Hydraulic control system for wet-type double-clutch automatic transmission

A hydraulic control system, wet double clutch technology, applied in clutches, transmission control, components with teeth, etc., can solve the problems of unreasonable flow usage, large size, throttling energy loss, etc. Compact design, contributing to overall size reduction, the effect of reducing displacement and driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

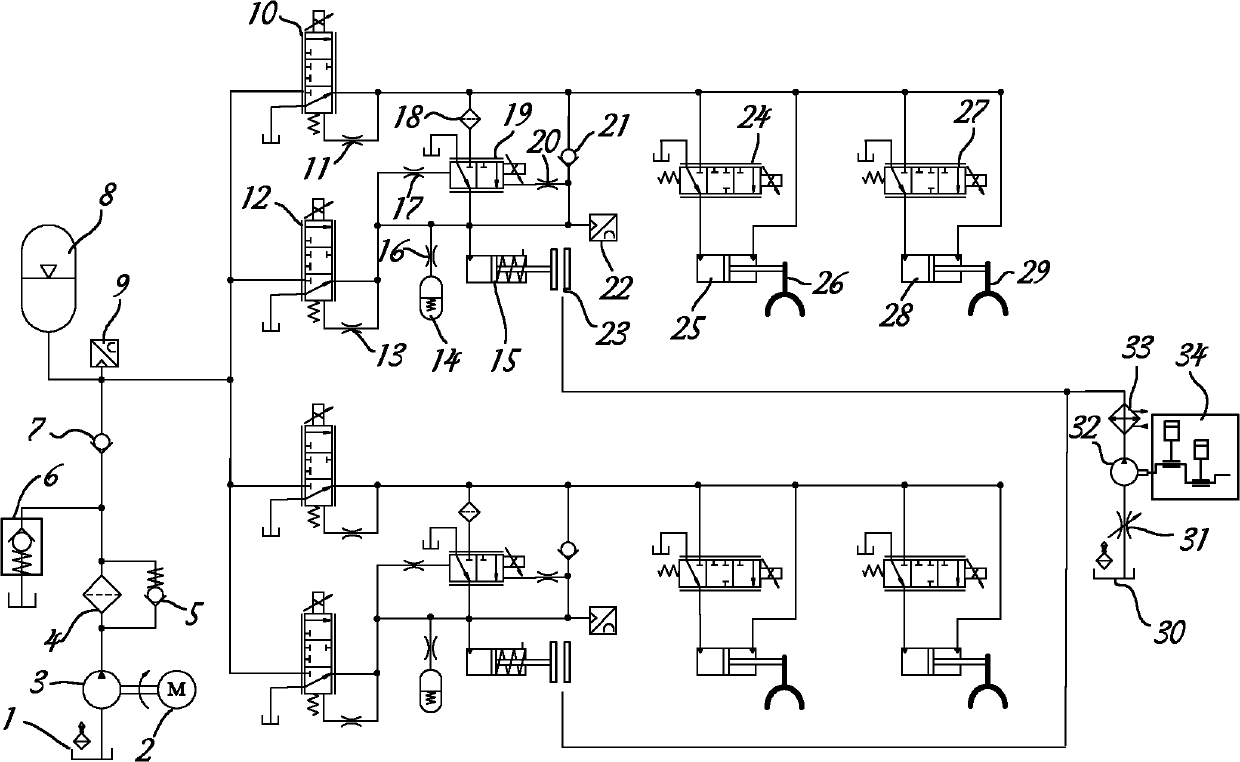

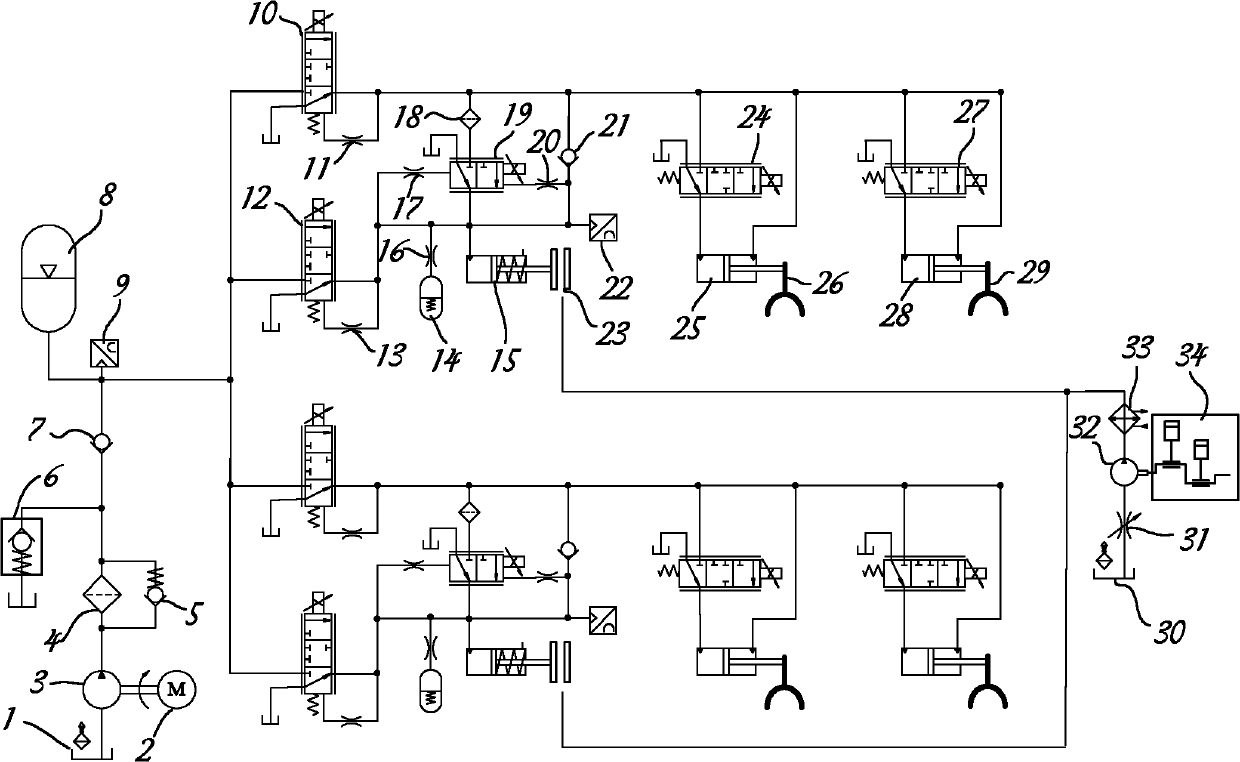

[0028] A specific embodiment of the present invention will be described below in conjunction with the schematic diagram of the hydraulic system in the accompanying drawings.

[0029] As shown in the figure, a hydraulic control system for a wet dual-clutch automatic transmission consists of two independent subsystems, a clutch and shift mechanism hydraulic control subsystem, which is mainly based on the control signals sent by the electronic control unit Manipulate the separation and combination of odd-numbered clutches and even-numbered clutches, and manipulate the shift mechanism to control the oil cylinder to complete the switching of each gear synchronizer; the other is the clutch cooling and lubricating subsystem, which can be two wet-type The clutch provides the required cooling and lubrication flow.

[0030] The hydraulic control subsystem of the clutch and gear shifting mechanism is an energy-saving speed-regulating hydraulic oil source composed of an oil pump 3 driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com