A kind of high-strength high-plastic single-phase inconel 625 nickel-based alloy and its preparation method

A nickel-based alloy, high plasticity technology, used in metal processing equipment, manufacturing tools, additive manufacturing, etc., can solve the problem of low strength of Inconel625 nickel-based alloy, achieve good plasticity, high yield strength and tensile strength, tensile strength, tensile strength Excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

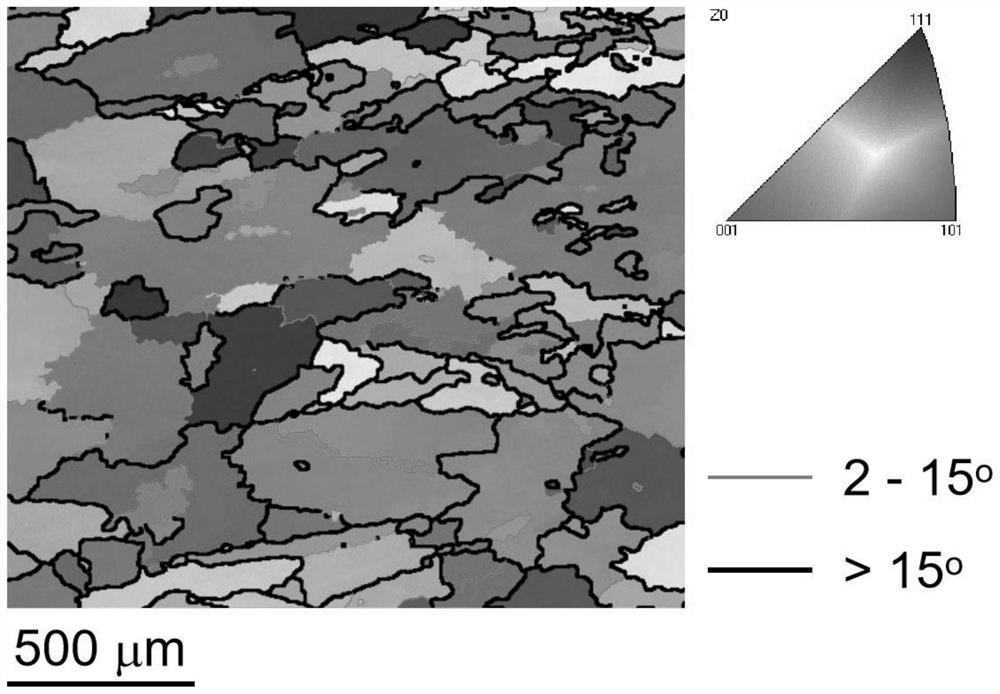

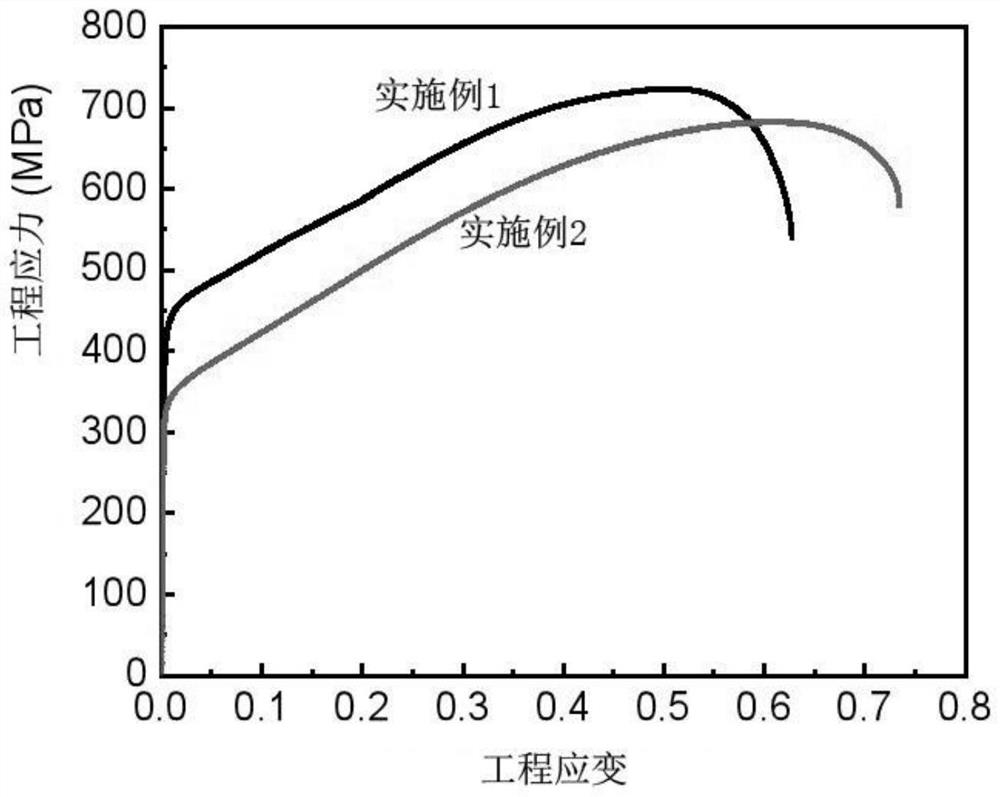

Embodiment 1

[0040] The single-phase Inconel 625 nickel-based alloy with a coarse-grained columnar crystal structure is obtained by rapidly depositing and depositing layer by layer on the carbon steel substrate according to the set path under the protection of protective gas by using the method of arc-added material. The crystal structure has high strength and high plasticity. The chemical elements in the nickel-based alloy are measured by atomic percentage (at.%) as follows: Ni:>58.00%, Cr:20.00-23.00%, Mo:8.00-10.00%, Nb:3.15-4.15%, Fe:≤5.00 %, Co: ≤1.00%, Si: ≤0.50%, Mn: ≤0.50%, Ti: ≤0.40%, Al: ≤0.40%, Cu: ≤0.30%, C: ≤0.10%, S: ≤0.02%, P:≤0.02%, Ta:≤0.02%.

[0041] The arc process parameters are as follows: CMT MIG process is adopted, and the wire is NiCrMo-3 (625 nickel-based alloy) wire with a diameter of 1.2 mm. The printing adopts ArcMan 600 equipment, its process is DC CMT, and the arc additive software used is IungoPNT. The welding expert library version used in the experiment ...

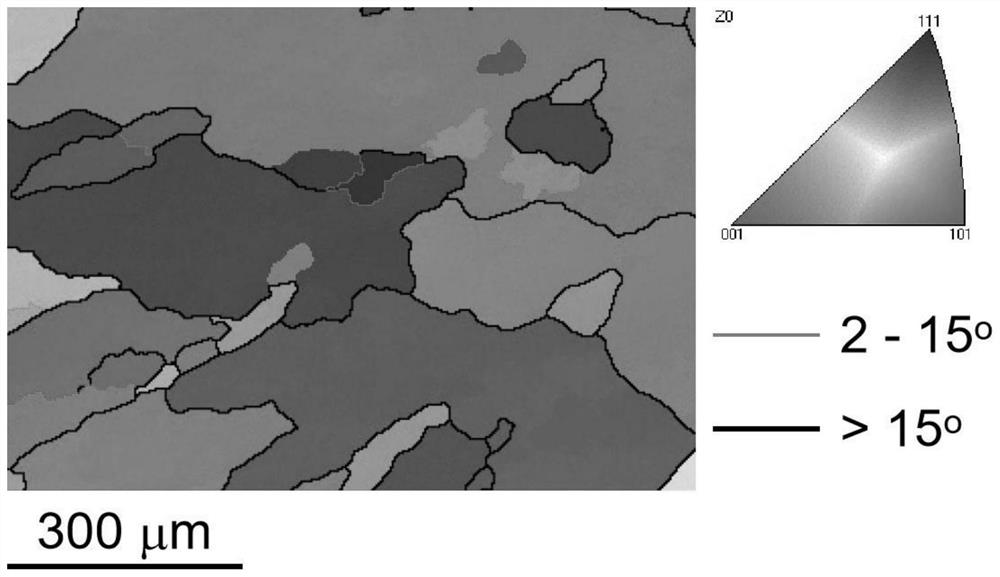

Embodiment 2

[0045] The difference from Example 1 is:

[0046] Inconel 625 nickel-based alloy with columnar crystal single-phase structure with a high proportion of small-angle grain boundaries is obtained by rapidly depositing layer by layer on the carbon steel substrate according to the set path under the protection of protective gas by using arc additive technology. The columnar grain structure with angled grain boundaries has the characteristics of high strength and high plasticity. The arc process parameters are as follows: CMT MIG process is adopted, and the wire is NiCrMo-3 (625 nickel-based alloy) wire with a diameter of 1.2mm. The printing process adopts ArcMan 600 equipment, its process is DC CMT, and the arc additive software used is IungoPNT. The welding expert library version used in the experiment is 1693 (NIBAS625), the wire feeding speed is 4.6m / min, the arc length correction is 0, and the inductance correction is 0. Then, the obtained material was subjected to solution t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com