Duplex-metal coupling

A bimetal and alloy technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of fluid corrosion in oil well pipe couplings, affecting the performance of couplings, stress failure, etc., to ensure corrosion resistance , Improving the anti-corrosion performance and the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

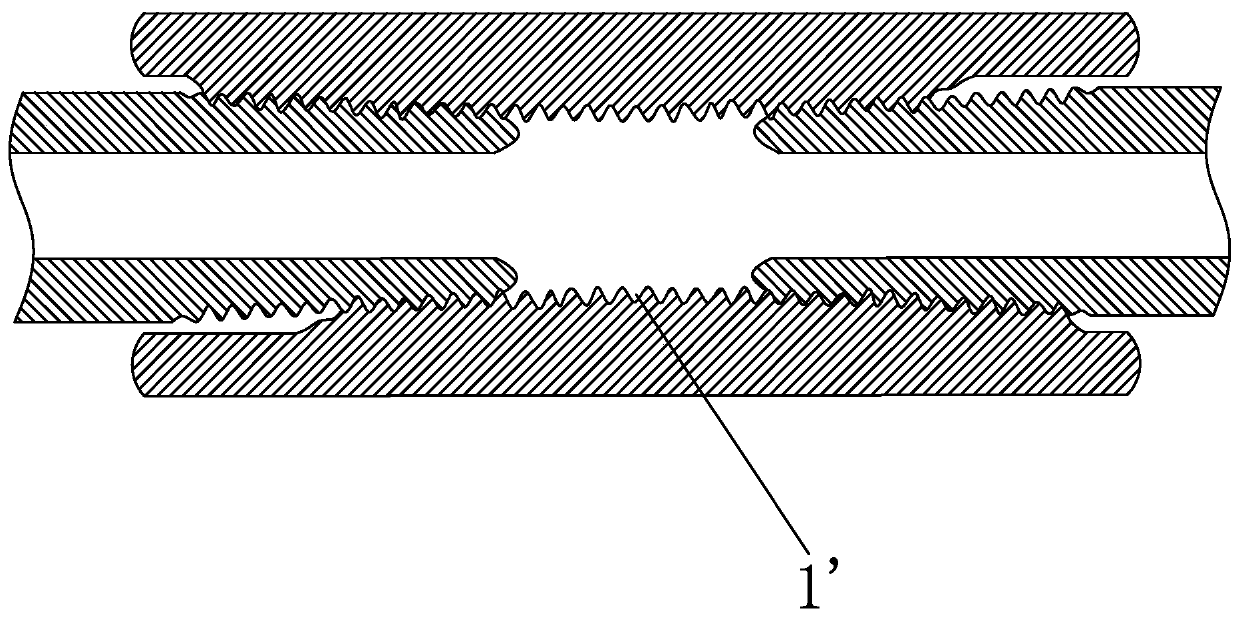

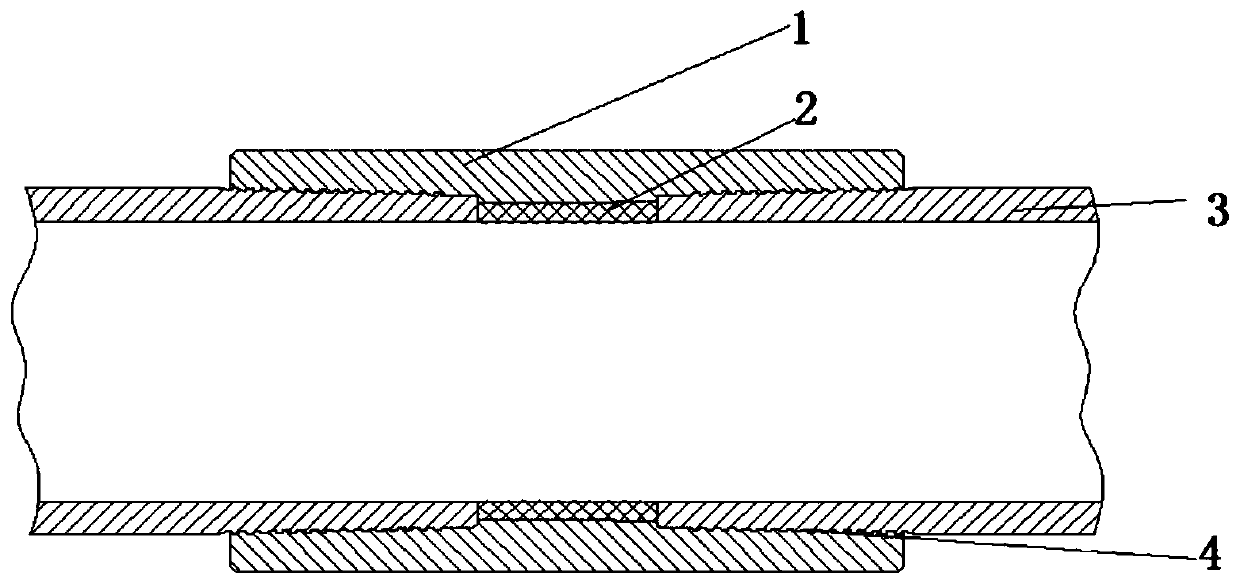

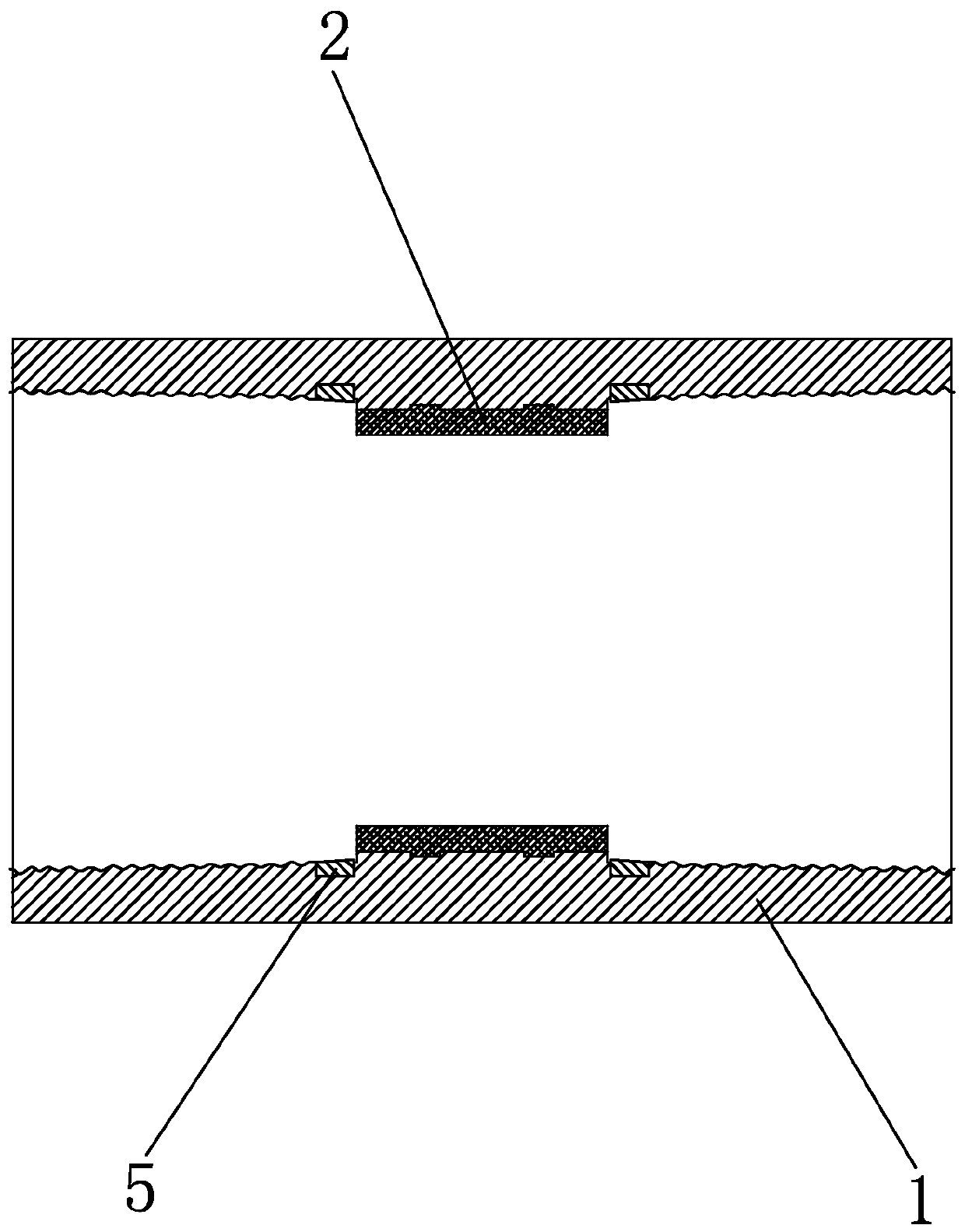

[0022] combine figure 2 with image 3 , the present invention is a bimetallic coupling used as a connecting piece between oil well pipes 3 . The present invention includes a coupling body 1 . The coupling body 1 can be made of carbon steel or nickel-based alloy, preferably nickel-based alloy. The coupling body 1 is in the form of a hollow sleeve structure, and connection interfaces are arranged symmetrically at both ends of the coupling body 1 . The connecting interface is used for mating connection with the oil well pipe 3 . The connection interface converges gradually toward the middle of the coupling body 1 along the axial direction, forming a trumpet-shaped opening structure; an internal thread 4 is provided on the inner wall of the connection interface. An alloy composite layer 2 is clad on the inner wall of the coupling body 1 by overlay welding. The alloy composite layer 2 is located between the two connection interfaces and has a ring-shaped boss structure. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com