Sn-based soldering flux and preparation method thereof

A technology of solder and base alloy, which is applied in the field of Sn-based solder and its preparation, can solve problems such as the inconsistency between the amount of nanoparticles added and the theoretical amount, and the uneven distribution of nanoparticles, so as to solve microscopic cracking, reduce crystal nucleation energy, and improve creep life changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

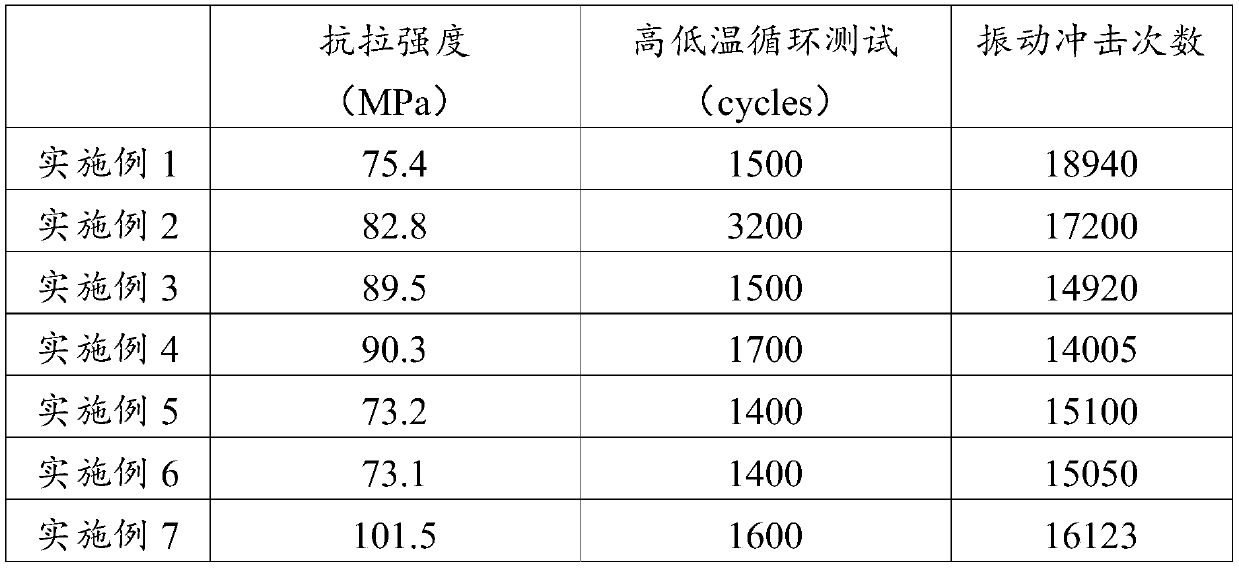

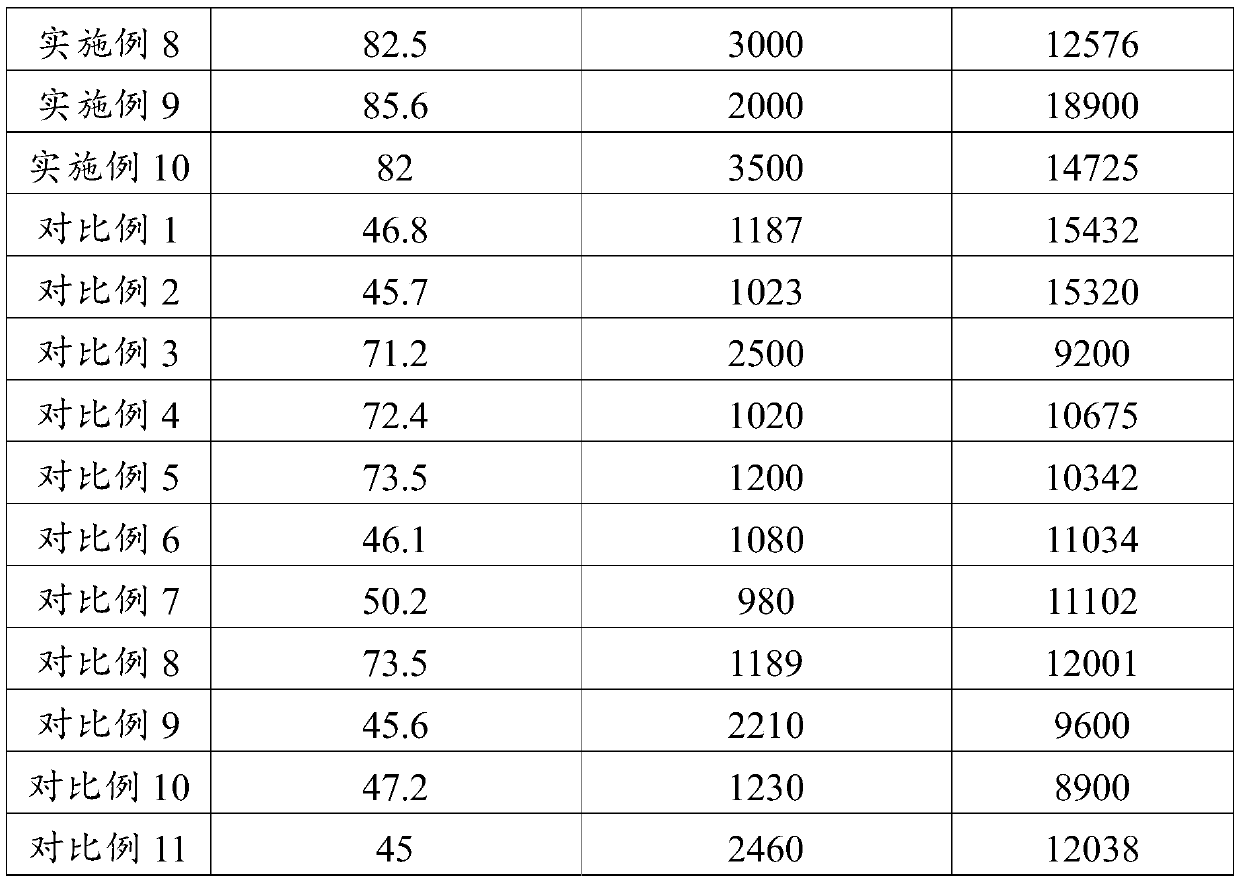

Examples

Embodiment 1

[0049] A high-reliability Sn-based solder alloy, in weight percentage, the solder alloy comprises: SnAg 3.0 Cu 0.5 Alloy 80%; nano-alumina dispersion strengthened copper (Cu-Al 2 o 3 ) powder is 20%, of which Al 2 o 3 The weight percentage is 5.0%, the rest is Cu, nano Al 2 o 3 The scale of the phase is 5nm. The method for preparing the solder alloy comprises the following steps:

[0050] 1) Preparation of SnAg 3.0 Cu 0.5 Solder alloy, according to the alloy ratio, the Sn, Ag, Cu raw materials are melted in a vacuum melting furnace and kept warm, SnAg 3.0 Cu 0.5 The melting point is 217°C, and the holding temperature is 302-310°C;

[0051] 2) The nano-alumina dispersion strengthened copper (Cu-Al 2 o 3 ) powder was added to the molten Sn-based alloy solution according to the design ratio, and vacuumized to 1×10 -2 -1×10 -1 Pa, filled with nitrogen and stirred at a high speed, the stirring time is 30-40min, and the stirring speed is 6000-8000rpm, so that the Sn-b...

Embodiment 2

[0053] A high-reliability Sn-based solder alloy, in weight percentage, the solder alloy comprises: SnBi 45 Sb 1.0 Ag 0.9 Alloy 85%, nano-alumina dispersion strengthened copper (Cu-Al) prepared by mechanical alloying method 2 o 3) powder is 15%, of which Al 2 o 3 The weight percentage is 2%, the rest is Cu, nano Al 2 o 3 The scale of the phase is 15 nm. The method for preparing the solder alloy comprises the following steps:

[0054] 1) Preparation of SnBi 45 Sb 1.0 Ag 0.9 Solder alloy, the raw materials are melted and kept warm in a vacuum melting furnace according to the alloy ratio, SnBi 45 Sb 1.0 Ag 0.9 The melting point is 146°C, and the holding temperature is 230-240°C;

[0055] 2) Nano-alumina dispersion-strengthened copper (Cu-Al 2 o 3 ) powder is added to the molten SnBi according to the design ratio 45 Sb 1.0 Ag 0.9 In the alloy melt, vacuumize to 1×10 -2 -1×10 -1 Pa, filled with nitrogen and then stirred, the stirring time is 30-40min, and the st...

Embodiment 3

[0058] A high-reliability Sn-based solder alloy, in weight percentage, the solder alloy comprises: SnIn 48 Bi 10 Alloy 82%, nano-alumina dispersion strengthened copper (Cu-Al) prepared by mechanical alloying method 2 o 3 ) powder is 18%, of which Al 2 o 3 The weight percentage content is 50ppm, the rest is Cu, nano Al 2 o 3 The scale of the phase is 100 nm. The method for preparing the solder alloy comprises the following steps:

[0059] 1) Preparation of SnIn 48 Bi 10 Solder alloy, the raw materials are melted and kept warm in a vacuum melting furnace according to the alloy ratio, SnIn 48 Bi 10 The melting point is 130°C, and the holding temperature is 217-225°C;

[0060] 2) Nano-alumina dispersion-strengthened copper (Cu-Al 2 o 3 ) powder is added to the molten SnIn according to the design ratio 48 Bi 10 In the molten gold, vacuumize to 1×10 -2 -1×10 -1 Pa, filled with nitrogen and stirred, the stirring time is 30-40min, and the stirring speed is 6000-8000rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com