Preparing method for composite valve

A valve and metallurgy combination technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of long delivery cycle, high price, unfavorable national industry, etc., and achieve the effect of good composite effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

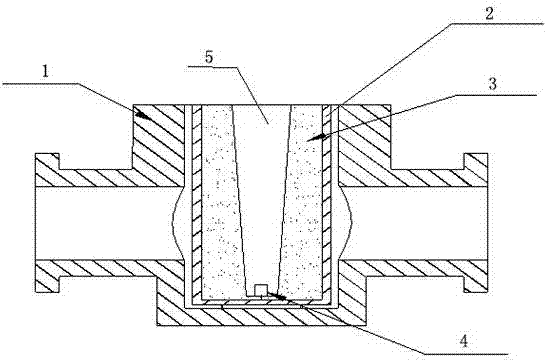

[0023] figure 1 Shown is the structural representation of the present invention.

[0024] The reference signs therein are: valve 1, Inconel 625 tube 2, explosive layer 3, detonator 4, cavity 5.

[0025] The preparation method of composite valve in the present embodiment, wherein: comprise the following steps:

[0026] Step 1. Place metal material Inconel 625 pipe 2 in the inner wall of valve 1 to be compounded, keep a certain gap between Inconel 625 pipe 2 and the inner wall of valve 1, and Inconel 625 pipe 2 is perpendicular to the side opening of valve 1;

[0027] Step 2: Lay the explosive layer 3 in the Inconel 625 tube 2. The explosive layer 3 is attached to the inner wall of the Inconel 625 tube 2 and the amount of explosive is gradually reduced from the bottom upwards. The amount of explosive is controlled so that the Inconel 625 tube 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Detonation velocity | aaaaa | aaaaa |

| Hot | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com