Gas turbine combustor transition section with cooling structure

A technology of gas turbine and cooling structure, which is applied in combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of thermal barrier coating peeling off easily, temperature rise in transition section, thermal barrier coating damage, etc. Thermal effect, low pressure loss, effect of reducing metal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

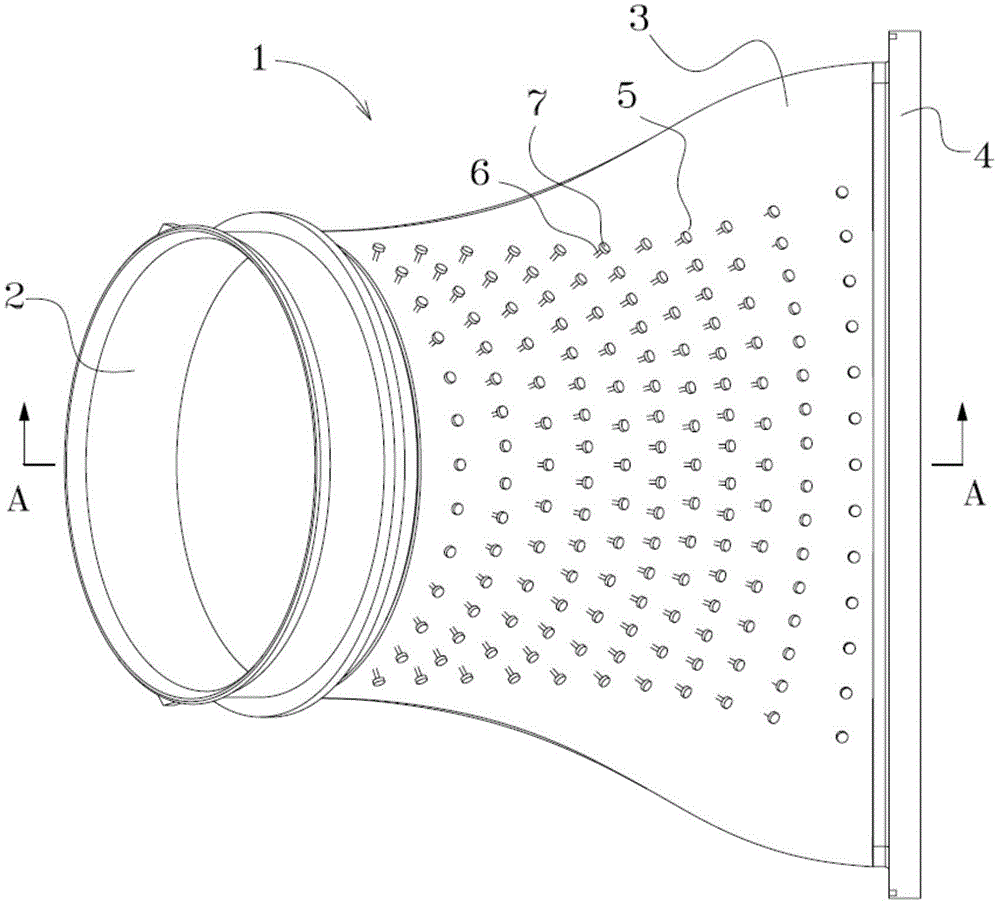

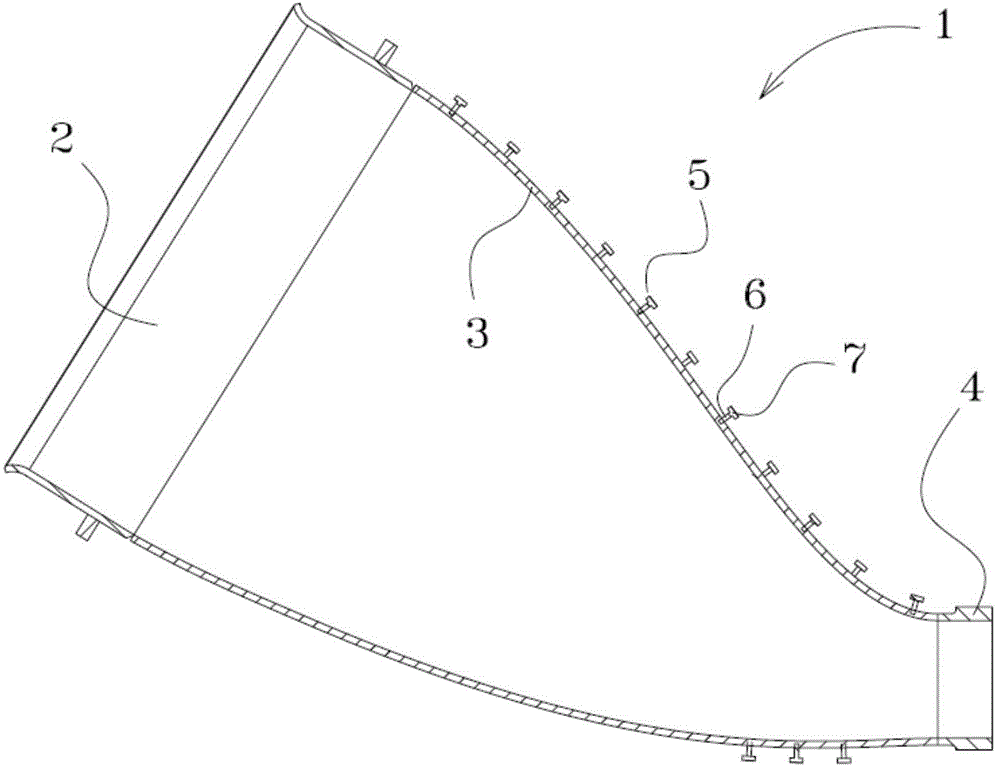

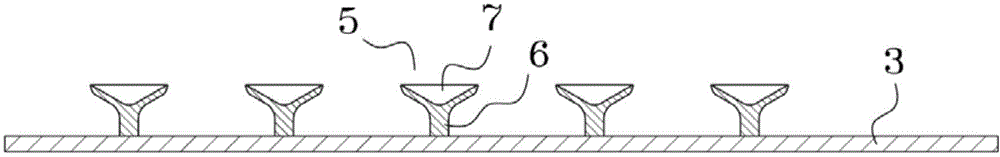

[0017] Such as figure 1 and figure 2 As shown, the transition section 1 includes a transition section inlet 2, a transition section body 3 and a transition section outlet 4. High-temperature gas enters the transition section through the transition section inlet 2, flows inside the transition section body 3, and gradually transitions from a circular cross section As far as the fan-shaped section is concerned, the outlet 4 of the transition section is also fan-shaped, and a plurality of transition sections 1 are arranged in a circle around the axis of the gas turbine. There are a plurality of cooling components 5 on the transition section body 3, each of the cooling compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com