A heat-resistant flame-retardant magnesium alloy and its deformation heat treatment method

A deformation heat treatment and magnesium alloy technology, applied in the field of heat-resistant and flame-retardant magnesium alloys and their deformation heat treatment, can solve the problems of loss of yield strength of magnesium alloys, limited increase in ignition point, decreased creep life, etc., to improve heat resistance and resistance. flammability, reduced creep strain, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

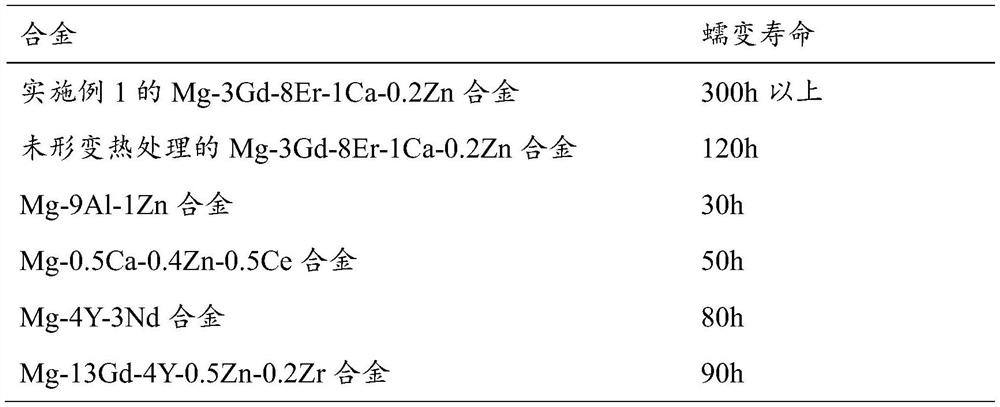

[0022] The raw material is Mg-3Gd-8Er-1Ca-0.2Zn alloy (mass percentage), the Ca / Zn mass ratio is 5, and the plate with a thickness of 5mm is obtained by semi-continuous casting and hot rolling. Aging treatment and water quenching were carried out for 24 hours, followed by deformation to a true strain of 0.1 at 100°C, followed by aging treatment and water quenching at 220°C for 12 hours. The creep life and ignition point test samples of the alloy were prepared, and the creep life test was carried out at 200°C and 180MPa, and the ignition point was tested during the uniform temperature rise process from room temperature to 1000°C. The results are shown in Table 1 and Table 5.

Embodiment 2

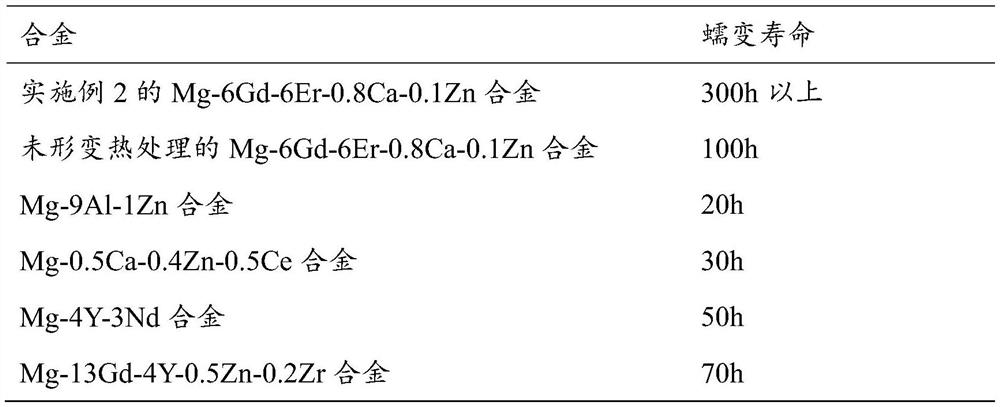

[0024] The raw material is Mg-6Gd-6Er-0.8Ca-0.1Zn alloy (mass percentage), the Ca / Zn mass ratio is 8, and the plate with a thickness of 10 mm is obtained by semi-continuous casting and hot rolling. ℃ for 72h of aging treatment, water quenching, then, at room temperature for deformation to a true strain of 0.05, and then 150 ℃ for 48h of aging treatment, water quenching. The creep life and ignition point test samples of the alloy were prepared, and the creep life test was carried out at 250°C and 150MPa, and the ignition point was tested in the process of uniform temperature rise from room temperature to 1000°C. The results are shown in Table 2 and Table 5.

Embodiment 3

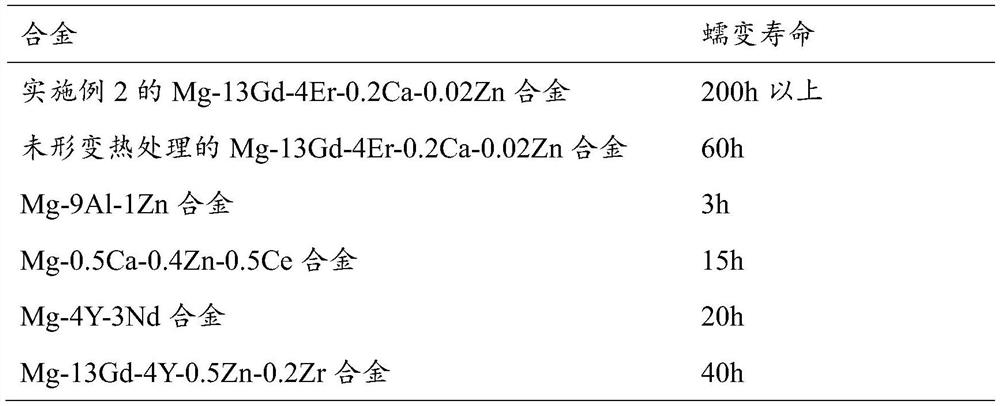

[0026] The raw material is Mg-13Gd-4Er-0.2Ca-0.02Zn alloy (mass percentage), the Ca / Zn mass ratio is 10, and the plate with a thickness of 20mm is obtained by semi-continuous casting and hot extrusion. After solution treatment, the Aging treatment and water quenching were carried out at 220°C for 36 hours, followed by deformation at room temperature to a true strain of 0.02, and then aging treatment and water quenching at 170°C for 6 hours. The creep life and ignition point test samples of the alloy were prepared, and the creep life test was carried out at 300°C and 120MPa, and the ignition point was tested during the uniform temperature rise process from room temperature to 1000°C. The results are shown in Table 3 and Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com