Refractory metal surface in-situ reaction self-generation high-temperature diffusion barrier and preparing method thereof

A refractory metal, high temperature diffusion technology, applied in solid diffusion coating, metal material coating process, coating and other directions, can solve the problem of weakening the solid solution strengthening effect of solid solution elements, reducing the high temperature oxidation resistance of the coating, and shortening the coating. Layer life and other issues, to achieve excellent high-temperature structure and chemical stability, ensure high-temperature oxidation resistance, and prolong high-temperature service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

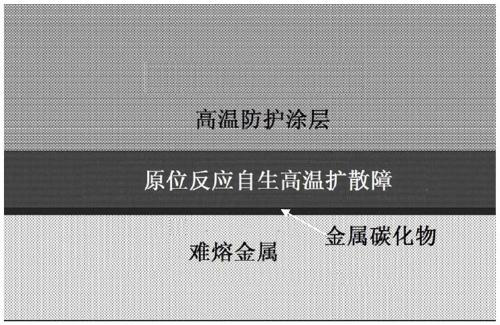

[0030] The surface of the Ta12W alloy in this embodiment reacts in situ and the self-generated high-temperature diffusion barrier is located between the Ta12W alloy and the Si-Cr-Ti-Zr high-temperature protective coating coated on the surface of the Ta12W alloy, and the high-temperature chemical reaction between Si and graphene oxide The generated SiC is the main phase, and the thickness of the in-situ reaction self-generated high-temperature diffusion barrier is 10 μm.

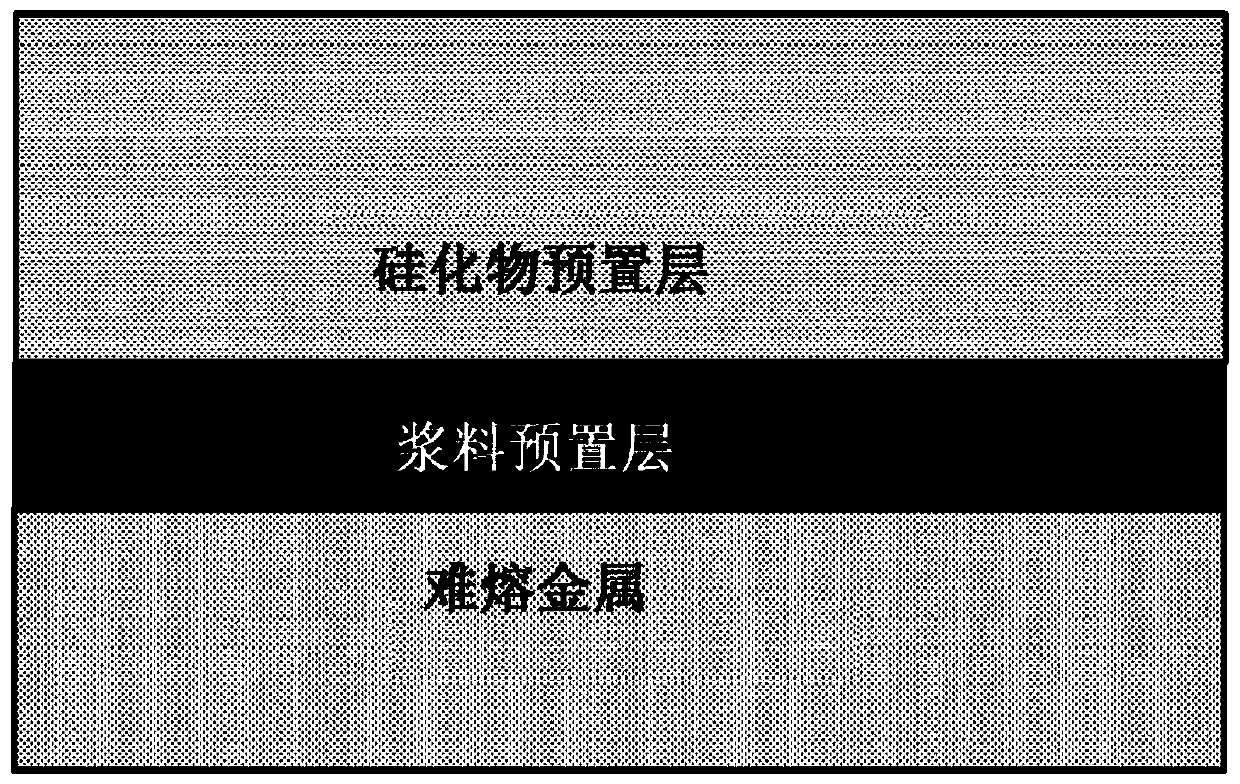

[0031] The preparation method of the Ta12W alloy surface in-situ reaction self-generated high-temperature diffusion barrier in this embodiment includes the following steps:

[0032] Step 1. Use 600 # The surface of the Ta12W alloy is polished with SiC sandpaper, then sand blasted and pickled, and then immersed in acetone for degreasing to obtain the pretreated Ta12W alloy; the sand used for the sand blast is corundum sand, and the sand blasted The pressure is 0.8MPa, and the sandblasting time is 8min; the ac...

Embodiment 2

[0039] The in-situ reaction self-generated high-temperature diffusion barrier on the surface of the Nb521 alloy in this embodiment is located between the Nb521 alloy and the Si-Mo-Zr high-temperature protective coating coated on the surface of the Nb521 alloy, and the SiC formed by the high-temperature chemical reaction between Si and graphene As the main phase, the thickness of the in-situ reaction self-generated high-temperature diffusion barrier is 6 μm.

[0040] The preparation method of the in-situ reaction self-generated high-temperature diffusion barrier on the surface of Nb521 alloy of this embodiment comprises the following steps:

[0041] Step 1. Use 600 # The surface of the Nb521 alloy is polished with SiC sandpaper, then sand blasted and pickled, and then immersed in acetone for degreasing to obtain the pretreated Nb521 alloy; the sand used in the sand blasting is zirconia sand, and the sand blasting The pressure is 0.6MPa, and the sandblasting time is 4min; the a...

Embodiment 3

[0048] The self-generated high-temperature diffusion barrier of in-situ reaction on the surface of Mo1 in this example is located between Mo1 and the Si-Cr-Ti high-temperature protective coating coated on the surface of Mo1, mainly SiC formed by the high-temperature chemical reaction between Si and graphene oxide Phase, the thickness of the in-situ reaction self-generated high-temperature diffusion barrier is 0.5 μm.

[0049] The preparation method of the Mo1 surface in situ reaction self-generated high-temperature diffusion barrier in this embodiment includes the following steps:

[0050] Step 1. Use 600 # The surface of Mo1 is polished by SiC sandpaper, then sand blasted and pickled, then immersed in acetone for degreasing to obtain pretreated Mo1; the sand used in the sand blasting is glass beads, and the sand blasting pressure is 0.2MPa, sandblasting time is 8min; The acid solution that described pickling adopts is mixed according to the volume ratio of 7:4 by hydrofluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com