Radiant Superheater

a superheater and radiant technology, applied in the field of radiant superheaters, can solve the problems of reducing the thermal efficiency of the boiler, affecting the durability of the radiant superheater, and affecting the performance of the boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

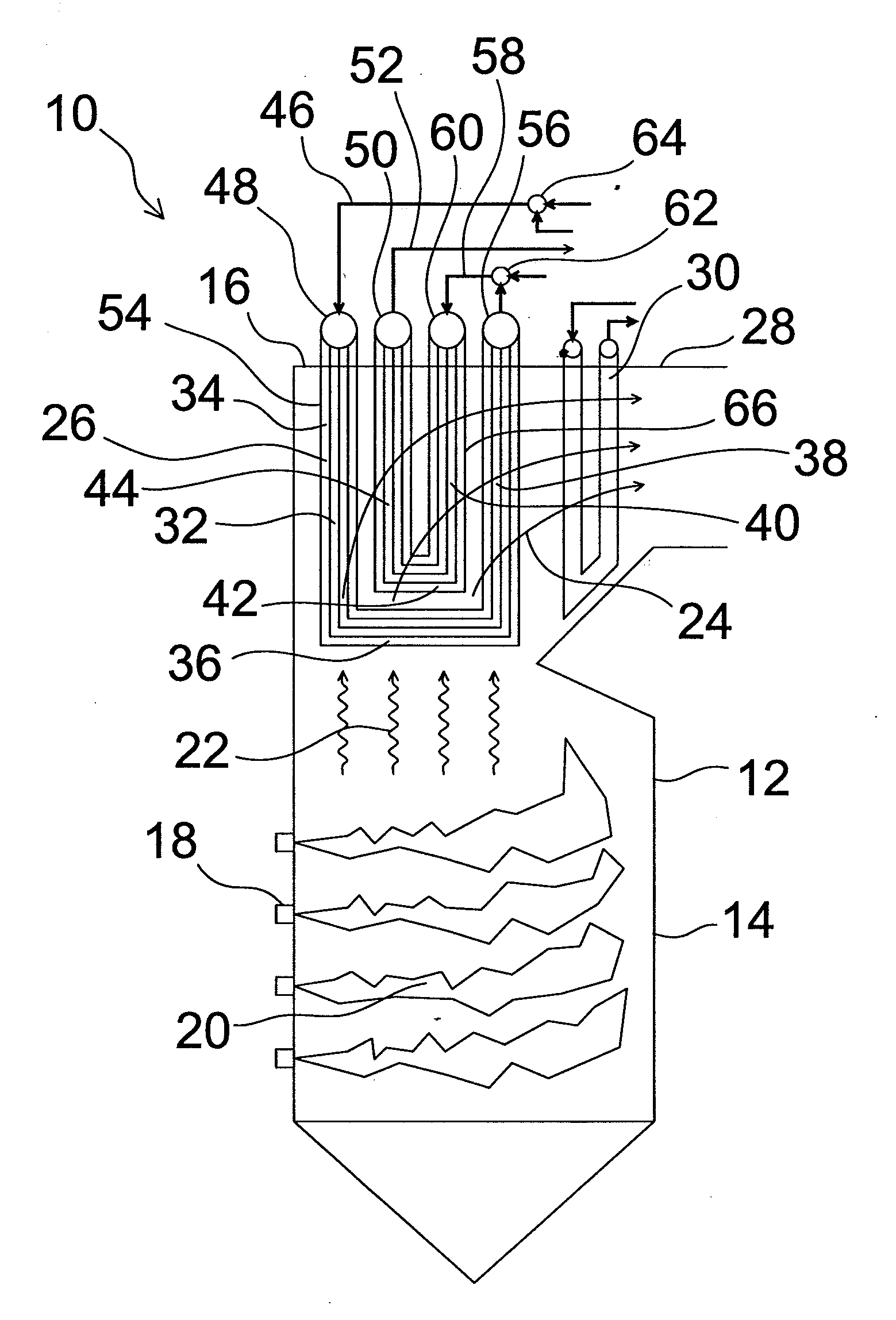

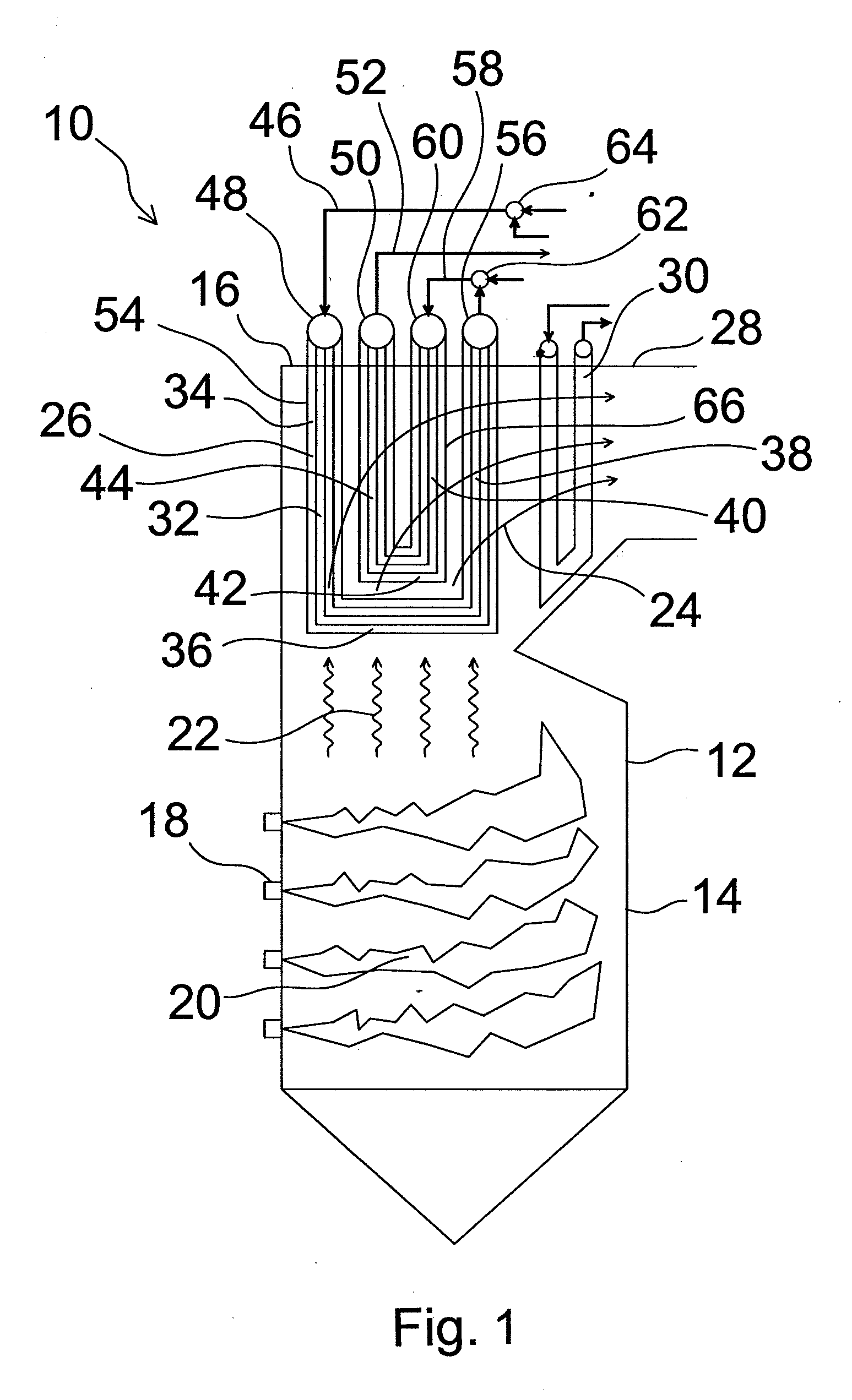

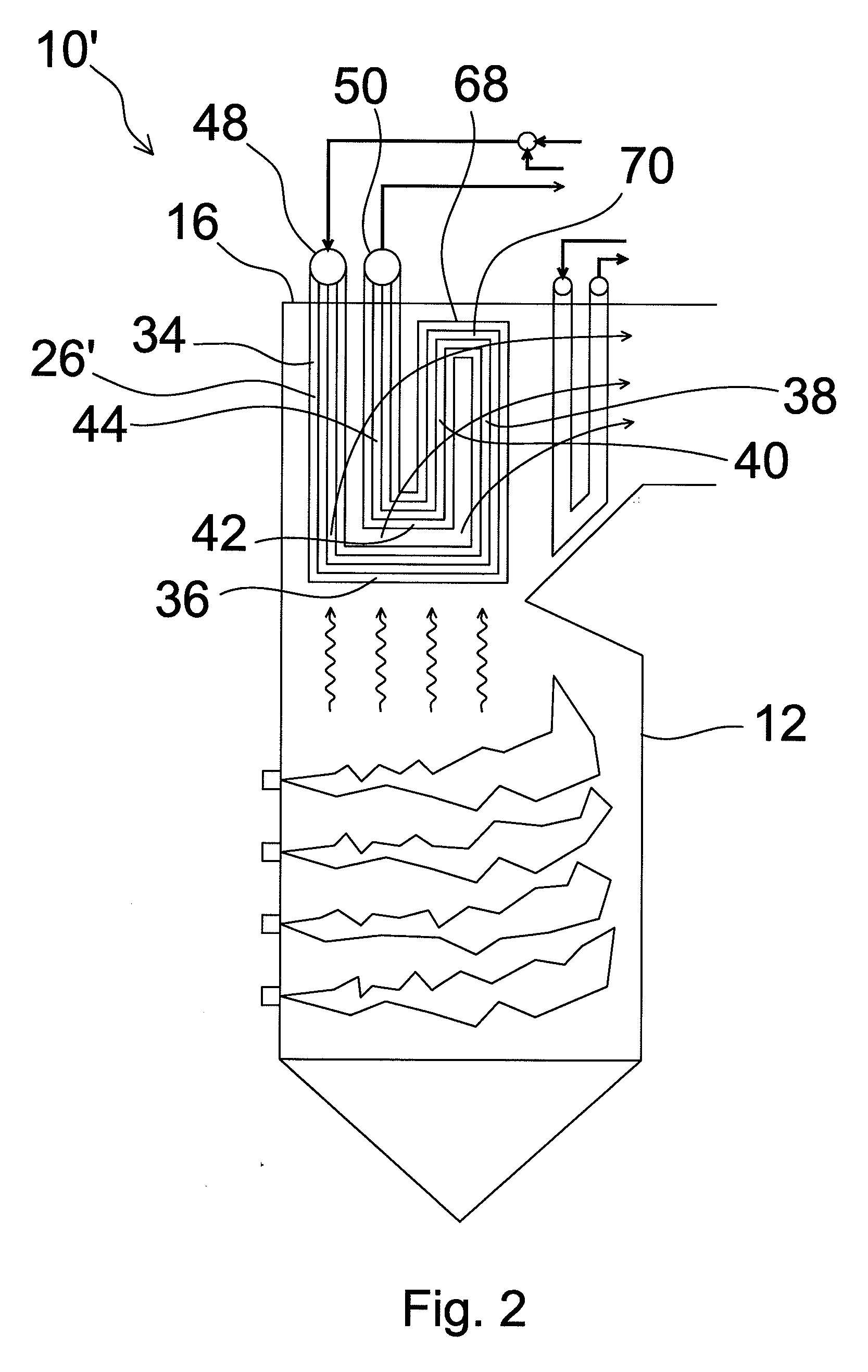

[0024]FIG. 1 schematically shows a pulverized coal firing supercritical or ultrasupercritical boiler 10 in accordance with a first embodiment of the present invention. The boiler comprises a furnace 12 with water-cooled enclosure walls 14 and a roof 16. At the boiler walls 14 are arranged burners 18 for firing pulverized coal and producing a flame zone 20 into the furnace 12. From the flame zone 20 is conducted heat by radiation 22 and by hot flue gases 24. Because the radiation heat depends on the fourth power of the absolute temperature, heat conduction by radiation dominates in regions having direct visibility to the high temperature flame zone 20. The upper portion of the furnace 12 comprises a hanging radiant superheater 26, in which steam is superheated, to be finally conducted to a steam turbine (not shown) to generate power. Horizontal pass 28 immediately downstream of the furnace 12 comprises further hanging superheaters, such as finishing superheaters 30.

[0025]The radiant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com