A self-generated high-temperature diffusion barrier by in-situ reaction on the surface of refractory metal and its preparation method

A refractory metal, high-temperature diffusion technology, applied in the direction of solid-state diffusion coating, metal material coating process, coating, etc. problems such as layer life, to achieve excellent high-temperature structure and chemical stability, ensure high-temperature oxidation resistance, and prolong the effect of high-temperature service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

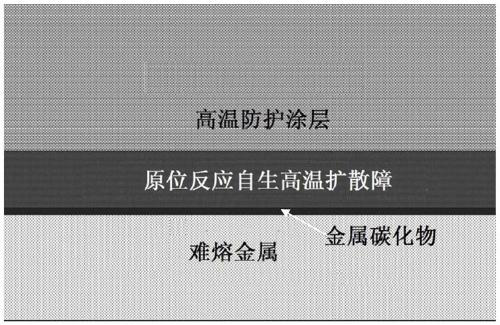

[0030] The surface of the Ta12W alloy in this embodiment reacts in situ and the self-generated high-temperature diffusion barrier is located between the Ta12W alloy and the Si-Cr-Ti-Zr high-temperature protective coating coated on the surface of the Ta12W alloy, and the high-temperature chemical reaction between Si and graphene oxide The generated SiC is the main phase, and the thickness of the in-situ reaction self-generated high-temperature diffusion barrier is 10 μm.

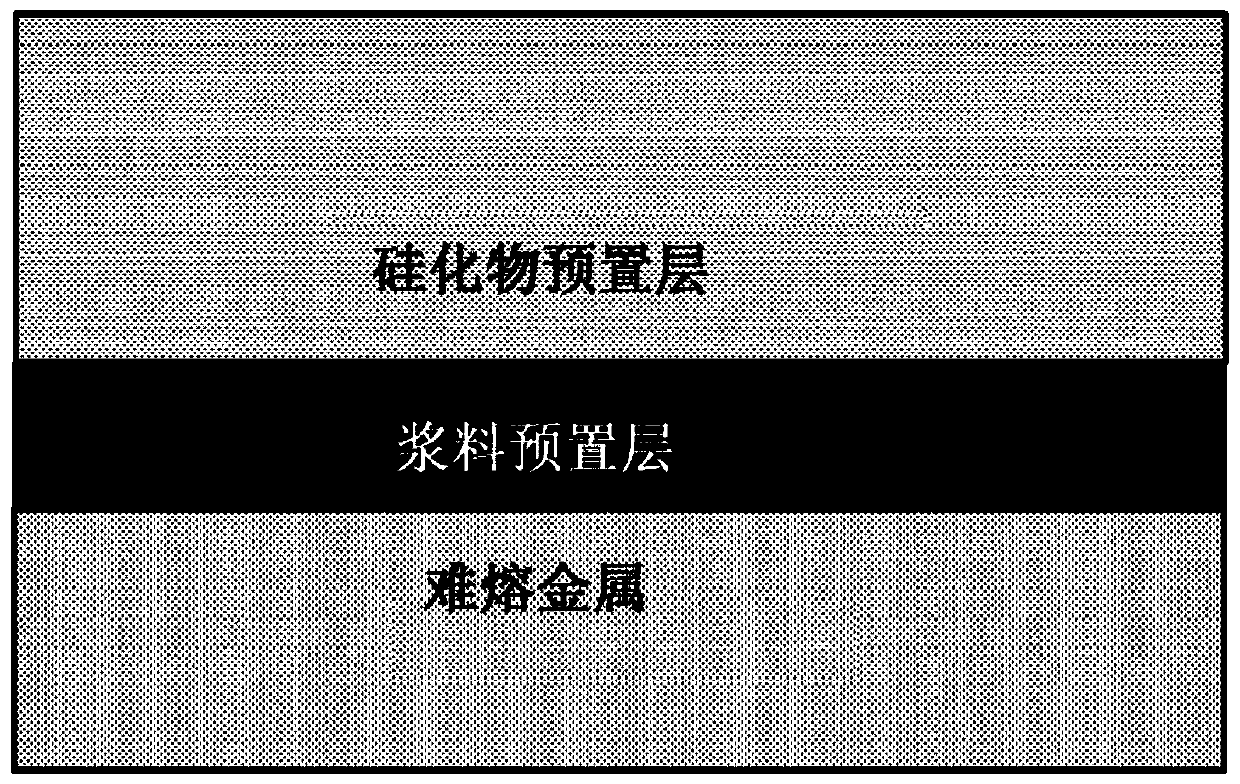

[0031] The preparation method of the Ta12W alloy surface in-situ reaction self-generated high-temperature diffusion barrier in this embodiment includes the following steps:

[0032] Step 1. Use 600 # The surface of the Ta12W alloy is polished with SiC sandpaper, then sand blasted and pickled, and then immersed in acetone for degreasing to obtain the pretreated Ta12W alloy; the sand used for the sand blast is corundum sand, and the sand blasted The pressure is 0.8MPa, and the sandblasting time is 8min; the ac...

Embodiment 2

[0039] The in-situ reaction self-generated high-temperature diffusion barrier on the surface of the Nb521 alloy in this embodiment is located between the Nb521 alloy and the Si-Mo-Zr high-temperature protective coating coated on the surface of the Nb521 alloy, and the SiC formed by the high-temperature chemical reaction between Si and graphene As the main phase, the thickness of the in-situ reaction self-generated high-temperature diffusion barrier is 6 μm.

[0040] The preparation method of the in-situ reaction self-generated high-temperature diffusion barrier on the surface of Nb521 alloy of this embodiment comprises the following steps:

[0041] Step 1. Use 600 # The surface of the Nb521 alloy is polished with SiC sandpaper, then sand blasted and pickled, and then immersed in acetone for degreasing to obtain the pretreated Nb521 alloy; the sand used in the sand blasting is zirconia sand, and the sand blasting The pressure is 0.6MPa, and the sandblasting time is 4min; the a...

Embodiment 3

[0048] The self-generated high-temperature diffusion barrier of in-situ reaction on the surface of Mo1 in this example is located between Mo1 and the Si-Cr-Ti high-temperature protective coating coated on the surface of Mo1, mainly SiC formed by the high-temperature chemical reaction between Si and graphene oxide Phase, the thickness of the in-situ reaction self-generated high-temperature diffusion barrier is 0.5 μm.

[0049] The preparation method of the Mo1 surface in situ reaction self-generated high-temperature diffusion barrier in this embodiment includes the following steps:

[0050] Step 1. Use 600 # The surface of Mo1 is polished by SiC sandpaper, then sand blasted and pickled, then immersed in acetone for degreasing to obtain pretreated Mo1; the sand used in the sand blasting is glass beads, and the sand blasting pressure is 0.2MPa, sandblasting time is 8min; The acid solution that described pickling adopts is mixed according to the volume ratio of 7:4 by hydrofluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com