Use of a lubricating composition

a technology of lubricating composition and composition, which is applied in the direction of lubricant composition, additives, combustion engines, etc., can solve the problems of excessive vibration and even engine damage, and achieve the effect of reducing the fuel flow requirement of spark-ignition internal combustion engines and reducing brake specific fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0135 consisted of the same reference oil used in Comparative Example 1 with the addition of anti-knock additive 1,2,3,4-tetrahydroquinoline (THQ) (commercially available from Sigma Aldrich) dissolved in Priolube 1940. 742 g of THQ was dissolved in 1.5 litres of Priolube 1940. This was added to the oil of Comparative Example 1 so as to provide a concentration of anti-knock additive in the sump of approximately 10 wt % (assuming the sump is 8 litres).

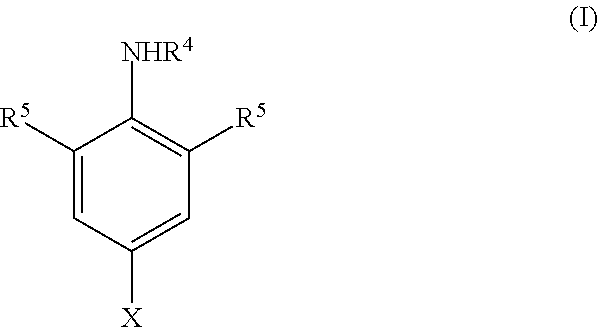

[0136]Example 2 consisted of the same reference oil used in Comparative Example 1 with the addition of anti-knock additive N-methyl aniline, commercially available from Sigma Aldrich) dissolved in Priolube 1940. 742 g of N-methyl aniline (750 ml) was dissolved in 1.5 litres of Priolube 1940 (50 wt %). This was added to the reference oil of Comparative Example 1 so as to provide a concentration of anti-knock additive in the sump of approximately 10 wt % (assuming the sump volume is 8 litres).

[0137]The fuel used in the following experiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com