High-temperature vertical waste heat boiler with coil pipes

A technology for waste heat boilers and coils, which is applied to steam boilers, heat exchange equipment, heat exchanger shells, etc., which can solve problems such as difficulty in adapting to larger scale requirements and poor cooling effects, and achieve uniform cooling effects and protect metal Materials, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

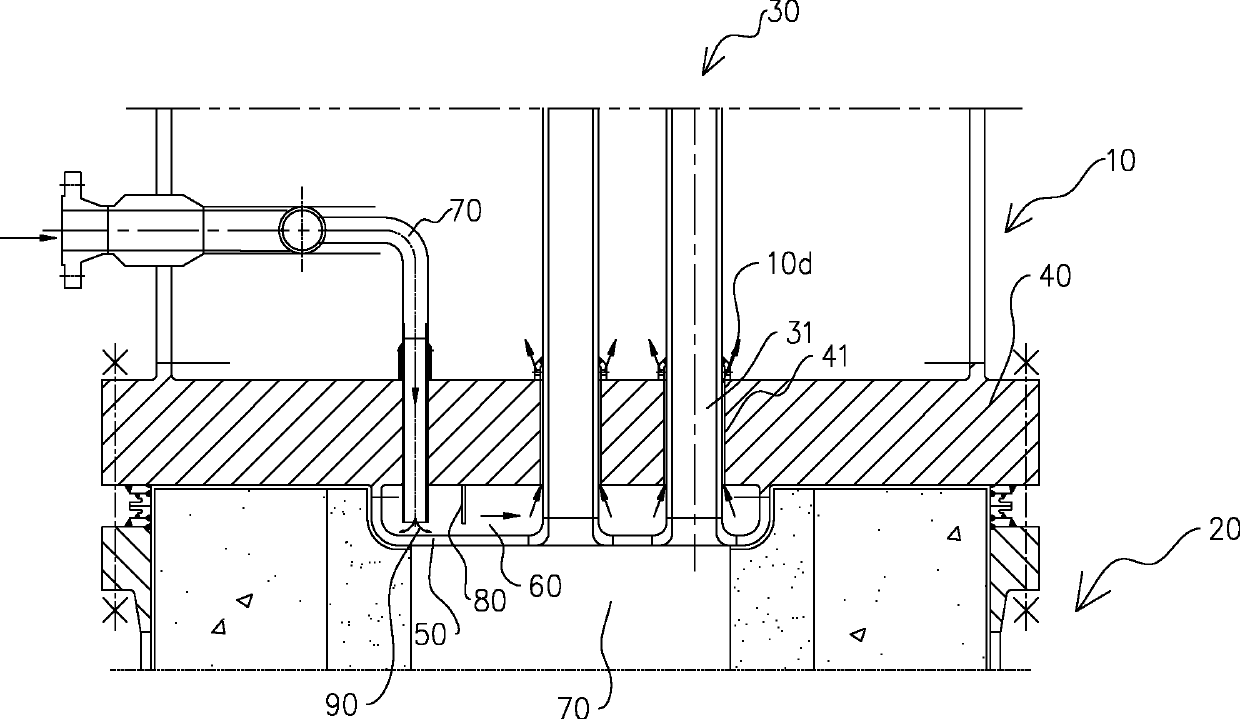

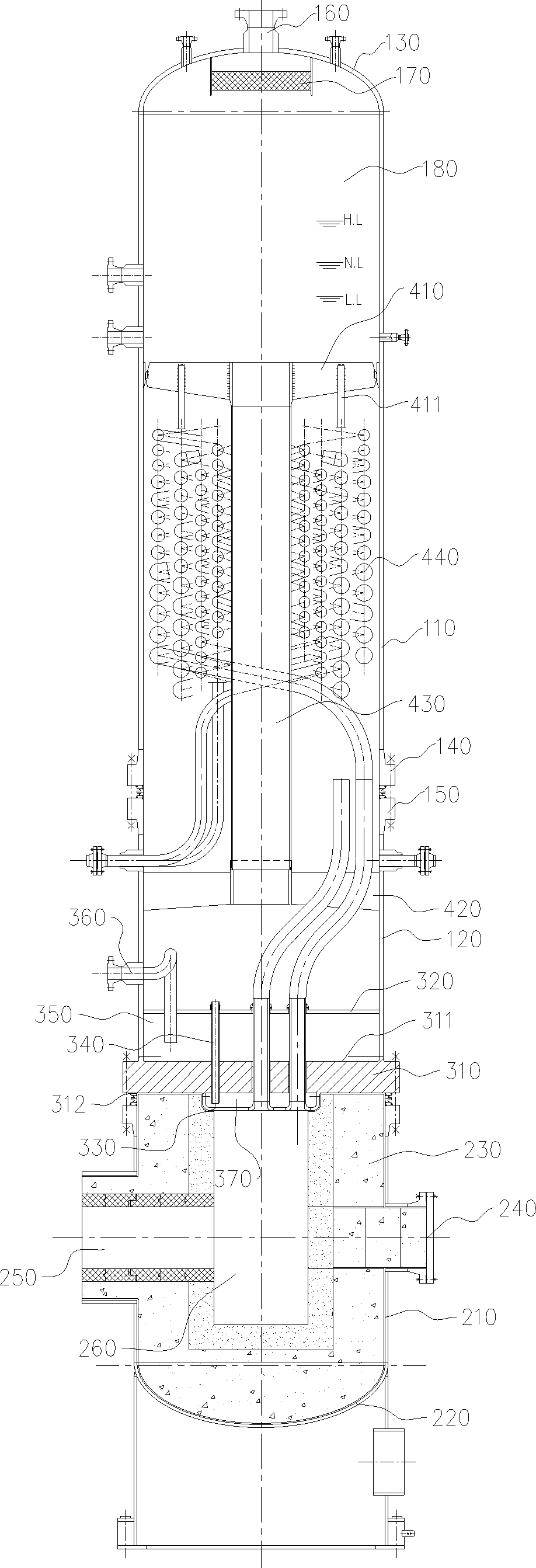

[0045] see figure 2 , a high-temperature vertical coil waste heat boiler shown in the figure includes a pot shell part, a pipe box part, a water circulation cooling structure part and a coil part arranged in the heat exchange chamber of the pot shell part.

[0046] The pot shell part includes a pot shell, which is welded by two sections of cylinder body 110, 120 and upper head 130. The upper ends are connected by flanges 140, 150 and fasteners. A steam outlet 160 is welded on the upper head 130 , and a steam-water separation element 170 is installed in the upper head 130 at the inlet end of the steam outlet 160 . A steam-water separation space 180 is provided on the upper part of the whole barrel; steam generated in the steam-water separation space 180 is exported through the steam-water separation element 170 and the steam outlet 160 . The cylinder body of this embodiment is composed of two sections of cylinder body 110, 120, which can facilitate the inspection and mainten...

Embodiment 2

[0061] The structure of the high-temperature vertical coil waste heat boiler of this embodiment is basically the same as that of the high-temperature vertical coil waste heat boiler of Embodiment 1, the difference is that the coil assembly 440 is slightly different in its coiling mode, see Figure 6 and Figure 7 , the coiled tube assembly 440 in this embodiment includes twelve coiled tubes, and the twelve coiled tubes are divided into six groups of coiled tube bundles 440a, 440b, 440c, 440d, 440e, 440f, and each group of coiled tube bundles is composed of two coiled tubes. Coiled. The six groups are installed around the center pipe 430 in a uniform manner in the circumferential direction.

Embodiment 3

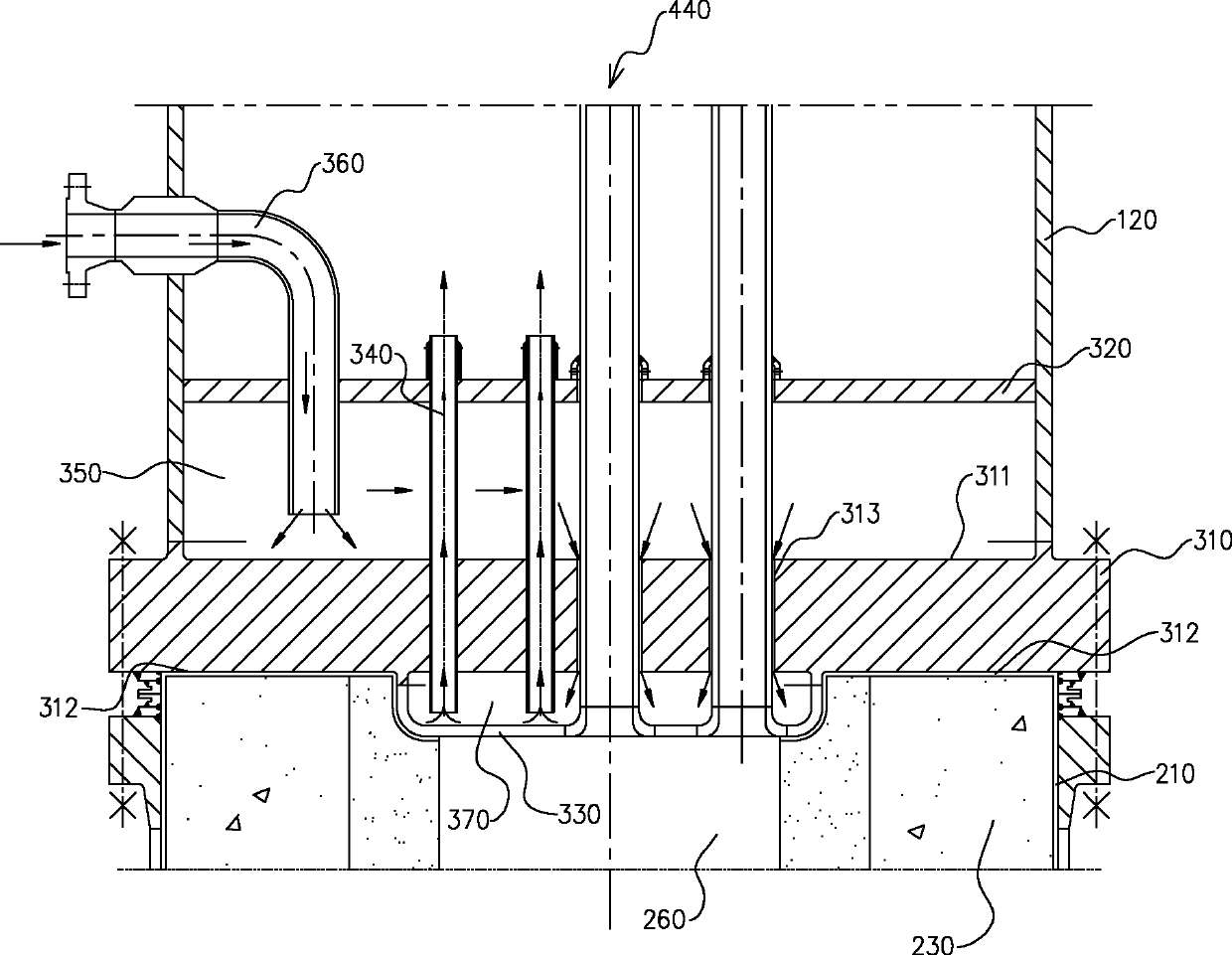

[0063] The difference between the high-temperature vertical coil waste heat boiler in this embodiment and the high-temperature vertical coil waste heat boiler in Example 1 is that the water circulation cooling structure is different, see Figure 7 , its water circulation cooling structure includes a thick tube plate 310 , a flexible tube plate 330 , several drain pipes 340 and a cover 380 . The thick tube plate 310 and the cover body 390 are in contact with the boiler water and mainly play a pressure bearing role.

[0064]The bottom end of the cylinder 120 is welded with a lower head 190, the thick tube plate 310 is welded on the bottom of the cylinder 120, the cover 390 is welded on the surface 311 of the thick tube plate 310 adjacent to the side of the pot shell, the inner surface of the cover 390 The space bounded by the surface 311 of the thick tube plate 310 adjacent to the side of the pot shell constitutes a circulating water distribution chamber 350 . A number of coile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com