Nickel-based welding wire, manufacturing method of nickel-based welding wire and welding process of nickel-based welding wire

A technology of manufacturing method and welding process, applied in the direction of manufacturing tools, welding equipment, welding medium, etc., can solve the problems of poor welding effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

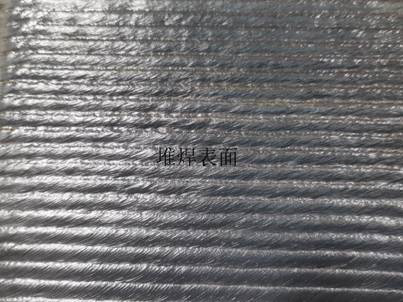

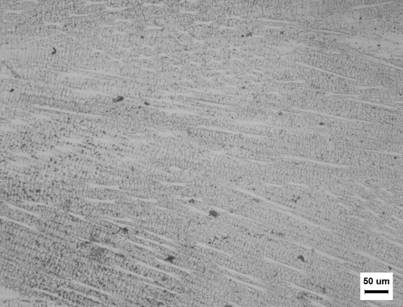

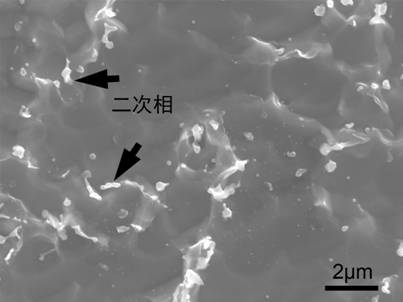

Image

Examples

Embodiment 1

[0076] Step 1: Weigh the powder, and weigh the powder according to the following mass percentages: Co powder 28.0%, Cr powder 19.0%, Mo powder 7.0%, Nb powder 1.5%, Cu powder 1.0%, W powder 1.5%, B powder 0.6% , La powder 0.4%, the rest is Ni powder, wherein, the sum of the mass percentages of all the above components is 100%.

[0077] Step 2: Dry the medicinal powder, place the medicinal powder in a vacuum heating furnace to heat, the heating temperature is 260°C, and the holding time is 1h. to remove moisture from the powder.

[0078] Step 3: Mix the medicinal powder, place the dried medicinal powder in a powder mixer for thorough mixing, and the mixing time is 1 hour.

[0079] Step 4: Fill the powder, choose Inconel 625 as the sheath of the flux-cored wire, use alcohol to remove the grease on the surface of the raw material of the sheath, and bend the sheath into a U shape by a flux-cored wire forming machine, fill the mixed medicine powder into the sheath, and Close the ...

Embodiment 2

[0086] Step 1: Weigh the powder, and weigh the powder according to the following mass percentages: Co powder 32.0%, Cr powder 23.0%, Mo powder 9.0%, Nb powder 3.5%, Cu powder 1.5%, W powder 3.5%, B powder 1.0% , La powder 0.6%, and the rest is Ni powder, wherein the sum of the mass percentages of all the above components is 100%.

[0087] Step 2: Dry the medicinal powder, place the medicinal powder in a vacuum heating furnace to heat, the heating temperature is 280°C, and the holding time is 2h. to remove moisture from the powder.

[0088] Step 3: Mix the medicinal powder, place the dried medicinal powder in a powder mixer for full mixing, and the mixing time is 2 hours.

[0089] Step 4: Fill the powder, choose Inconel 625 as the sheath of the flux-cored wire, use alcohol to remove the grease on the surface of the raw material of the sheath, and bend the sheath into a U shape by a flux-cored wire forming machine, fill the mixed medicine powder into the sheath, and Close the ...

Embodiment 3

[0096] Step 1: Weigh the powder, and weigh the powder according to the following mass percentages: Co powder 30.0%, Cr powder 21.0%, Mo powder 8.0%, Nb powder 2.5%, Cu powder 1.3%, W powder 2.5%, B powder 0.8% , La powder 0.5%, and the rest is Ni powder, wherein the sum of the mass percentages of all the above components is 100%.

[0097] Step 2: Dry the medicinal powder, place the medicinal powder in a vacuum heating furnace to heat, the heating temperature is 270°C, and the holding time is 1.5h. to remove moisture from the powder.

[0098] Step 3: Mix the medicinal powder, place the dried medicinal powder in a powder mixer for thorough mixing, and the mixing time is 1.5 hours.

[0099] Step 4: Fill the powder, choose Inconel 625 as the sheath of the flux-cored wire, use alcohol to remove the grease on the surface of the raw material of the sheath, and bend the sheath into a U shape by a flux-cored wire forming machine, fill the mixed medicine powder into the sheath, and Cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com