Cladding powder for improving wear resistance of nickel-based laser cladding layer and preparation method of cladding powder

A laser cladding and wear-resistant technology, which is applied in the field of cladding powder and cladding powder preparation to improve the wear resistance of the nickel-based laser cladding layer, to achieve the effects of reducing porosity, enhancing flow, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

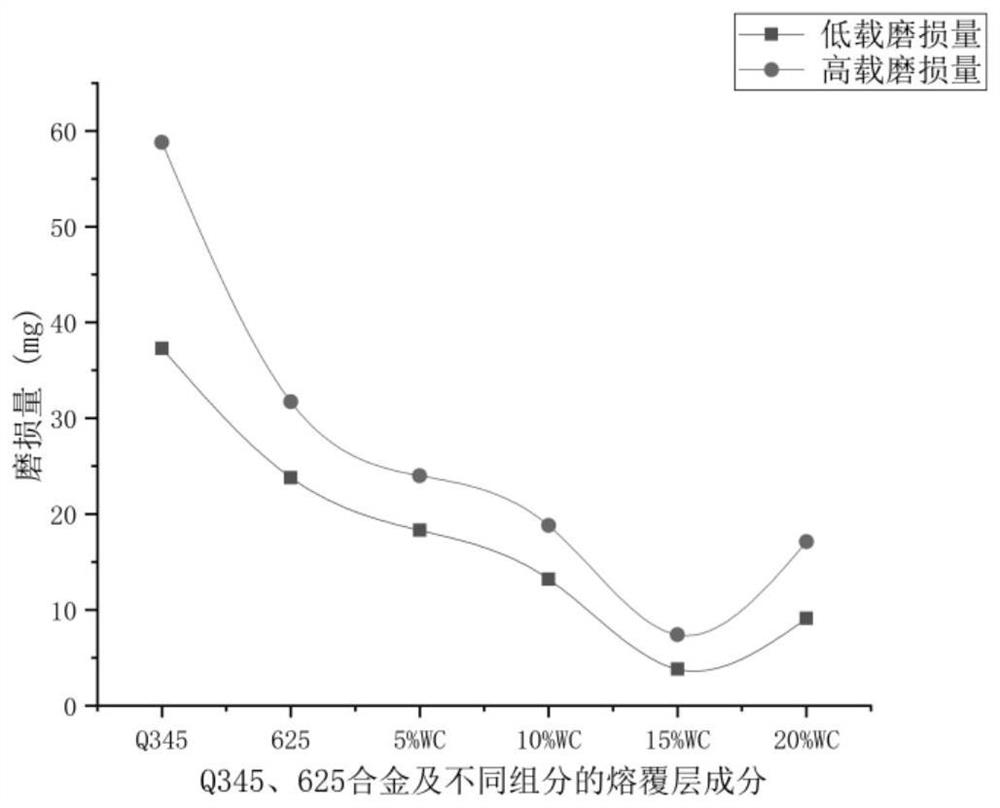

[0036] The raw material composition of a laser cladding powder for improving the wear resistance of an Inconel 625 nickel-based laser cladding layer is: Inconel 625-XWC nickel-based alloy, wherein X=5wt.%.

[0037] The preparation steps and experimental operations are as follows:

[0038] Step 1, use the QM-3SP2 planetary ball mill to mechanically mix the ratio by 600g, set the ball-to-material ratio to 1:5, the rotational speed to 350rpm, and the set time to 60min, in which forward rotation and reverse rotation account for half;

[0039] Step 2, using a drying box to dry the nickel-based alloys with different gradients after mechanical mixing respectively, set the temperature to 160 ° C, and dry for 30 min;

[0040] Step 3: Use ISDL-3008 fiber input semiconductor laser for laser cladding, and rub the clad layer at room temperature under low load (5N) and under high load (10N), and rub the grinding disc and sample before and after the experiment. Ultrasonic cleaning and weigh...

Embodiment 2

[0043] The raw material composition of a laser cladding powder for improving the wear resistance of an Inconel 625 nickel-based laser cladding layer is: Inconel 625-XWC nickel-based alloy, wherein X=10wt.%.

[0044] The preparation steps and experimental operations are as follows:

[0045] Step 1, use the QM-3SP2 planetary ball mill to mechanically mix the ratio by 600g, set the ball-to-material ratio to 1:5, the rotational speed to 350rpm, and the set time to 60min, in which forward rotation and reverse rotation account for half;

[0046]Step 2, using a drying box to dry the nickel-based alloys with different gradients after mechanical mixing respectively, setting the temperature to 160°C, and drying for 1 hour;

[0047] Step 3: Use ISDL-3008 fiber input semiconductor laser for laser cladding, and rub the clad layer at room temperature under low load (5N) and under high load (10N), and rub the grinding disc and sample before and after the experiment. Ultrasonic cleaning and ...

Embodiment 3

[0050] The raw material composition of a laser cladding powder for improving the wear resistance of an Inconel 625 nickel-based laser cladding layer is: Inconel 625-XWC nickel-based alloy, wherein X=15wt.%.

[0051] The preparation steps and experimental operations are as follows:

[0052] Step 1, use the QM-3SP2 planetary ball mill to mechanically mix the ratio by 500g, set the ball-to-material ratio to 1:5, the rotating speed to 350rpm, and the setting time to 60min, in which forward rotation and reverse rotation account for half;

[0053] Step 2, using a drying box to dry the nickel-based alloys with different gradients after mechanical mixing respectively, setting the temperature to 160°C, and drying for 1 hour;

[0054] Step 3: Use ISDL-3008 fiber input semiconductor laser for laser cladding, and rub the clad layer at room temperature under low load (5N) and under high load (10N), and rub the grinding disc and sample before and after the experiment. Ultrasonic cleaning a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| L | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com