Patents

Literature

31 results about "Inconel 625" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inconel Alloy 625 (UNS designation N06625) is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications.

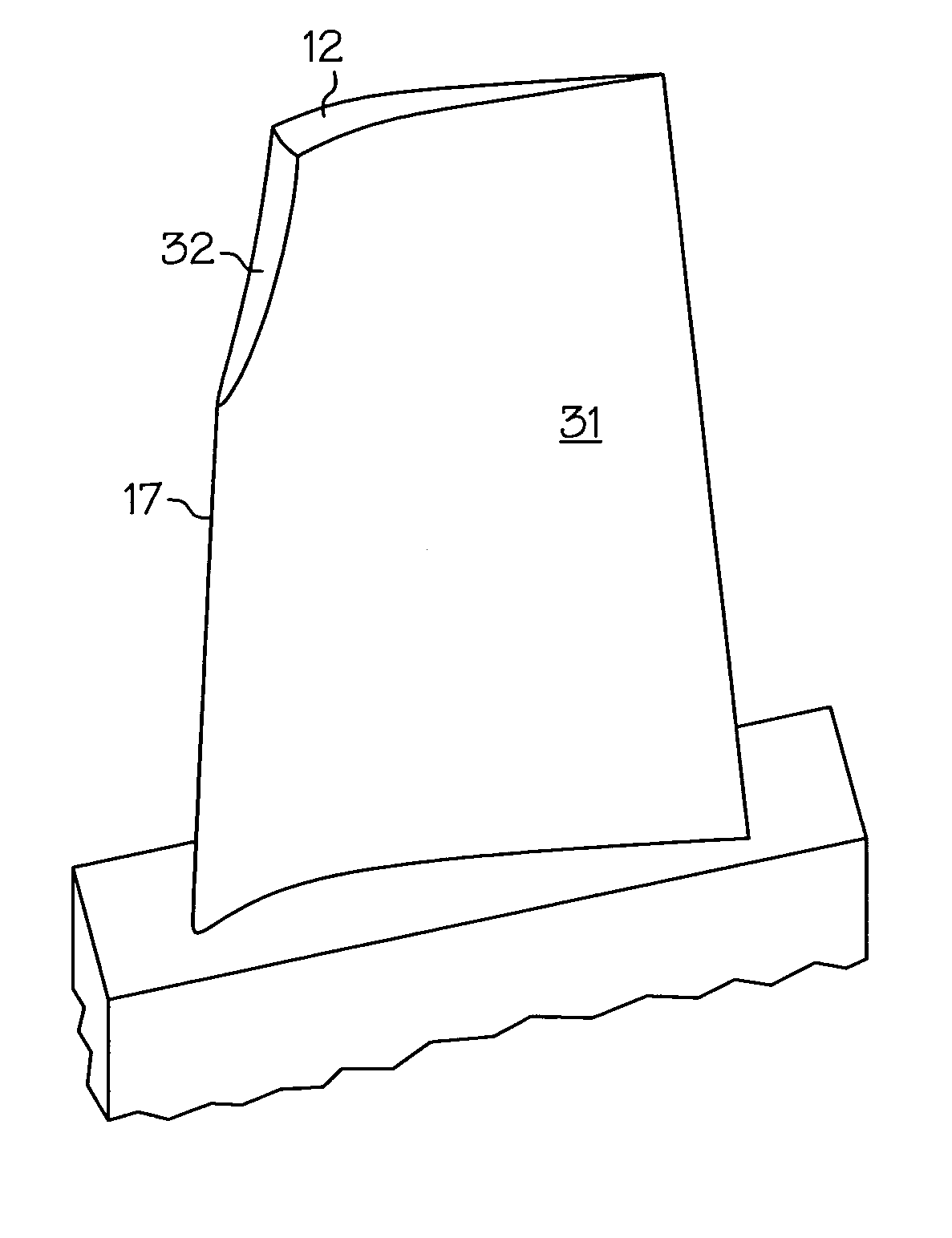

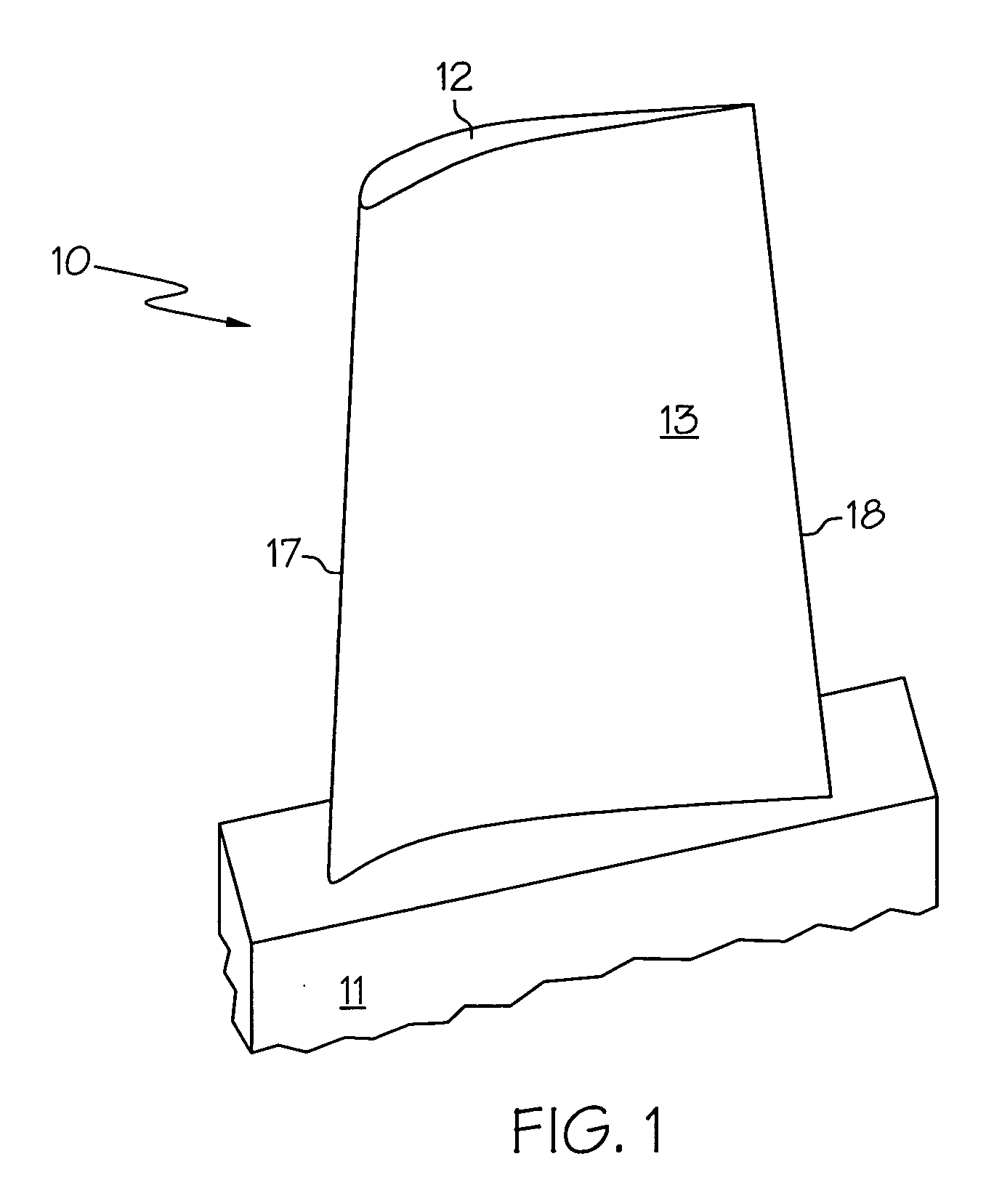

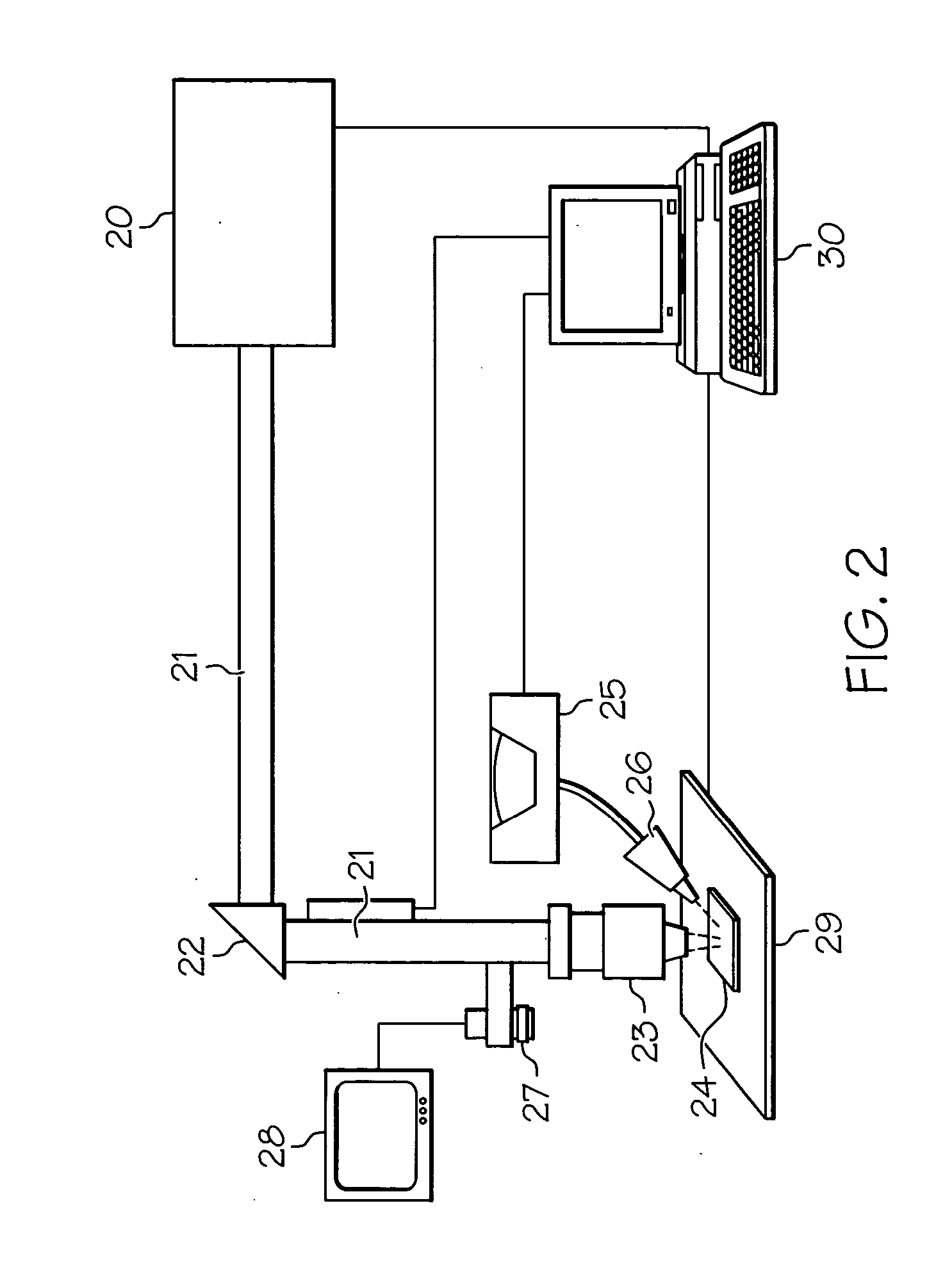

Method to restore an airfoil leading edge

The present invention provides methods and apparatus to restore a blade leading edge on a gas turbine engine component such as an airfoil of a turbine blisk. The method utilizes welding image technology and power control systems in order to provide effective welding with superalloy materials such as Inconel 713 and Inconel 625. The method includes machining away a damaged leading edge and providing a repaired region through successive depositions of superalloy powder filler through laser fusion welding. Deposition material is added until the repaired region exceeds the original dimensions of the airfoil. The airfoil is then machined and finished to return it to original airfoil dimensions.

Owner:HONEYWELL INT INC

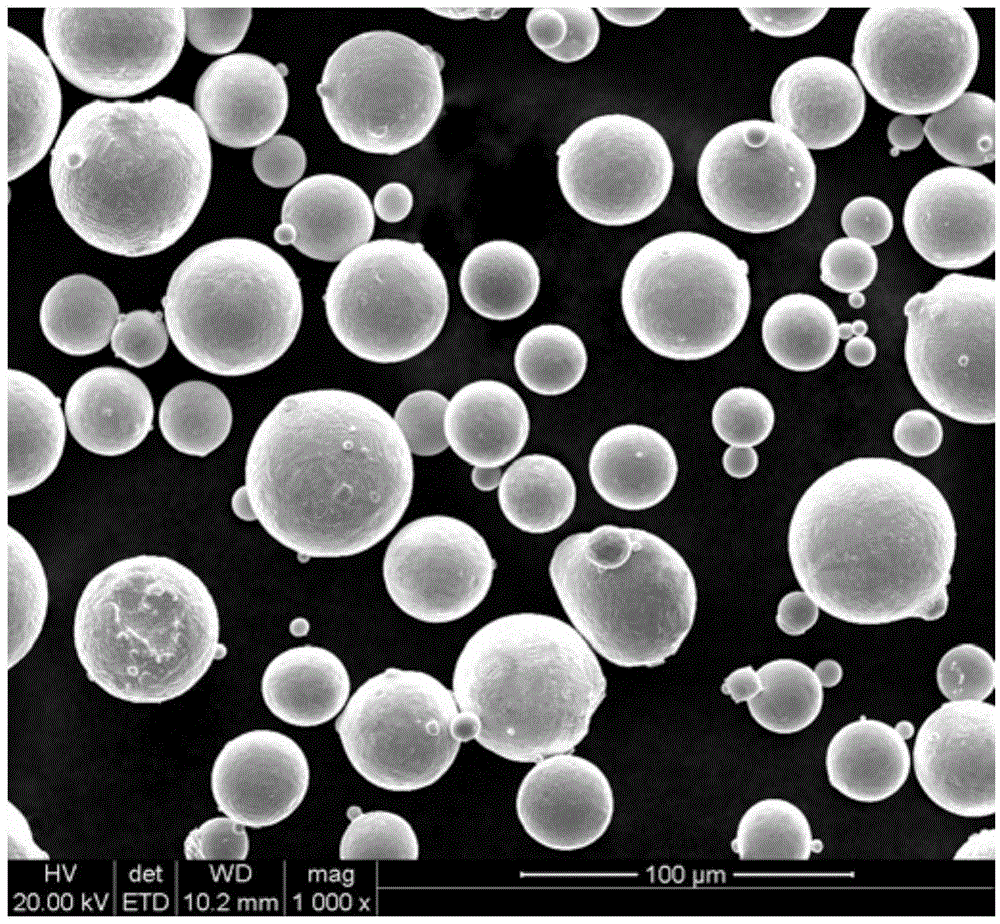

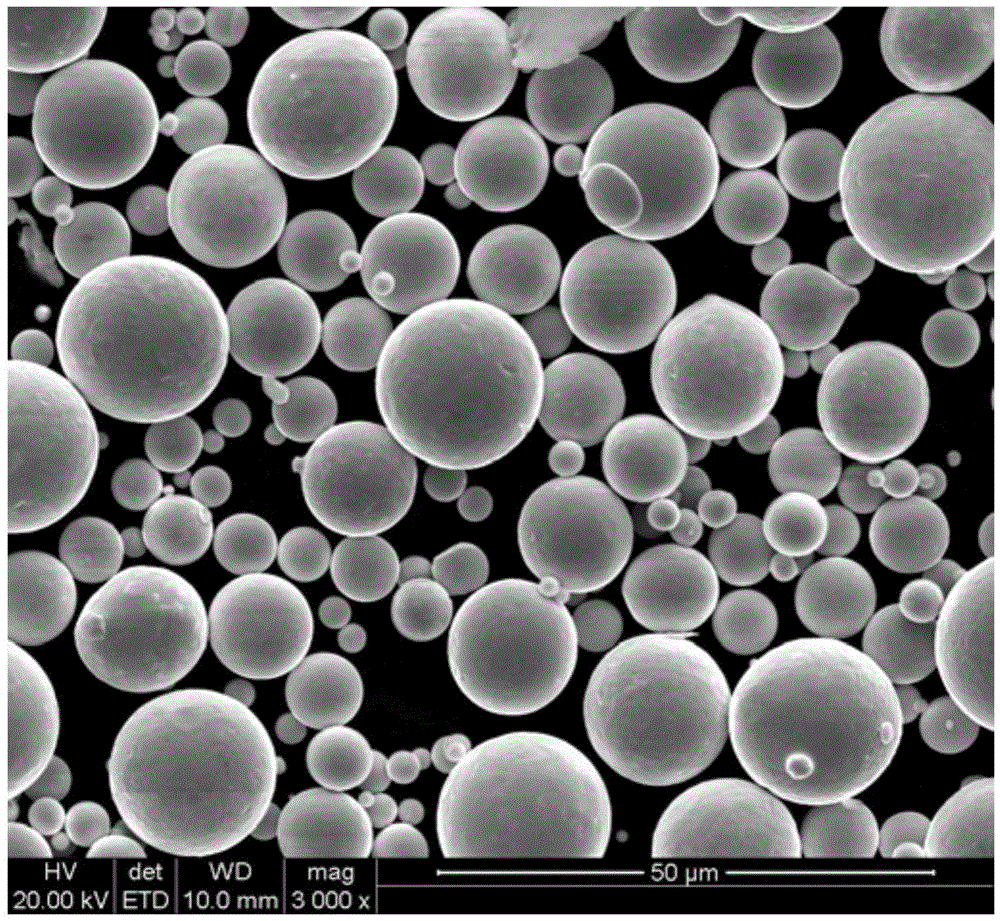

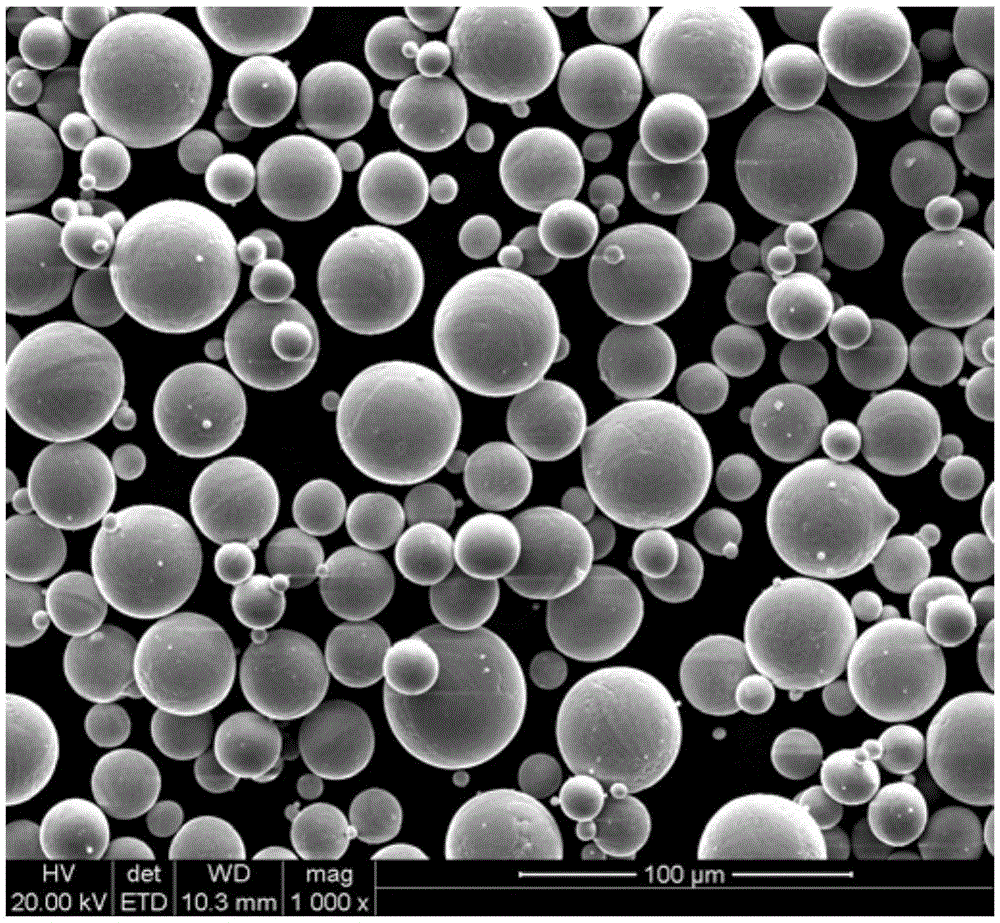

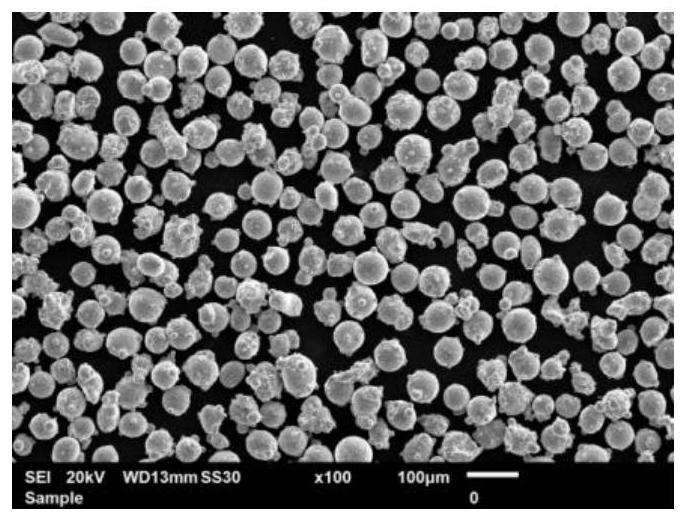

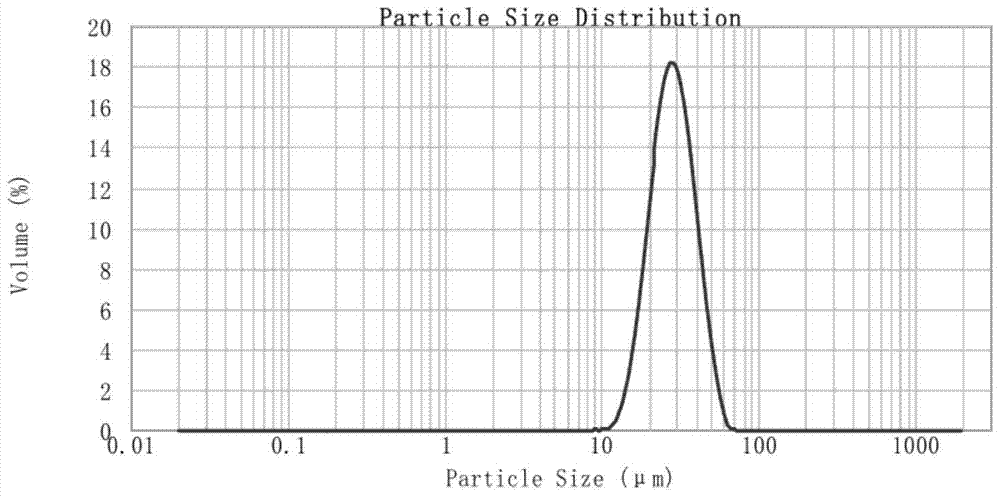

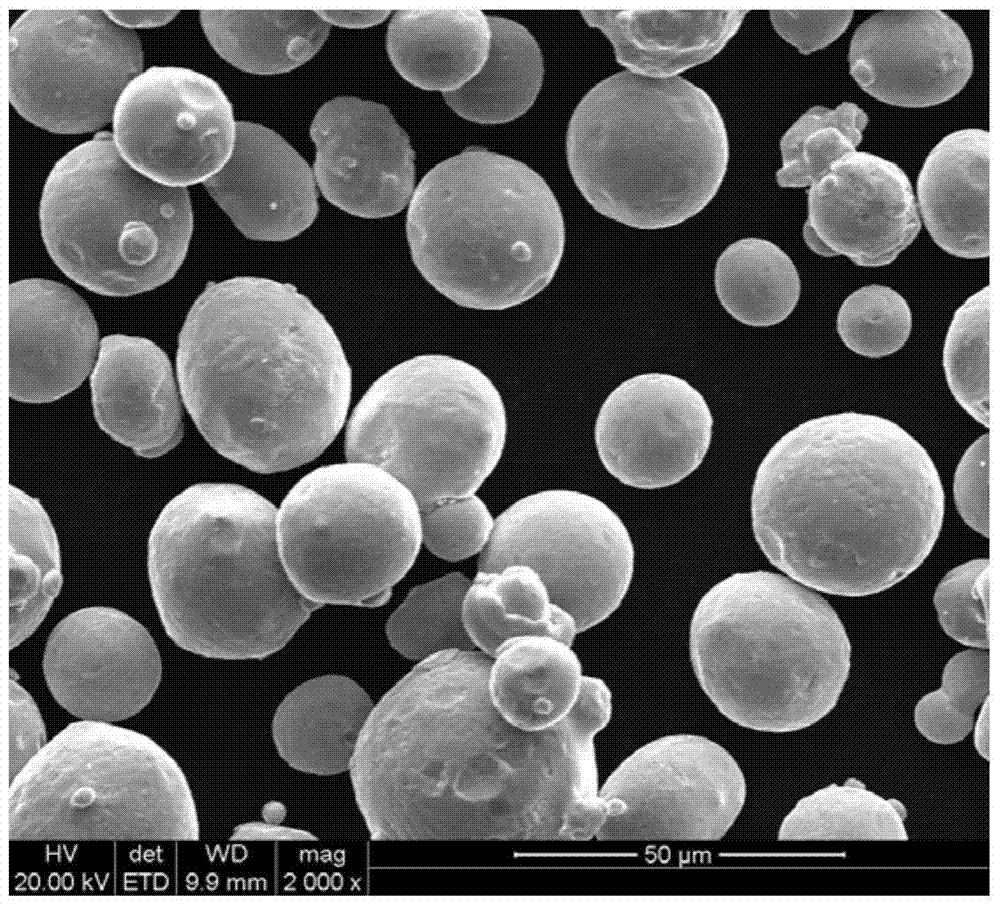

High-sphericity Inconel 625 alloy powder and preparation method and application thereof

The invention relates to high-sphericity Inconel 625 alloy powder and a preparation method and application thereof. According to the method, vacuum smelting technology is adopted, the Si content is controlled to improve the sphericity of Inconel 625 alloy powder particles, an ultrasonic vibration and airflow classification method is applied for matching the powder of different particle sizes, and the Inconel 625 alloy powder applicable to different metal 3D printing technologies is obtained through preparation. Compared with the prior art, the obtained Inconel 625 alloy powder has the beneficial effects of being uniform in component, low in impurity content, high in sphericity degree, optimized in particle size distribution and the like, the requirement of different metal 3D printing technologies for the Inconel 625 alloy powder material is met, and the application field of the metal material increasing manufacturing is expanded.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD +1

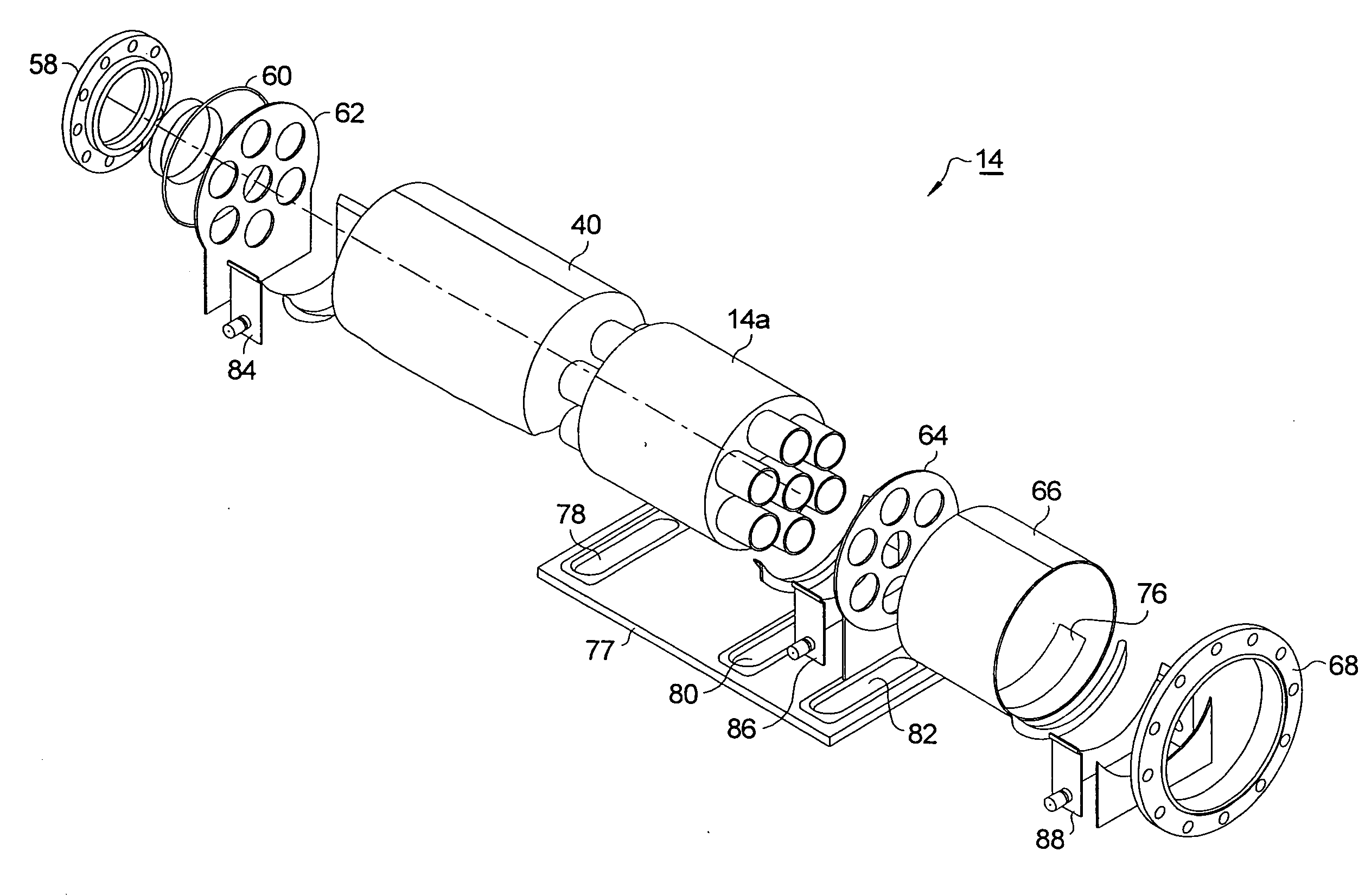

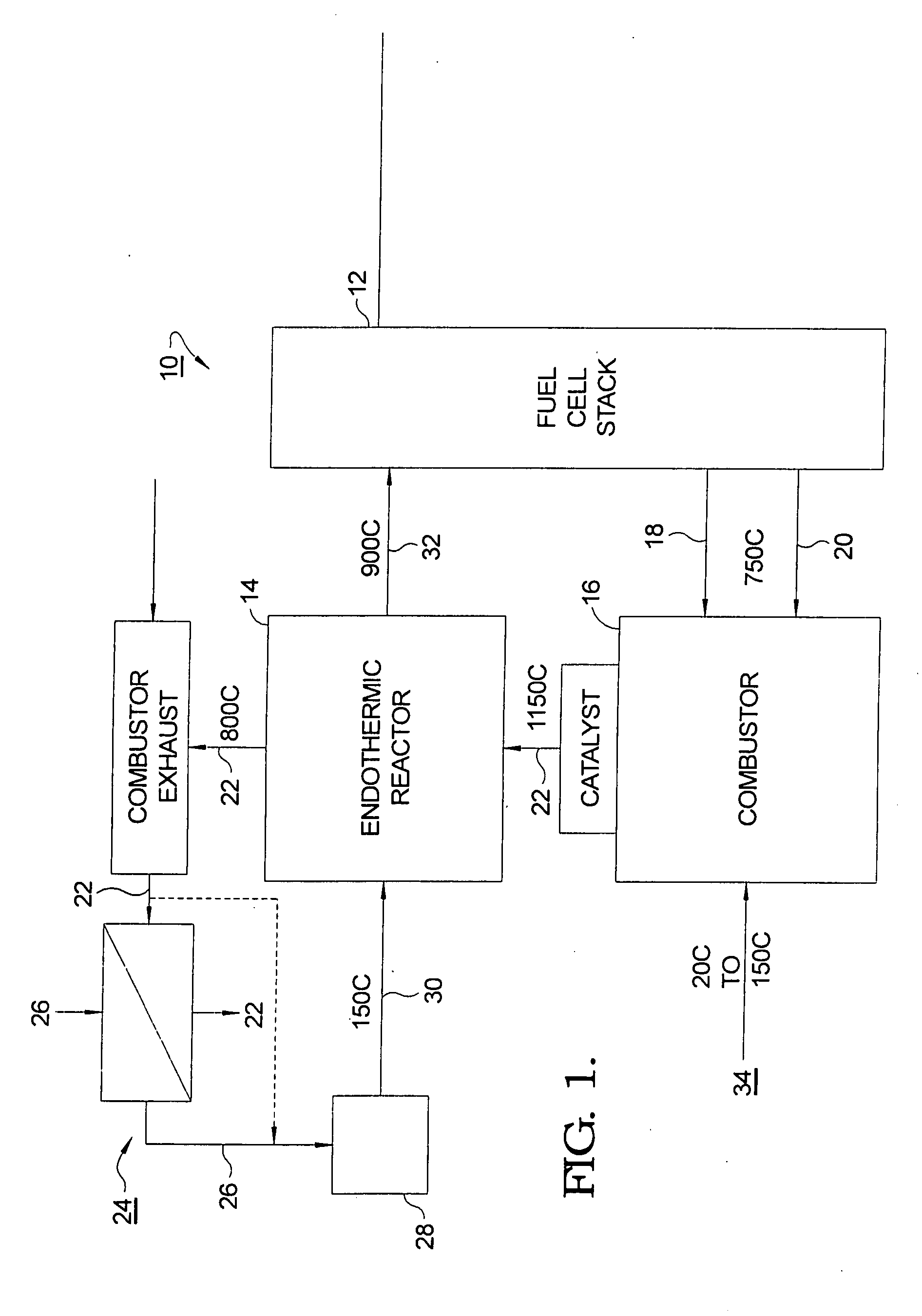

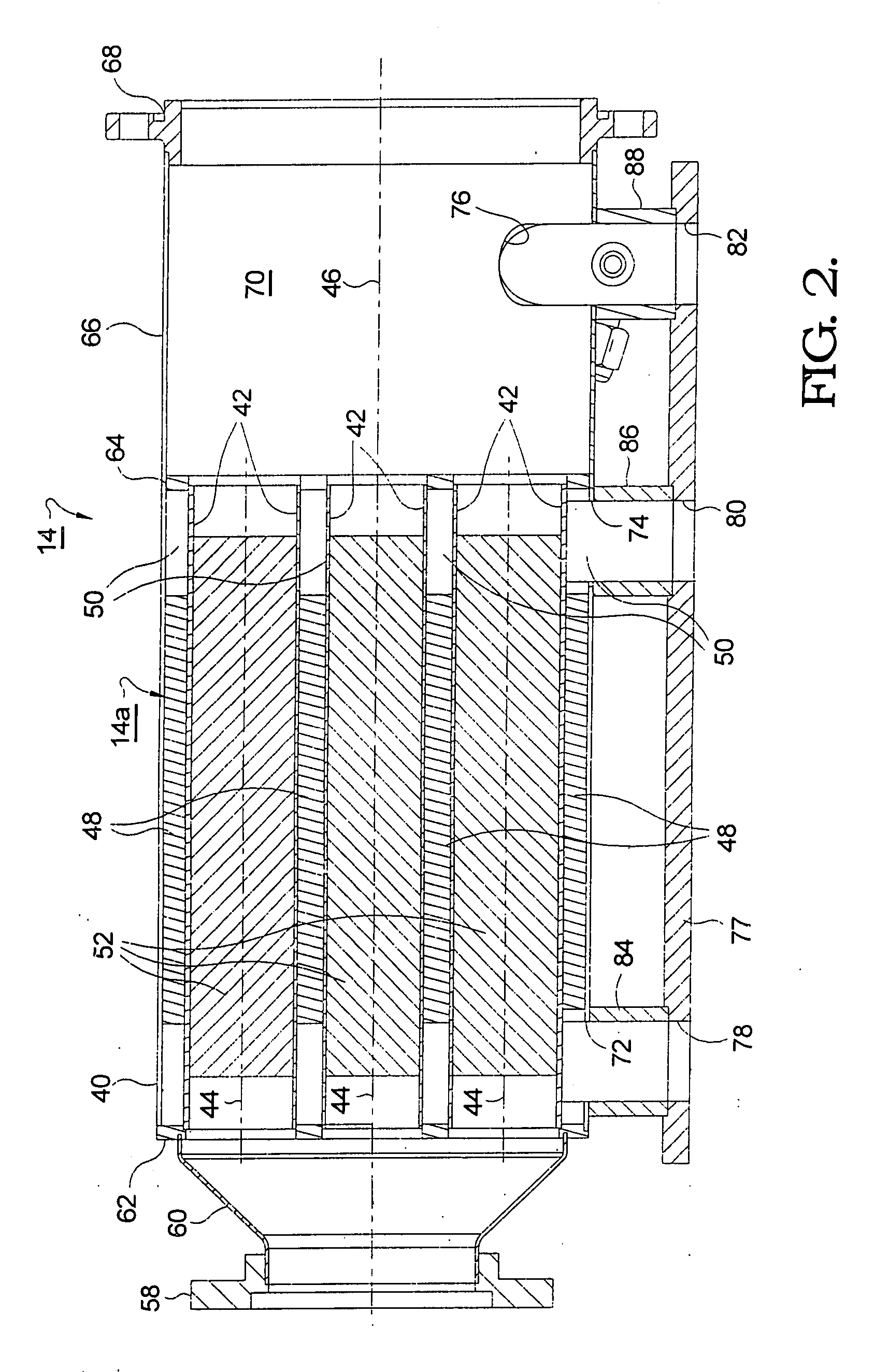

Multi-tube fuel reformer with augmented heat transfer

InactiveUS20090042071A1Improve mechanical stabilityPromote oxidationCatalytic gas-gas reactionHydrogenCatalytic reformingEngineering

A catalytic reformer assembly including a reactor comprising a plurality of parallel tubes arranged within a tubular housing. A metal substrate, formed preferably as a metal foam lattice, is brazed to the tubes on both their inside and outside surfaces. A catalytic washcoat is applied to the metal substrate within the tubes, defining thereby the tubes as individual catalytic reforming reactors. Endothermic reforming reactions within the tubes are supported by heat from hot combustor exhaust flowing around the tubes in contact with the augmenting heat transfer metal substrates outside the tubes. Radial temperature gradients are small because of excellent heat transfer across the tube walls, resulting in excellent mechanical stability of the washcoat on the metal substrate. Preferably, the tubes are formed of Inconel 625 and the metal substrate is formed of Fecralloy®, a high temperature alloy having excellent thermal conductivity and oxidation resistance.

Owner:DELPHI TECH INC

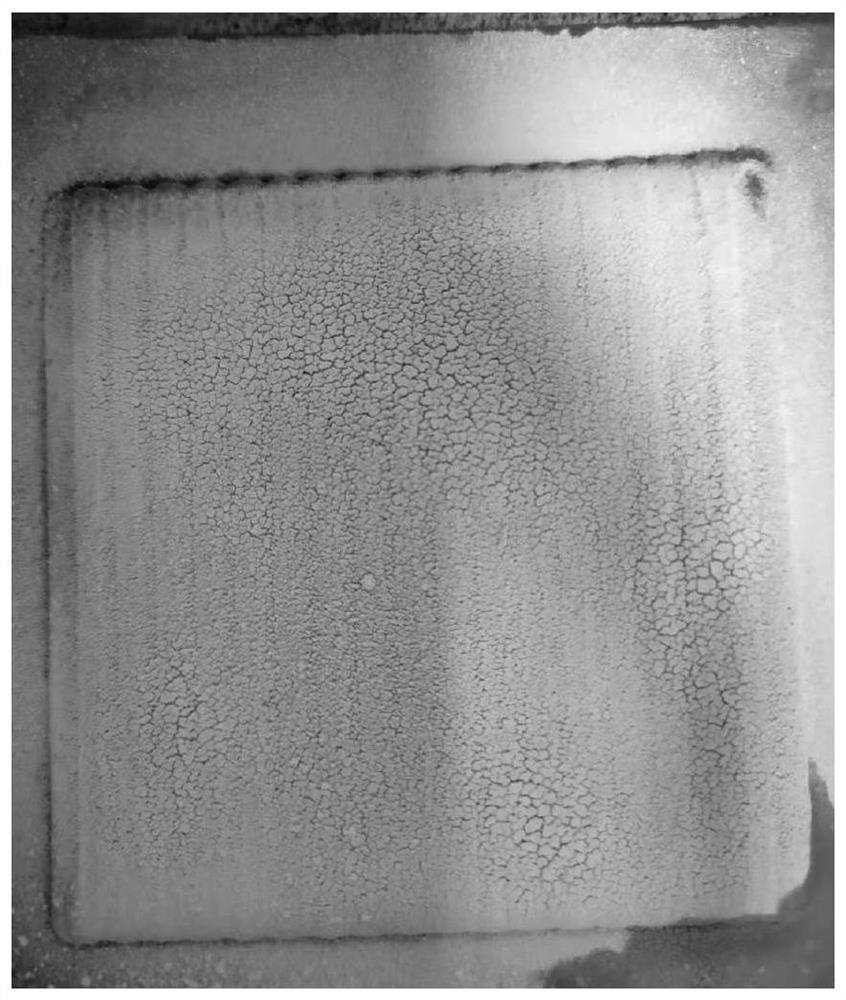

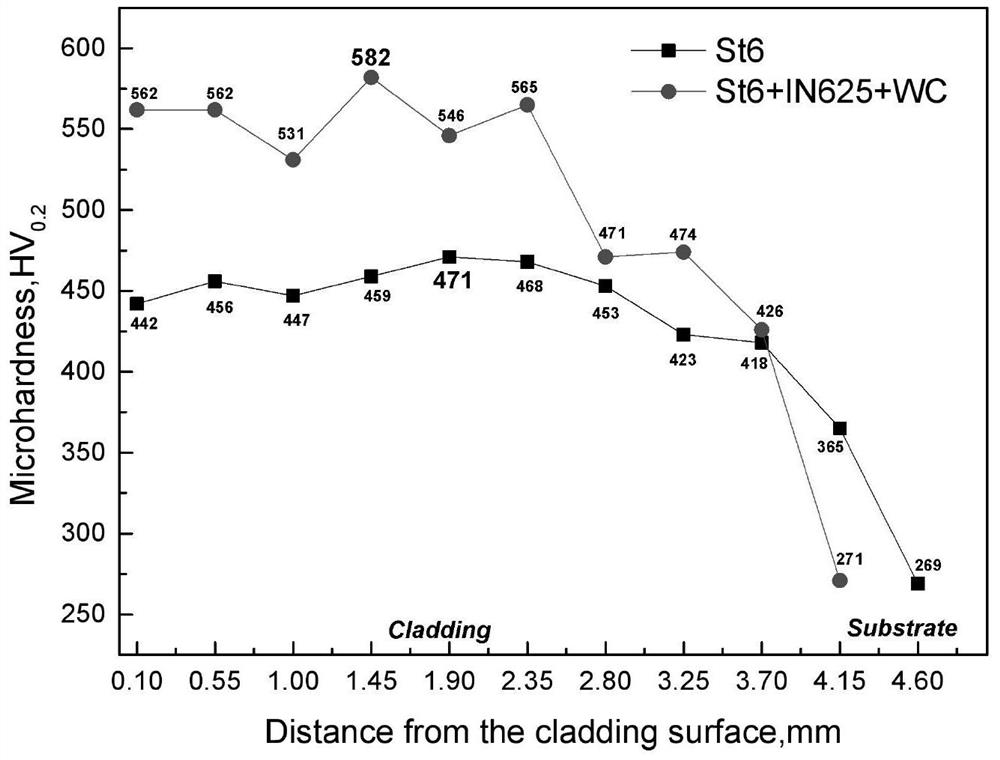

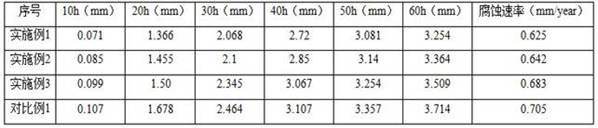

Preparation method of cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance

ActiveCN112647076AHigh hardnessImprove wear resistanceIncreasing energy efficiencyMetallic material coating processesSS - Stainless steelStellite

The invention discloses a preparation method of a cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance. The preparation method comprises the following steps that (1) oxide skin and oil stain on the surface of a duplex stainless steel base material are removed; (2) three kinds of material powder, namely Stellite 6, Inconel 625 and WC ceramic particles are weighed; (3) the three kinds of powder are uniformly mixed and dried; (4) technological parameters are set, and laser cladding is conducted on the surface of the duplex stainless steel base material; (5) finish machining is conducted. The Stellite 6 widely applied to cobalt-based alloy is selected as a powder main body, the high-hardness WC ceramic particles are added as an enhancer, the nickel-based alloy Inconel 625 powder with excellent welding performance is added, and the coating is prepared by changing the proportion of composite powder and adjusting laser cladding process parameters. The preparation process is simple, the traditional procedures of base material preheating treatment and workpiece post-treatment can be omitted, the powder preparation cost can be reduced, and the problem that the cobalt-based ceramic particle composite powder cracks in large-area cladding in actual engineering application is solved.

Owner:浙江翰德圣智能再制造技术有限公司

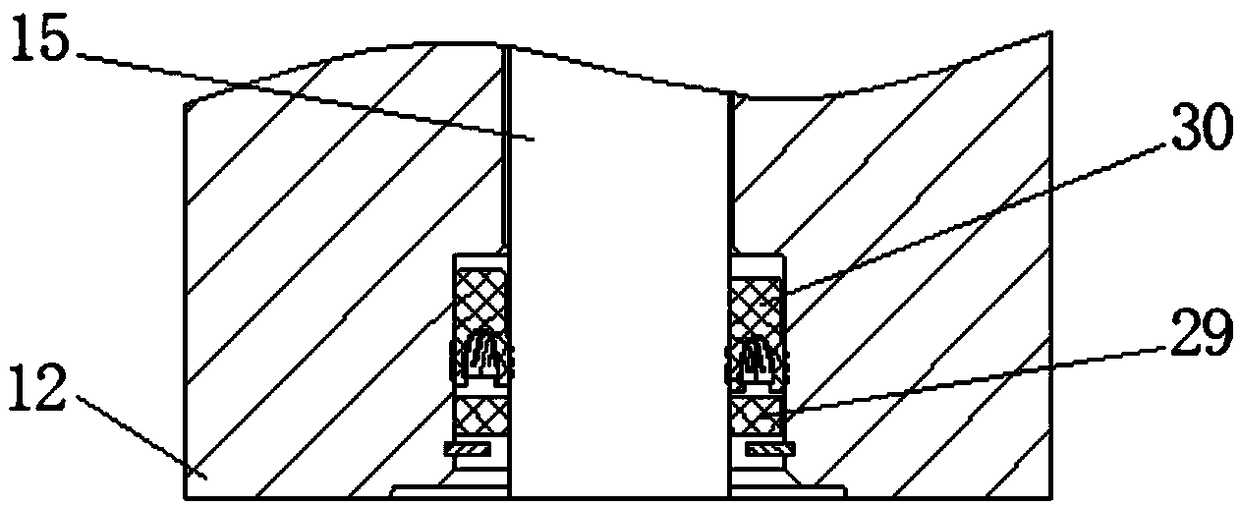

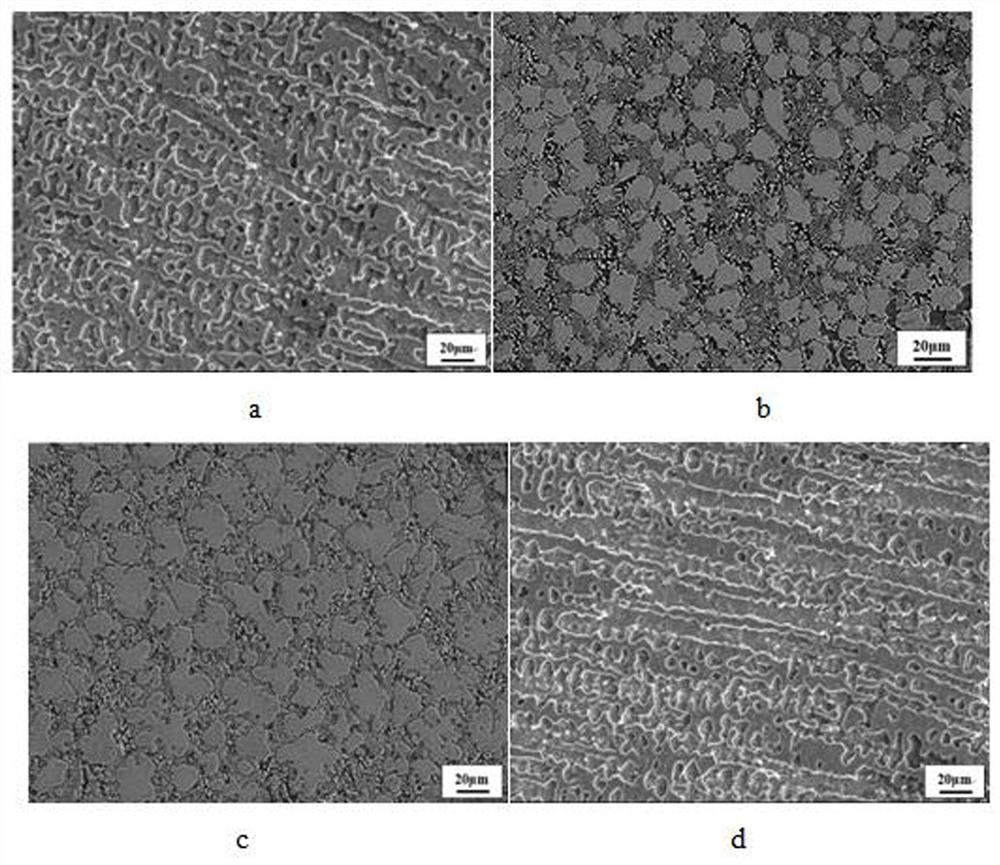

Inconel 625 alloy dendrite morphology method

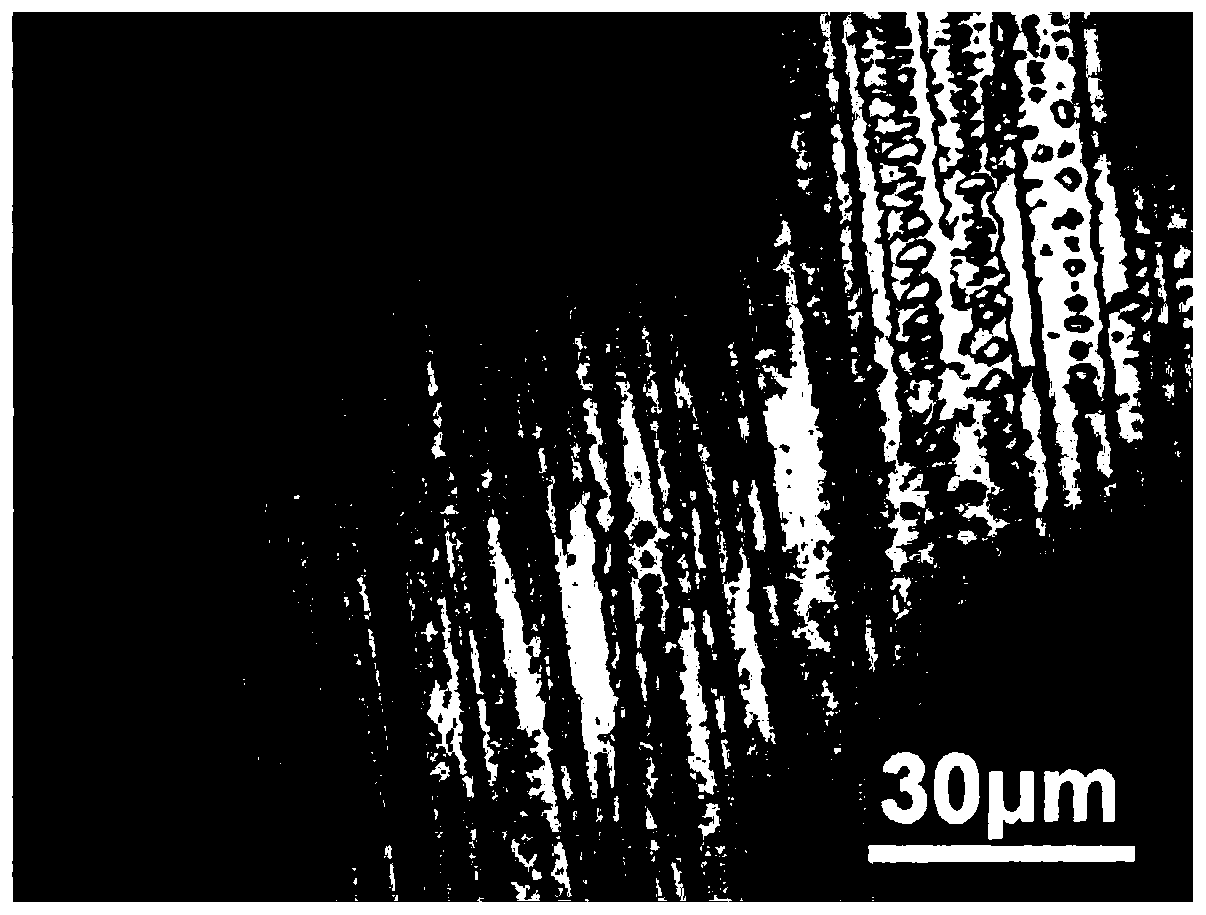

ActiveCN110935877AImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyTemperature curveInconel 625

In the invention, a fixed-point temperature change curve is acquired through recording a temperature change when a molten pool passes through a middle position of a single-channel cladding layer during laser additional material forming process of Inconel 625 alloy. According to the fixed point temperature change curve, a peak temperature T of the fixed-point temperature change curve, an interceptt of a liquid phase line and a temperature curve, and an average cooling rate xi of a molten pool cooling stage are calculated. A laser additional material forming parameter of the Inconel 625 alloy is optimized, and finally a process parameter of columnar dendrites and the process parameter of equiaxed dendrites are obtained so as to realize adjustment and control of the Inconel 625 alloy dendrite morphology. A mechanical property of a formed part can be effectively increased.

Owner:FOSHAN UNIVERSITY

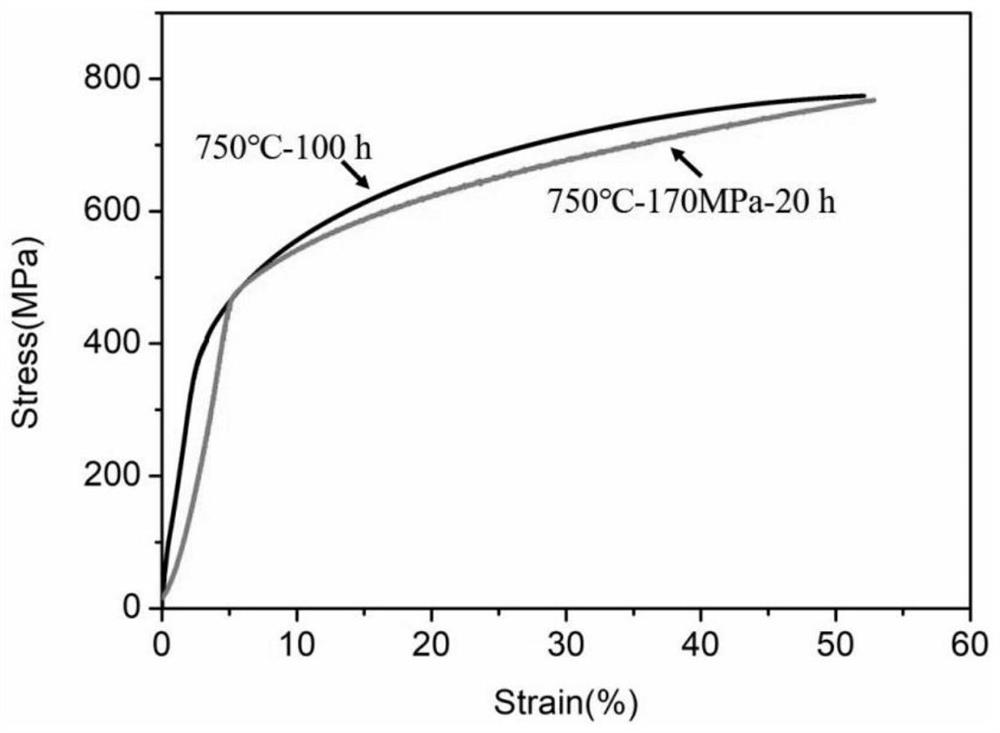

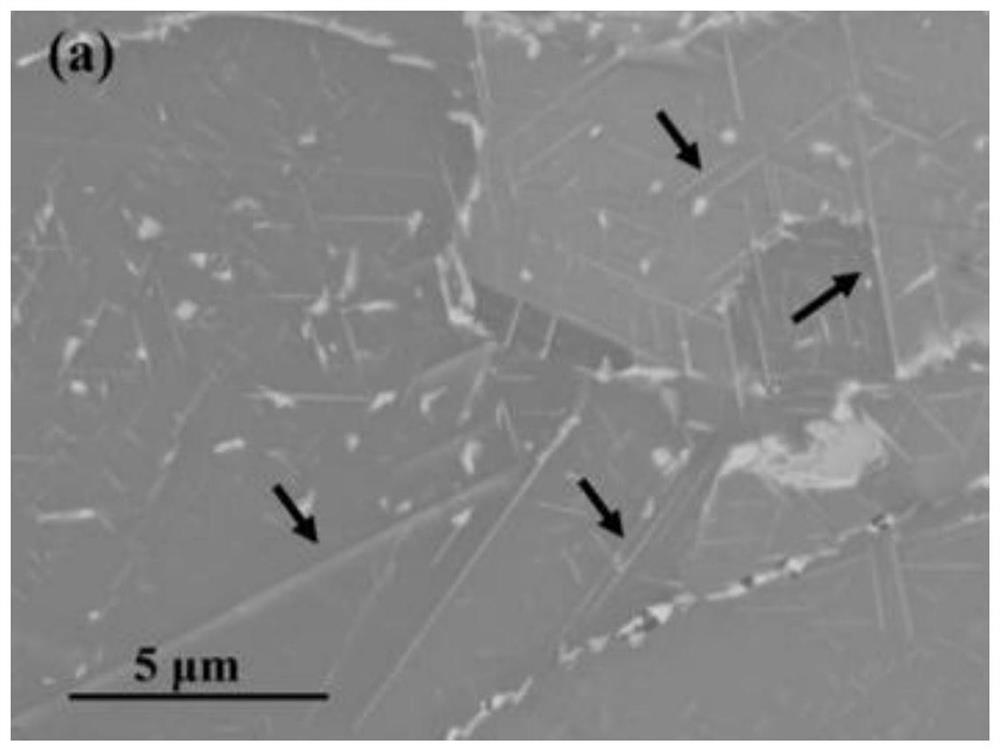

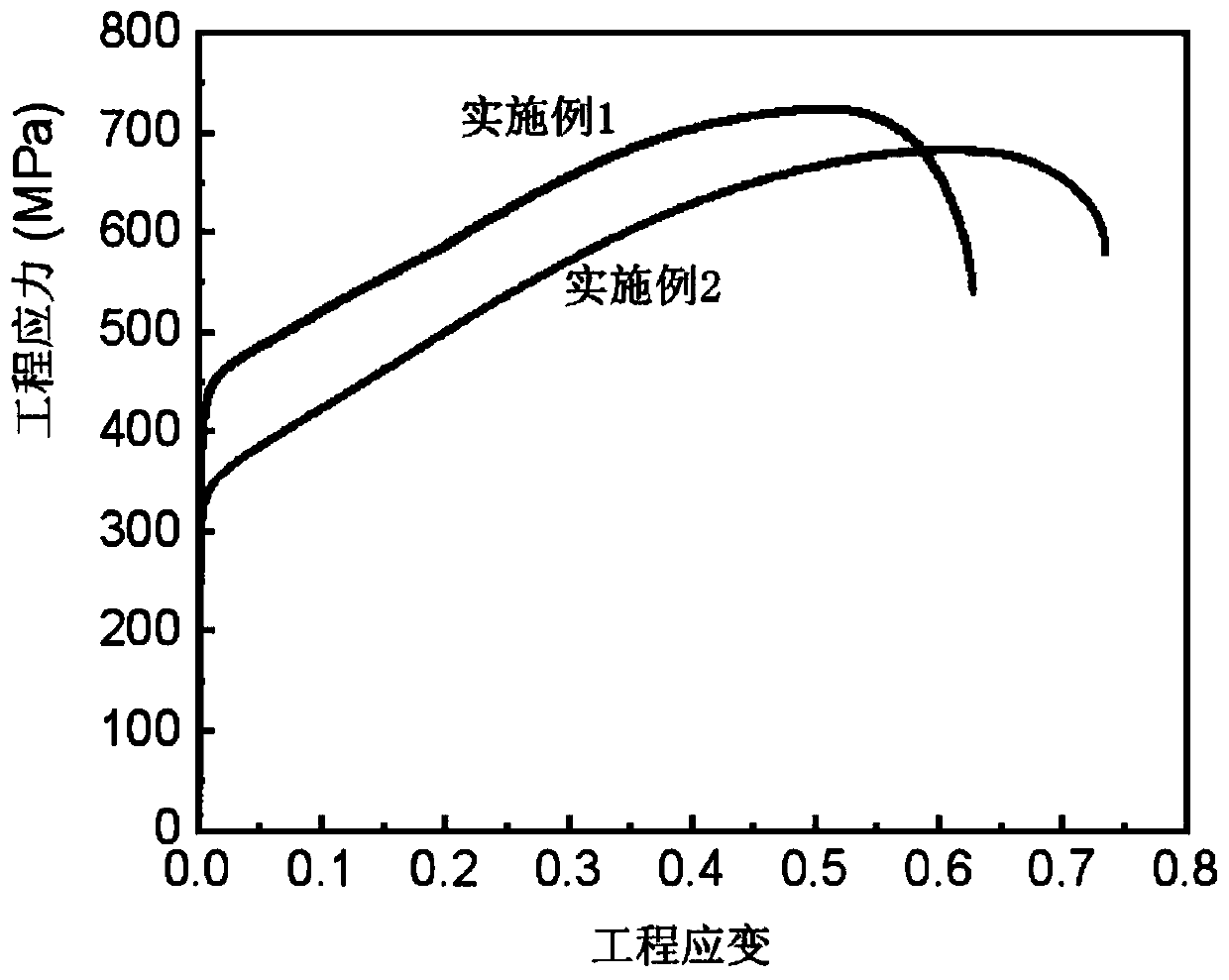

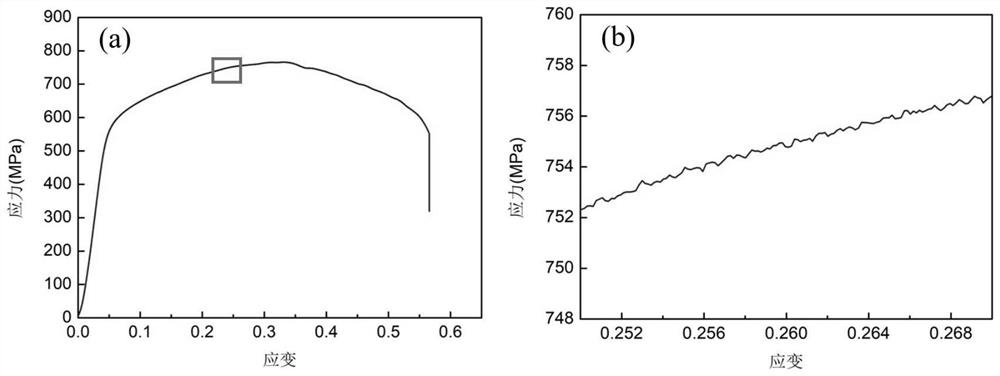

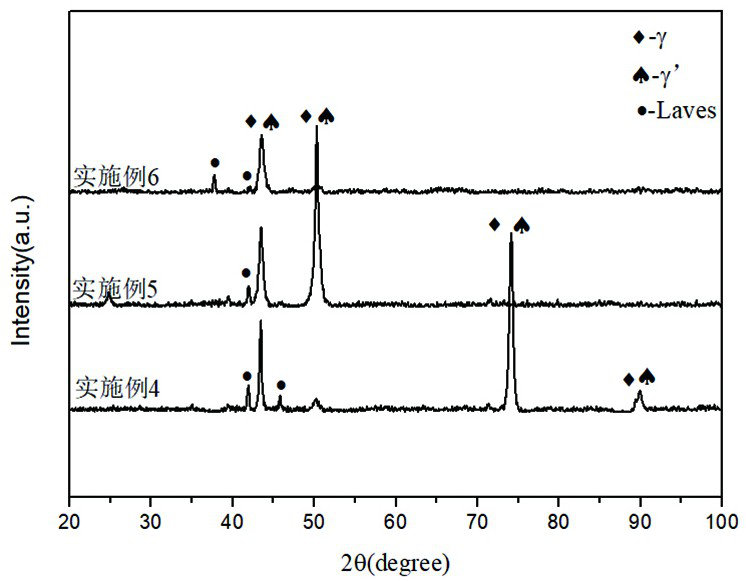

Aging heat treatment process for efficiently strengthening nickel-based superalloy

ActiveCN114214583AHigh tensile strengthImprove production efficiencyChemical industryFurnace temperatureHeat conservation

The aging heat treatment process comprises the following steps that S1, the furnace temperature is increased to 1100-1160 DEG C, an Inconel 625 alloy is put in, heat preservation is conducted for (d * 0.6 + 30)-(d * 0.6 + 70) min, d is the straight product of the cross section of the Inconel 625 alloy, and the unit is mm; s2, the Inconel 625 alloy is taken out and put into water to be quenched, and the quenching water temperature ranges from 10 DEG C to 25 DEG C; s3, the Inconel 625 alloy subjected to primary quenching is put into the furnace at the temperature of 750 DEG C to 800 DEG C again, tensile stress is applied, heat preservation is conducted for 20 h to 40 h, and the stress level ranges from 100 MPa to 250 MPa; and S4, the Inconel 625 alloy is taken out, secondary quenching is conducted, and the quenching water temperature ranges from 10 DEG C to 25 DEG C. According to the method, the tensile stress is applied to the Inconel 625 alloy subjected to solution strengthening, creep aging heat treatment is conducted, the generation efficiency of the delta phase is improved, hundreds of and thousands of hours of heating is not needed, the practicability of the alloy is effectively improved, in the heat treatment process, due to application of the tensile stress, the forming speed of the delta phase is higher, the number of the delta phase is larger, and distribution is more uniform; the size is smaller, and the tensile strength is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

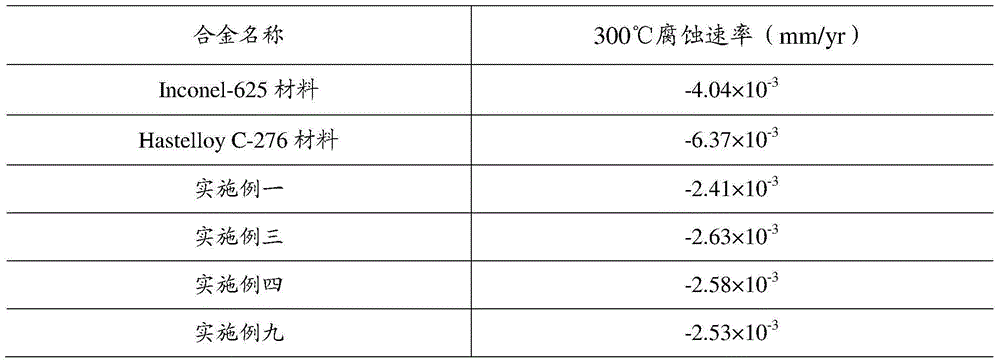

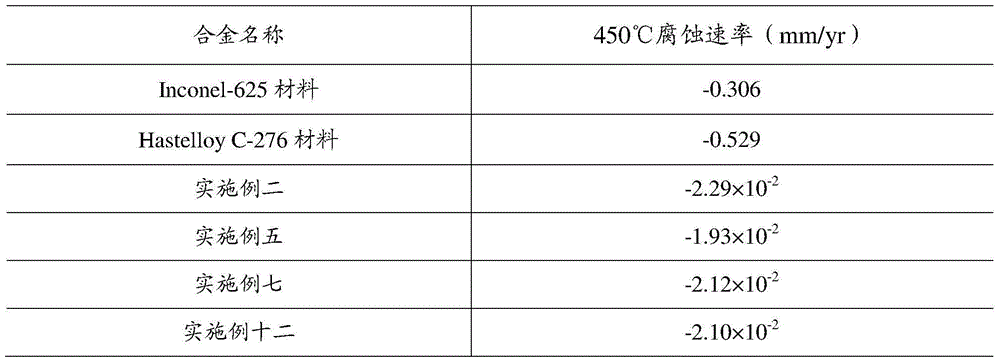

Nickel-based alloy and preparation method and application thereof

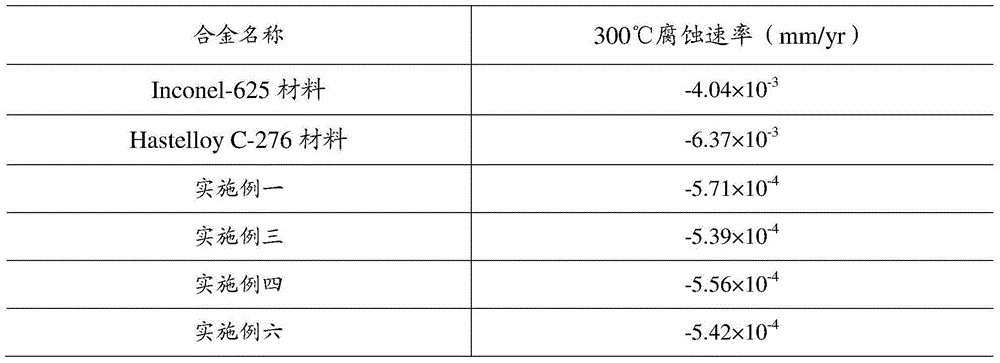

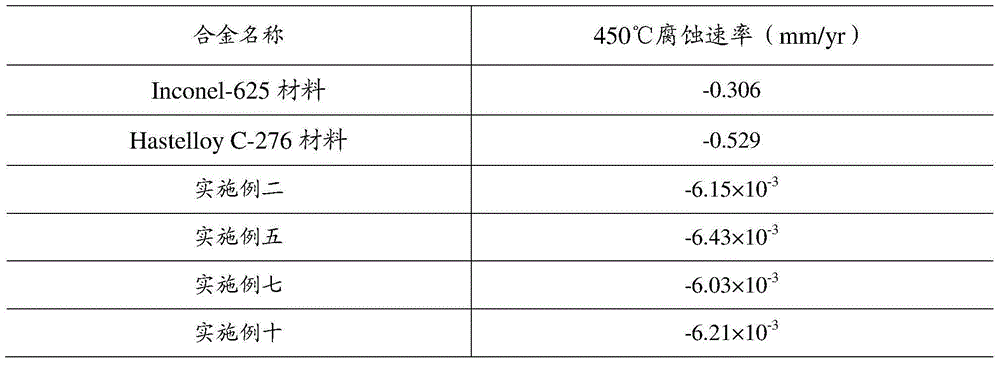

InactiveCN104862534AHigh strengthImprove antioxidant capacityWater/sewage treatment by oxidationCorrosion resistantInconel 625

The invention discloses nickel-based alloy and a preparation method and application thereof, and relates to the technical field of anti-corrosion materials. The nickel-based alloy and the preparation method and application thereof aim to solve the problem that an existing Inconel-625 material or a Hastelloy C-276 material causes poor corrosion resistance of supercritical equipment in an acidic oxidizing medium where various ions coexist. The nickel-based alloy comprises, by mass, 15-28% of Cr, 4-13% of Mo, 0.5-1.5% of Ti, 1-4% of Cu, 6-15% of Fe, 0-0.03% of C, 0-0.5% of microelements and the balance Ni. According to the preparation method of the nickel-based alloy, Ni, Cr, Mo and Fe are mixed and melted under a vacuum condition till being clarified, then refining is carried out, after refining is finished, Ti and the microelements are added and evenly stirred, desulfuration is carried out, and finally casting molding is carried out to obtain the nickel-based alloy. The nickel-based alloy can be used in the supercritical equipment as a corrosion-resistant material.

Owner:ENN SCI & TECH DEV

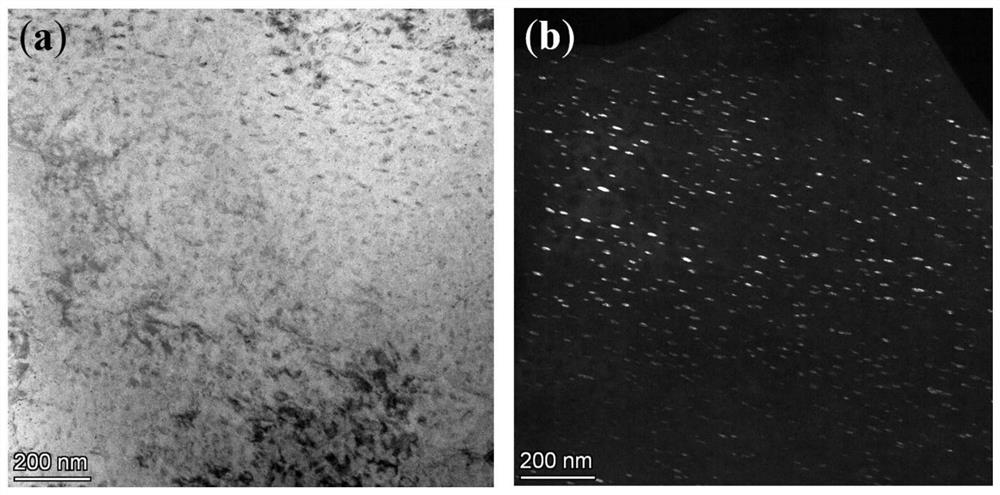

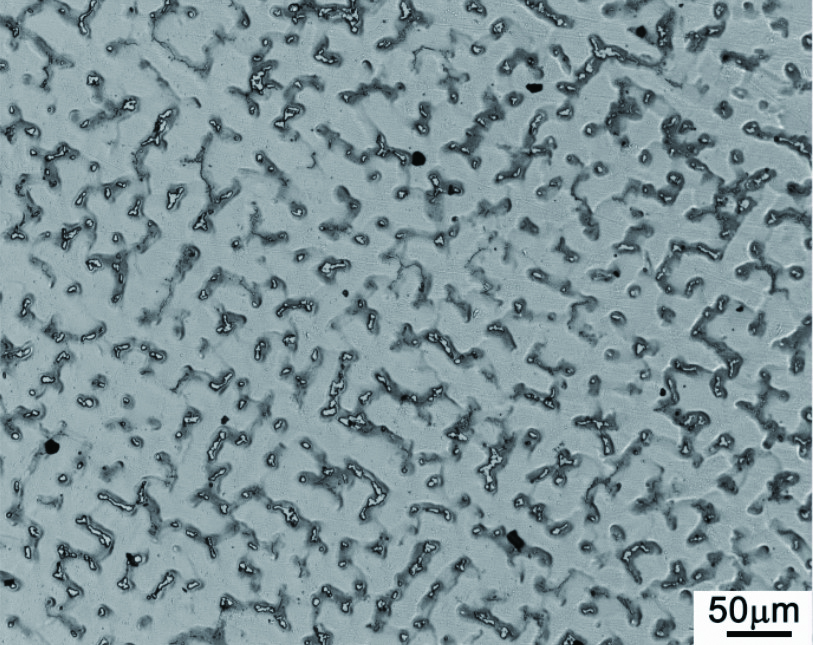

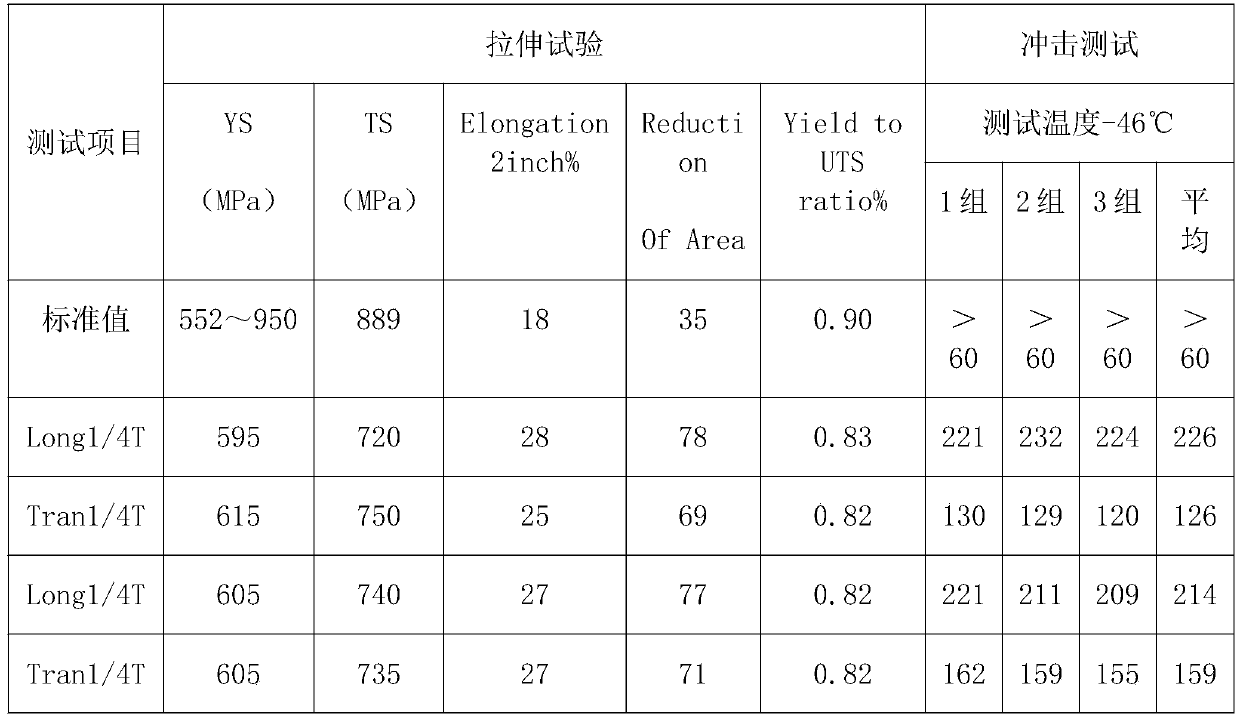

High-strength and high-plasticity single-phase Inconel 625 nickel-based alloy and preparation method thereof

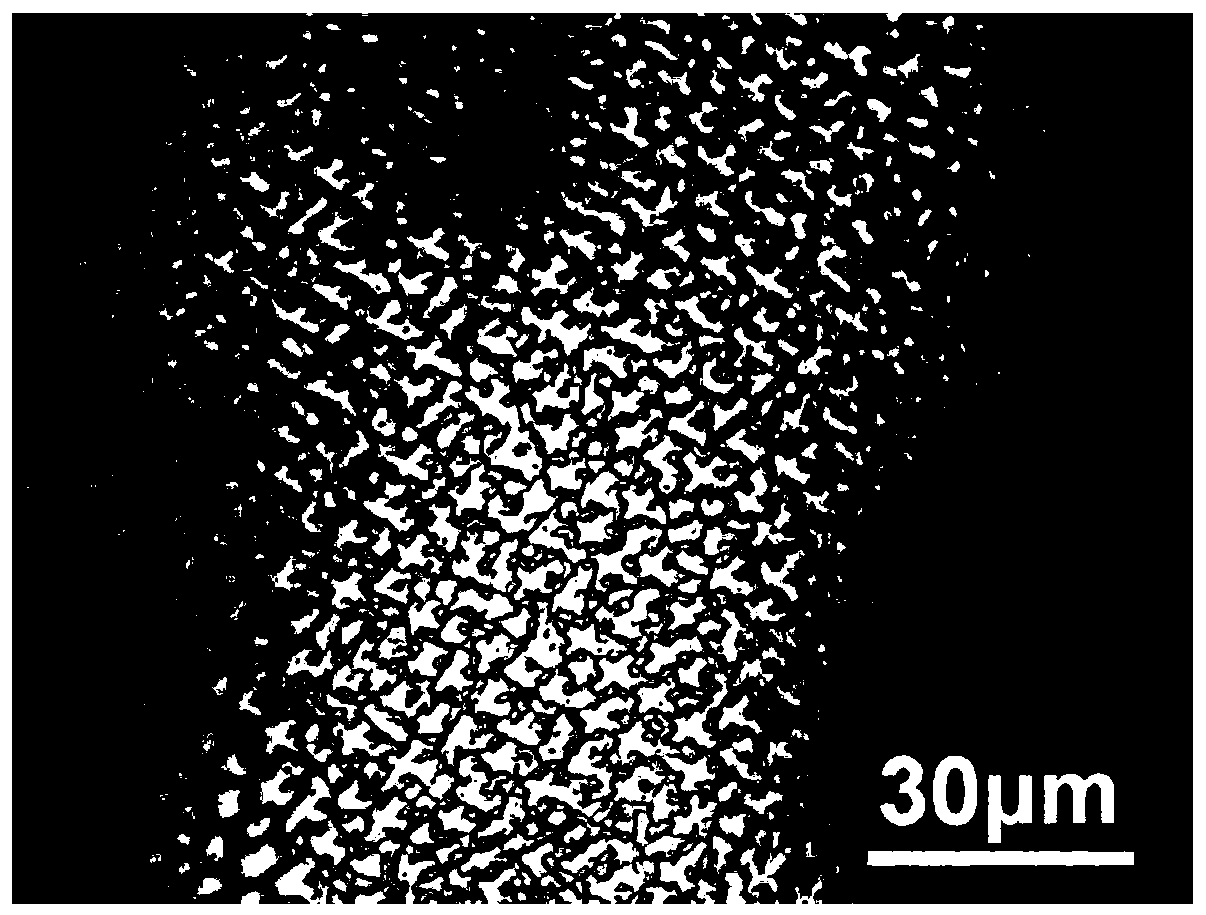

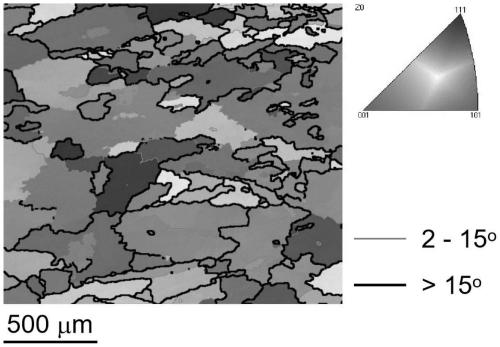

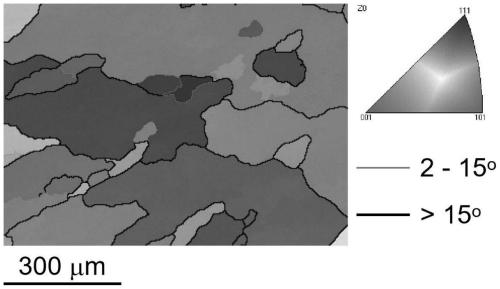

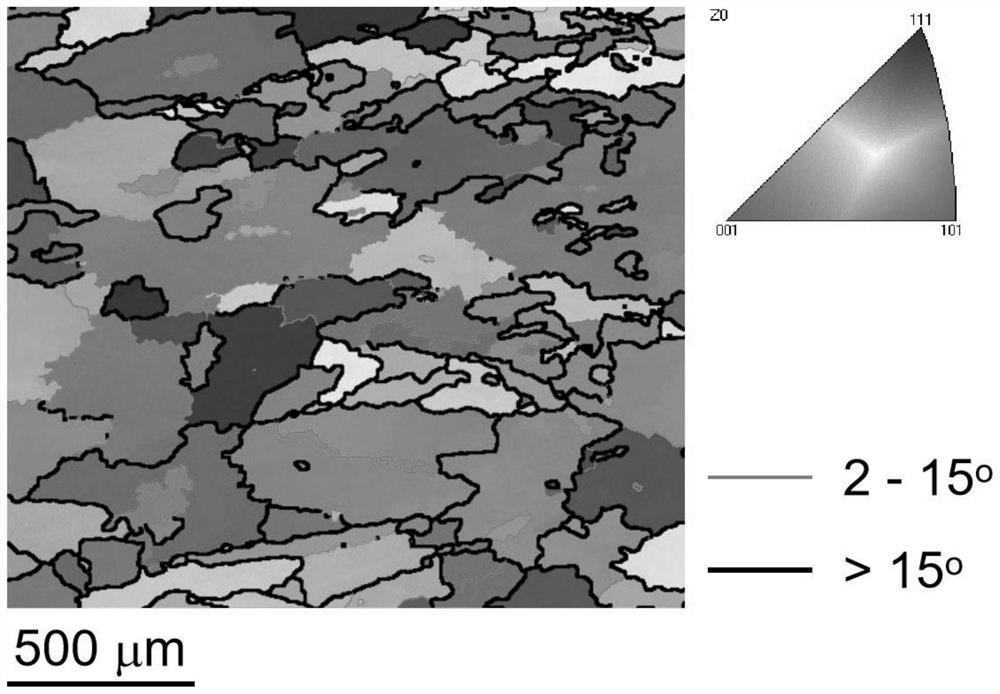

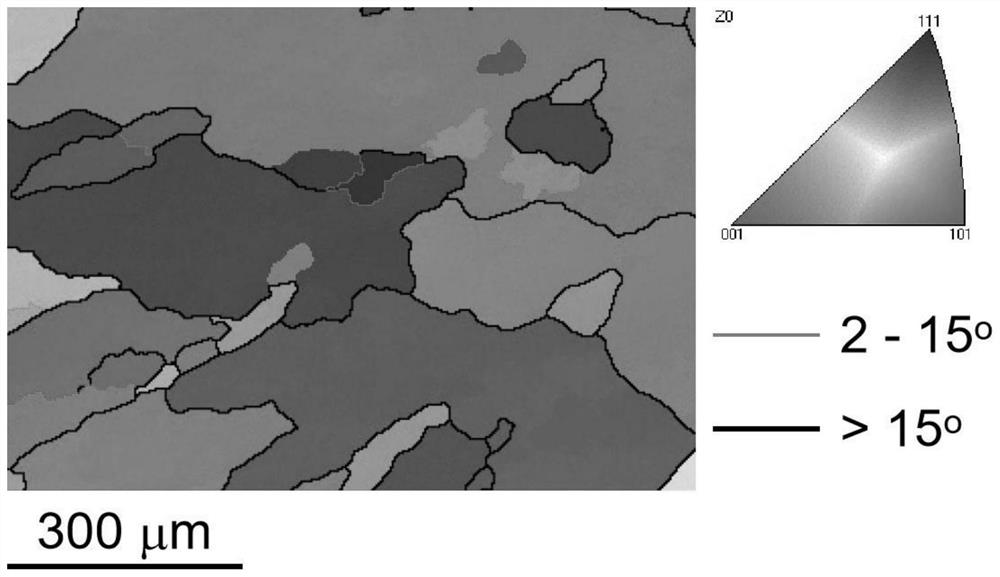

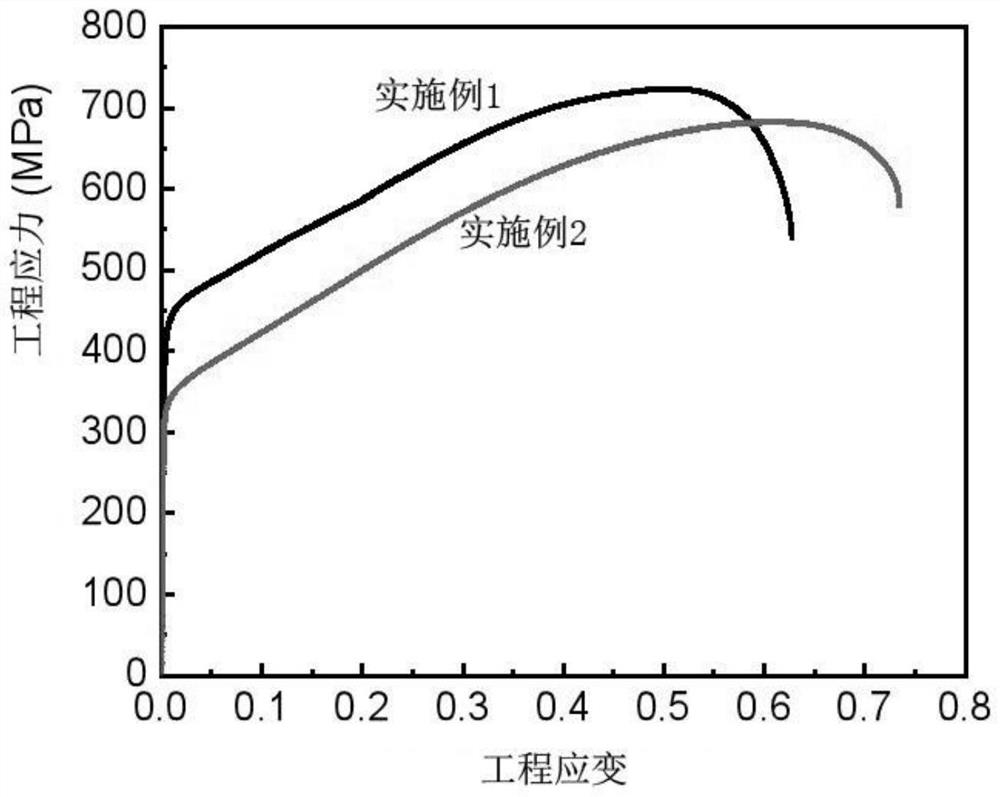

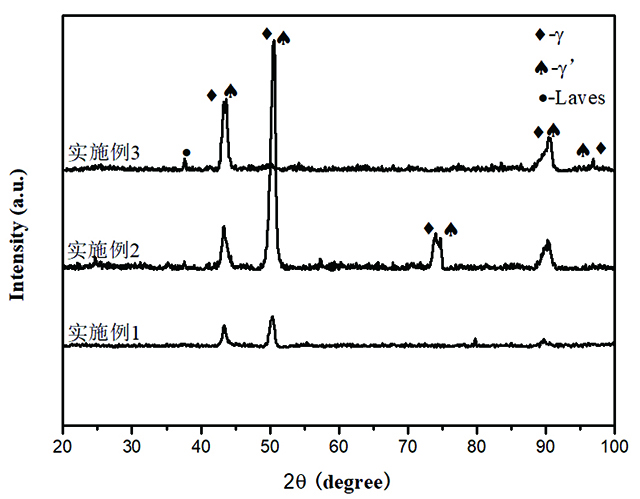

ActiveCN111206169AHigh yield strengthHigh tensile strengthAdditive manufacturing apparatusWelding accessoriesMetallic materialsGrain structure

The invention relates to the technical field of arc additive metal materials, in particular to a high-strength and high-plasticity single-phase Inconel 625 nickel-based alloy and a preparation methodthereof. The Inconel 625 nickel-based alloy is of a single-phase columnar coarse-grain structure with a grain size of 45-360m. Crystal grains have a low angle grain boundary of 15 to 33 percent by mass. The invention also discloses a preparation method of the Inconel 625 nickel-based alloy. The Inconel 625 nickel-based alloy prepared according to the method is 720 to 730MPa in tensile strength, is390 to 415MPa in yield strength, and is 54 to 63 percent in uniform elongation percentage. Compared with a conventional as-cast 625 nickel-based alloy, the Inconel 625 nickel-based alloy has the advantages that the strength and plasticity of the alloy are improved significantly.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

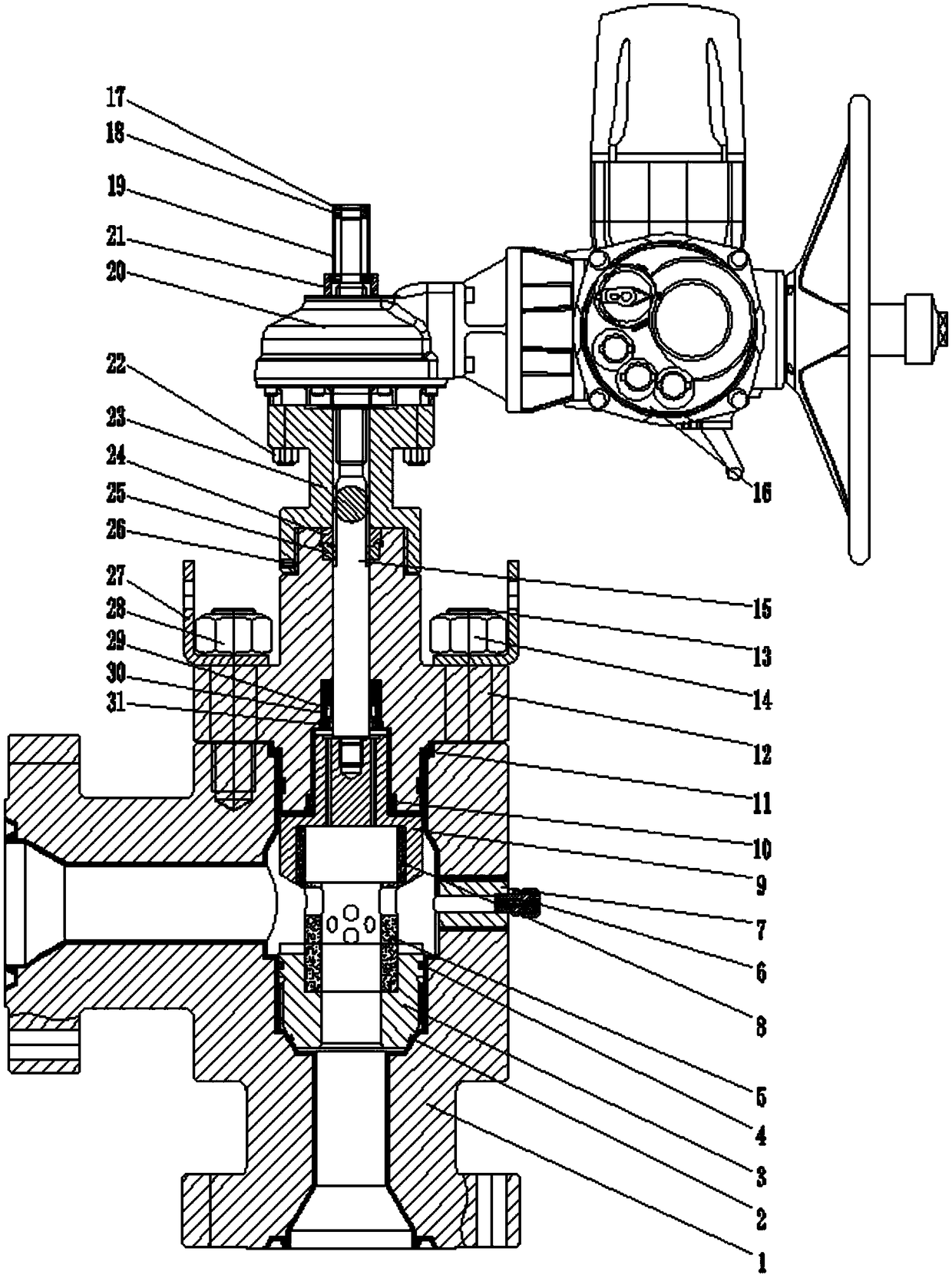

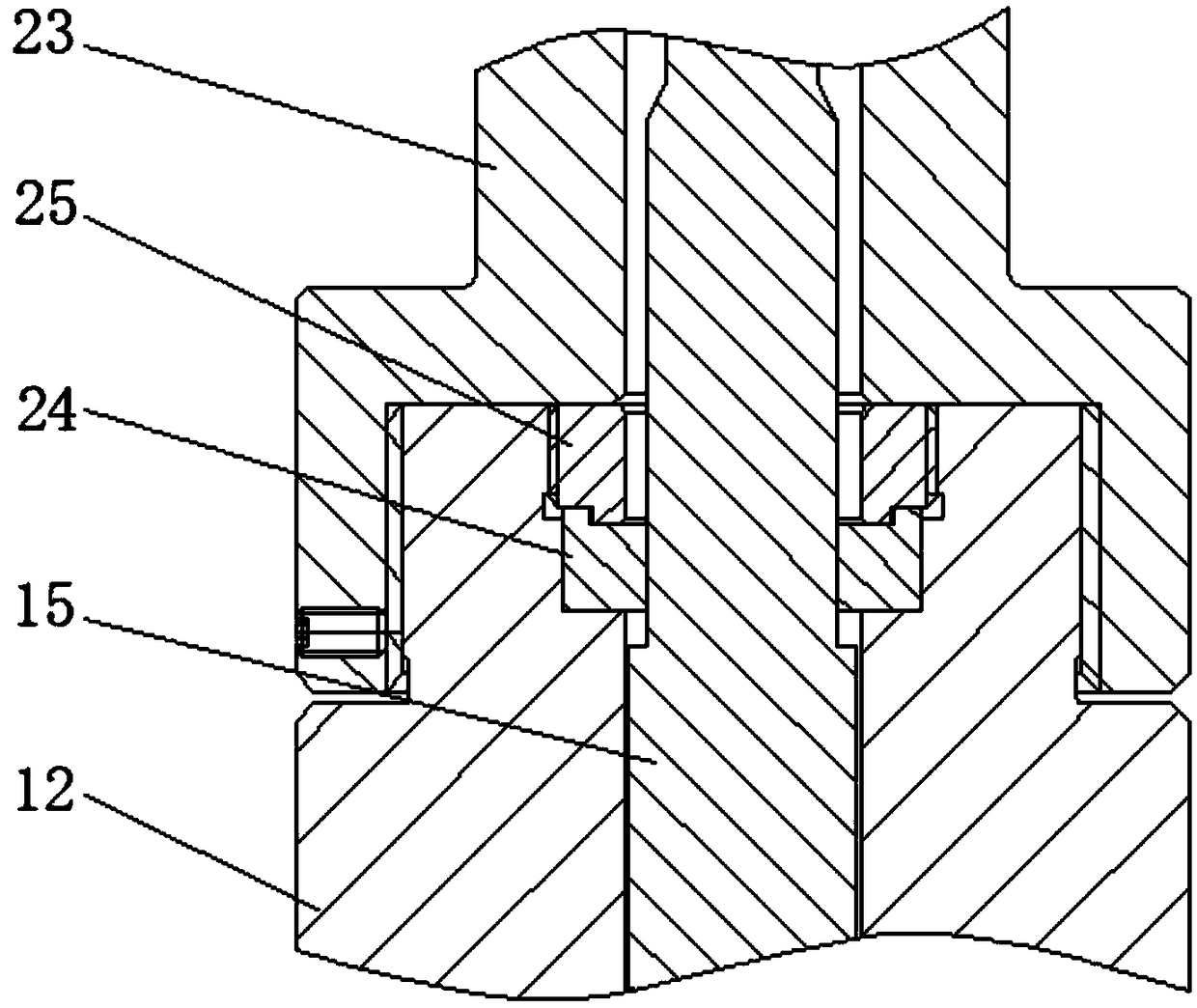

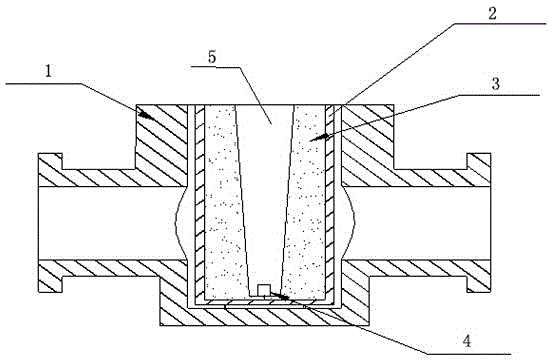

Electric sleeve type adjustable throttling valve

PendingCN108626405AAvoid destructionExtended service lifeLift valveValve member-seat contactsEngineeringHardness

The invention relates to the technical field of flow valves, and discloses an electric sleeve type adjustable throttling valve. The electric sleeve type adjustable throttling valve comprises a valve body, an O-shaped ring is fixedly connected to the inner wall of the valve body, a valve seat body is movably connected to the inner wall of the O-shaped ring, a rolling wheel on the upper surface of the valve seat body is provided with a sleeve body, an inner lining body is fixedly connected to the surface of the sleeve body, a valve clack body is fixedly connected to the surface of the inner lining body, a valve rod is movably connected to the top of the valve clack body, and a lower anti-rotation gasket and an upper anti-rotation gasket are movably connected to the surface of the valve rod.The electric sleeve type adjustable throttling valve has the advantages that when the electric sleeve type adjustable throttling valve is opened, all the inner cavity surfaces which fluid passes through are provided with Inconel 625 nickel-based alloys in a surfacing mode, the hardness is high, the wear resistance is good, the corrosion resistance is excellent, scouring by the fluid at high pressure for a long time can be resisted, the valve can be prevented form being eroded and damaged, and therefore the service life of the valve can be prolonged, and accidents caused by the damage to the valve can be effectively avoided.

Owner:CEPAI GRP CO LTD

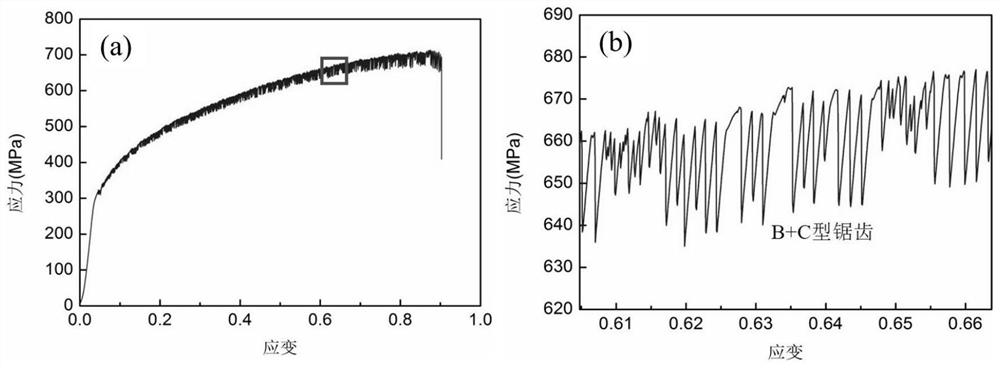

Method for inhibiting sawtooth rheological phenomenon of nickel-based superalloy

The invention discloses a method for inhibiting a sawtooth rheological phenomenon of nickel-based superalloy. The method includes the following steps: a heat treatment furnace is heated to a target solution treatment temperature, an Inconel 625 alloy sample is put into a hearth of the heat treatment furnace, the Inconel 625 alloy sample is immediately taken out of the heat treatment furnace after the solution treatment heat preservation time is reached, and the Inconel 625 alloy sample is quenched and cooled to the room temperature; the target solution treatment temperature is higher than the temperature of the MC type carbide precipitate of the Inconel 625 alloy, and the solution treatment heat preservation time is t1 = (d * 0.6 + 40) min-(d * 0.6 + 80) min; the Inconel 625 alloy sample obtained after solution treatment is put into the hearth, and then the temperature of the heat treatment furnace is increased to the target aging treatment temperature; after the aging treatment heat preservation time is reached, the Inconel 625 alloy sample is taken out, and quenched and cooled to the room temperature; and the target aging temperature is within the temperature interval of precipitating gamma ''-delta phases in the Inconel 625 alloy, and the aging treatment heat preservation time is 200-800 h. The method can effectively inhibit the sawtooth rheological phenomenon.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

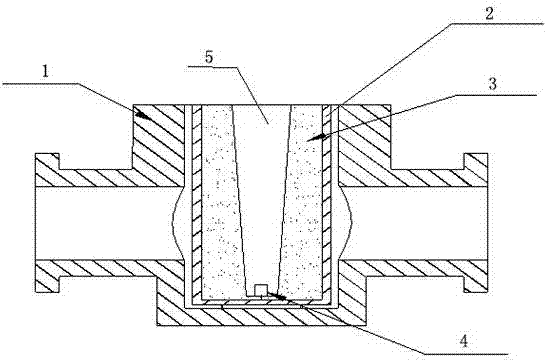

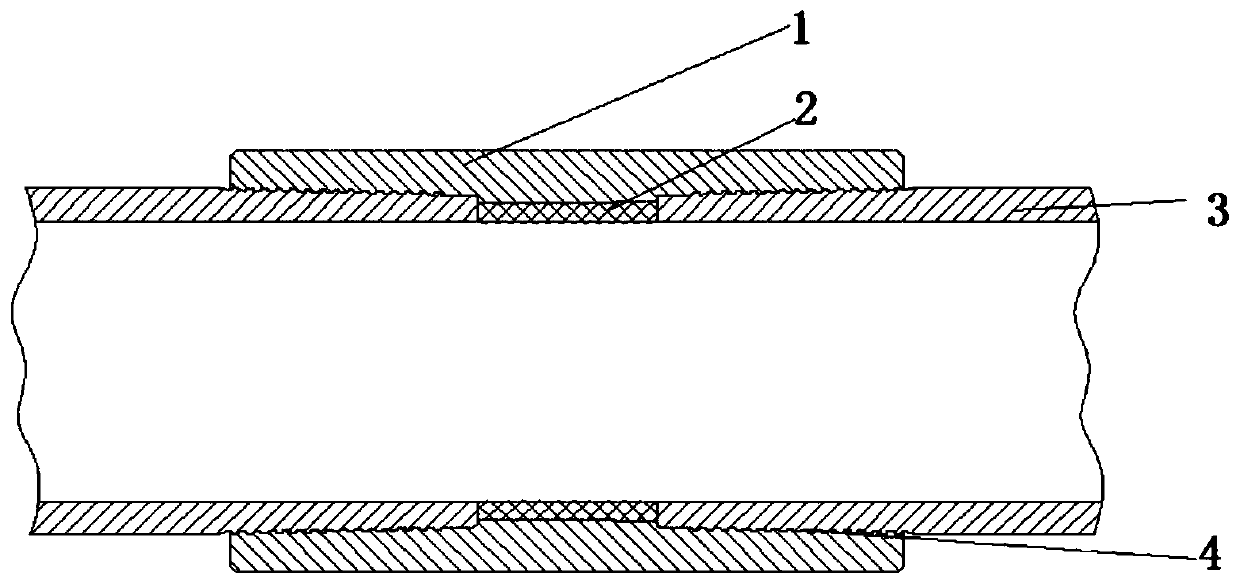

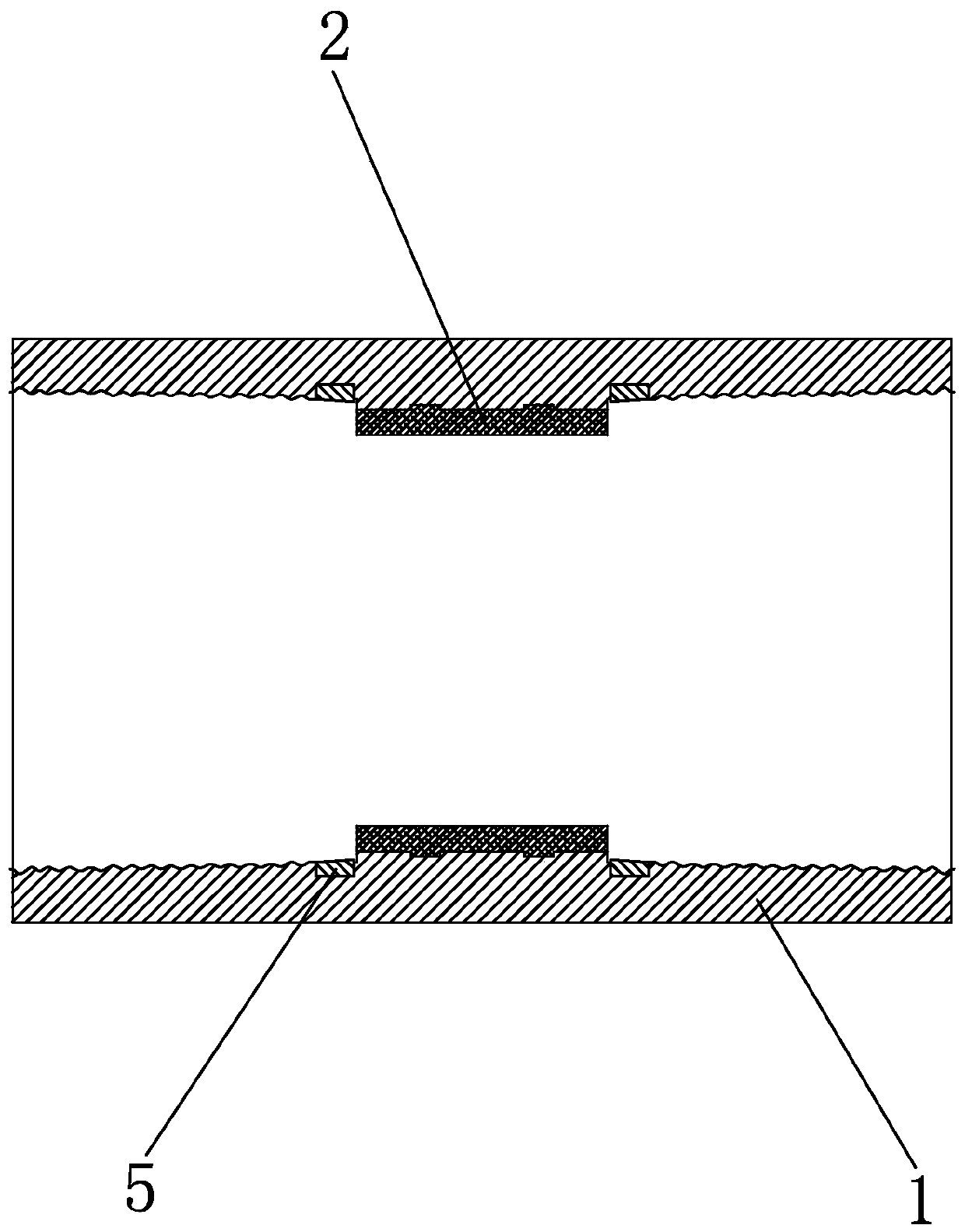

Preparing method for composite valve

ActiveCN104708193AAvoid deformationAvoid crackingNon-electric welding apparatusMetallic materialsEngineering

The invention discloses a preparing method for a composite valve. A metal material Inconel 625 pipe is arranged in the inner wall of the valve to be combined, and a certain gap is kept between the Inconel 625 pipe and the inner wall of the valve; an explosive layer is laid in the Inconel 625 pipe, the explosive layer is attached to the inner wall of the Inconel 625 pipe, the amount of explosive is gradually reduced from bottom to top, the explosive dosage is controlled, the Inconel 625 pipe can sequentially move towards the inner wall of the valve in an accelerated mode from bottom to top through the function of the explosive energy in the explosive combining process, a certain bent angle is formed when the outer wall of the Inconel 625 pipe makes contact with the inner wall of the valve, and then the outer wall of the Inconel 625 pipe and the inner wall of the valve are combined. The preparing method has the advantages that the inner wall of the valve can be combined with abrasion resisting materials, the combination effect is good, and cost is low.

Owner:安徽宝泰特种材料有限公司

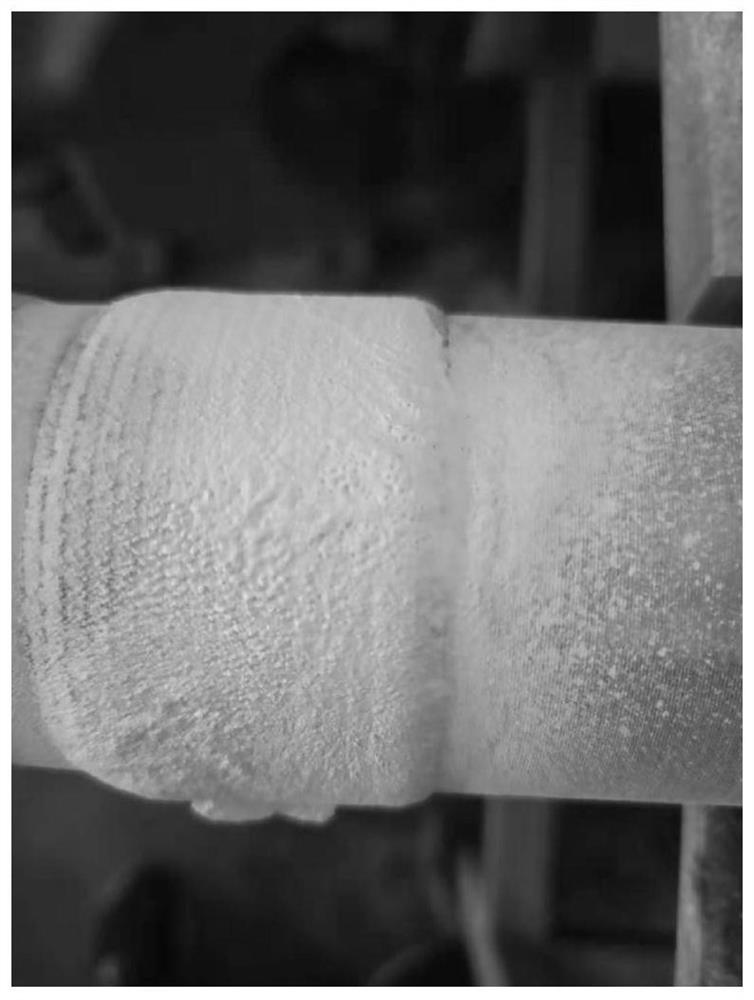

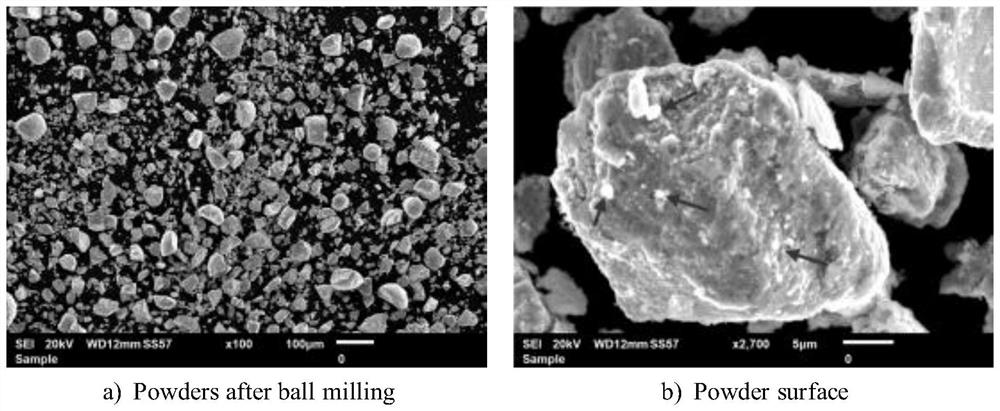

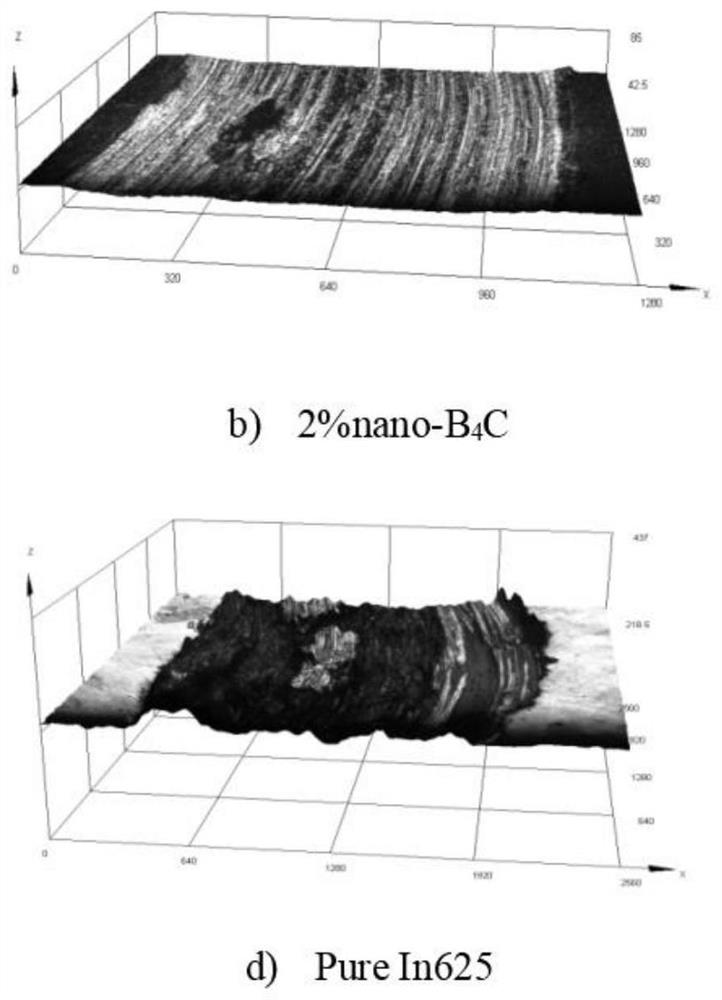

Method for improving performance of Inconel 625 nickel-based powder laser cladding layer

ActiveCN112626515ANon-destructiveQuality assuranceIncreasing energy efficiencyMetallic material coating processesNanostructured carbonMachining

The invention discloses a method for improving the performance of an Inconel 625 nickel-based powder laser cladding layer. The method comprises the following steps that (1) Inconel 625 nickel-based powder and nano boron carbide are weighed as raw materials for preparing reinforced powder; (2) the Inconel 625 nickel-based powder and nano boron carbide are subjected to ball milling and mixing, and reinforced powder is obtained; (3) the reinforced powder is screened; (4) the screened reinforced powder is dried, and the surface of a workpiece to be cladded is pretreated; and (5) laser cladding is carried out on the to-be-cladded surface of the to-be-cladded workpiece, and then finish machining is carried out. The laser cladding workpiece obtained through the method for improving the performance of the Inconel 625 nickel-based powder laser cladding layer is high in hardness and excellent in abrasion performance, the use performance is improved, and the service life is prolonged.

Owner:浙江翰德圣智能再制造技术有限公司

Separation method of non-metallic inclusions in inconel625 series superalloys

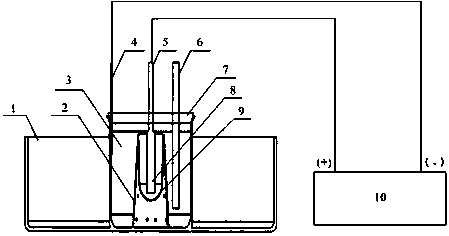

ActiveCN105738188BAvoid serious shedding problemsLossless extractionPreparing sample for investigationElectrolysisMetallic materials

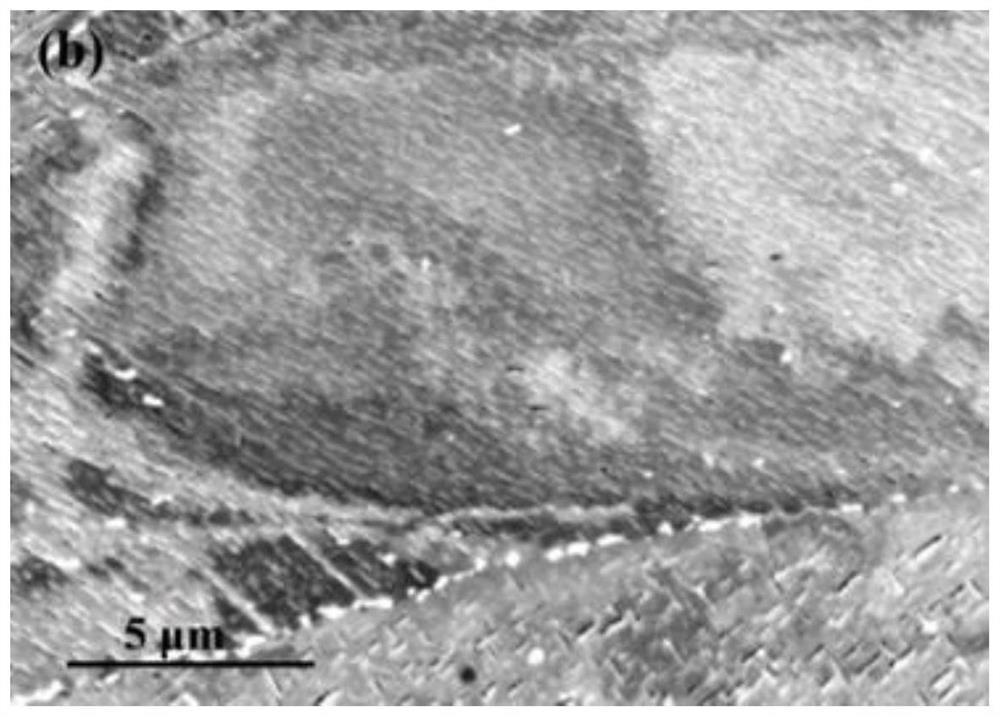

The invention discloses a separation method for nonmetallic inclusions in an Inconel625-series high-temperature alloy, and belongs to the technical field of methods for researches on nonmetallic inclusions in metallic materials. A proper electrolyte is selected to electrolyze a high-temperature alloy test sample; a collected extract mixture is separated by virtue of a chemical method after electrolysis, and carbides are dissolved to completely and nondestructively extract fine oxide inclusions in the Inconel625-series high-temperature alloy; the obtained oxide inclusions are observed to have obvious particle shapes under a scanning electron microscope, and are proven to be Al and Mg containing composite oxide inclusions by energy spectrum analysis.

Owner:常州市申鑫新材料科技有限公司

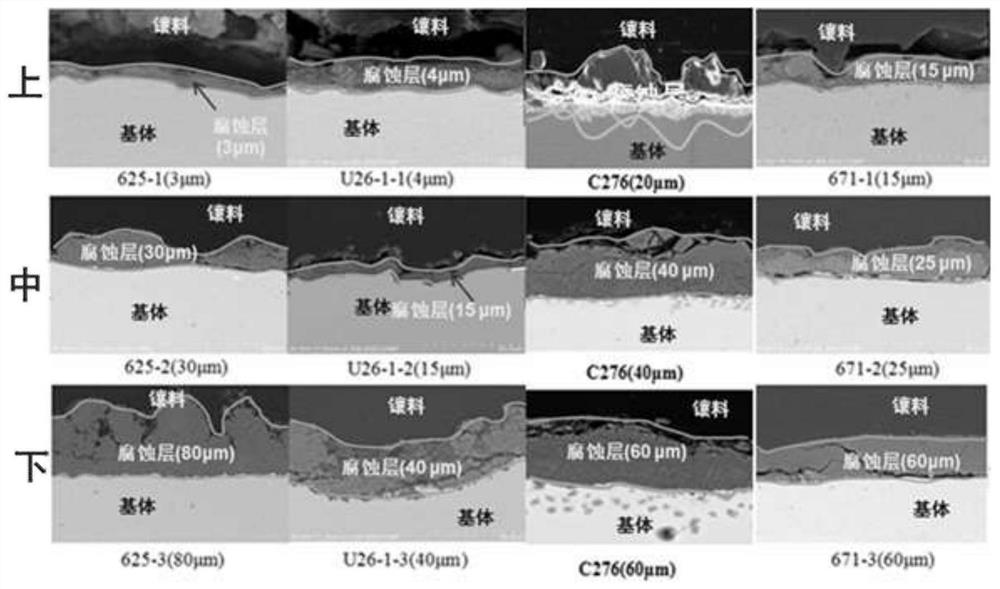

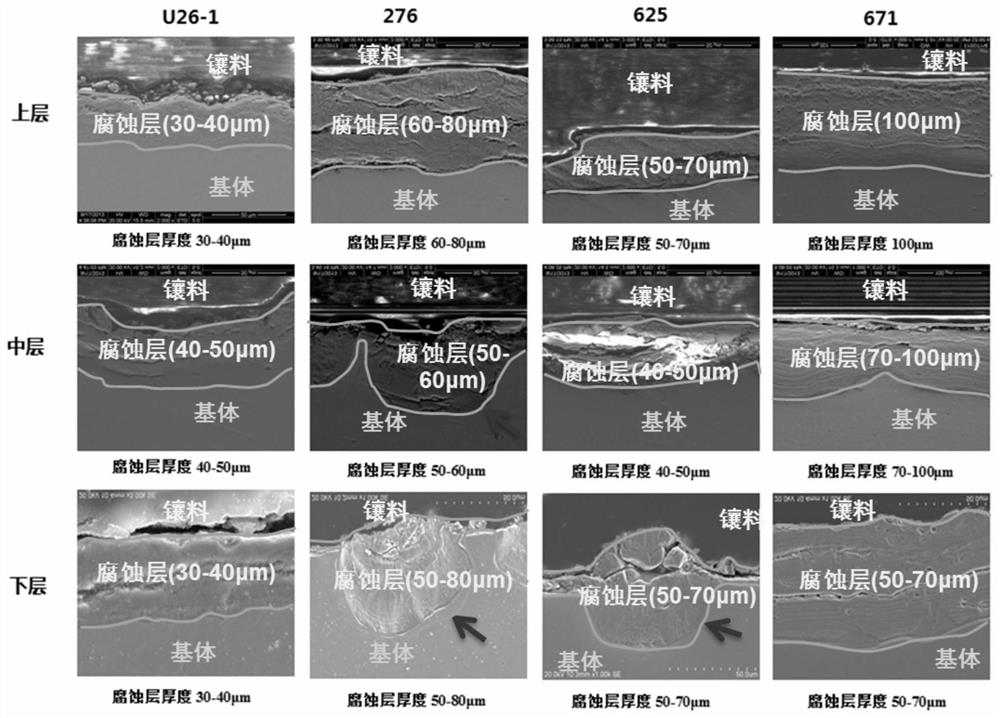

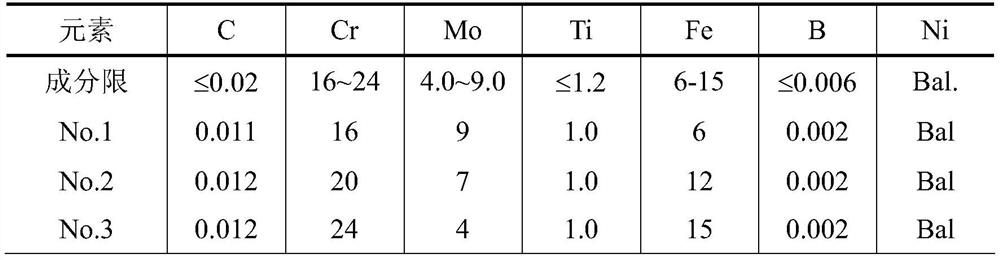

Medium-temperature oxidation-resistant nickel-based corrosion-resistant alloy and preparation process thereof

The invention discloses a medium-temperature oxidation-resistant nickel-based corrosion-resistant alloy and a preparation process thereof, and belongs to the technical field of corrosion-resistant alloys. The alloy comprises the following chemical components of, in percentage by weight, less than or equal to 0.02% of C, 16%-24% of Cr, 4%-9% of Mo, less than or equal to 1.2% of Ti, 6%-15% of Fe, less than or equal to 0.006% of B and the balance Ni. The alloy belongs to a solid solution strengthened nickel-based corrosion-resistant alloy and has excellent high-temperature oxidation resistance. When the alloy is used under the supercritical conditions that PO4 < 3-> serves as a main component, SO4 < 2- >, NO3 < - >, H < + >, OH < - > and other multi-ions coexist, the temperature ranges from 350 DEG C to 600 DEG C, and the pressure intensity ranges from 20 MPa to 30 MPa, the corrosion resistance of the alloy is obviously better than that of Inconel 671, Inconel 625 and Hastelloy C-276, and the alloy can be used as a reactor material for wastewater treatment and municipal sludge equipment under the supercritical water oxidation environment condition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of inconel625 nickel-based alloy powder for laser selective melting technology

ActiveCN104923797BAppropriate ratioImprove purityAdditive manufacturing apparatusSelective laser meltingPresent method

Owner:SHANGHAI RES INST OF MATERIALS CO LTD +1

A kind of high-strength high-plastic single-phase inconel 625 nickel-based alloy and its preparation method

ActiveCN111206169BHigh yield strengthHigh tensile strengthAdditive manufacturing apparatusWelding accessoriesMetallic materialsGrain structure

The invention relates to the technical field of arc-added metal materials, in particular to a high-strength and high-plastic single-phase Inconel 625 nickel-based alloy and a preparation method thereof. The invention discloses a high-strength and high-plasticity single-phase Inconel 625 nickel-based alloy, wherein the structure of the Inconel 625 nickel-based alloy is a single-phase columnar coarse-grained structure, and its grain size is 45-360 μm. In percentage terms, the grains have small-angle grain boundaries in a proportion of 15-33%. The invention also discloses a preparation method of the Inconel 625 nickel base alloy. The tensile strength of the Inconel 625 nickel-based alloy obtained according to this method is 720-730MPa, the yield strength is 390-415MPa, and the elongation is 54-63%. Compared with the traditional cast 625 nickel-based alloy, it significantly improves the strength and plasticity.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Inconel 625 modified alloy surfacing welding wire and preparation method thereof

PendingCN114769933AGood welding performanceGood mechanical properties at room temperatureWelding/cutting media/materialsSoldering mediaChemical compositionIncineration

The invention relates to a surfacing welding wire, in particular to an Inconel 625 modified alloy surfacing welding wire and a preparation method thereof, and belongs to the technical field of anti-corrosion and anti-wear materials. The wire material comprises the following chemical components in percentage by mass: 18.0 to 25.0 percent of Cr, 6.0 to 12.0 percent of Mo, 0 to 3.0 percent of Fe, 0 to 1.0 percent of Co, 0 to 1.0 percent of Nb, 0 to 0.5 percent of Ti, 0 to 0.5 percent of Al, 0 to 0.5 percent of Mn, 0 to 0.5 percent of Si, 0 to 0.2 percent of La, 0 to 0.2 percent of Ce, 0 to 0.1 percent of C and the balance of Ni. The wire has good forging and cold-drawing process properties, the prepared surfacing layer has excellent high-temperature corrosion resistance and wear resistance, and the corrosion resistance, high-temperature oxidation resistance and wear resistance of boilers, especially garbage incinerator boilers, can be greatly improved.

Owner:JIANGXI HENGDA HI TECH CO LTD

High-aluminum Inconel 625 alloy and preparation method thereof

PendingCN114836655AReduce Cr contentSimple production equipmentIncreasing energy efficiencySolution treatmentShielding gas

The high-aluminum Inconel 625 alloy comprises the following components in percentage by mass: 13 to 5 percent of Cr, 5 percent of Fe, 4.15 percent of Nb, 10 percent of Mo, 5 to 9 percent of Al and the balance of Ni. The preparation method comprises the following steps: (1) weighing reaction materials according to a preset proportion, and putting the reaction materials into a planetary ball mill for ball milling; (2) pressing the ball-milled reaction material into a cake-shaped blank with the diameter of 80 mm and the height of about 50 mm on a press machine; (3) putting the cake-shaped blank into a reaction kettle, putting an ignition agent on a blank body, filling protective gas for gas washing, then filling the protective gas for pressure maintaining, and continuously heating until a self-propagating reaction occurs in a system, so as to obtain a base metal alloy; (4) the base metal alloy is subjected to vacuum induction secondary smelting, and a cast ingot is obtained; and (5) the cast ingot is subjected to solution treatment for 30 min at the temperature of 1150 DEG C, and water cooling is conducted.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Alloy steel high-temperature-resistant high-pressure-resistant sulfur-resistant throttling valve and manufacturing method

InactiveCN111101060AGuaranteed thicknessImprove corrosion resistanceFurnace typesHeat treatment furnacesTemperingHeat conservation

The invention discloses an alloy steel high-temperature-resistant high-pressure-resistant sulfur-resistant throttling valve and a manufacturing method. The design improvement is performed on the basisof an F22 material component, the initial forging temperature is lower than or equal to 1200 DEG C, the heat preserving time is 0.5-1.5 hours per inch, the final forging temperature is 850-950 DEG C,transverse and longitudinal three-time repeated heading and drawing are performed on a steel ingot through a WHF forging method with a hydraulic machine and an FM forging method with a forging hammerduring forging, and the total forging ratio is larger than 6:1; the normalizing at 950 DEG C, quenching at 930 DEG C and tempering at 663 DEG C are adopted, and the heat preserving time is 1.0-1.5 hours per inch; by means of a Fronius TIG automatic build-up welding technology and a build-up welding Inconel 625 nickel-base alloy, a machining base surface is designed before build-up welding; and cutting machining is performed. The throttling valve has the advantages that a forging technological control and thermal treatment process is optimized, and a high-temperature-resistant high-pressure-resistant sulfur-resistant forging with super-long service life and high safety coefficient and meeting actual use requirements is obtained.

Owner:苏州雷格姆海洋石油设备科技有限公司

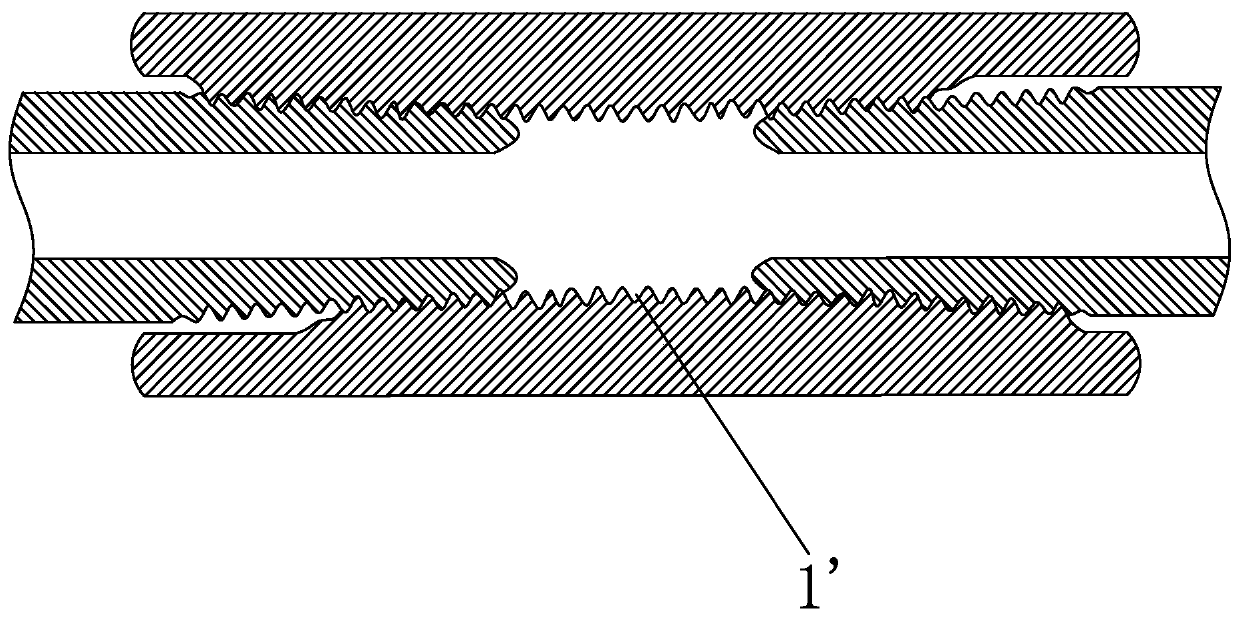

Duplex-metal coupling

PendingCN111485831AAvoid corrosionImprove corrosion resistanceDrilling rodsDrilling casingsCouplingStructural engineering

The invention discloses a duplex-metal coupling. The duplex-metal coupling comprises a coupling body. The coupling body is of a hollow pipe sleeve structure. Connectors are arranged at the two ends ofthe coupling body respectively and symmetrically. Each connector gradually narrows axially in the direction of the middle of the coupling body to be of a horn-shaped open structure. Internal threadsare formed in the inner wall of each connector. An alloy composite layer is arranged on the inner wall of the coupling body in a bead weld composition manner. The alloy composite layer is located between the two connectors and is of a circular boss structure. According to the duplex-metal coupling, on the basis of a mono-metal coupling, the alloy composite layer is formed in the bead weld composition manner with an Inconel 625 alloy material, corrosion caused to the coupling body by fluid in a pipeline can be effectively prevented, and the corrosion resistance is improved; and furthermore, modification can be carried out on a coupling in the prior art, the modification cost is low, the application range is broad, connection is solid and reliable, and the durability is good.

Owner:SHANGHAI TIAN YANG STEEL TUBE

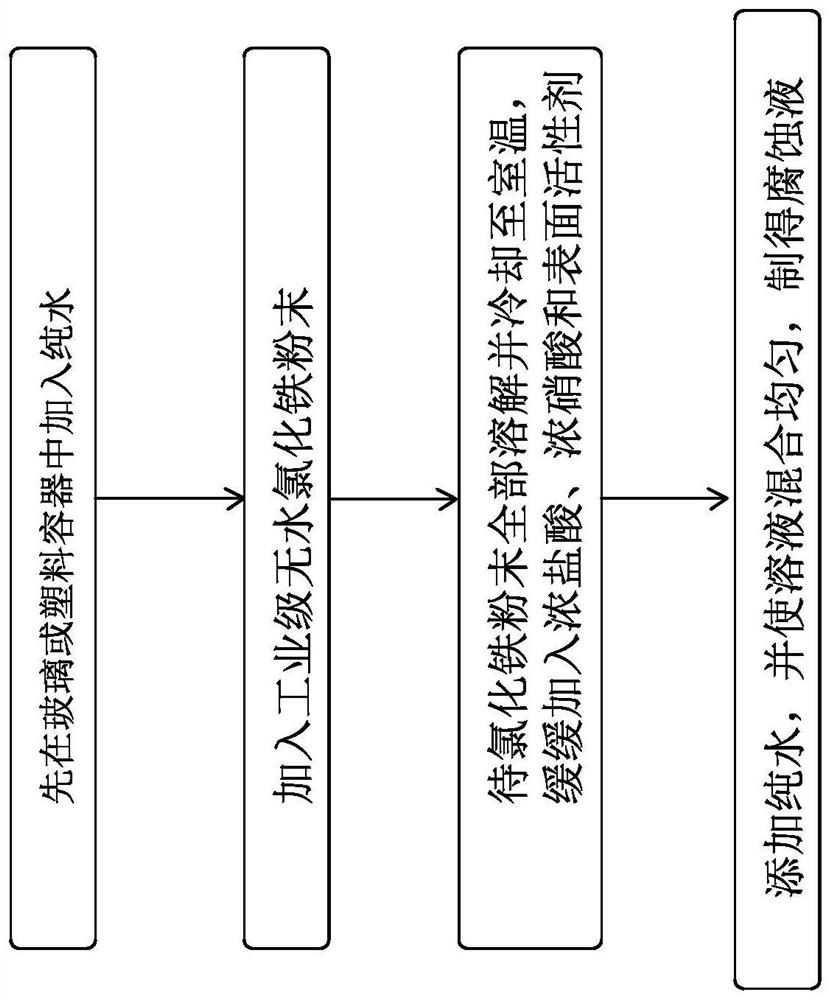

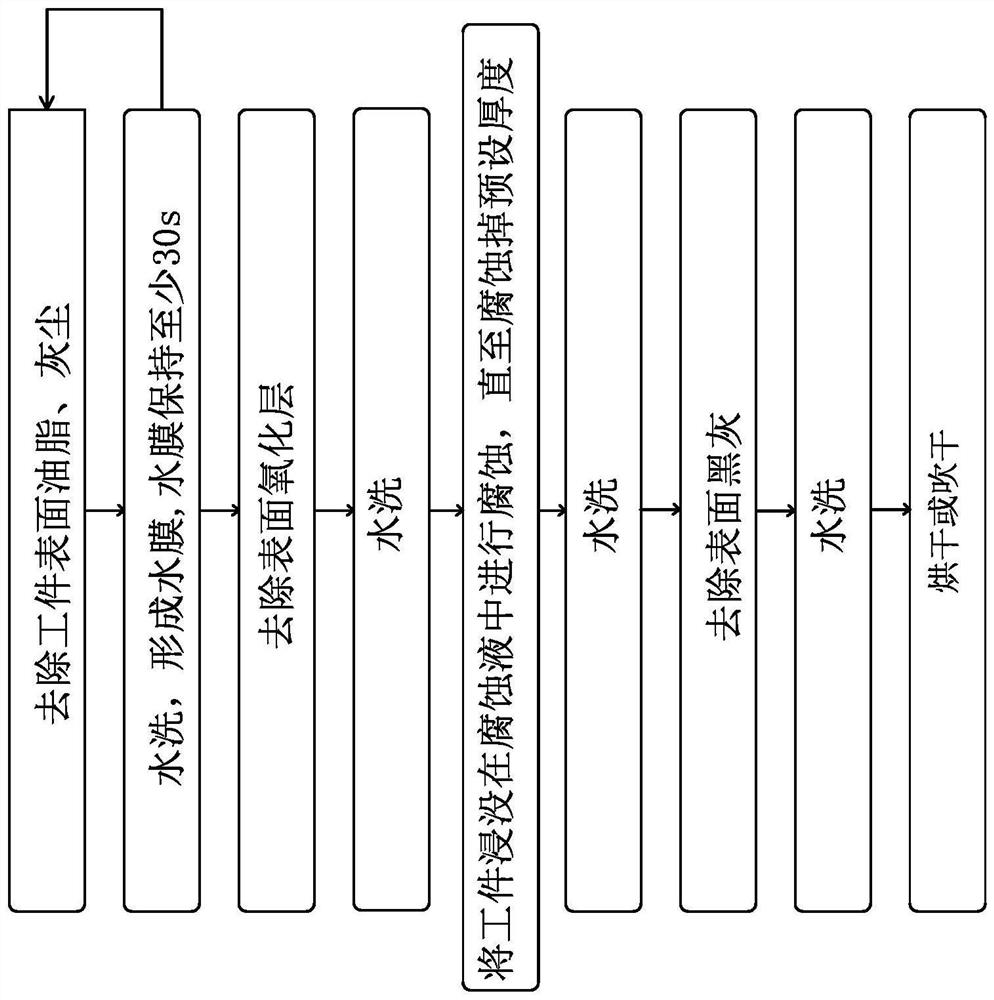

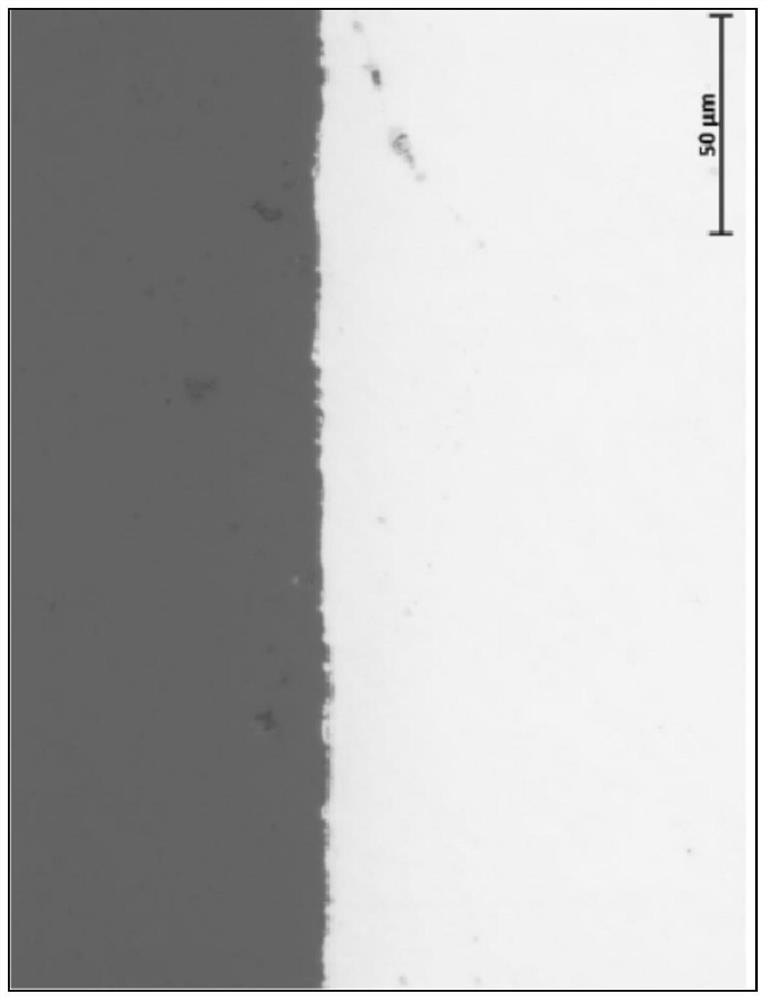

Corrosion liquid, preparation method of corrosion liquid and corrosion process of Incone625 nickel alloy

The invention provides a corrosive liquid, a preparation method of the corrosive liquid and a corrosion process of the corrosive liquid applied to Incone625 nickel alloy, and belongs to the technical field of corrosion. The invention relates to a corrosive liquid, which is characterized by comprising the following aqueous solutions of substances with the following concentrations: 30-50ml / L of nitric acid with the mass fraction of 65%-68%, 500-550ml / L of hydrochloric acid with the mass fraction of 35%-36.5%, 130-160g / L of industrial grade anhydrous ferric chloride and 5-10ml / L of a surfactant. The method has the advantages that the Inconel 625 nickel alloy is difficult to corrode or high in efficiency and can be controlled when the Inconel 625 nickel alloy is corroded.

Owner:海宁红狮宝盛科技有限公司

A novel high-temperature cl-corrosion-resistant nitrogen-containing low-nickel alloy and preparation method thereof

The invention belongs to the technical field of alloy materials, and in particular relates to a novel high temperature resistant Cl ‑ Corroded nitrogen-containing low-nickel alloy and preparation method. A new type of high temperature resistant Cl ‑ The corroded nitrogen-containing low-nickel alloy, measured by mass percentage, comprises the following components: Ni: 42.0-46.0wt%, Cr: 20.0-26.0wt%, Mn: 7.0-8.0wt%, Si: 1.6wt% and below, Mo: 6.0‑8.0wt%, Cu: 0.5wt% or less, Co: 0.8‑1.0wt%, N: 0.12‑0.21wt%, Ti+Al=2.8‑3.0wt%; Ti / Al=1.0‑1.3, Nb: 6-7%, W: 2.0-3.0wt%, V: 1.25-1.55wt%, and the rest are Fe and inevitable impurities. The optimization of the alloy composition of the present invention enables the nitrogen-containing low-nickel alloy to have excellent Cl resistance at high temperature ‑ Corrosive, can replace Inconel 625 alloy, used in high temperature, high pressure chemical, energy and marine engineering fields, such as facing 900 ℃, Cl ‑ Corrosion of the energy storage medium in the solar heat storage tube.

Owner:SHENYANG POLYTECHNIC UNIV

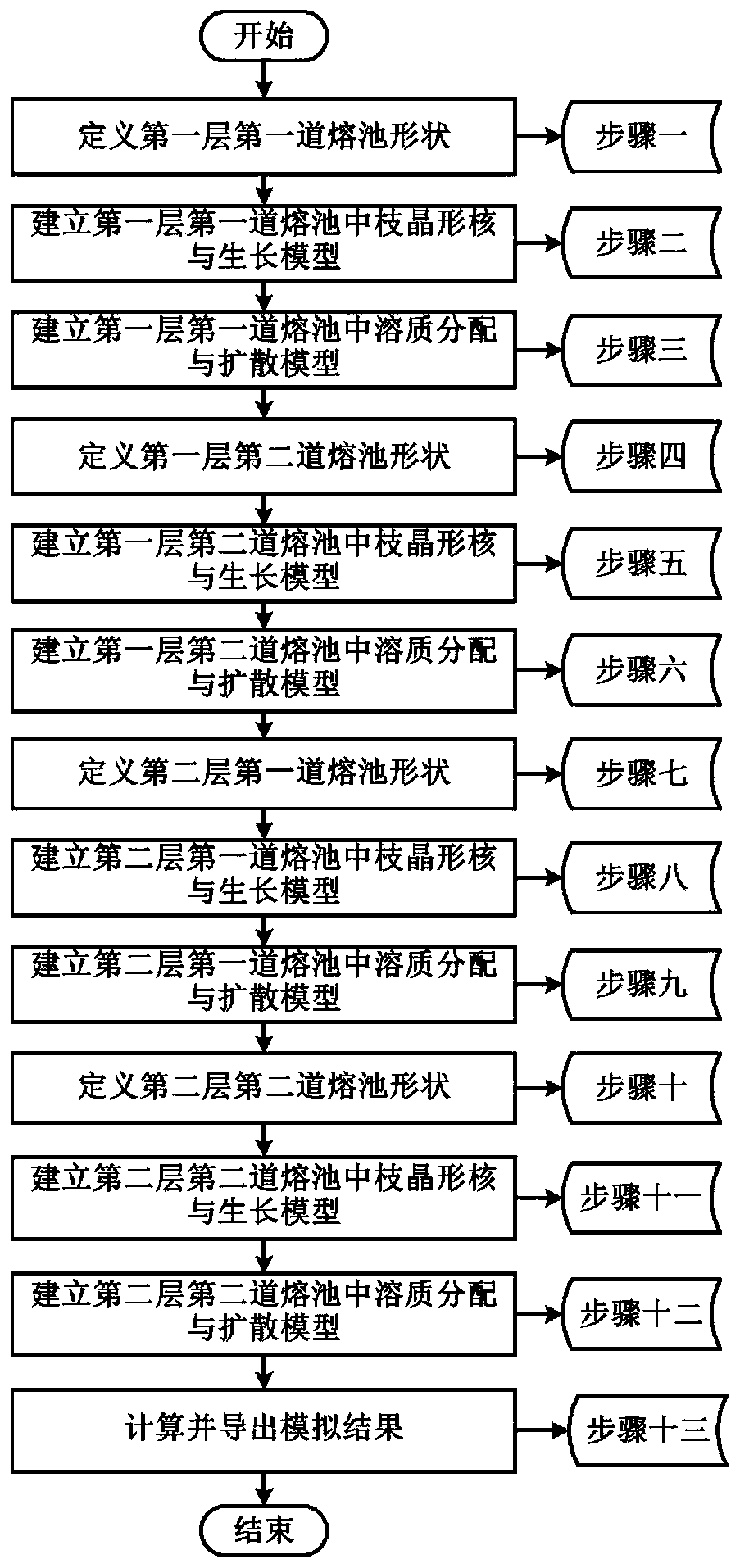

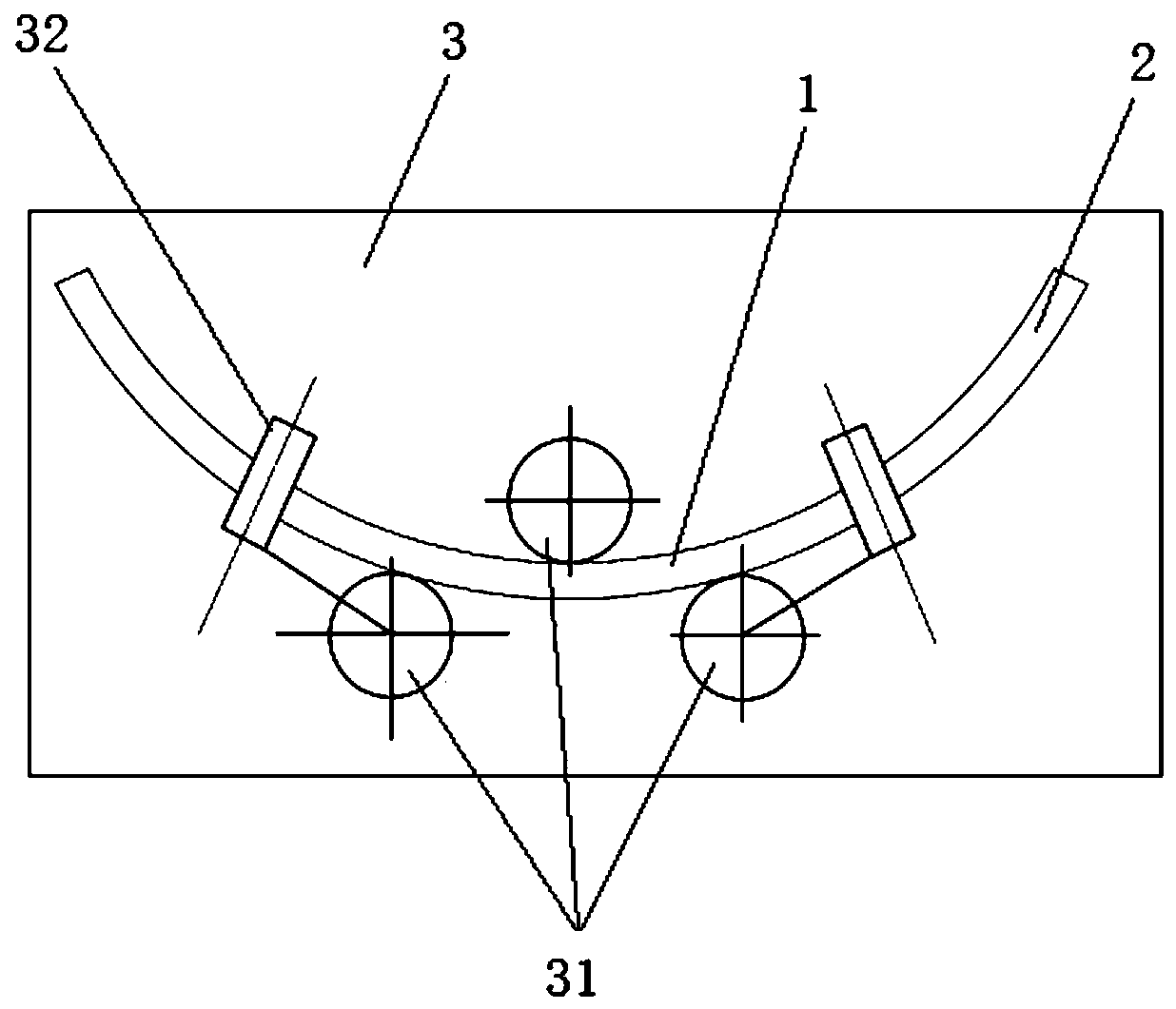

Numerical simulation method for crystal growth of Inconel 625 alloy during multi-layer multi-channel laser cladding

ActiveCN111370078ASave resourcesIncreasing energy efficiencyDesign optimisation/simulationAnalogue computationCrystal growth

The invention discloses a numerical simulation method for crystal growth of Inconel 625 alloy during multi-layer multi-channel laser cladding. The method comprises the following specific steps: defining the shape of a first molten pool of a first layer, and establishing a dendrite nucleation and growth model; establishing a solute distribution and diffusion model; sequentially establishing crystalgrowth models for a second molten pool of the first layer, a first molten pool of a second layer and a second molten pool of the second layer; and finally, writing a computer program, inputting thermophysical parameters of the Inconel 625 alloy and various laser cladding process parameters, importing the computer program into simulation calculation software, and performing calculation to obtain asimulation result. Compared with experimental research, the model disclosed in the invention is more time-saving, labor-saving and resource-saving, can simulate dendrite growth conditions under different laser cladding process parameters, and provides reference for selection of an actual laser cladding process.

Owner:XIAN UNIV OF TECH

Nickel-based alloy and preparation method and application thereof

The invention discloses nickel-based alloy and a preparation method and application thereof, and relates to the technical field of anti-corrosion materials. The nickel-based alloy and the preparation method and application thereof aim to solve the problem that an existing Inconel-625 material or a Hastelloy C-276 material causes poor corrosion resistance of supercritical equipment in an oxidizing medium where various ions coexist. The nickel-based alloy comprises, by mass, 35-42% of Cr, 1.3-1.7% of Ti, 0.1-0.3% of Mn, 0.5-5% of Fe, 0-0.1% of C, 0-0.6% of microelements and the balance Ni. According to the preparation method of the nickel-based alloy, Ni, Cr, Mn and Fe are mixed and melted under a vacuum condition till being clarified, then refining is carried out, after refining is finished, Ti and the microelements are added and evenly stirred, desulfuration is carried out, and finally casting moulding is carried out to obtain the nickel-based alloy. The nickel-based alloy can be used in the supercritical equipment as a corrosion-resistant material.

Owner:ENN SCI & TECH DEV

Manufacturing process of built-in low-temperature pump nitrogen screen bent pipe

ActiveCN110977339ALow induced eddy currentSmall footprintStructural engineeringMechanical engineering

The invention discloses a manufacturing process of a built-in low-temperature pump nitrogen screen bent pipe. The manufacturing process comprises the steps of bent pipe manufacturing, filling, rollingand bending forming and twisting monitoring. An bent pipe main body is made of an Inconel 625 alloy material; after the bent pipe is filled with quartz sand, the bent pipe is put into a three-wheel rolling bender additionally provided with correction wheels for rolling and bending forming; and finally, laser generators are used for monitoring the distortion condition of the bent pipe. According to the manufacturing process of the built-in low-temperature pump nitrogen screen bent pipe, a spiral welded pipe made of the Inconel 625 alloy material is used as the bent pipe main body, and comparedwith bent pipes made of other materials, the built-in low-temperature pump nitrogen screen bent pipe has the advantages of being low in induced eddy current and small in occupied space; and the matched improved rolling and bending forming equipment and the torque monitoring device can ensure that the ellipse degree and the distortion amplitude can be controlled within a proper range on the basisof using the spiral welded pipe made of the Inconel 625 alloy material as the bent pipe main body.

Owner:合肥聚能电物理高技术开发有限公司

Repair material and repair method for directional solidification crystal turbine blade tip deep cracks

ActiveCN112427637ASolving problems affecting the quality of blade tip additivesGuaranteed StrengthTurbinesAdditive manufacturing apparatusEngineeringStructural engineering

The invention discloses a repair material and a repair method for directional solidification crystal turbine blade tip deep cracks, relates to the field of aero-engine blade maintenance, and solves the problem that existing repair materials are likely to generate micro-cracks. According to the technical scheme, the repair material for the directional solidification crystal turbine blade tip deep cracks is formed by fully mixing 35%-45% of Inconel 625 alloy powder and 55%-65% of Rene 142 alloy powder by mass. The repair method for the directional solidification crystal turbine blade tip deep cracks comprises the steps that after a high-pressure turbine working blade is decomposed, flaw detection is conducted firstly, the crack position is determined, and a groove is formed; then, the aboverepairing material is adopted for laser additive manufacturing; a repair area is polished, and the blade is placed in a vacuum furnace for annealing treatment; and finally, flaw detection is conductedon the blade. The repair material and the repair method are suitable for repairing the deep cracks of the blade tip of the directional solidification nickel-based superalloy DZ125 turbine rotor blade.

Owner:PLA NO 5719 FACTORY

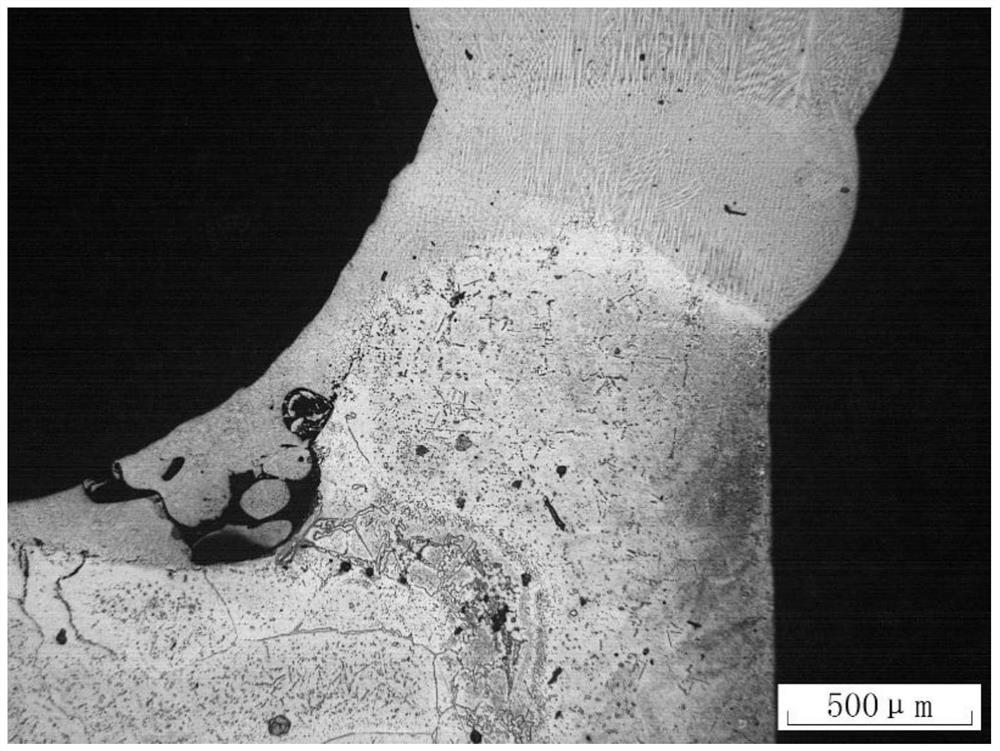

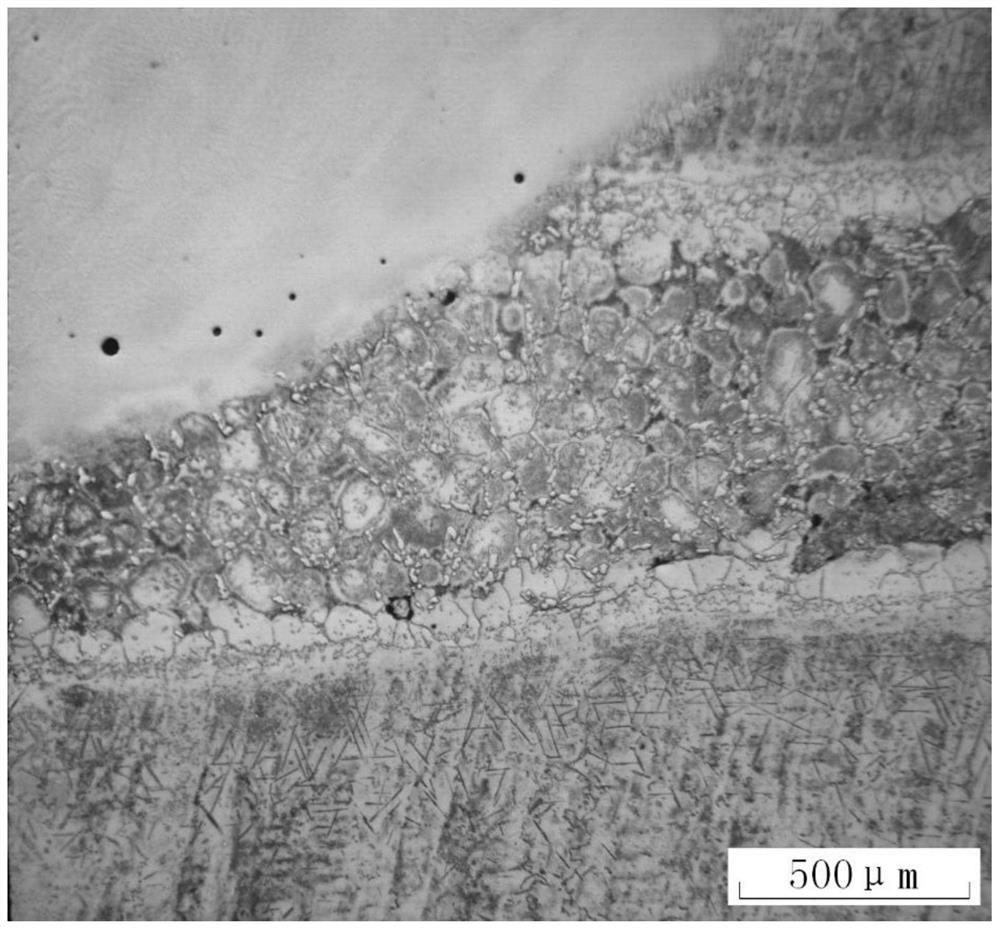

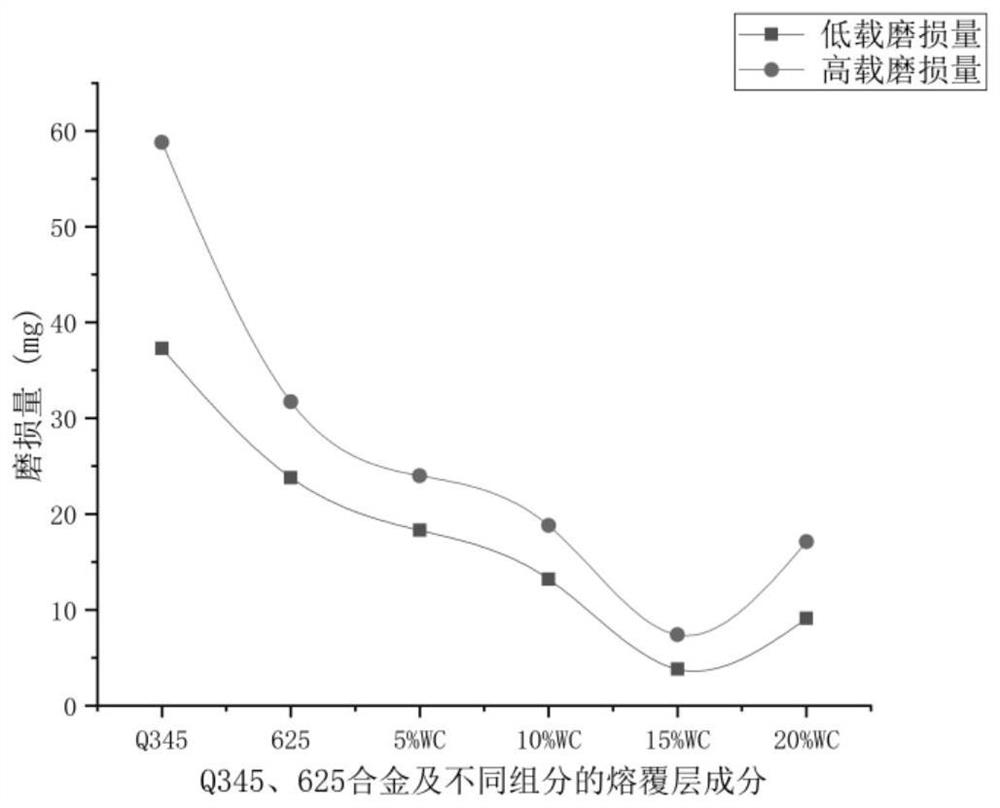

Cladding powder for improving wear resistance of nickel-based laser cladding layer and preparation method of cladding powder

PendingCN114525505AImprove wear resistanceExtended service lifeIncreasing energy efficiencyMetallic material coating processesInconel 625Molten pool

The invention discloses cladding powder for improving wear resistance of a nickel-based laser cladding layer, which is characterized in that Inconel 625-XWC nickel-based alloys with different gradients are designed according to mass percent, and X is equal to 5, 10, 15 and 20 wt.%; the invention further discloses a preparation method of the cladding powder for improving the wear resistance of the nickel-based laser cladding layer, by designing Inconel 625-XWC nickel-based alloy with different gradients, the wear resistance of the alloy cladding layer is effectively improved, a WC ceramic phase can enhance flowing of fluid in a welding pool, then defects are improved, the porosity is reduced, and the wear resistance of the nickel-based laser cladding layer is improved. Therefore, the service life of the base body is greatly prolonged, the production cost can be reduced, resources are saved, and the environment is protected.

Owner:XIAN UNIV OF TECH

A kind of preparation method of composite valve

ActiveCN104708193BImprove corrosion resistanceAvoid deformationNon-electric welding apparatusEngineeringInconel 625

The invention discloses a preparing method for a composite valve. A metal material Inconel 625 pipe is arranged in the inner wall of the valve to be combined, and a certain gap is kept between the Inconel 625 pipe and the inner wall of the valve; an explosive layer is laid in the Inconel 625 pipe, the explosive layer is attached to the inner wall of the Inconel 625 pipe, the amount of explosive is gradually reduced from bottom to top, the explosive dosage is controlled, the Inconel 625 pipe can sequentially move towards the inner wall of the valve in an accelerated mode from bottom to top through the function of the explosive energy in the explosive combining process, a certain bent angle is formed when the outer wall of the Inconel 625 pipe makes contact with the inner wall of the valve, and then the outer wall of the Inconel 625 pipe and the inner wall of the valve are combined. The preparing method has the advantages that the inner wall of the valve can be combined with abrasion resisting materials, the combination effect is good, and cost is low.

Owner:安徽宝泰特种材料有限公司

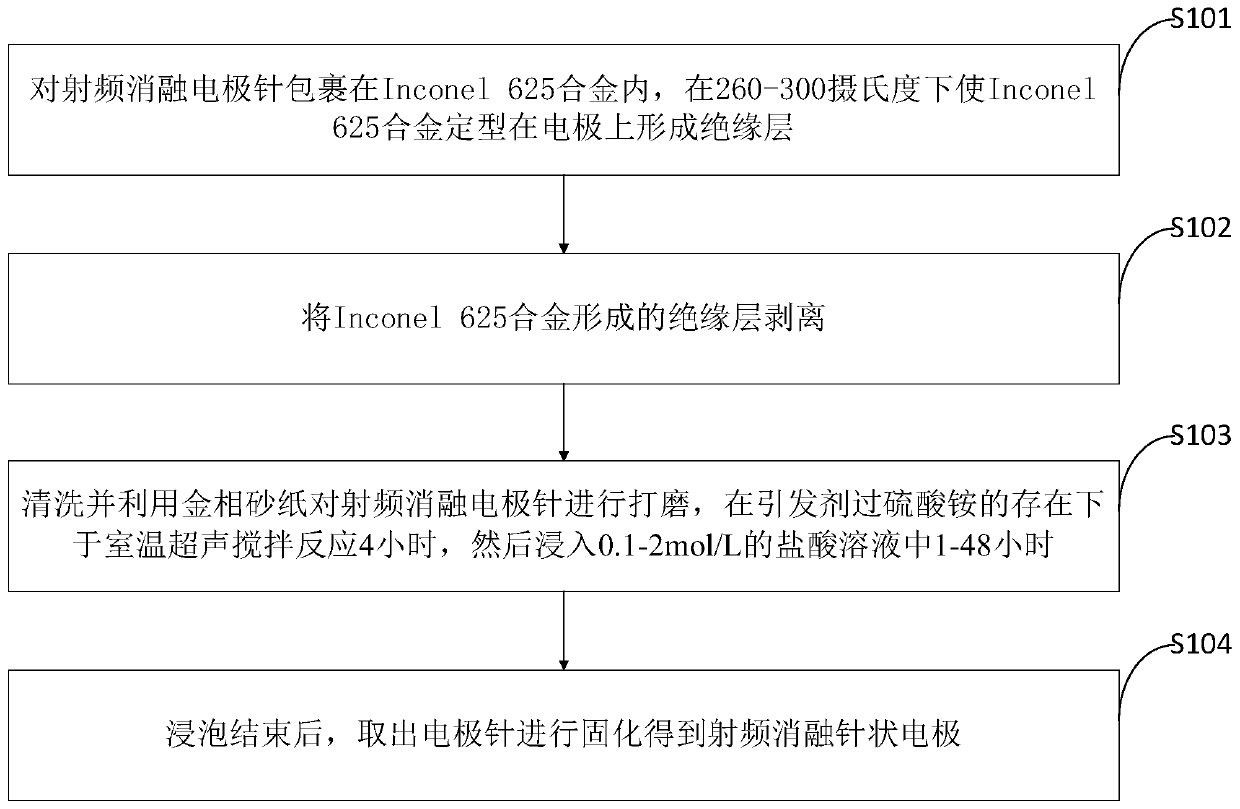

Radiofrequency ablation needle electrode and preparation method thereof

PendingCN110934640AImprove performanceEasy to operateSurgical instruments for heatingRf ablationExAblate

The invention belongs to the technical field of medical devices, and discloses a radiofrequency ablation needle electrode and a preparation method thereof. The preparation method of the radiofrequencyablation needle electrode specifically includes the following steps: wrapping a radiofrequency ablation electrode needle in an Inconel 625 alloy, and shaping the Inconel 625 alloy on an electrode at260-300 DEG C to form an insulating layer; peeling off the insulating layer formed by the Inconel 625 alloy; performing cleaning, polishing the radiofrequency ablation electrode needle by using abrasive paper for metallograph, performing a reaction under ultrasonic stirring at room temperature in the presence of initiator ammonium persulfate for 4 h, and performing immersion in a 0.1-2 mol / L hydrochloric acid solution for 1-48 h; after the immersion is completed, taking out an electrode needle, and performing curing to obtain the radiofrequency ablation needle electrode. The needle electrode prepared by the preparation method provided by the invention has high comprehensive performance, does not have any impact on surrounding tissue, and has a large ablation range.

Owner:日照天一生物医疗科技有限公司

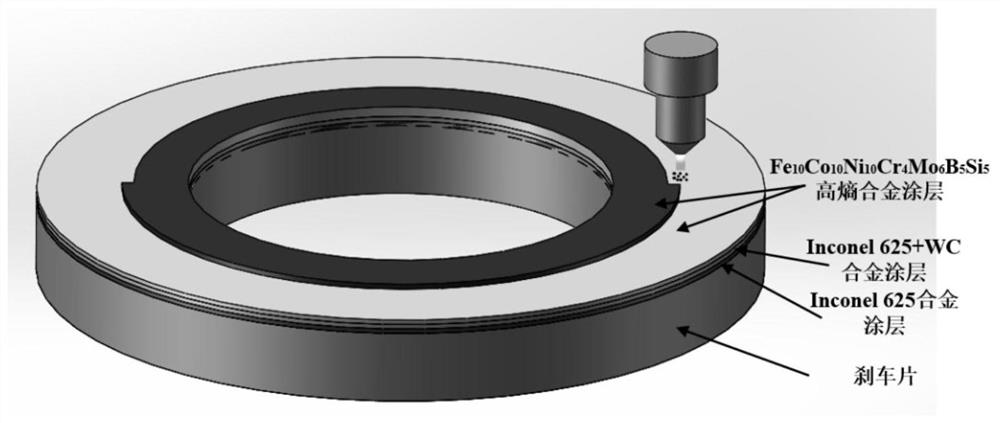

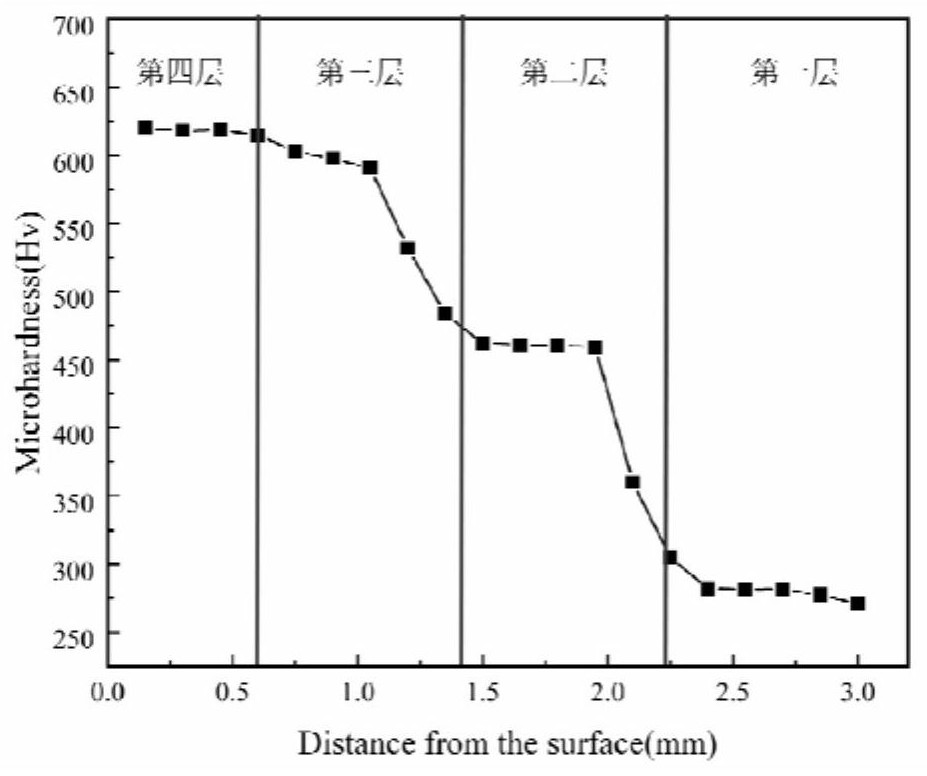

High-stability high-speed train brake disc coating and preparation method thereof

ActiveCN113913810AGood resistance to high temperature oxidationImprove corrosion resistanceMetallic material coating processesFriction liningBrakeAlloy coating

The invention discloses a high-stability high-speed train brake disc coating and a preparation method thereof. A high-speed laser cladding process is adopted to sequentially clad a base coating, a transition coating and two wear-resistant coatings on the surface of a brake disc from the bottom layer to the surface layer; the base coating is an Inconel 625 alloy coating, the transition coating is an Inconel 625 and WC alloy coating, and the wear-resistant coatings are Fe10Co10Ni10Cr4Mo6B5Si5 alloy coatings. The four layers of composite coatings are in gradient change, so that the expansion coefficient and thermal conductivity difference caused by component change is reduced; the hardness of the four coatings is increased in a gradient mode, the hardness of the wear-resistant coatings can reach 600 HV, the wear resistance is improved, and the wear-resistant coatings are of an FCC + BCC double-phase structure and have obdurability; and the friction coefficient of the composite coating ranges from 0.4 to 0.45, the composite coating meets the high-speed brake disc friction coefficient standard, can be completely matched with an abrasive disc and has application universality, the friction coefficient is kept constant in the braking process, braking stability is guaranteed, and train operation safety is improved.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com