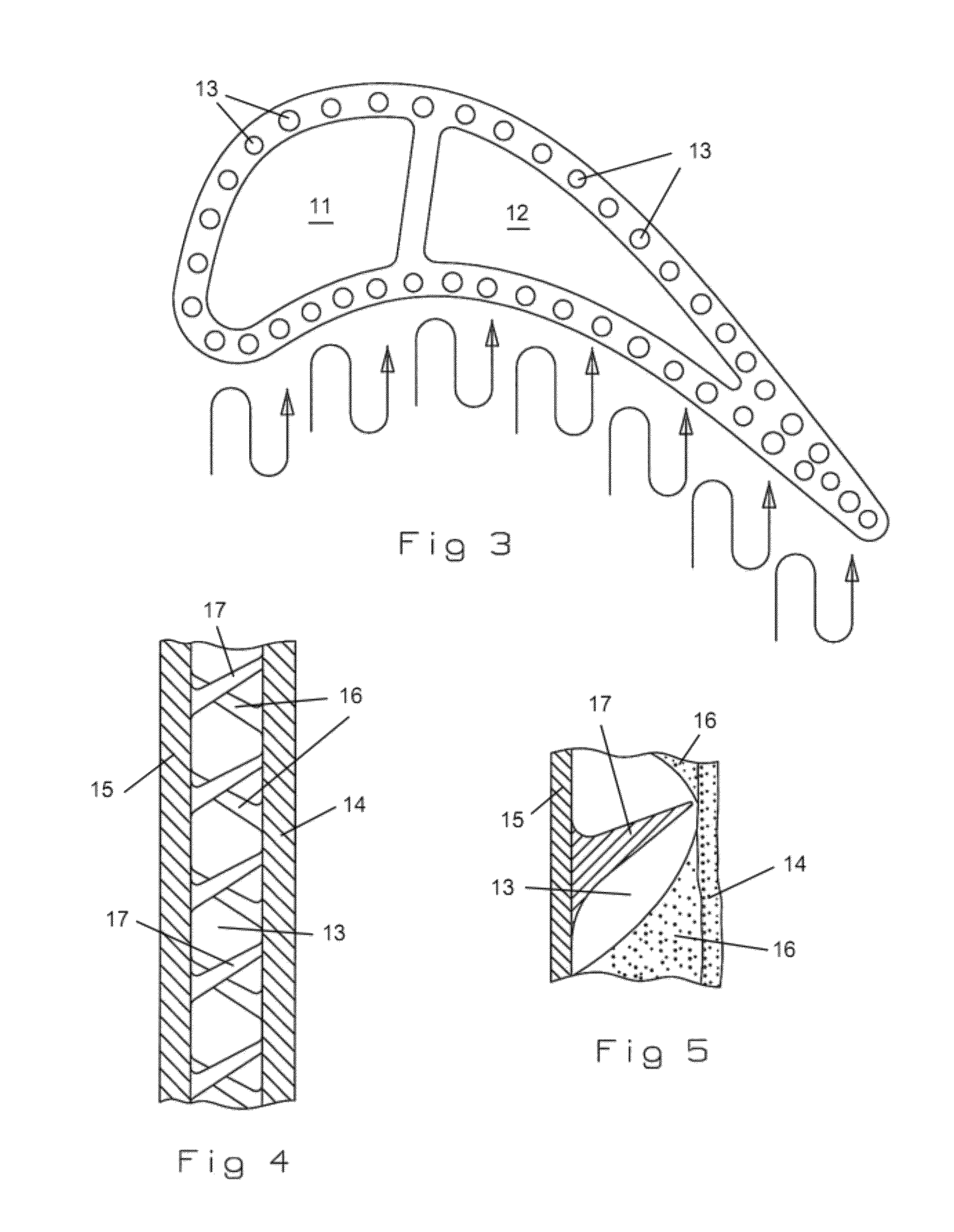

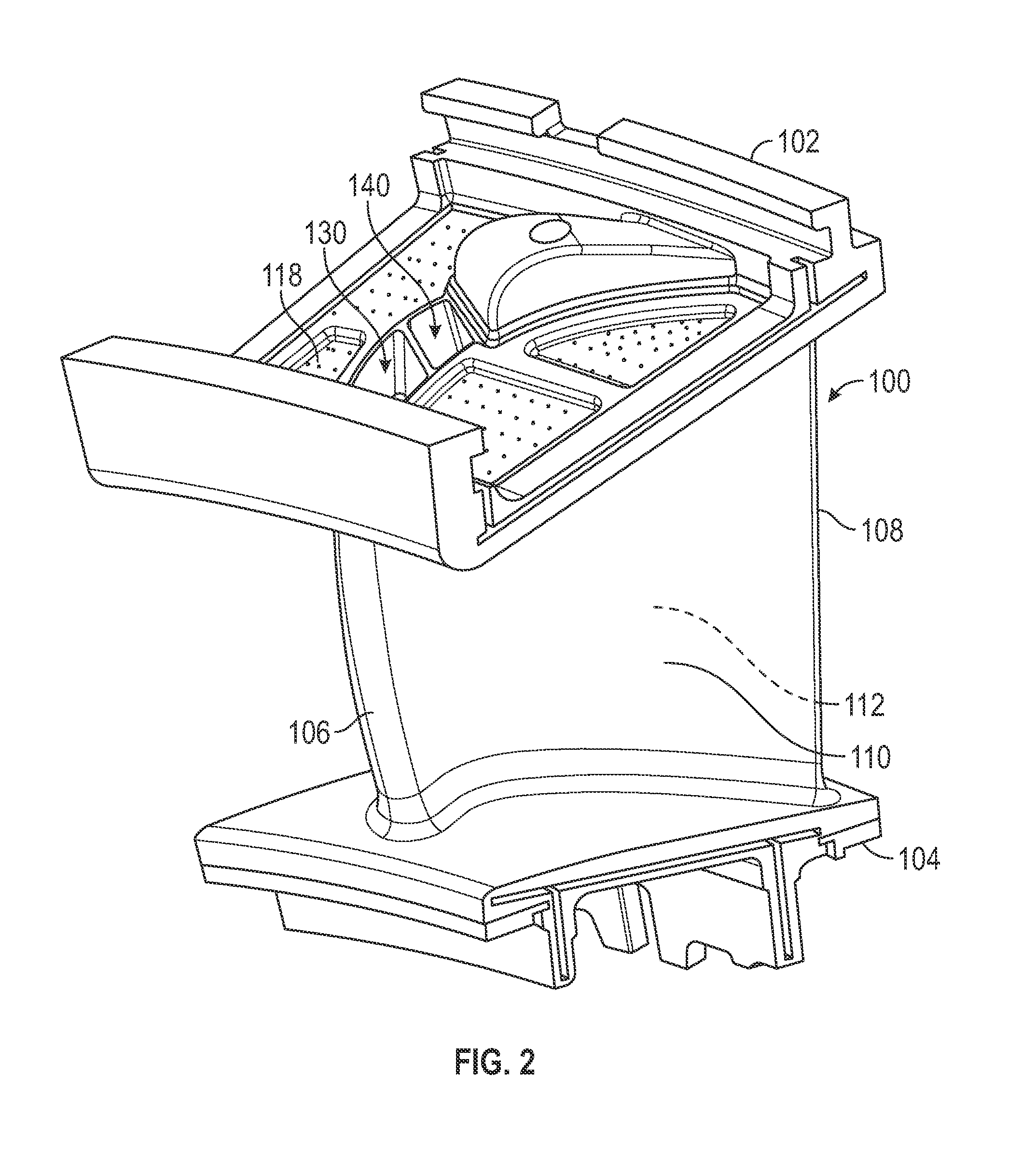

Turbine airfoil with near-wall serpentine cooling

ActiveUS8047788B1Improve efficiency of turbineReduced flow requirementsEngine manufactureEngine fuctionsTurbineLeading edge

A turbine airfoil with a leading edge cooling air supply channel located along the leading edge region of the airfoil to supply cooling air from an outside source and a series of serpentine flow cooling circuits positioned along the leading edge of the airfoil connected to the cooling supply channel to pass cooling air through the series of serpentine passages in a direction from the airfoil root to the airfoil tip. The series of serpentine circuits includes legs on the pressure side and the suction side of the leading edge. Cooling air from the supply channel is metered into the first leg of the serpentine circuit located near the root, flows through a series of serpentine circuits along the leading edge of the airfoil, and flows out to the tip through a tip hole in the last leg of the last serpentine circuit.

Owner:FLORIDA TURBINE TECH

Integrated TBC and cooling flow metering plate in turbine vane

ActiveUS8827632B1Increase efficiencyMore thermal protectionPump componentsBlade accessoriesTrailing edgeTurbine blade

An integrated thermal barrier coating and cooling flow metering plate for a turbine vane are disclosed. On an existing vane design, the thickness of the thermal barrier coating is increased in order to provide more thermal protection around the vane material itself. The increased insulation around the vane allows the volume of cooling air flow to be reduced, while still maintaining the vane temperature within specification. The reduced cooling air flow is obtained by adding a flow metering plate at the inlet of a vane trailing edge cooling circuit, thereby increasing turbine efficiency via reduced cooling air flow requirements, while allowing an existing vane casting design to be used.

Owner:SIEMENS ENERGY INC

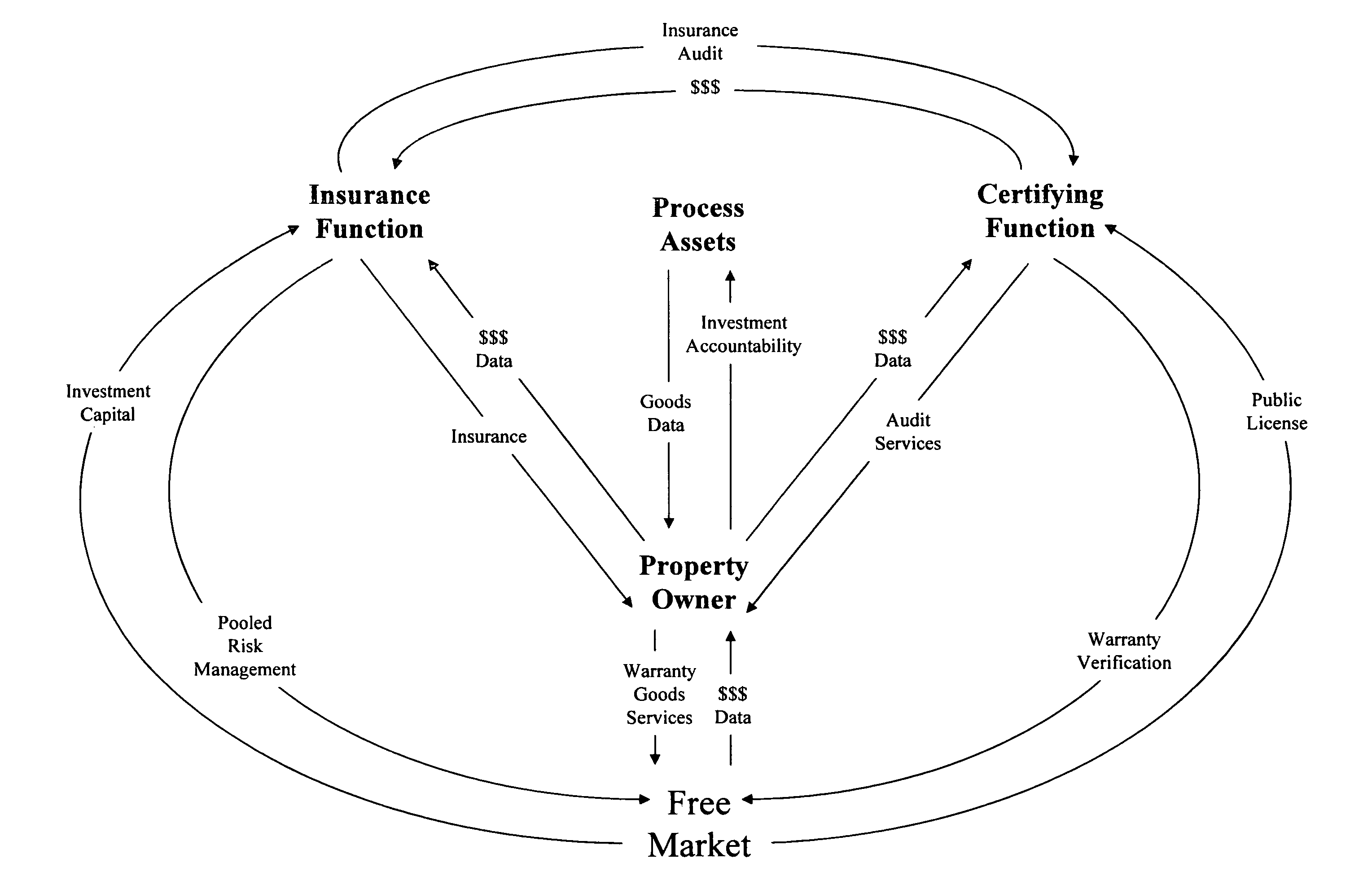

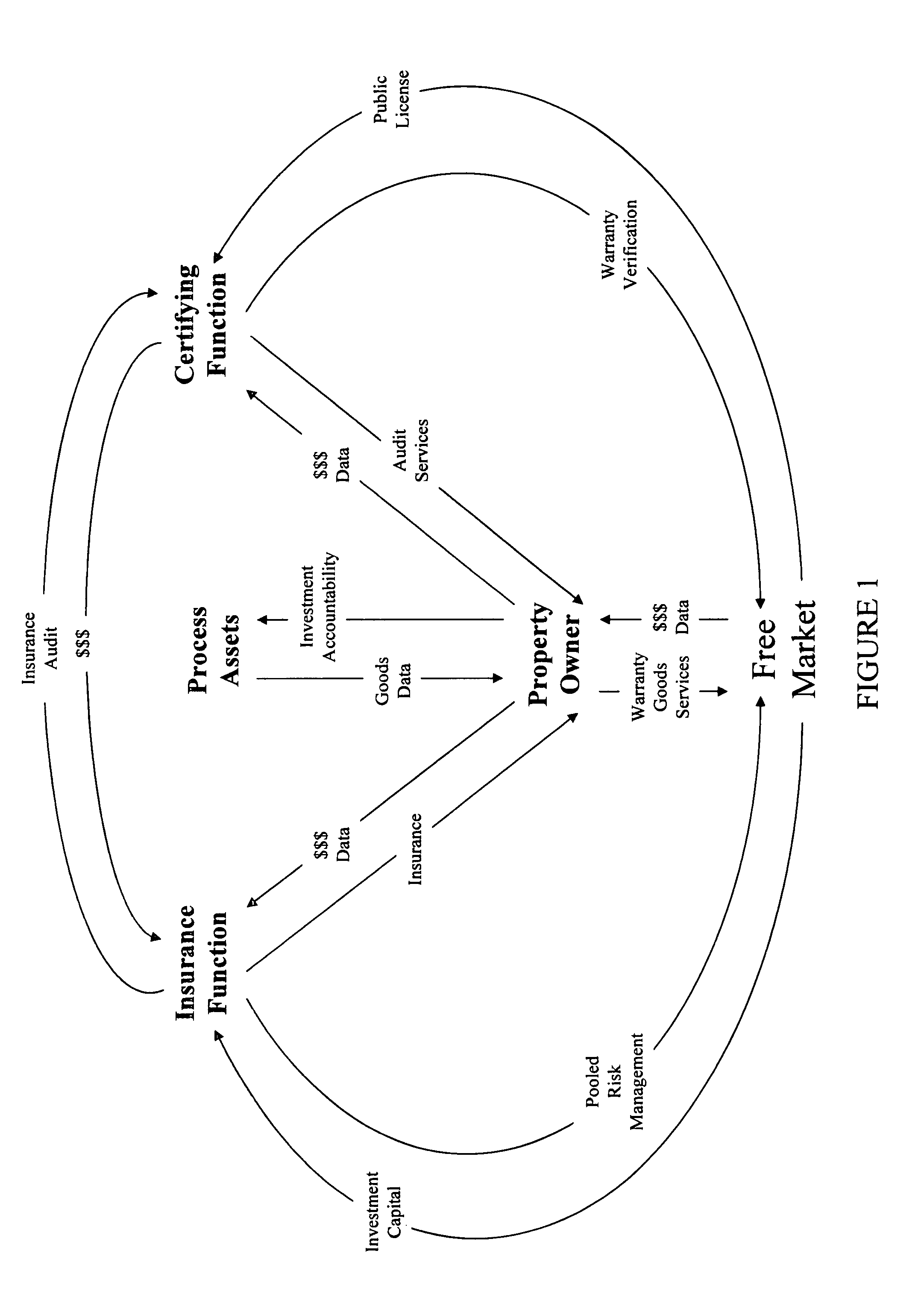

Free-market environmental management system having insured certification to a process standard

InactiveUS7401036B2Facilitate conductionReduce traffic requirementsFinancePayment architectureEnvironment effectSystems design

Environmental regulation by government is structurally incapable of satisfying its mandate. The present invention is an alternative, free-market management system designed to deliver a superior product, at lower cost, with an insured guarantee, and without regulatory oversight by government. The system uses an insured, certified best-practice form of process certification that objectively accounts the financial value of ecosystem resources. The conduct of practice within the system accounts the price of assets at risk and characterizes their function by which to market them for their ability to offset the environmental impacts of industrial, commercial, and residential activities.

Owner:VANDE POL MARK E

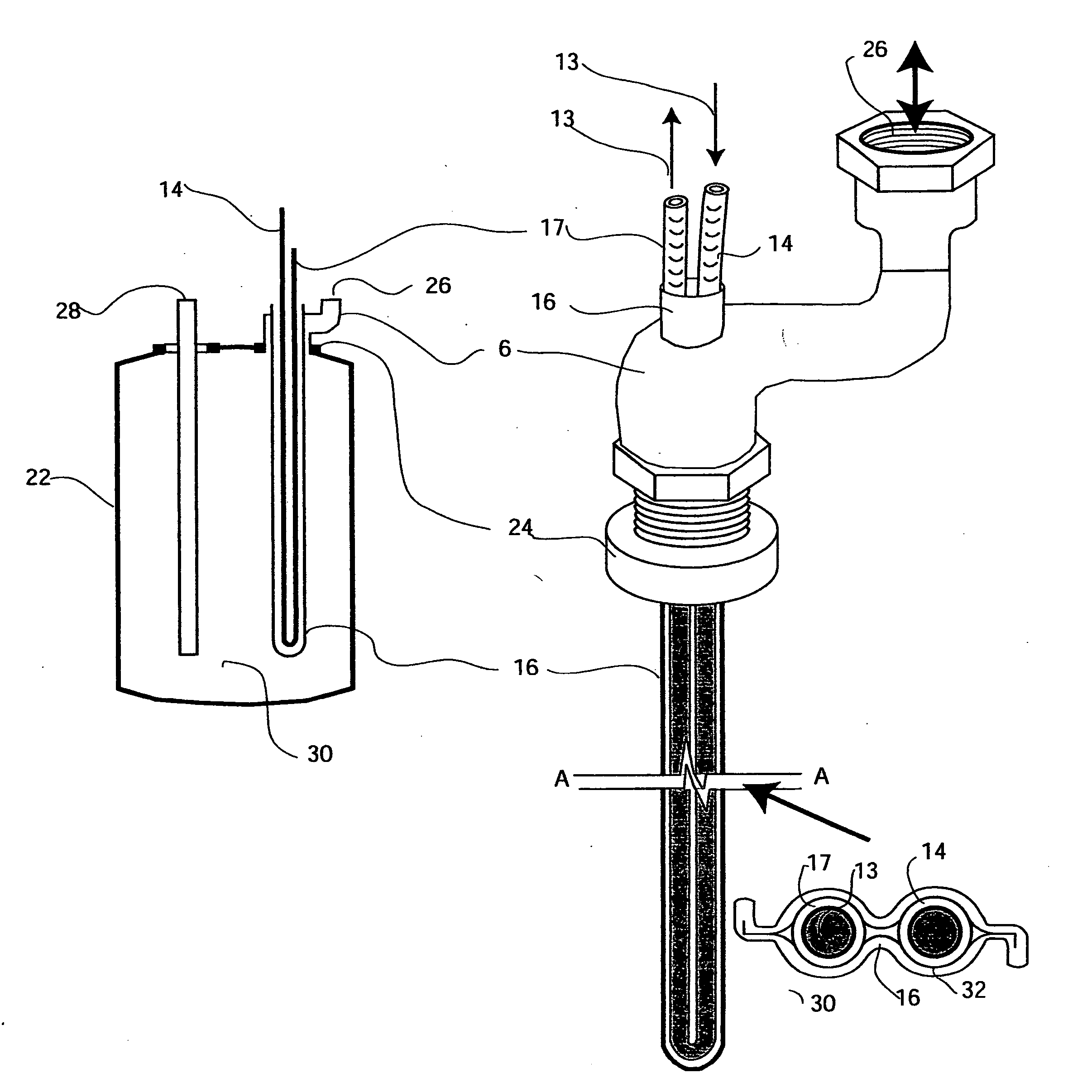

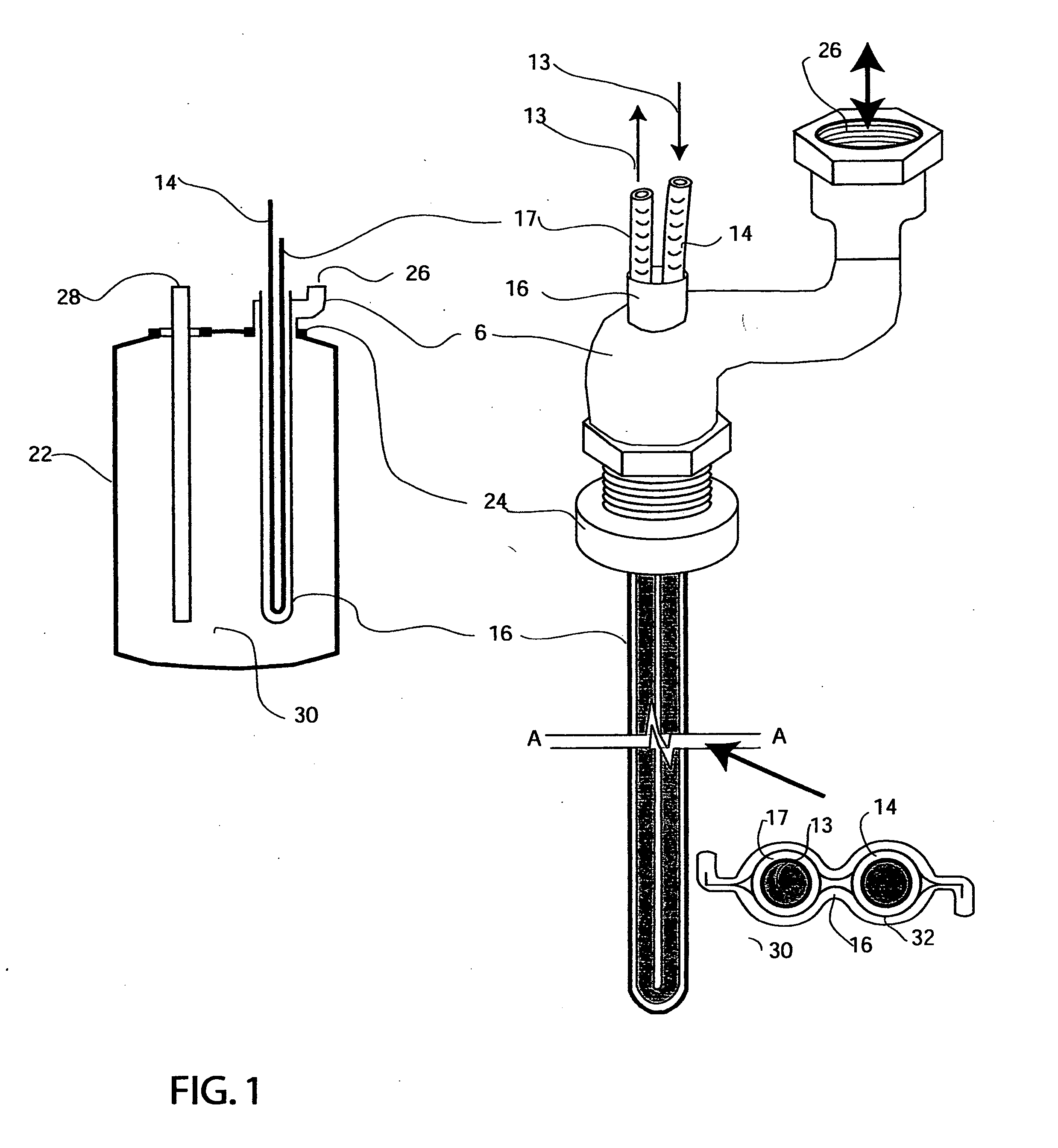

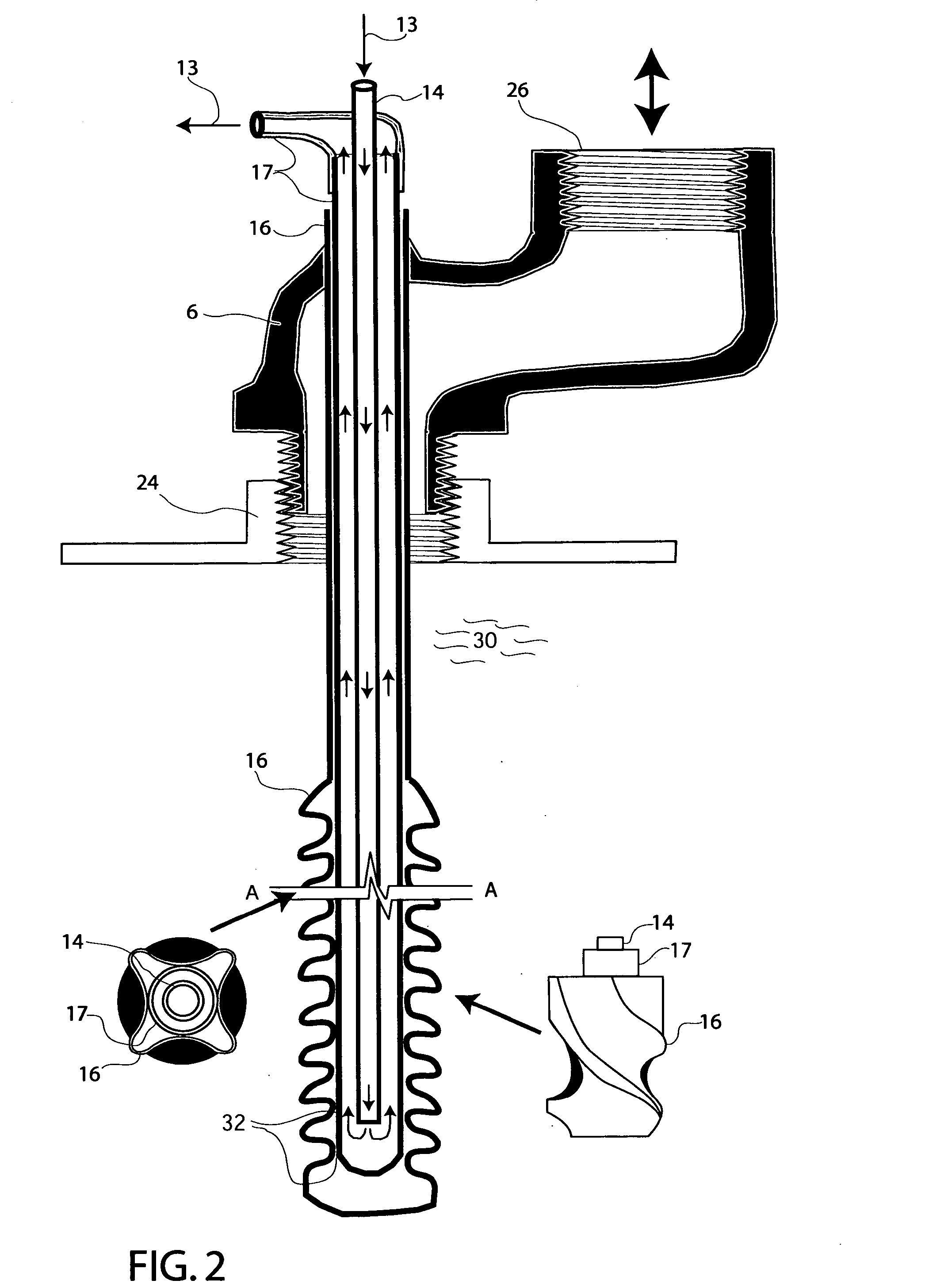

Internal water tank solar heat exchanger

InactiveUS20050139344A1Increase surface areaGreat heat transfer areaHeat storage plantsSafety devices for heat exchange apparatusSolar thermal collectorEngineering

A heat exchanger which is adapted to an existing water tank to allow it to be heated or cooled using a hot or cold toxic or non-toxic liquid. Solar collectors, other heat sources and heat pumps can provide hot or cold liquids. To transfer this heat economically to an existing hot water tank requires a simple, efficient, heat exchanger, which can be easily adapted to the existing tank. The invention recited fills this need by simply screwing into the existing hot or cold water tank and allows heat or cold to be added or extracted via a simple fluid loop which is double wall isolated for toxic and non-toxic heat exchange fluids.

Owner:BUTLER BARRY LYNN

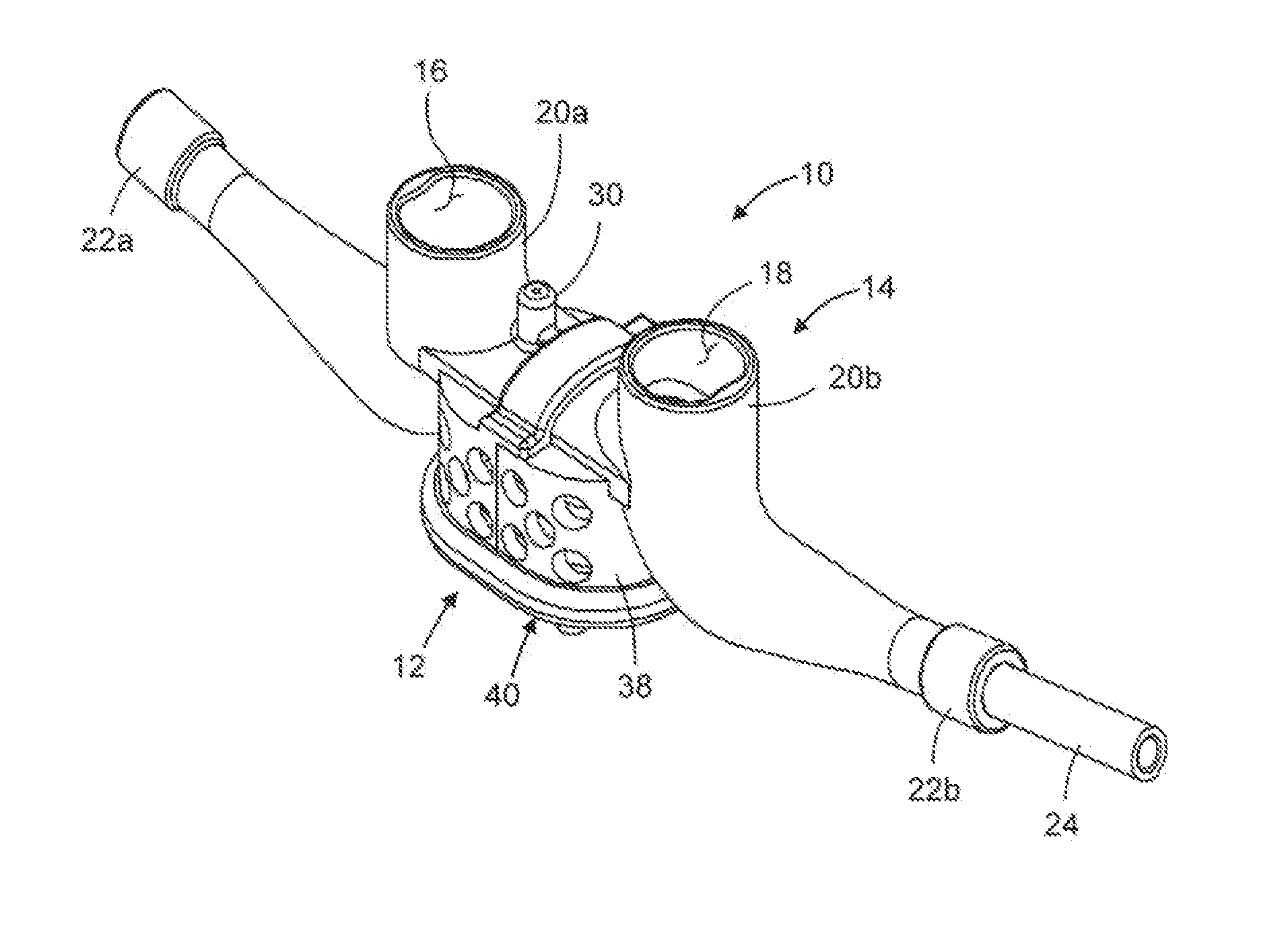

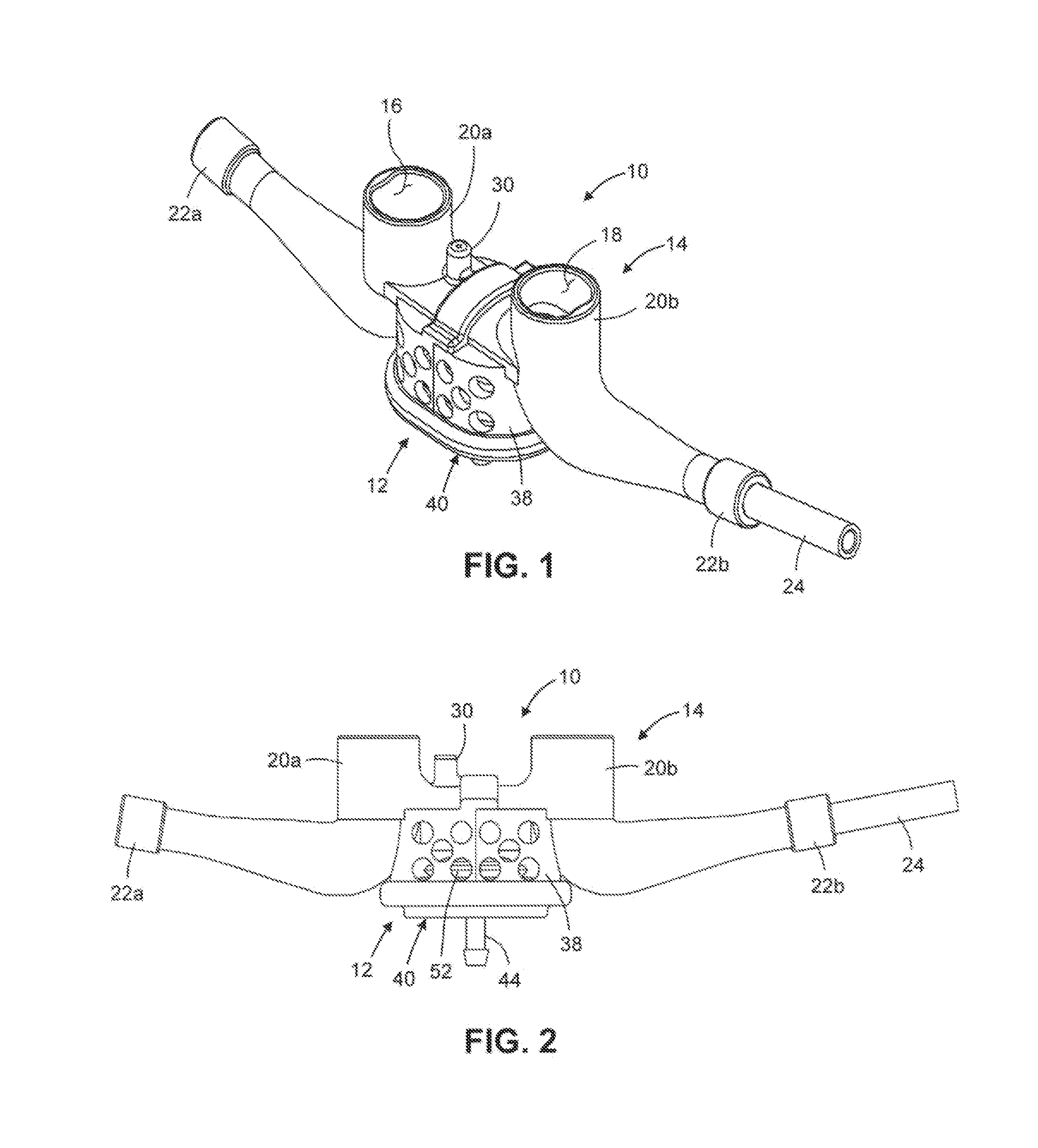

Vortex cooled turbine blade outer air seal for a turbine engine

InactiveUS7665955B2Enhanced convectionReduce traffic requirementsPump componentsEngine fuctionsTurbine bladeCooling fluid

A cooling system for a turbine blade outer air seal that is positioned in close proximity to a tip of a rotatable turbine airfoil to seal the gap between the tip of the turbine blade and the blade ring carrier. The turbine blade outer air seal may be formed from a housing including a cooling fluid collection chamber and one or more vortex cooling channels in fluid communication with the cooling fluid collection chamber via one or more vortex channel feed holes. In one embodiment, a plurality of vortex cooling channels may extend from proximate to an upstream edge of an outer sealing plate of the outer air seal to a downstream edge of the outer sealing plate. During use, cooling fluids pass through the vortex channel feed holes and into the vortex cooling channels, in which vortices may be created.

Owner:SIEMENS ENERGY INC

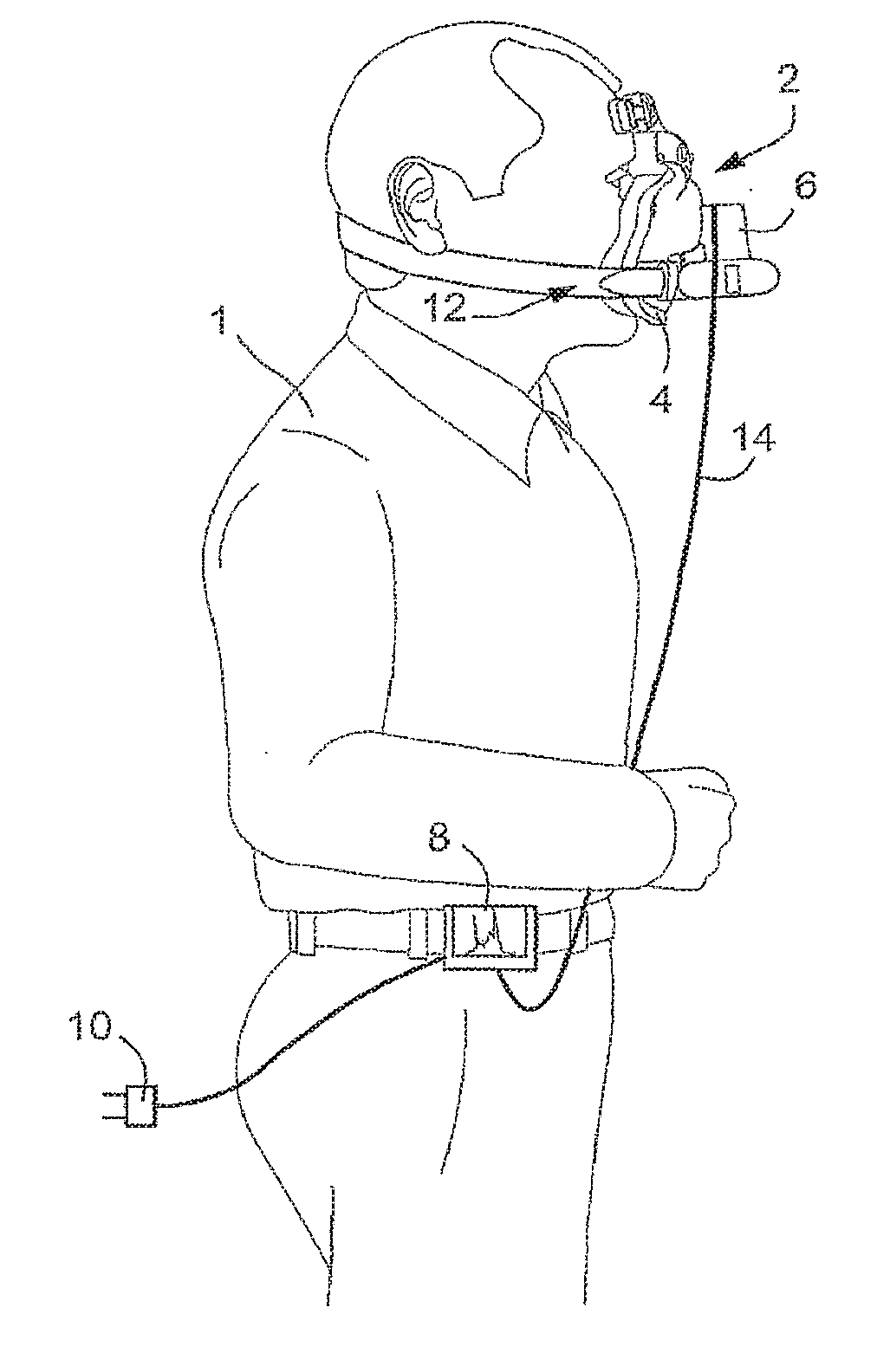

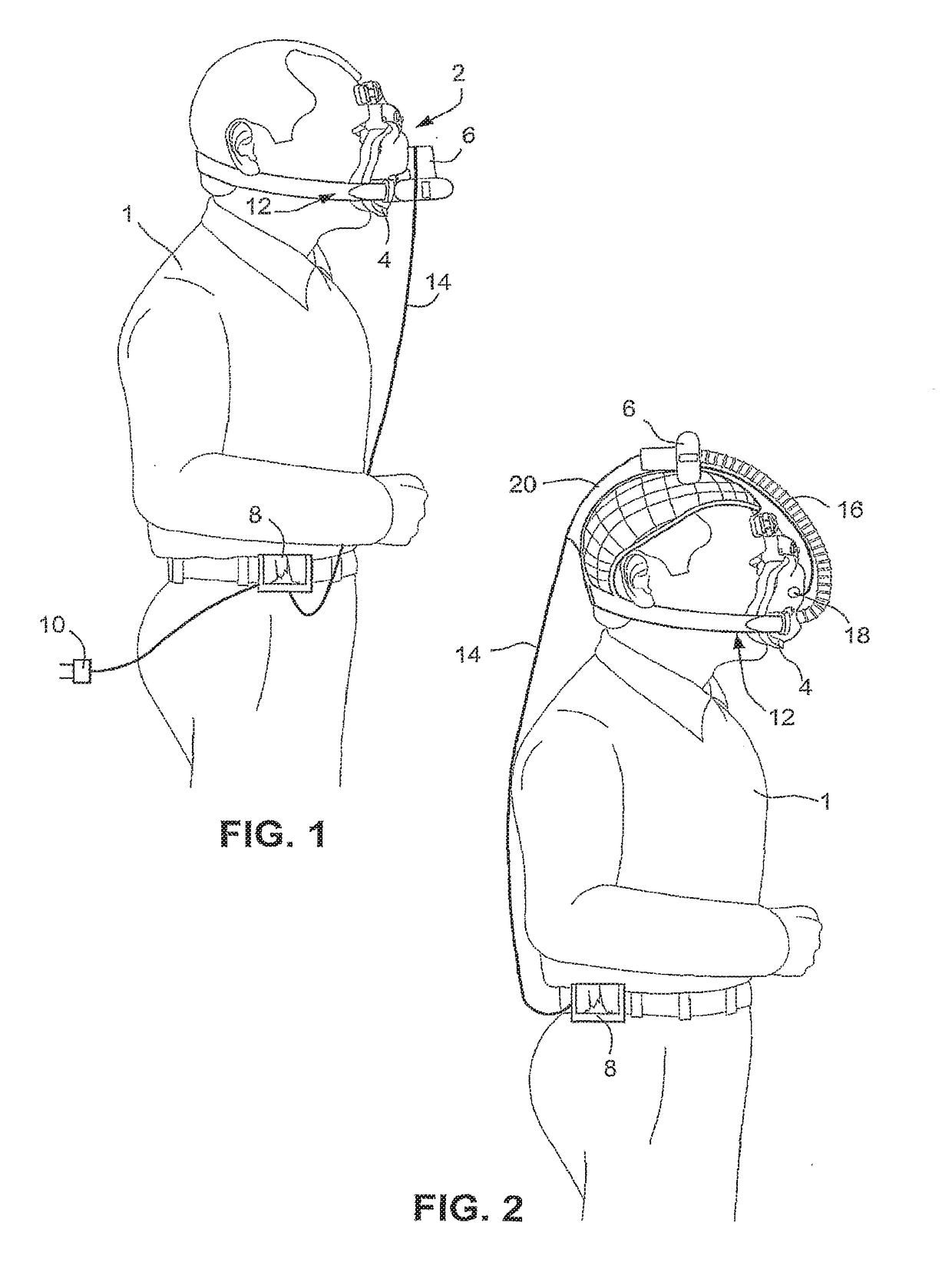

Ventilation mask with integrated piloted exhalation valve and method of ventilating a patient using the same

ActiveUS20120325211A1Preventing patient discomfortAlleviate patient discomfortOperating means/releasing devices for valvesRespiratory masksPositive pressureEngineering

In accordance with the present invention, there is provided a mask for achieving positive pressure mechanical ventilation (inclusive of CPAP, ventilator support, critical care ventilation, emergency applications), and a method for a operating a ventilation system including such mask. The mask of the present invention includes a piloted exhalation valve that is used to achieve the target pressures / flows to the patient. The pilot for the valve may be pneumatic and driven from the gas supply tubing from the ventilator. The pilot may also be a preset pressure derived in the mask, a separate pneumatic line from the ventilator, or an electro-mechanical control. Additionally, the valve can be implemented with a diaphragm or with a flapper.

Owner:BREATHE TECHNOLOGIES INC

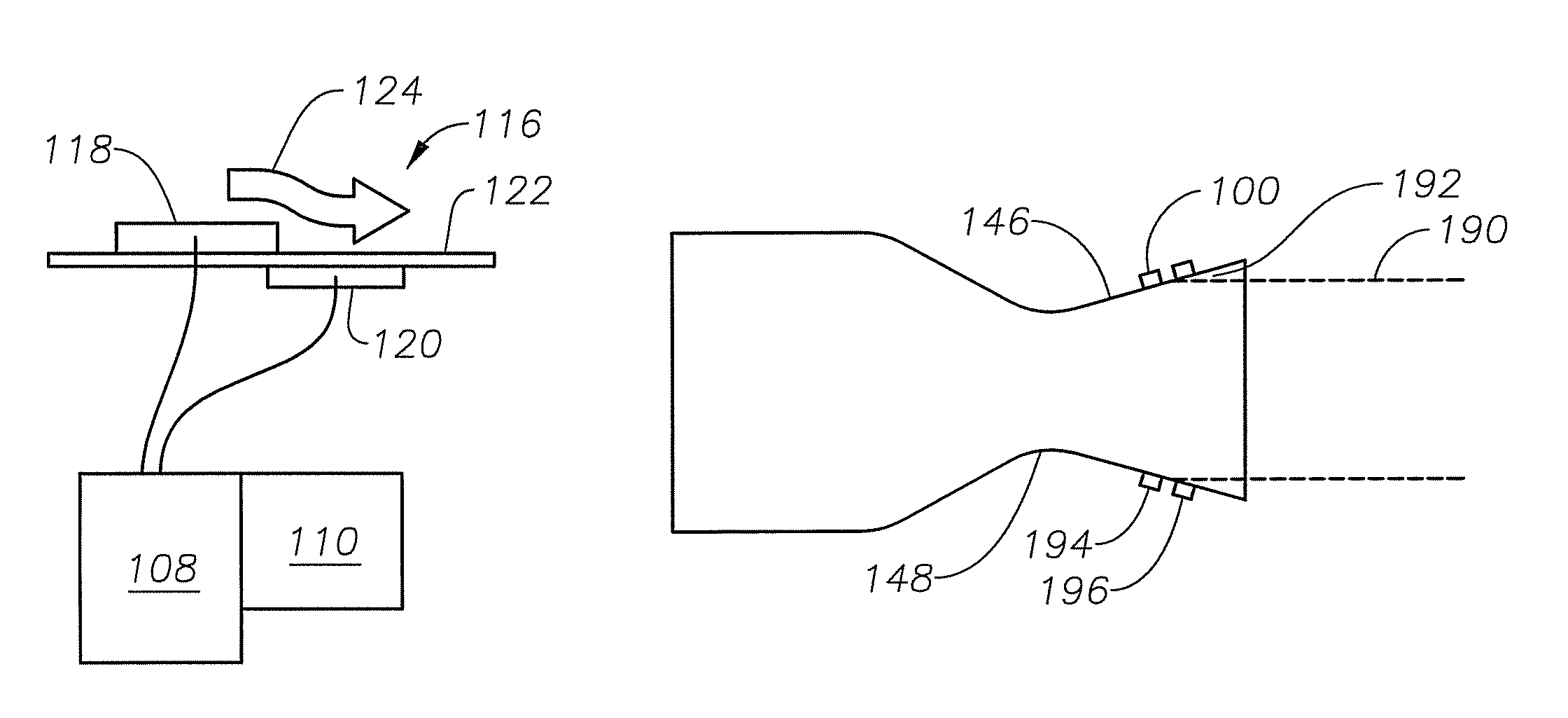

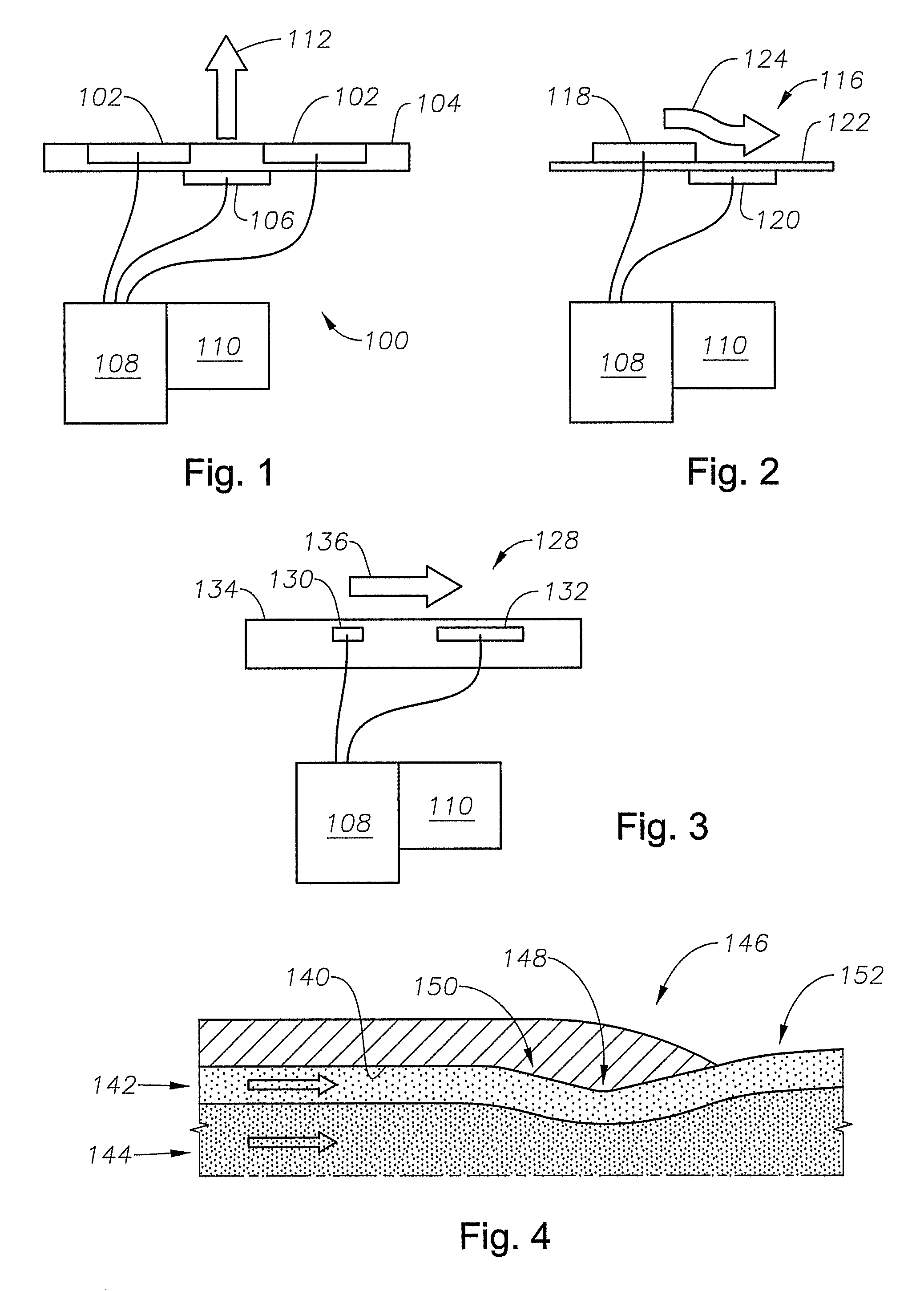

Nozzle plasma flow control utilizing dielectric barrier discharge plasma actuators

InactiveUS8453457B2Reduce gradientReduce the temperatureAircraft navigation controlGas-filled discharge tubesJet enginePlasma actuator

Dielectric barrier discharge plasma actuators are used to manipulate exhaust flow within and behind a jet engine nozzle. The dielectric barrier discharge plasma actuators may be used to direct cooling airflow near the surface of the nozzle to reduce heating of the nozzle, create thrust vectoring, and reduce noise associated with the exhaust flow exiting the nozzle.

Owner:LOCKHEED MARTIN CORP

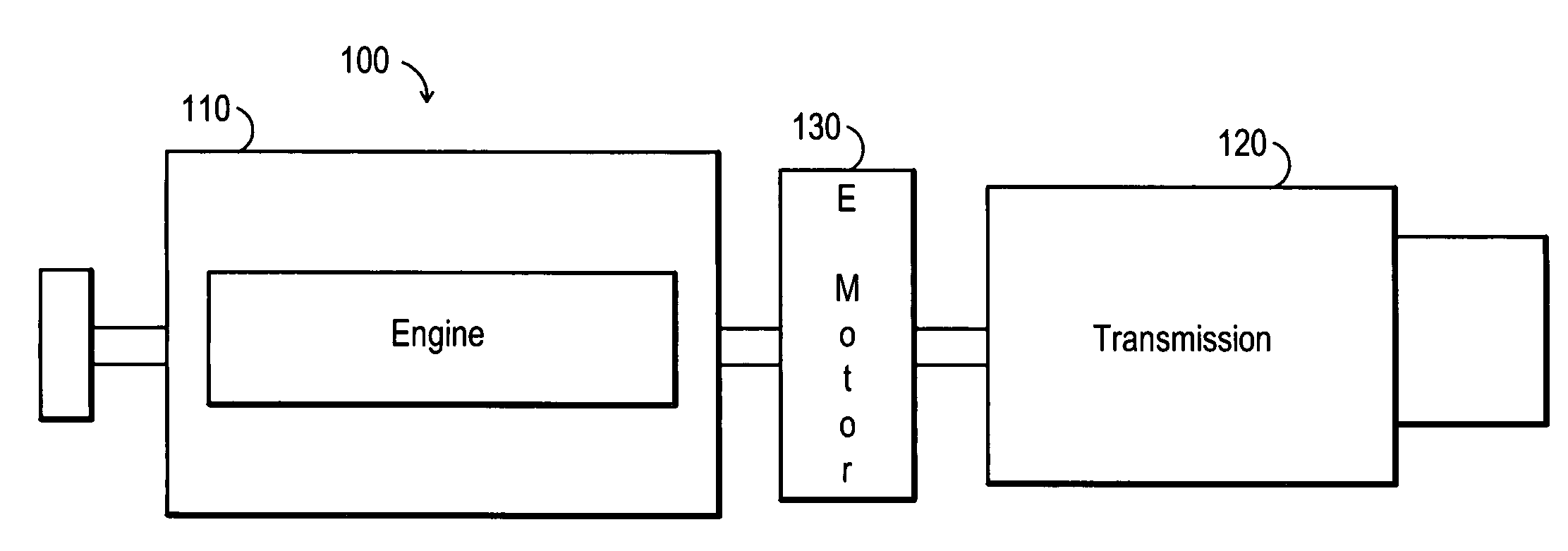

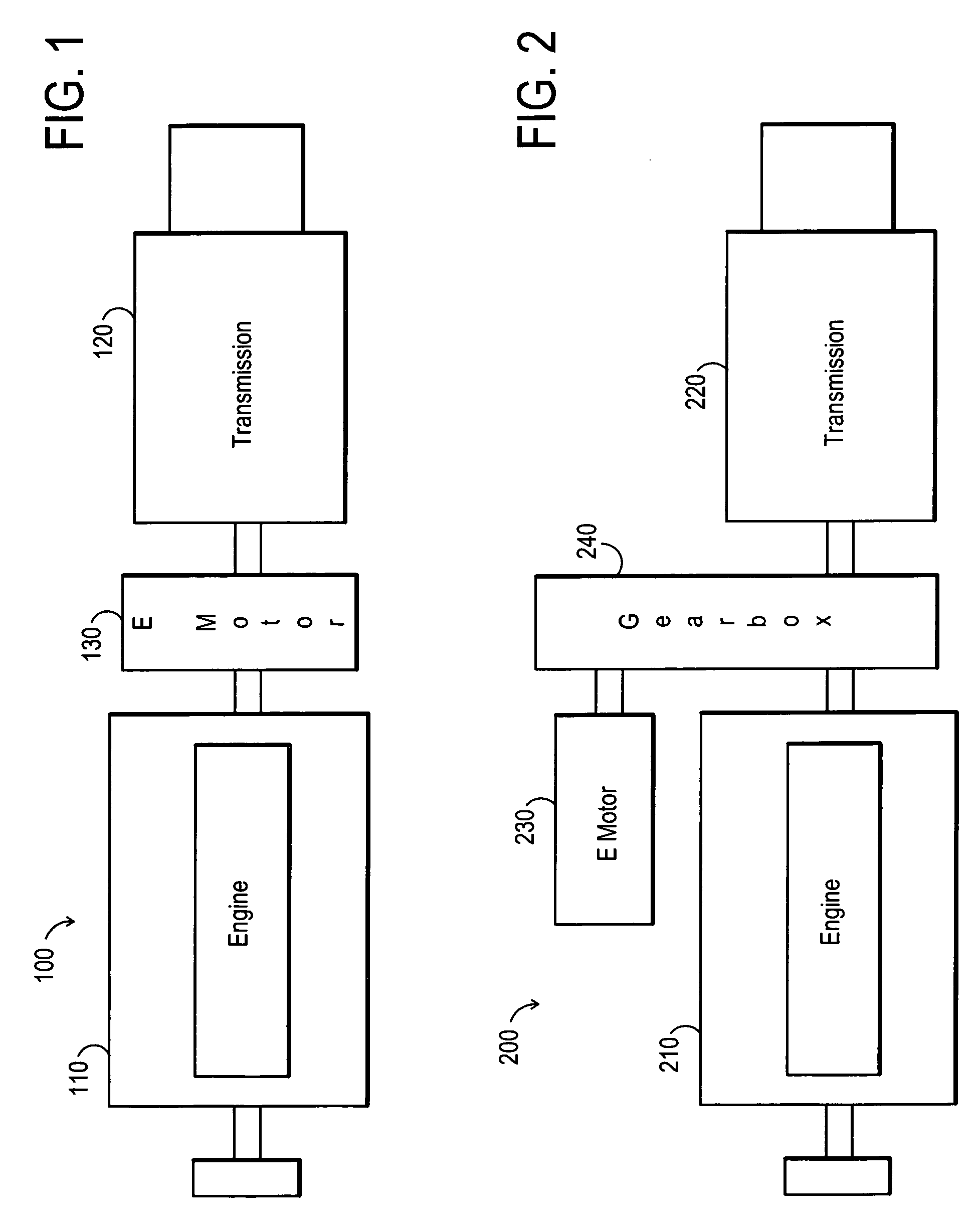

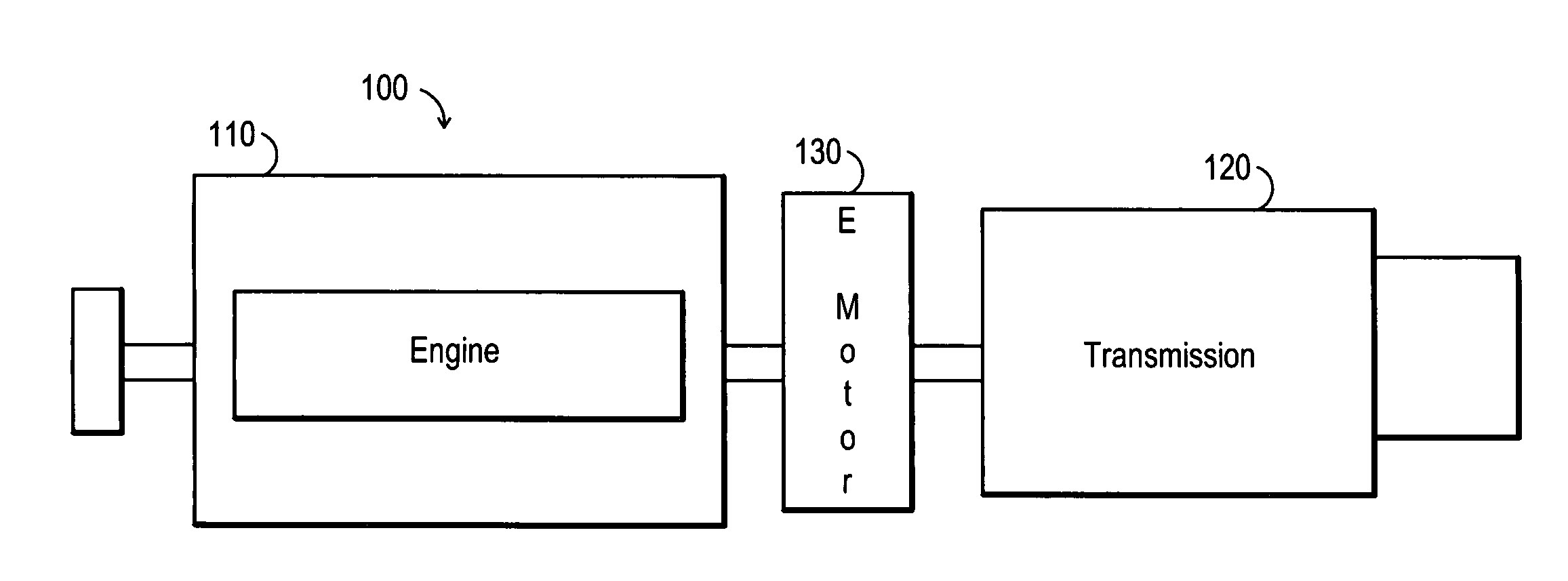

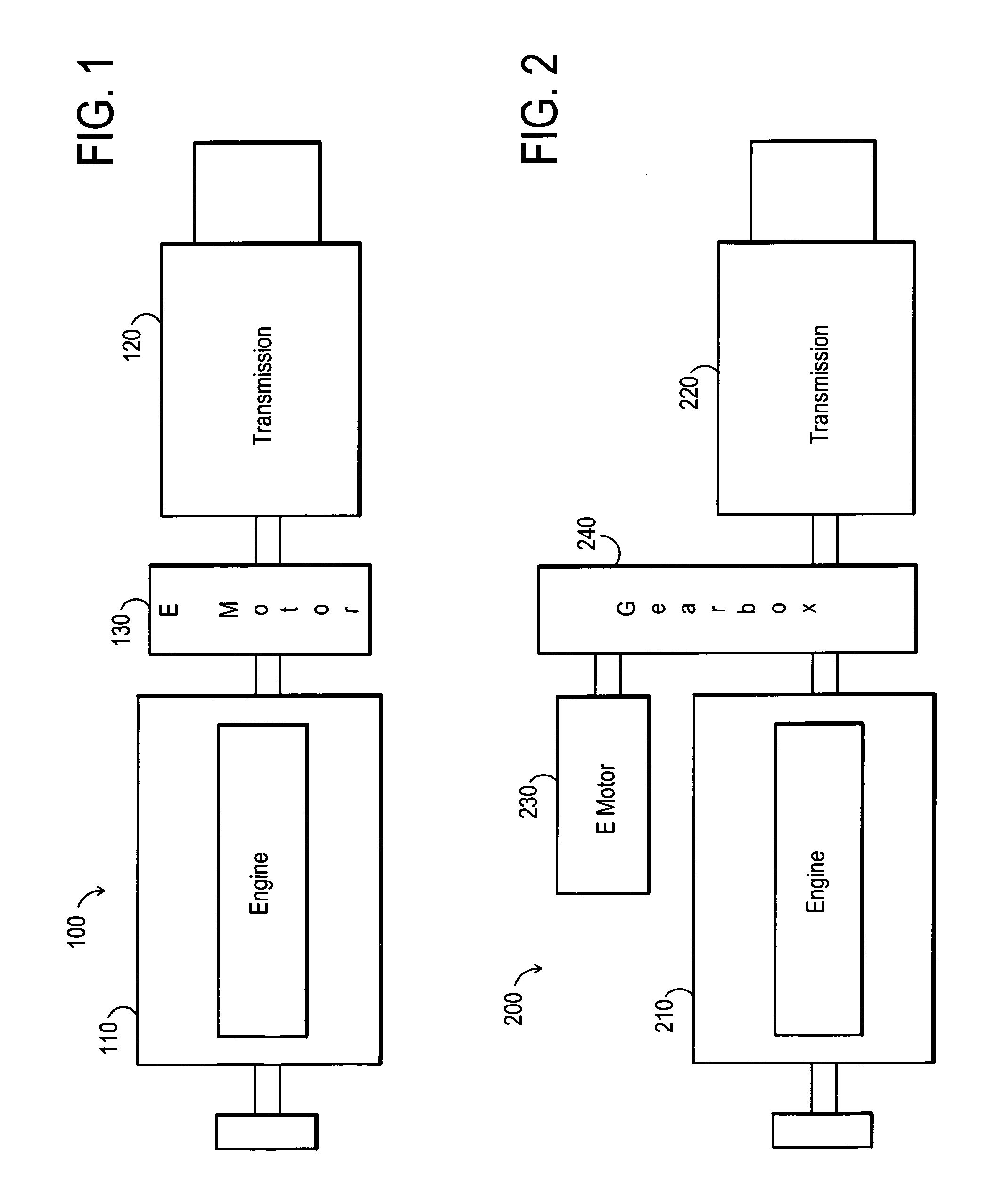

Hybrid technology for lean NOx trap and particulate filter regeneration control

ActiveUS7621120B2Reduce fuel consumptionPromote regenerationAuxillary drivesElectrical controlDiesel particulate filterHybrid power

A method for the use of hybrid technology to control lean NOx trap (LNT) and particulate filter regenerations using an electric motor wherein for the LNT (a) the electric motor is adapted to absorb torque excursions of the engine during regeneration of the LNT, (b) wherein the electric motor is adapted to add torque to thereby reduce the air required in the engine and to thereby reduce the amount of fuel needed to regenerate the LNT, or (c) both (a) and (b), or wherein for the particulate filter the electric motor is (a) adapted to load the engine to thereby increase the exhaust temperature to thereby facilitate regeneration of the particulate filter, (b) adapted to use a power source for the electric motor to power an electrically powered particulate filter regeneration unit to thereby facilitate regeneration of the particulate filter, or (c) both (a) and (b).

Owner:SOUTHWEST RES INST

Hybrid technology for lean NOx trap and particulate filter regeneration control

ActiveUS20070017215A1Minimize impactMaintains driveabilityAuxillary drivesElectrical controlEngineeringDiesel particulate filter

A method for the use of hybrid technology to control lean NOx trap (LNT) and particulate filter regenerations using an electric motor wherein for the LNT (a) the electric motor is adapted to absorb torque excursions of the engine during regeneration of the LNT, (b) wherein the electric motor is adapted to add torque to thereby reduce the air required in the engine and to thereby reduce the amount of fuel needed to regenerate the LNT, or (c) both (a) and (b), or wherein for the particulate filter the electric motor is (a) adapted to load the engine to thereby increase the exhaust temperature to thereby facilitate regeneration of the particulate filter, (b) adapted to use a power source for the electric motor to power an electrically powered particulate filter regeneration unit to thereby facilitate regeneration of the particulate filter, or (c) both (a) and (b).

Owner:SOUTHWEST RES INST

Fuel cell water management

InactiveUS20070284253A1Cost reductionReduce in sizeElectrolysis componentsVolume/mass flow measurementAutomotive engineeringCurrent collector

A polymer electrolyte membrane fuel cell water management device is provided. The device includes a hydrophilic water transport element spanning from inside the fuel cell to outside the fuel cell and disposed between a gas diffusion layer and a current collector layer in the cell. The transport element includes an intermediate wick outside the fuel cell that is hydraulically coupled to the transport element, and has a transport element structure integrated with a flow field structure within the fuel cell. The device further includes an electroosmotic pump, where the pump is located outside the fuel cell and is hydraulically coupled to the intermediate wick. The hydraulically coupled pump actively removes excess water from the flow field structure and the gas diffusion layer through the transport element, where a key aspect of the invention is the decoupling of water removal from oxidant delivery and reduced parasitic loads.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

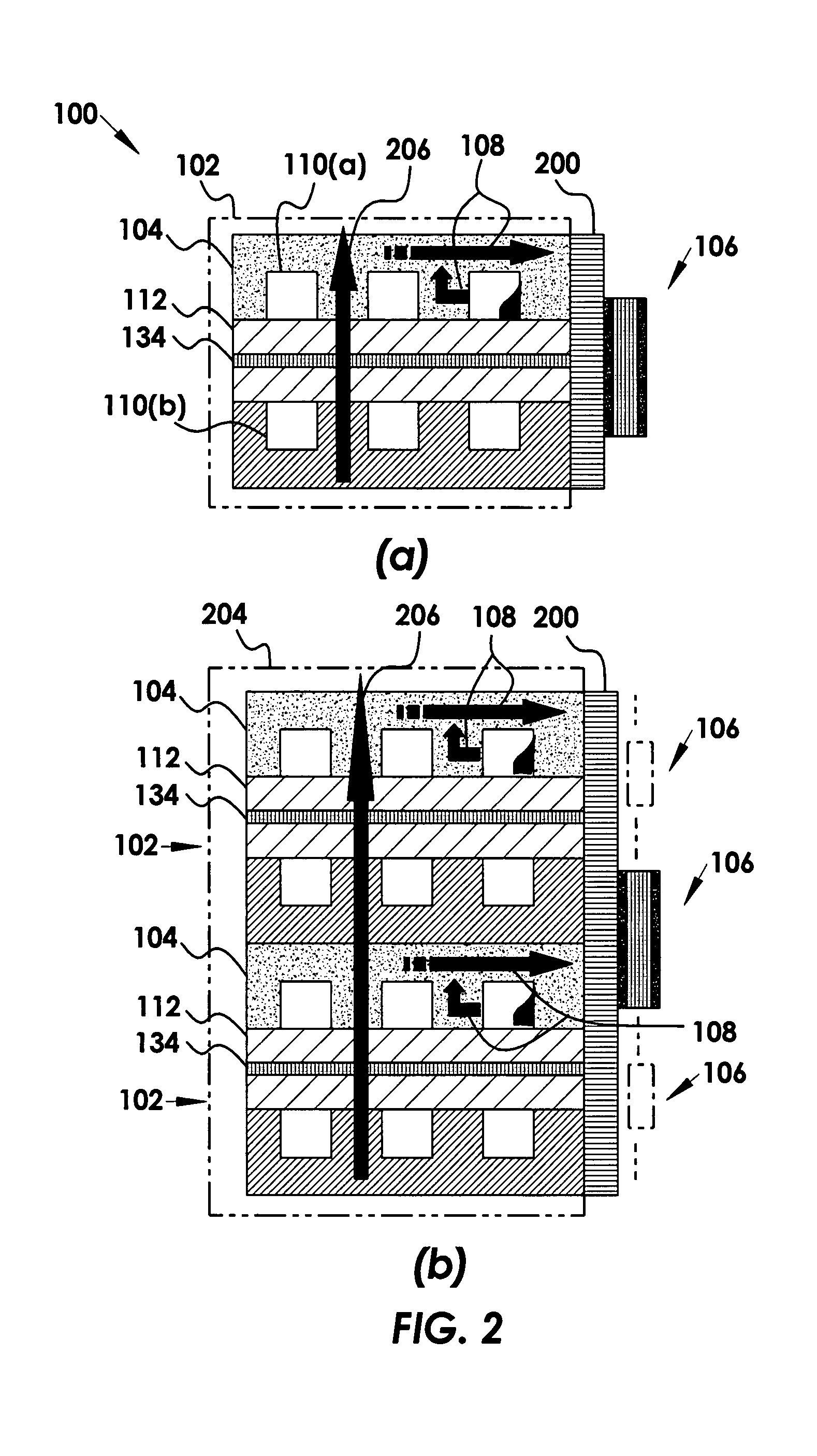

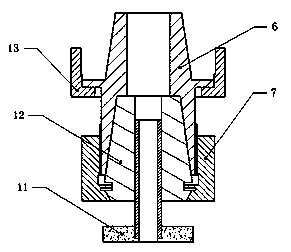

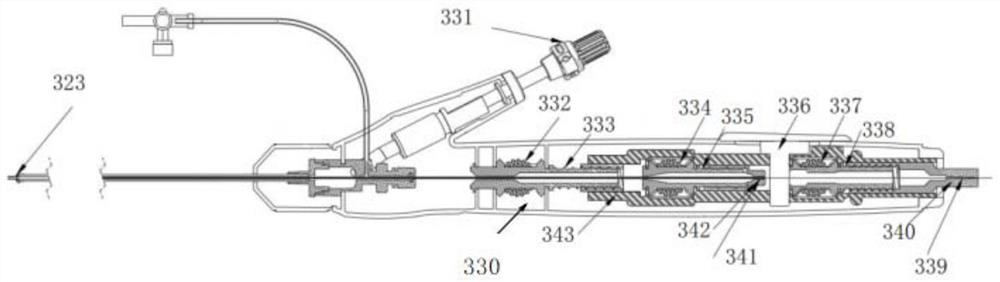

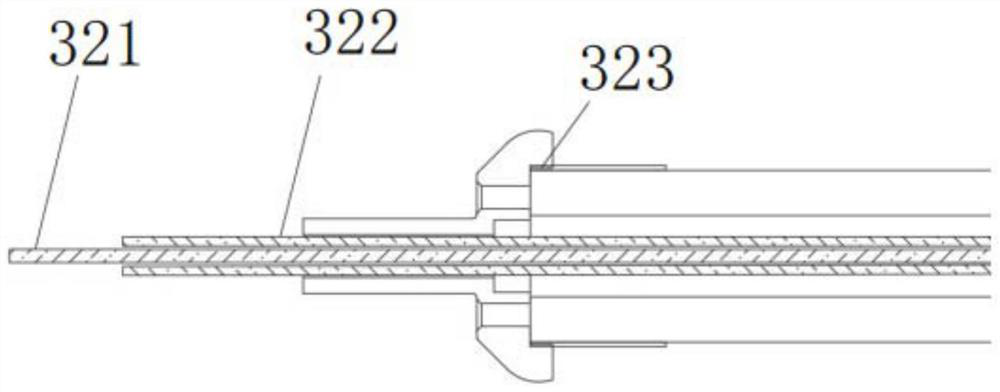

Electrolytic grinding device capable of realizing rotary solution feeding and working method thereof

InactiveCN103447640AReduce pressure requirementsReduce traffic requirementsEngineeringGrinding wheel

The invention provides an electrolytic grinding device capable of realizing rotary solution feeding and a working method thereof. The electrolytic grinding device comprises a motorized spindle stator and a motorized spindle rotor. A blind hole is formed inside the end, extending outside, of the motorized spindle rotor, the lower end of the motorized spindle rotor is connected with a conductive grinding wheel through a clamping device, a plurality of through holes are formed in the radial direction of the motorized spindle rotor, and a first sealing ring and a second sealing ring are arranged above and below the through holes respectively for sealing the same. An outer cover is arranged on the outer side of the motorized spindle rotor, and middle holes are formed in positions, corresponding to the through holes, of the outer cover. A first bearing and a second bearing are arranged between the motorized spindle rotor and the outer cover. An electrolyte solution passes through the middle holes of the outer cover, enters the inside blind hole from the through holes of the end, extending outside, of the motorized spindle rotor, and then passes a center hole of the clamping device to outflow around from clearances of the conductive grinding wheel and a workpiece. The electrolytic grinding device is low in requirement on pressure and flow of the electrolyte solution, good in solution feeding effect, and particularly suitable for electrolytic grinding of workpieces such as inner holes and inner cavities in special geometrical shapes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

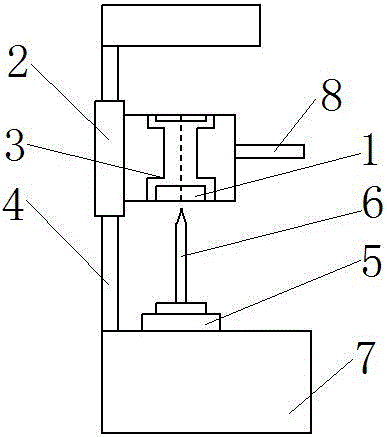

Inverted type drilling machine and operating method for machining fine drill holes

InactiveCN106077734AAvoid the effects of skewnessImprove distributionBoring/drilling componentsBoring/drilling machinesEngineeringDrill line

The invention relates to the field of machining devices, in particular to an inverted type drilling machine and an operating method for machining fine drill holes. The inverted type drilling machine comprises a base, a stand column, a feed supporting plate, a guide sleeve, a drill rod box and a drilling tool. A cooling hole of the drilling tool is a through hole. The cooling hole of the drilling tool and an inner hole of the drill rod box are located on the same center line during installation. A motor used for driving the drill rod box to rotate is arranged in the base. The inverted type drilling machine and the operating method for machining fine drill holes have the beneficial effects that the drilling tool is perpendicularly installed on the drill rod box, the direction of the gravity of the drilling tool coincides with the direction of a drill hole, the situation that deflection of the drill hole is caused under the effect of the gravity of a drill bit is avoided, and the machining precision can be improved easily; and the drilling tool is perpendicularly installed on the drill rod box, scrap iron generated in the drilling process can automatically fall to be discharged from a V-shaped groove of the drill bit under the effect of self weight, the requirements for the oil supply pressure and flow of a cooling system are lowered correspondingly, heat dissipation in the drilling process is facilitated, and energy can be saved easily.

Owner:黄大勇

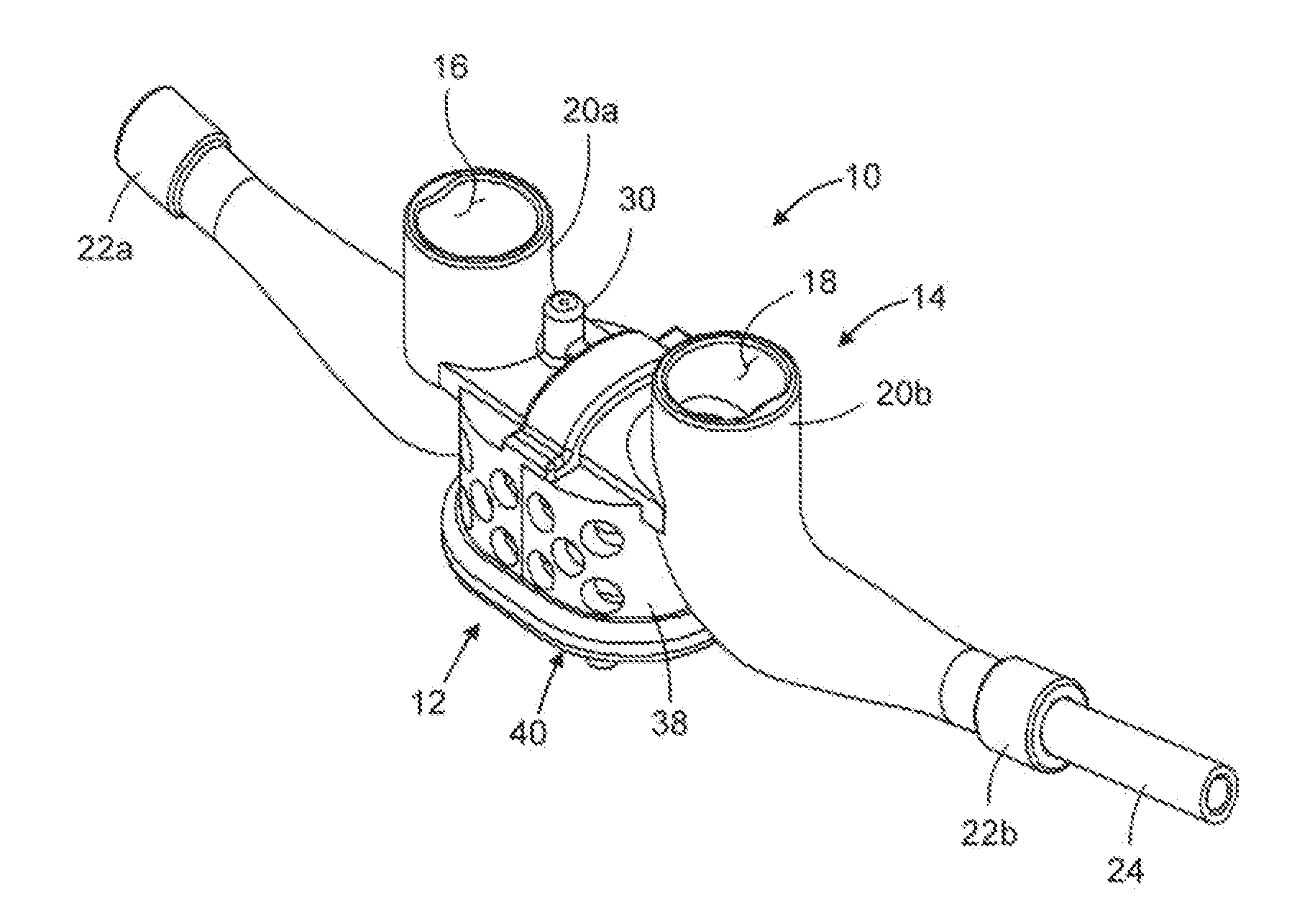

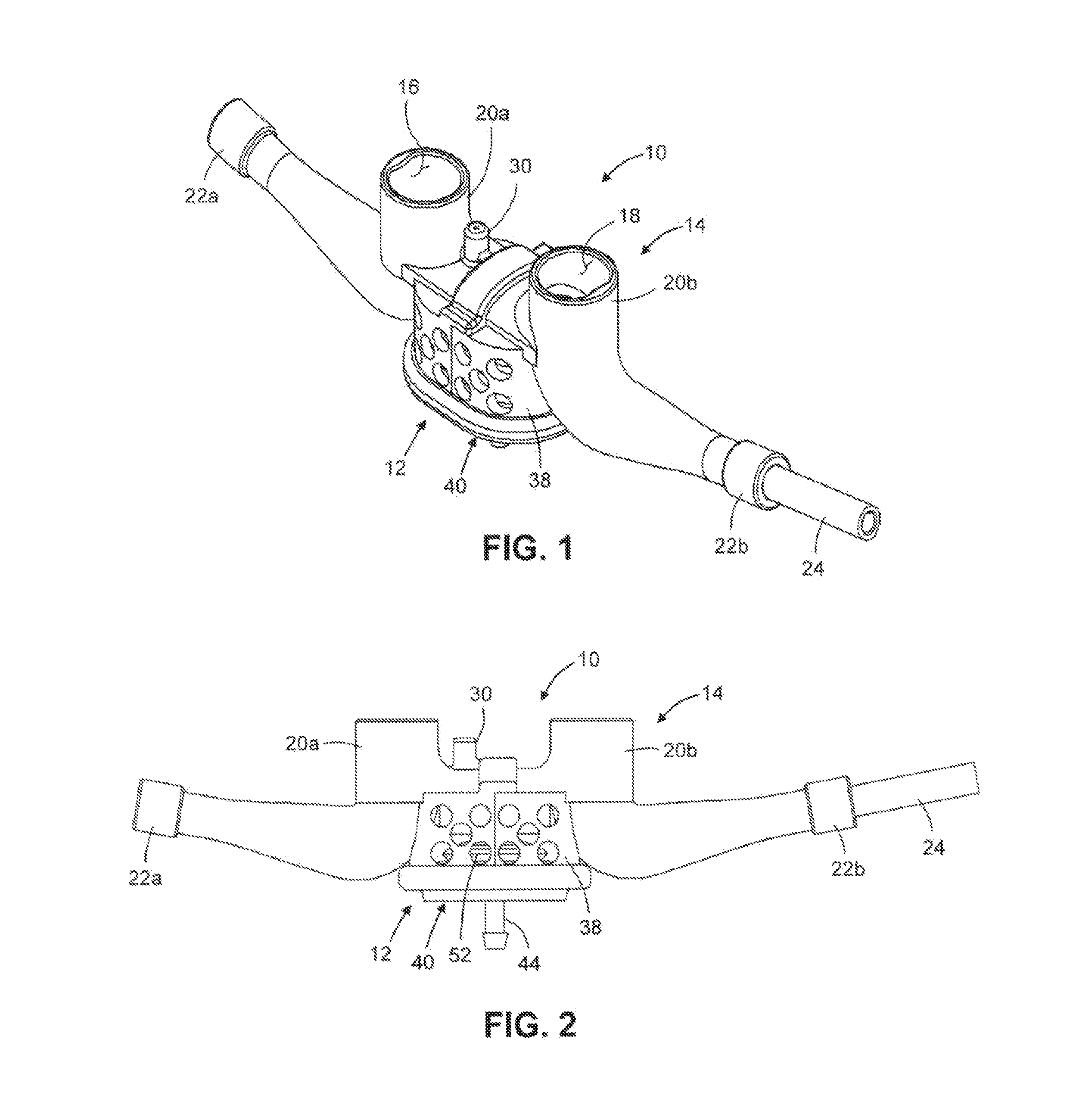

Ventilation mask with integrated piloted exhalation valve and method of ventilating a patient using the same

ActiveUS20120330183A1Prevent discomfortReduce noise generateRespiratory masksBreathing masksExhalationTraffic volume

In accordance with the present invention, there is provided a mask for achieving positive pressure mechanical ventilation (inclusive of CPAP, ventilator support, critical care ventilation, emergency applications), and a method for a operating a ventilation system including such mask. The mask of the present invention includes a piloted exhalation valve that is used to achieve the target pressures / flows to the patient. The pilot for the valve may be pneumatic and driven from the gas supply tubing from the ventilator. The pilot may also be a preset pressure derived in the mask, a separate pneumatic line from the ventilator, or an electro-mechanical control. Additionally, the valve can be implemented with a diaphragm or with a flapper.

Owner:BREATHE TECHNOLOGIES INC

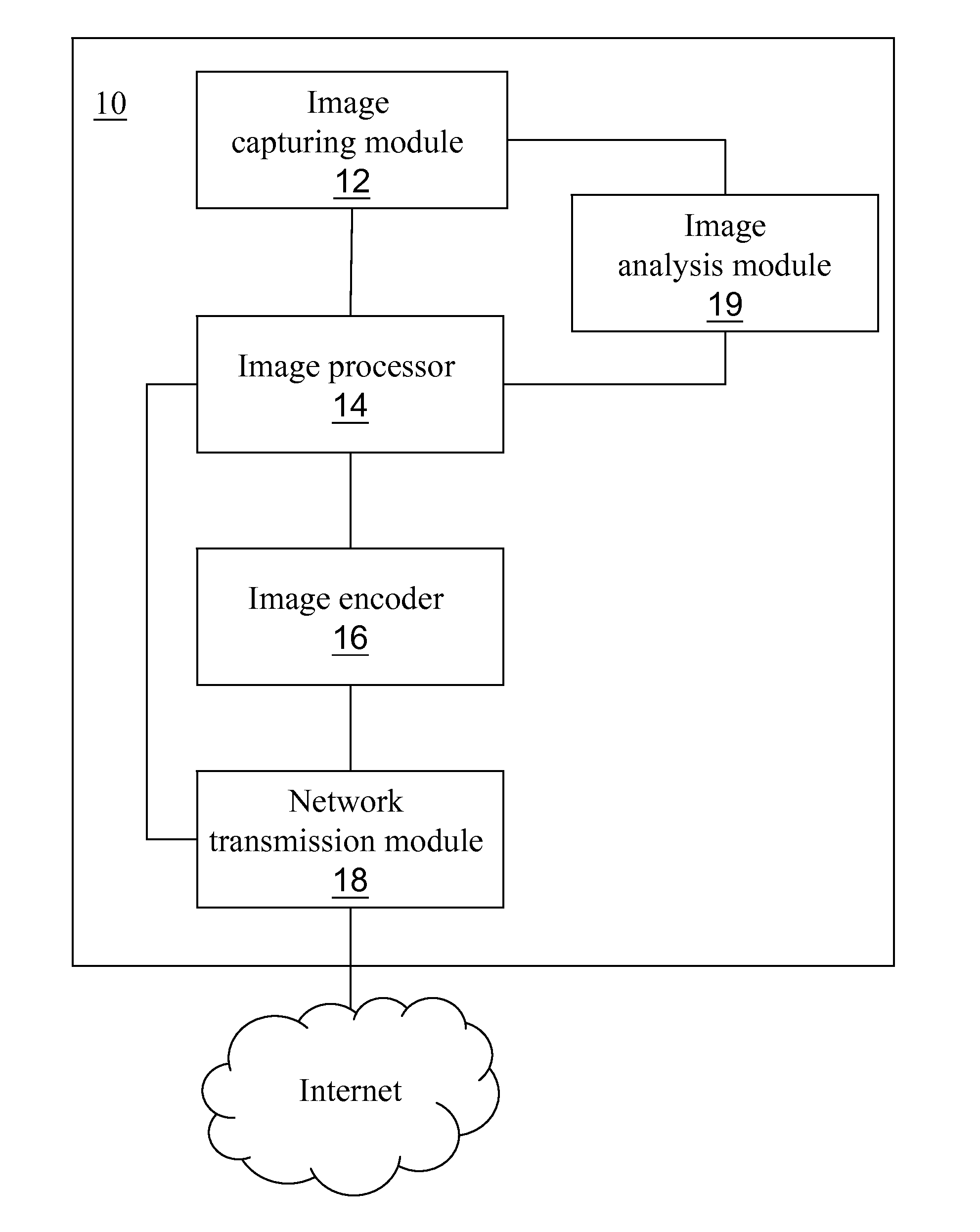

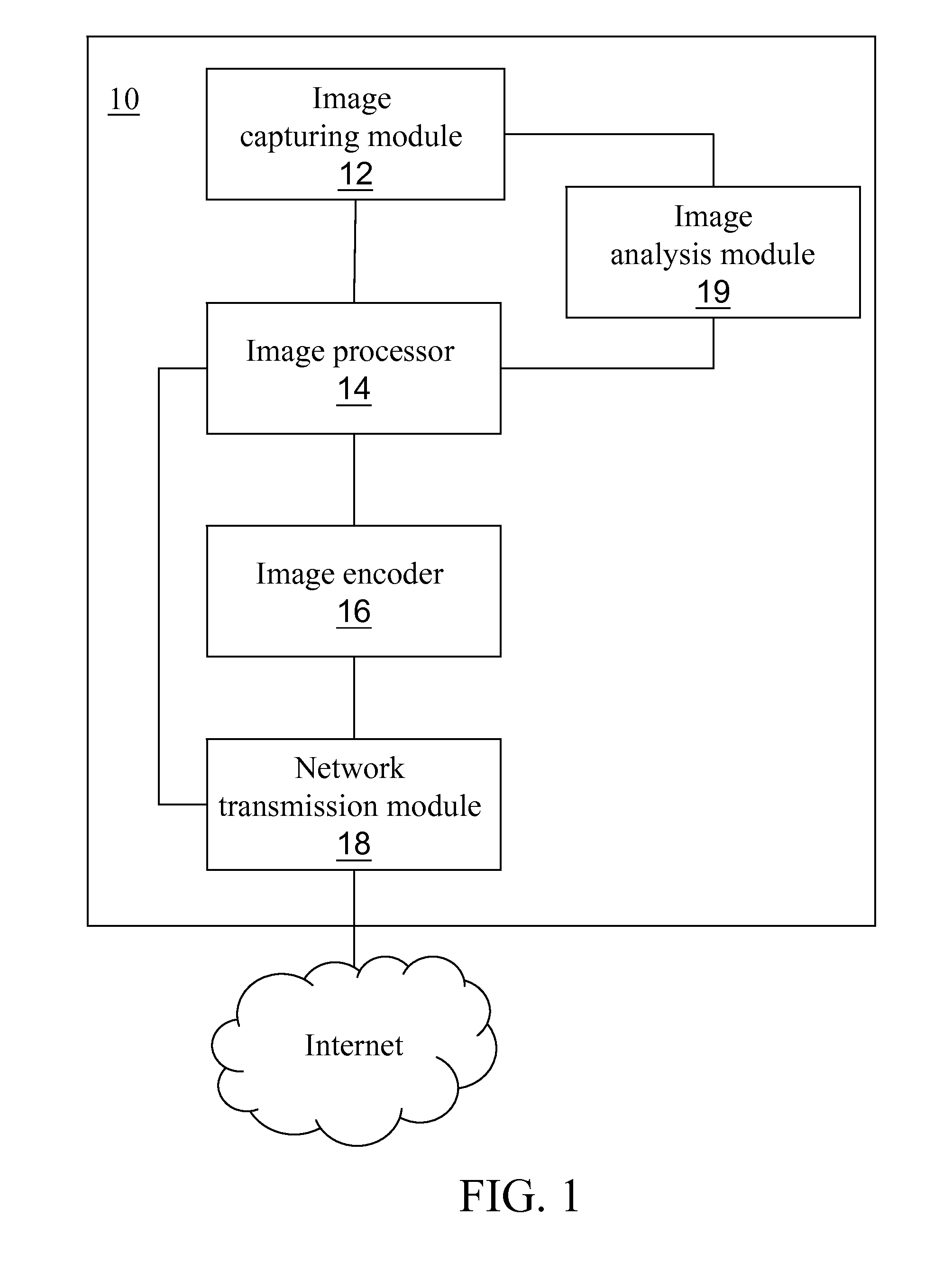

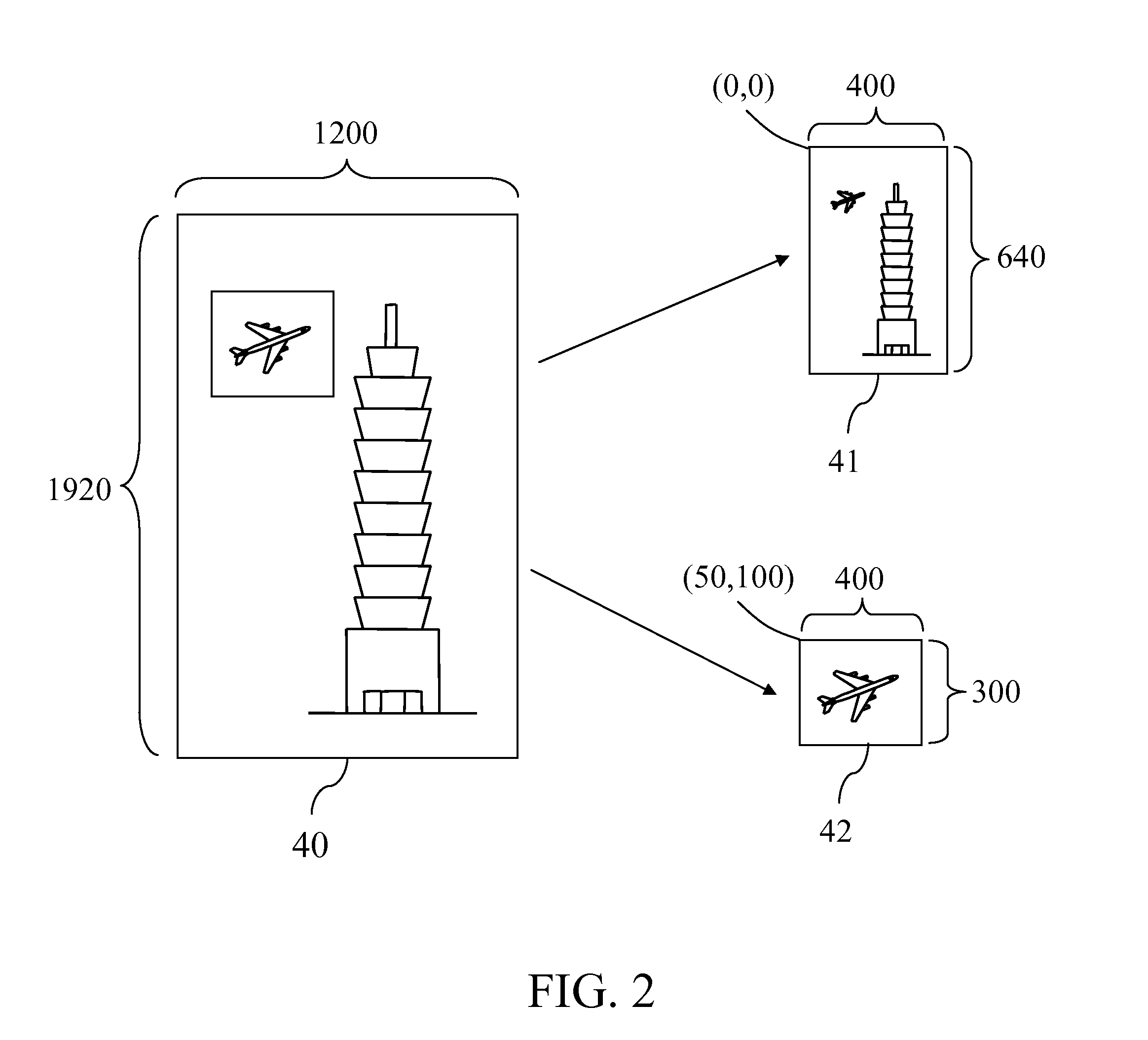

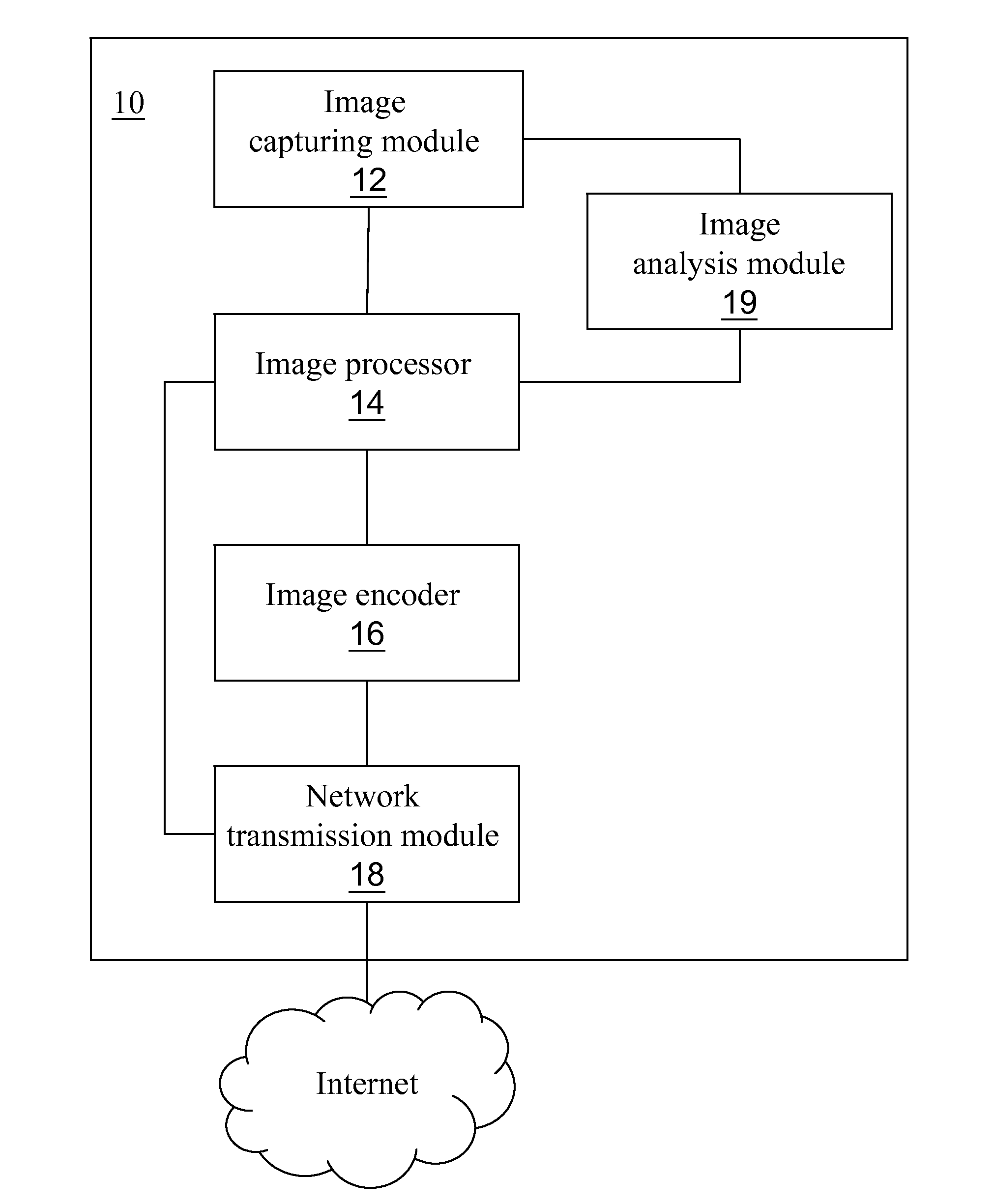

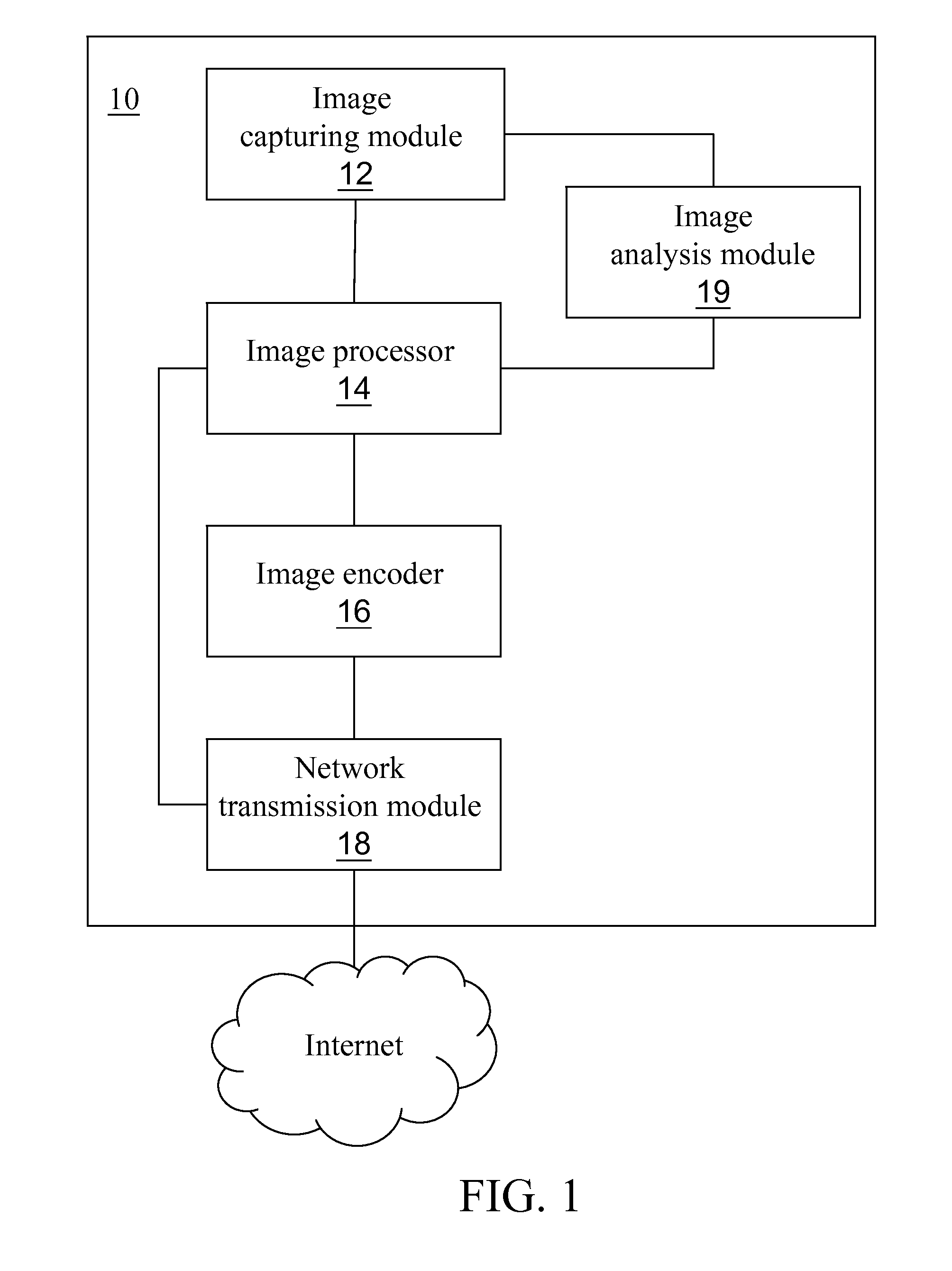

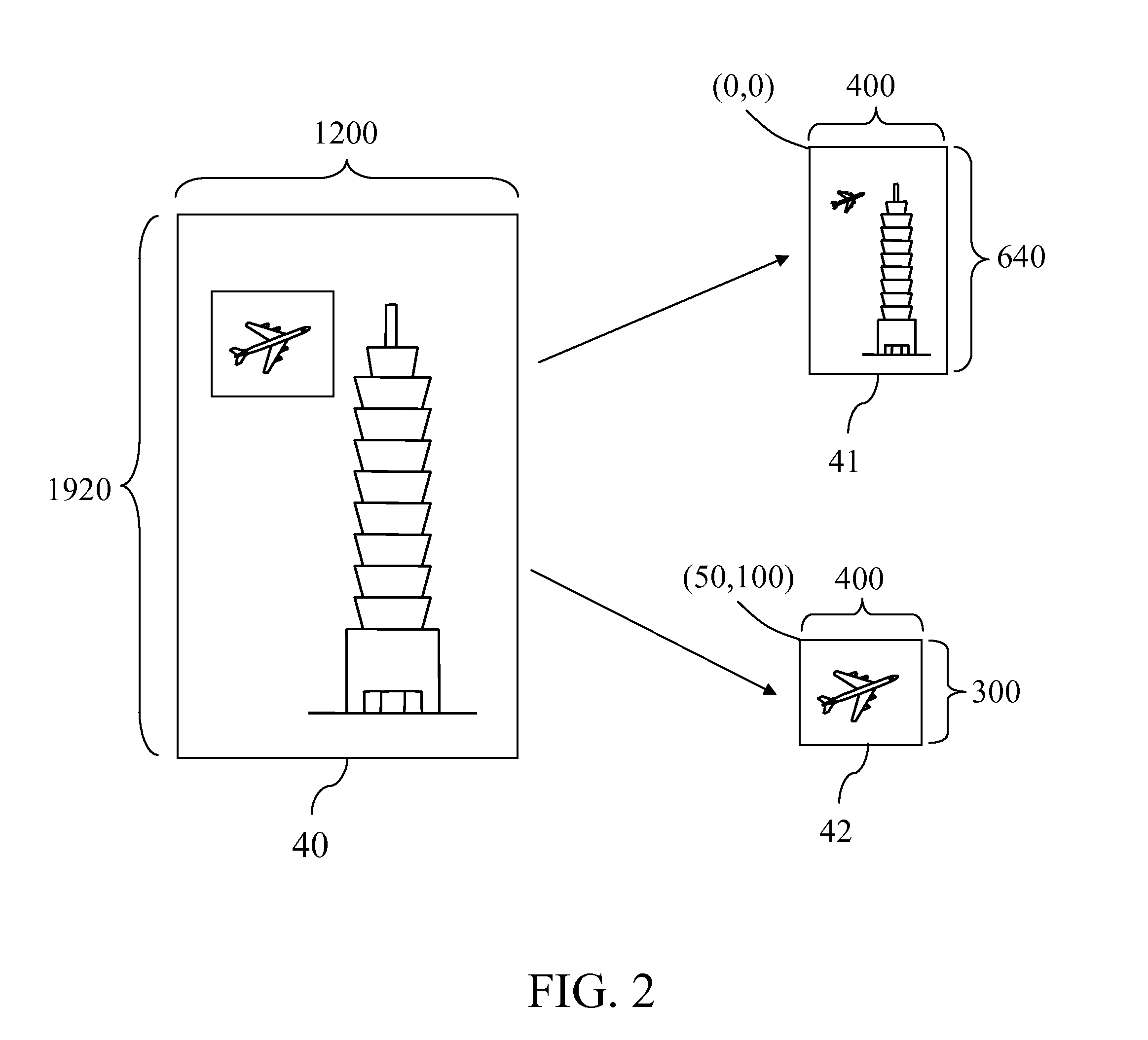

Image capturing and transmission device and image receiving and reconstruction device

ActiveUS8208555B2Reduce traffic requirementsReduce traffic problemsTelevision system detailsPicture reproducers using cathode ray tubesRatio valueImaging data

Owner:VIVOTEK INC

Ventilation Mask with Integrated Piloted Exhalation Valve And Method of Ventilating a Patient Using the Same

ActiveUS20130255684A2Alleviate patient discomfortReduce noiseOperating means/releasing devices for valvesRespiratory masksExpiratory valveIntensive care

In accordance with the present invention, there is provided a mask for achieving positive pressure mechanical ventilation (inclusive of CPAP, ventilator support, critical care ventilation, emergency applications), and a method for a operating a ventilation system including such mask. The mask of the present invention includes a piloted exhalation valve that is used to achieve the target pressures / flows to the patient. The pilot for the valve may be pneumatic and driven from the gas supply tubing from the ventilator. The pilot may also be a preset pressure derived in the mask, a separate pneumatic line from the ventilator, or an electro-mechanical control. Additionally, the valve can be implemented with a diaphragm or with a flapper.

Owner:BREATHE TECHNOLOGIES INC

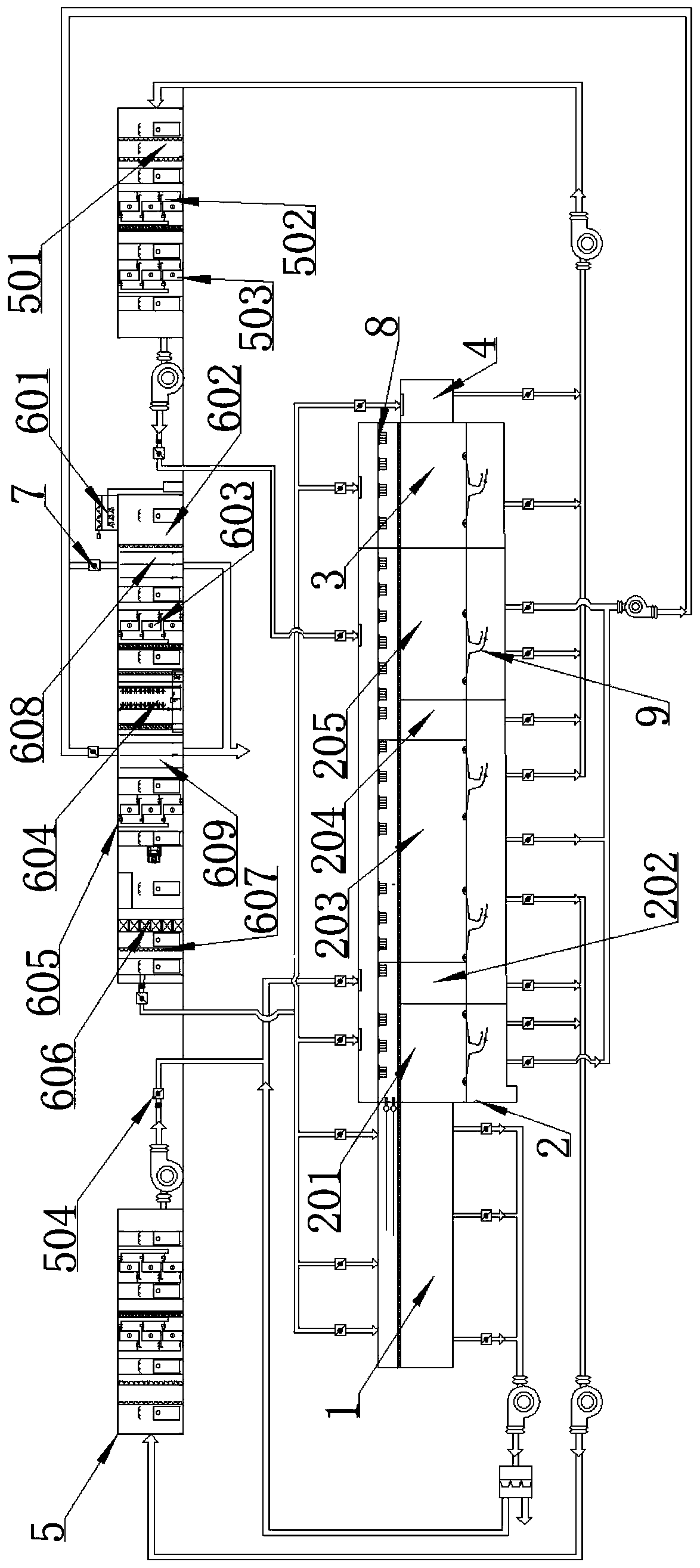

Energy conservation and emission reduction circulating air system of spraying chamber

PendingCN109865629AReduce traffic requirementsReduce energy consumptionSpray boothsFresh airEnergy consumption

The invention discloses an energy conservation and emission reduction circulating air system of a spraying chamber. The energy conservation and emission reduction circulating air system comprises a spraying production line, a circulating system and a fresh air system, wherein the spraying production line comprises a manual pretreatment section, a machine spraying section, an inspection section anda leveling section; a part of exhaust air of the machine spraying section, exhaust air of the inspection section, and exhaust air of the leveling section enter an inlet of the circulating system andare exhausted into the machine spraying section after exhaust air is filtered by the circulating system and temperature and humidity are adjusted; the other part of exhaust air of the machine sprayingsection is exhausted after follow-up treatment; exhaust air of the manual pretreatment section is directly exhausted to the machine spraying section; and the fresh air system sucks external fresh air, and external fresh air is exhausted to the manual pretreatment section, the machine spraying section, the inspection section and the leveling section after external fresh air is filtered and temperature and humidity are adjusted. According to the energy conservation and emission reduction circulating air system, the utilization rate of exhaust air of the spraying chamber can be effectively increased, energy consumption is greatly reduced, and energy conservation and emission reduction are achieved.

Owner:扬州琼花涂装工程技术有限公司

Image capturing and transmission device and image receiving and reconstruction device

ActiveUS20110134993A1Reduce traffic requirementsReduce traffic problemsTelevision system detailsPicture reproducers using cathode ray tubesImaging dataImage capture

An image capturing and transmission device includes an image capturing module, an image processor, an image encoder, and a network transmission module. The image capturing module is used for capturing a scene of an area to be displayed and outputting image data. The image processor converts the image data according to a first and a second cutting areas and a first and a second shrink ratio values, and outputs a first and a second sub-images. The first cutting area includes the second cutting area, and the first shrink ratio value is greater than the second shrink ratio value. The image encoder encodes the first and the second sub-images according to first and second encoding information, and outputs a first and a second streaming images. The network transmission module is used for transmitting the first and the second streaming images.

Owner:VIVOTEK INC

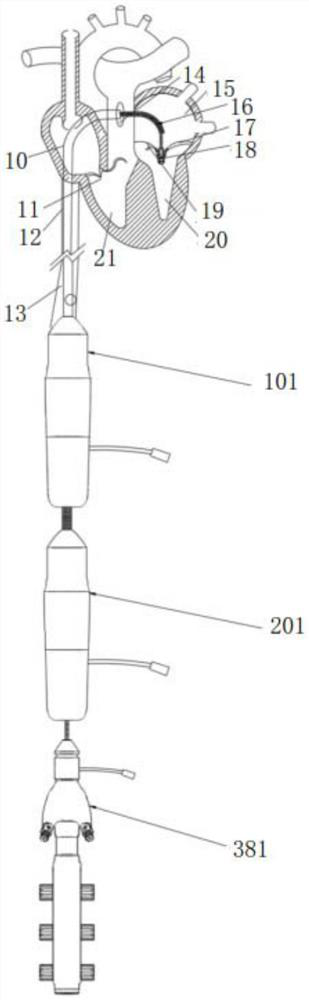

Medical device implantation unit

The invention discloses a medical device implantation unit which comprises a state control module used for adjusting the position of a moving element so as to control the working state of a medical device; the stay wire control module is used for pulling a stay wire to adjust the angle of an upper clamping piece of the medical instrument; the stay wire control module comprises an integrated stay wire element, and the integrated stay wire element comprises a sheath tube and a stay wire tube; wherein the stay wire tube extends out of the end portion of the sheath tube and extends along the axis of the sheath tube, the sheath tube and the stay wire tube are integrally formed, an inner hole of the stay wire tube is axially communicated with a first inner hole of the sheath tube, and the stay wire is arranged in the inner hole in a penetrating mode. According to the invention, an integrated stay wire element design scheme is adopted, i.e., the sheath tube and the stay wire tube are integrally manufactured, so that a gap caused by a fixed connection process between the sheath tube and the stay wire tube is effectively avoided, the problem of leakage of gas in an emptying process is finally avoided, air in an instrument can be efficiently and conveniently exhausted, the risk of gas embolism is eliminated, and the safety of the instrument is improved. And the gas discharge speed is accelerated.

Owner:SHANGHAI HUIHE HEALTHCARE TECH CO LTD

Mask and flow generator system

InactiveUS20180236197A1Reduction in functional dead spaceImprove the fit rangeRespiratory masksMedical devicesIntensive care medicineStreamflow

Owner:RESMED LTD

Hydraulic system for loading test

InactiveCN107605837AEasy to change loadEasy to controlServomotor componentsFluid-pressure actuator componentsTest performanceFuel tank

The invention discloses a hydraulic system for a loading test. The hydraulic system for the loading test comprises a motor, an oil feeding unit, a load ratio unit, a low-pressure cooling unit and an oil tank. The hydraulic system is easy to change the load, easy to control, stable in test performance, excellent in generality and low in investment cost.

Owner:柳州北斗星液压科技有限公司

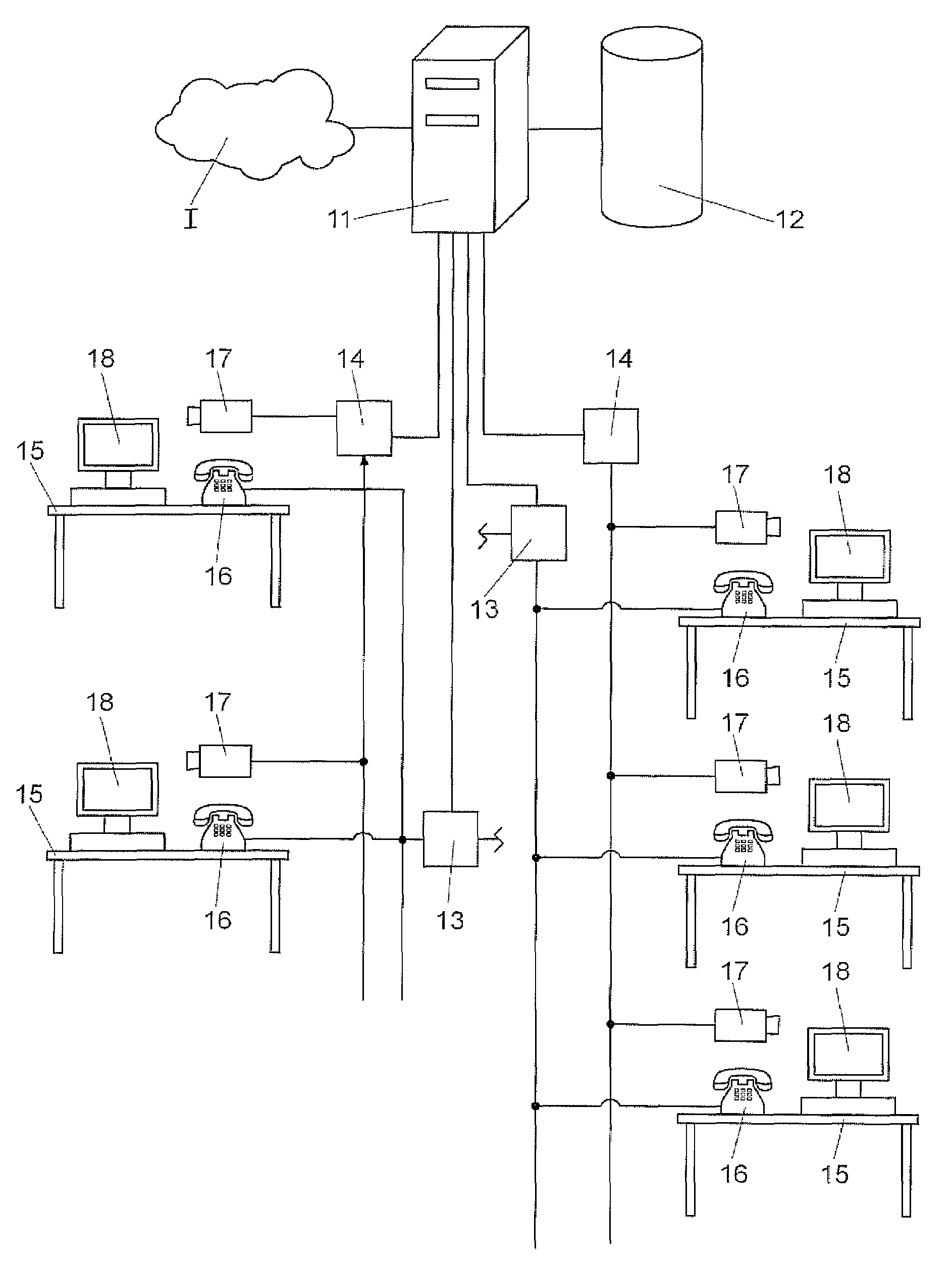

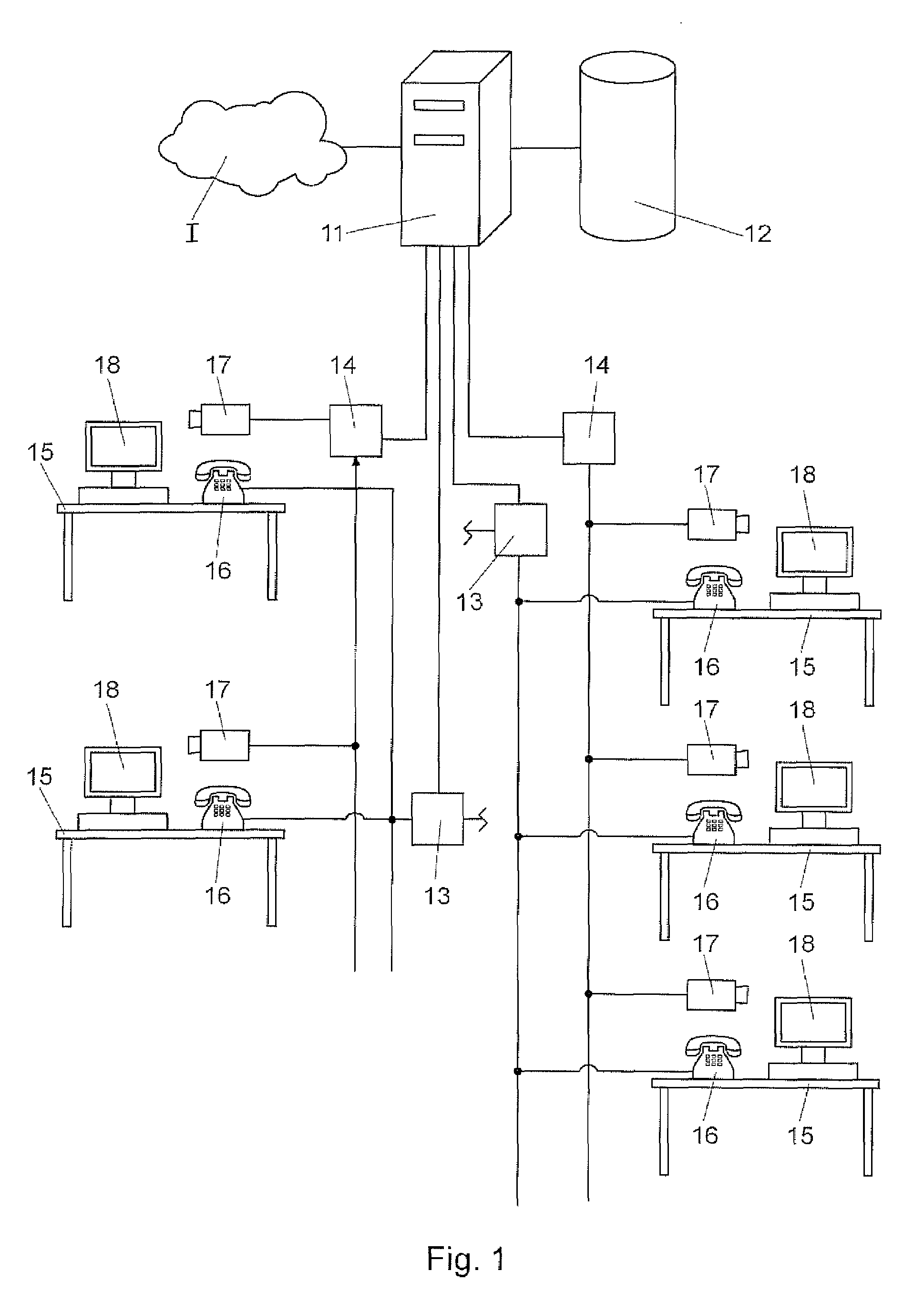

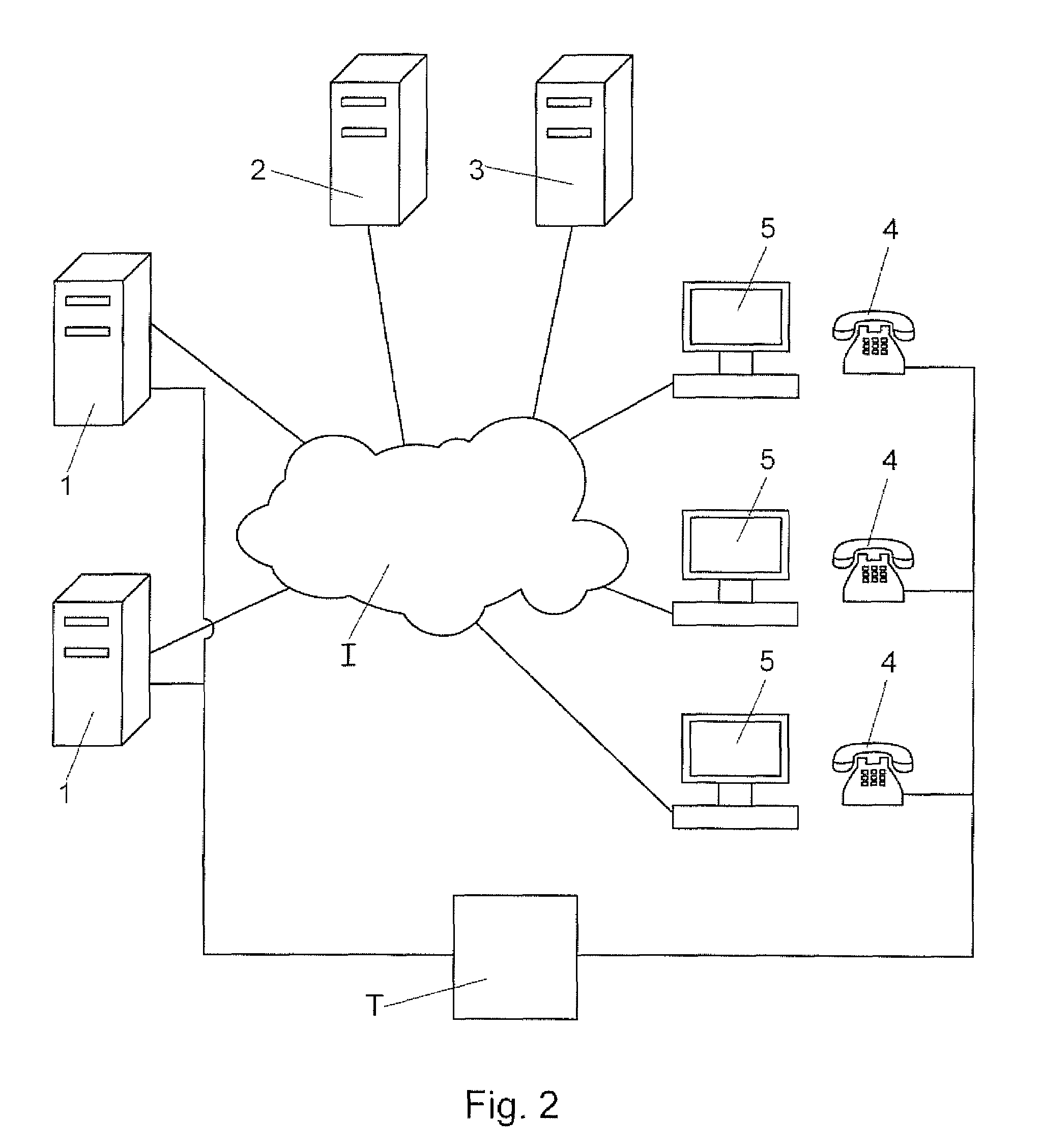

System and procedure for call centre communications

ActiveUS20100277564A1Improve communication qualityReduce bandwidth requirementsClosed circuit television systemsAutomatic exchangesWeb serviceTelephone terminal

System that includes a web server (2) enabling the user to access, from a remote computer (5), several nodes (1) that include a primary node server (11), which is connected to: —a management database (12); —at least one PABX (13), —at least one video server (14); —and a number of representative rooms (15), where there is a telephone terminal (16) connected to one of the PABXs (13) and a webcam (17) or video camera connected to one of the video servers (14), enabling two-way voice transmission between the representative and the user, by means of telephone communication through the telephone terminal (16) and the telephone (4), and one-way transmission of video images from the webcam (17) to the user's remote computer (5).

Owner:WHISBI TECH

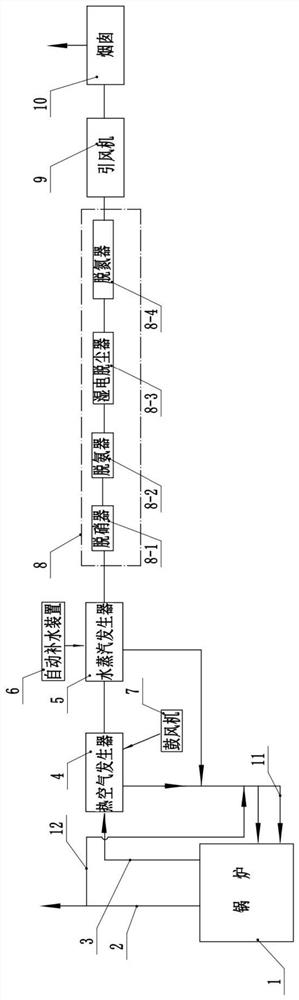

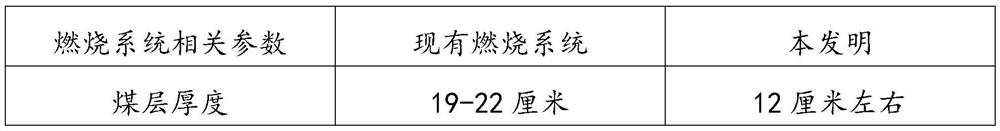

Coal fired boiler novel combustion system

InactiveCN111780151AIncrease contentIncrease oxygen contentEmission preventionDispersed particle separationAir blowerHeat consumption

The invention relates to a coal fired boiler novel combustion system. The coal fired boiler novel combustion system comprises a boiler and further comprises a steam outlet pipe and a flue which are connected with the boiler. The flue is connected with a chimney, and a pipeline between the flue and the chimney is provided with a hot air generator, a water steam generator, an air blower, a smoke treatment device and an induced draft fan. The hot air generator is connected with the air blower and an air inlet pipe of the boiler. The water steam generator is connected with the air inlet pipe of the boiler. The pipeline between the flue and the chimney is provided with the water steam generator, waste heat of smoke is utilized for converting water into the steam state from the liquid state, thewater steam is connected with the air inlet pipe of the boiler, and accordingly, the content of water steam in the boiler is increased. The water steam is used for adsorbing oxygen molecules in air,the oxygen content in the boiler is increased, sufficient combustion of fuel is guaranteed, accordingly, the oxygen content in smoke is reduced, and energy is saved; and waste heat of the smoke is utilized for heating air entering the boiler, and heat consumption of the boiler is reduced.

Owner:王苗苗

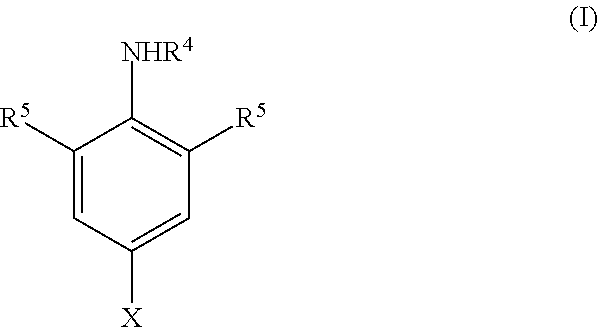

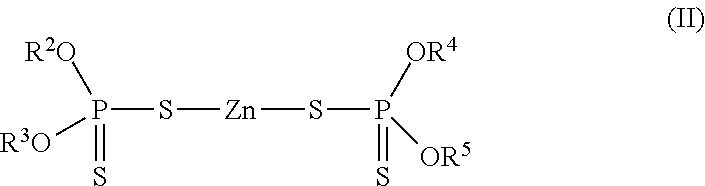

Use of a lubricating composition

InactiveUS20180037838A1Reduce traffic requirementsReducing brake specific fuel consumptionInternal combustion piston enginesAdditivesEngineeringBase oil

The present invention relates to a method for advancing the spark timing of a spark-ignited internal combustion engine, the method comprising lubricating the spark-ignited internal combustion engine with a lubricating composition comprising base oil and an anti-knock additive, wherein the anti-knock additive is an aromatic amine.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com