Internal water tank solar heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

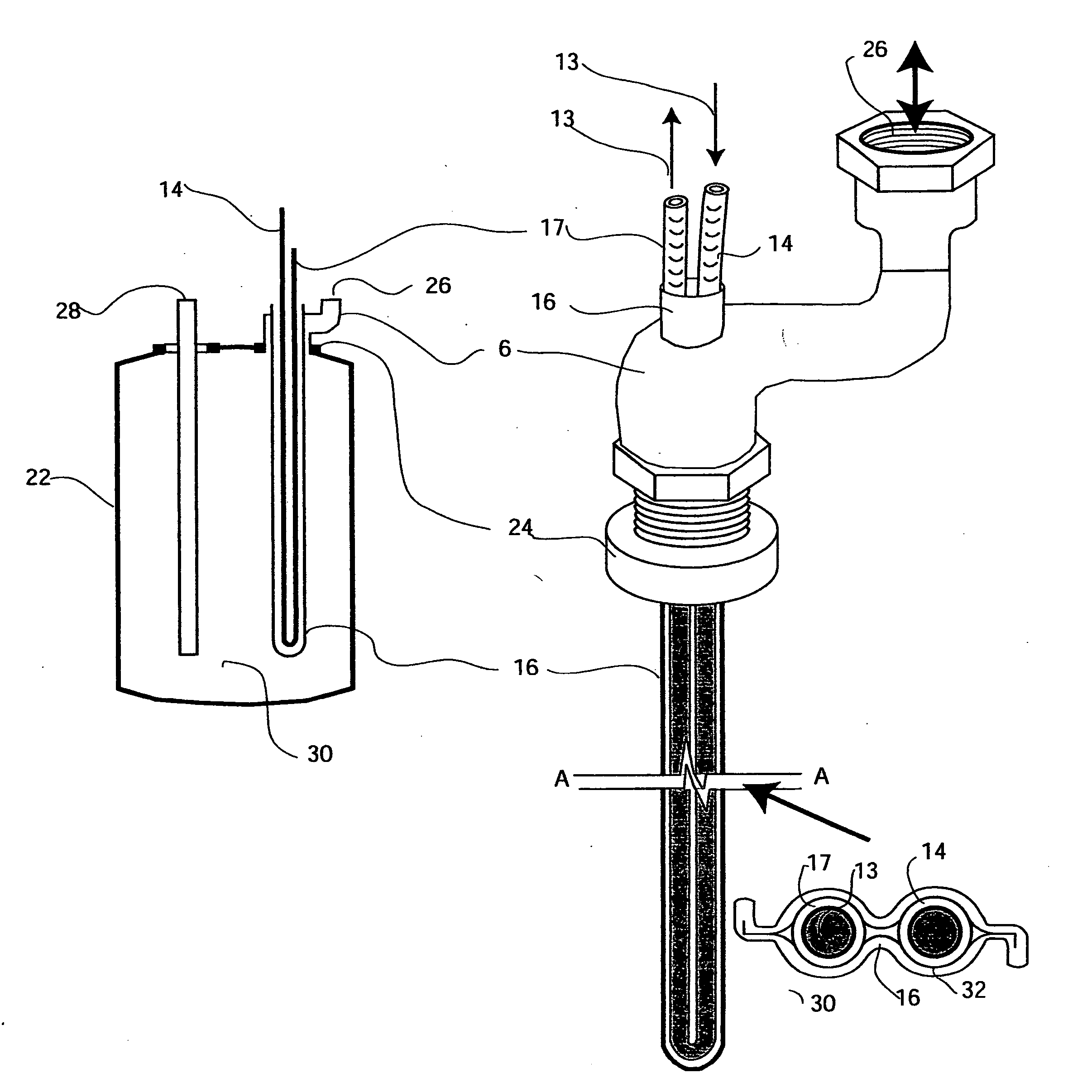

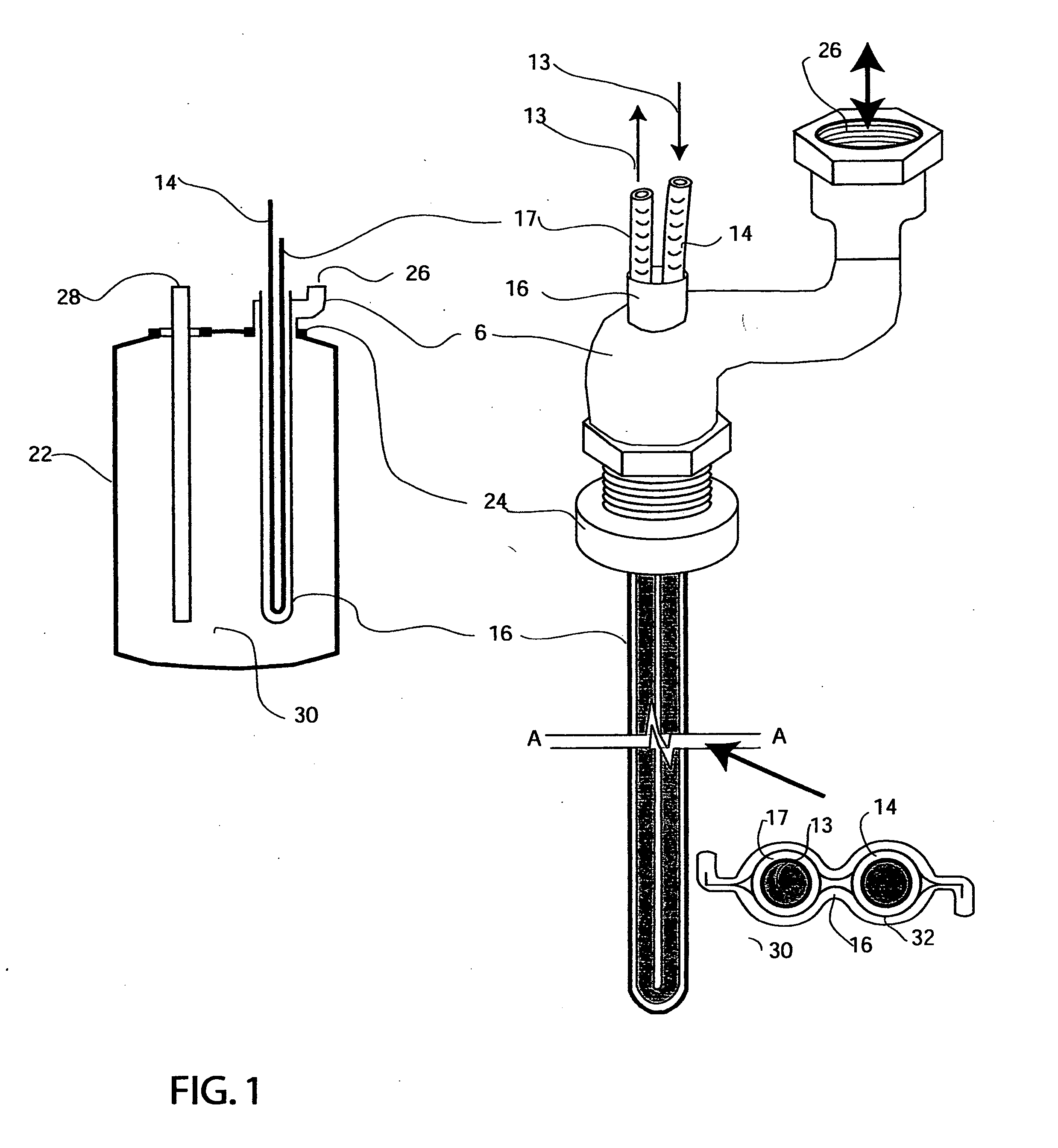

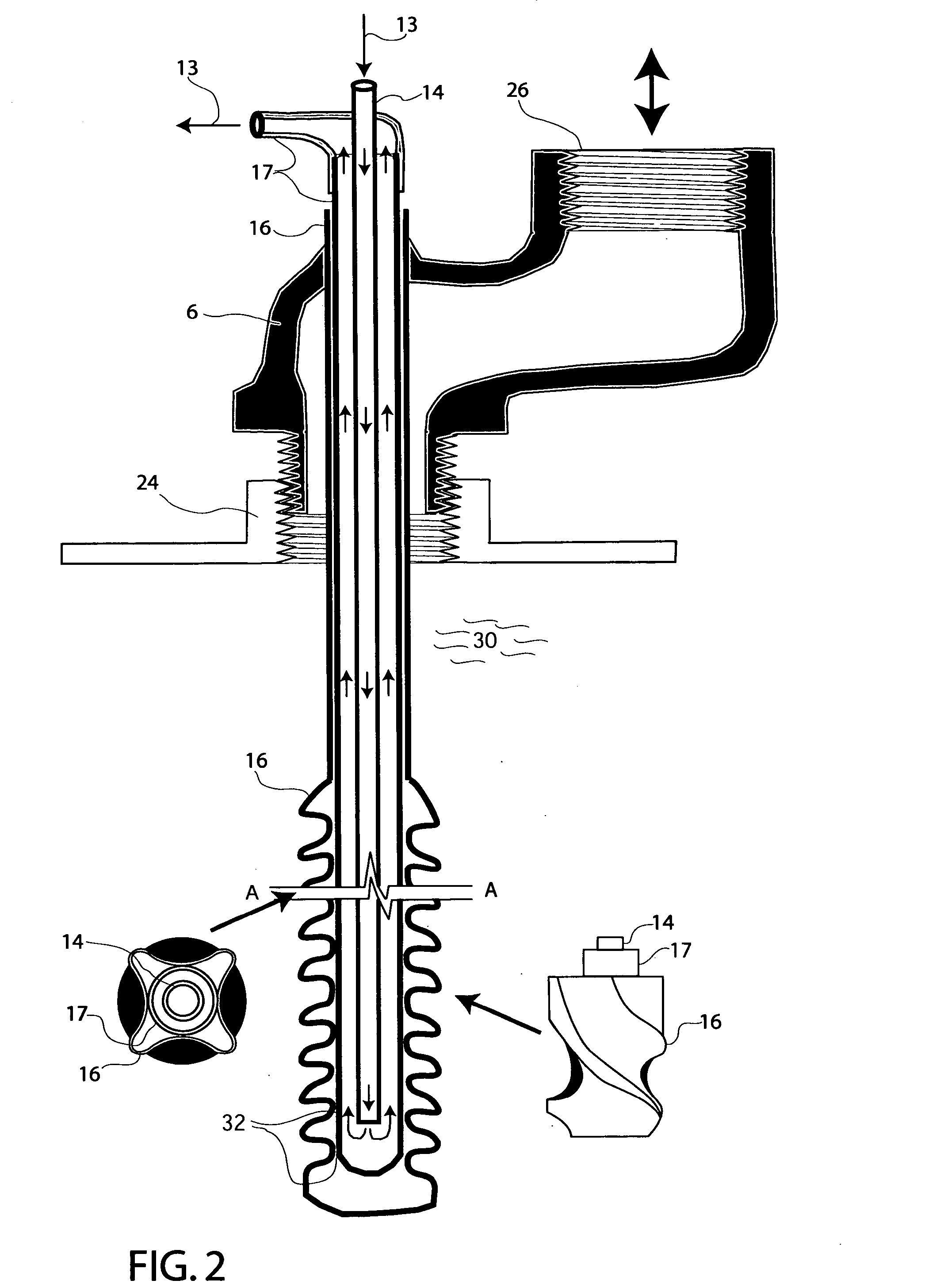

[0012] The invention consists of a screw in T-adapter (6), which replaces the hot water tank outlet (24) or coldwater inlet (28) lines. (FIG. 1) The water exits (or enters) the tank (22) now via a side arm of the adapter (26). Toxic or non toxic heating or cooling fluid (13), flows in small tubes (14&17), which go into the tank (14) and return (17) encased in an outer second tube labeled (16). Inside the tank, the tube labeled (16) has been deformed to make physical contact with the toxic fluid carrying tubes labeled (14&17). Heat is conducted between the toxic heat exchange fluid to or from the potable water. Because of the double wall design, toxic fluid leaking from tube (14&17) will not reach the potable water; it is stopped by tube wall (16). If a leak of potable water occurs, it is at high pressure and would again be leaked outside the tank between tubes (14&17) and second wall (16). This assures no chance for contamination of potable water with toxic heat transfer fluids, eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com