Impeller and turbocharger

A technology for impellers and blades, which is applied in the direction of machines/engines, non-variable pumps, pump components, etc., can solve the problems of increasing the loss of thrust bearings, and achieve the effect of improving the creep life of the impeller and reducing the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

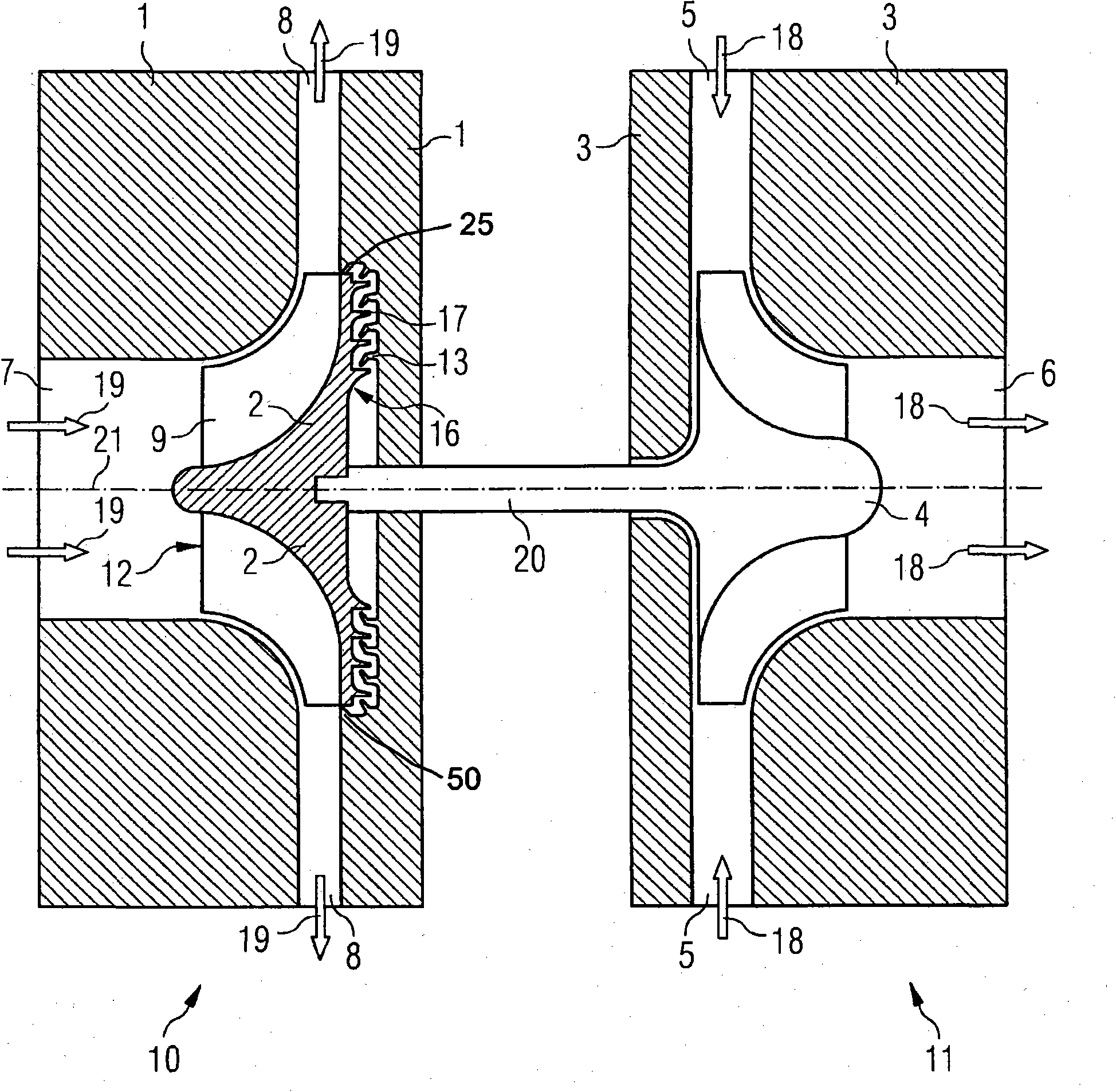

[0030] will refer to below Figure 1 to Figure 4 A first embodiment of the impeller of the present invention and the turbocharger of the present invention will be described. figure 1 The turbocharger is shown schematically in a sectional view. The turbocharger includes a turbine 11 and a compressor 10 . The turbine 11 and the compressor 10 are connected by a shaft 20 .

[0031] The turbine 11 includes a rotor 4 located within a turbine housing 3 . The turbine housing 3 has an exhaust gas inlet 5 to the rotor 4 such that the exhaust gas entering the exhaust gas inlet 5 drives the rotor 4 . Furthermore, the turbine housing 3 has an exhaust outlet 6 through which the exhaust gas from the rotor 4 leaves the turbine housing 3 . Arrow 18 indicates the exhaust gas flow which enters the turbine housing 3 through the exhaust gas inlet 5 , entrains the rotor 4 and leaves the turbine housing 3 through the exhaust gas outlet 6 .

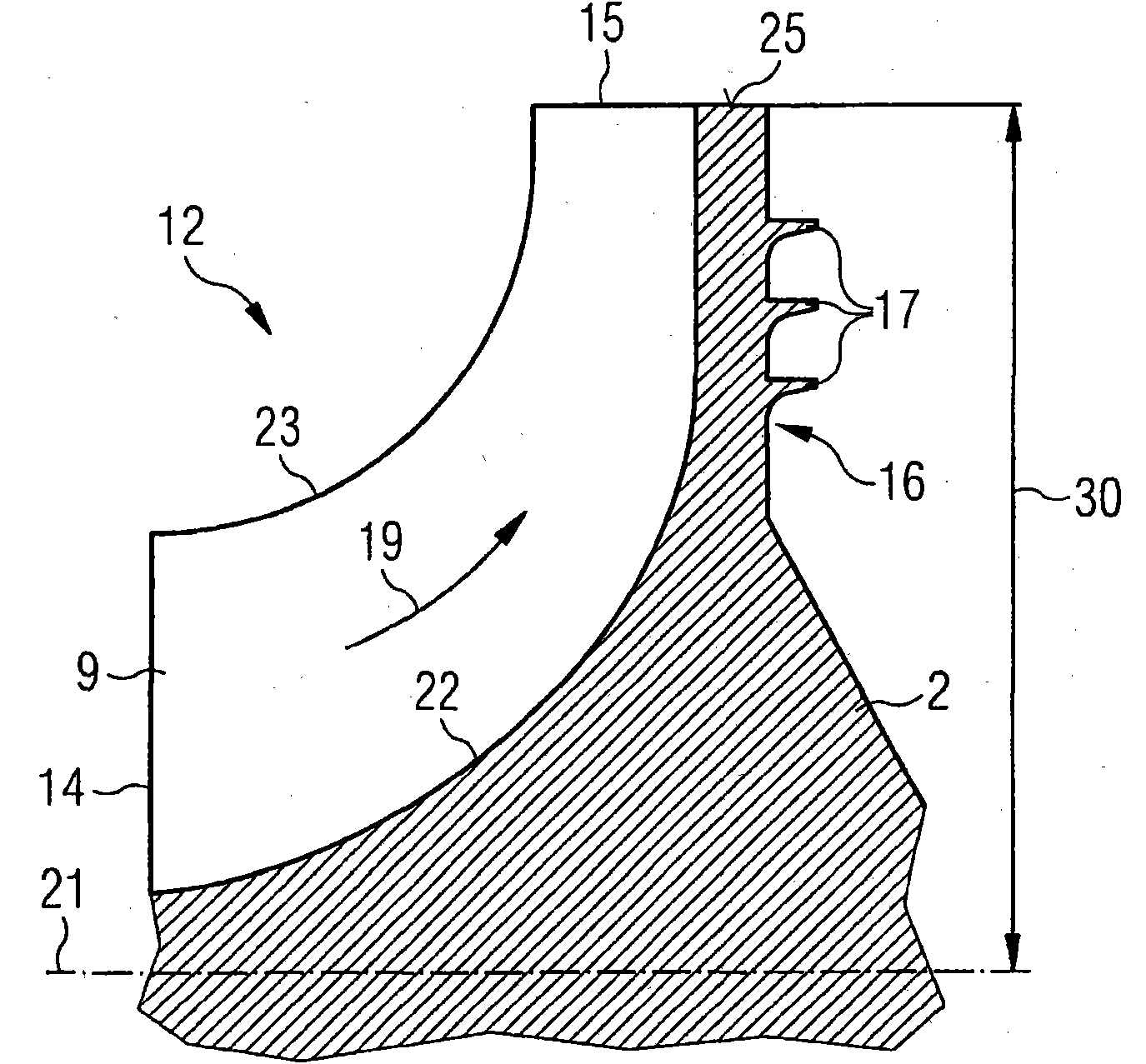

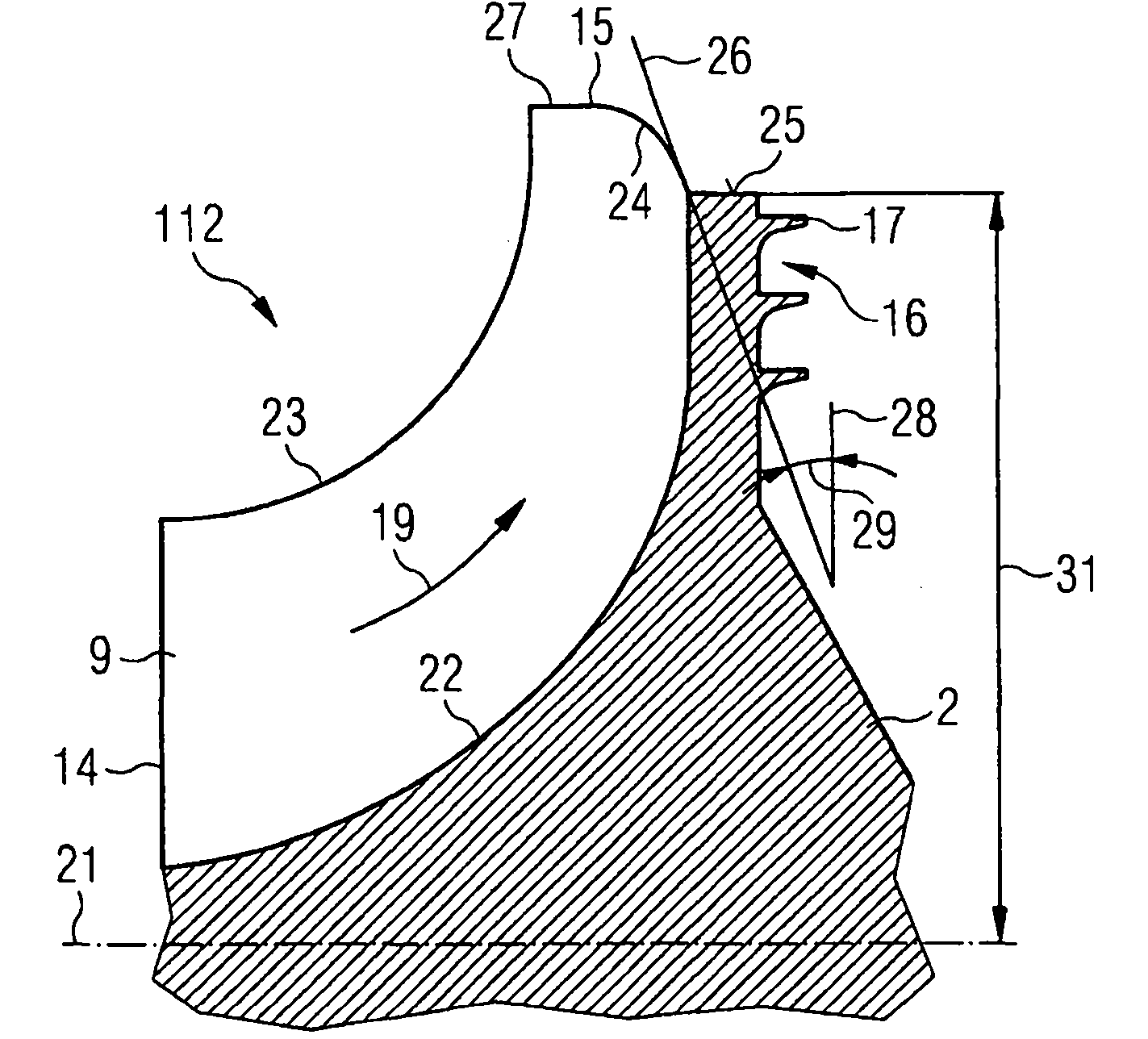

[0032] Compressor 10 includes an impeller 12 located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com