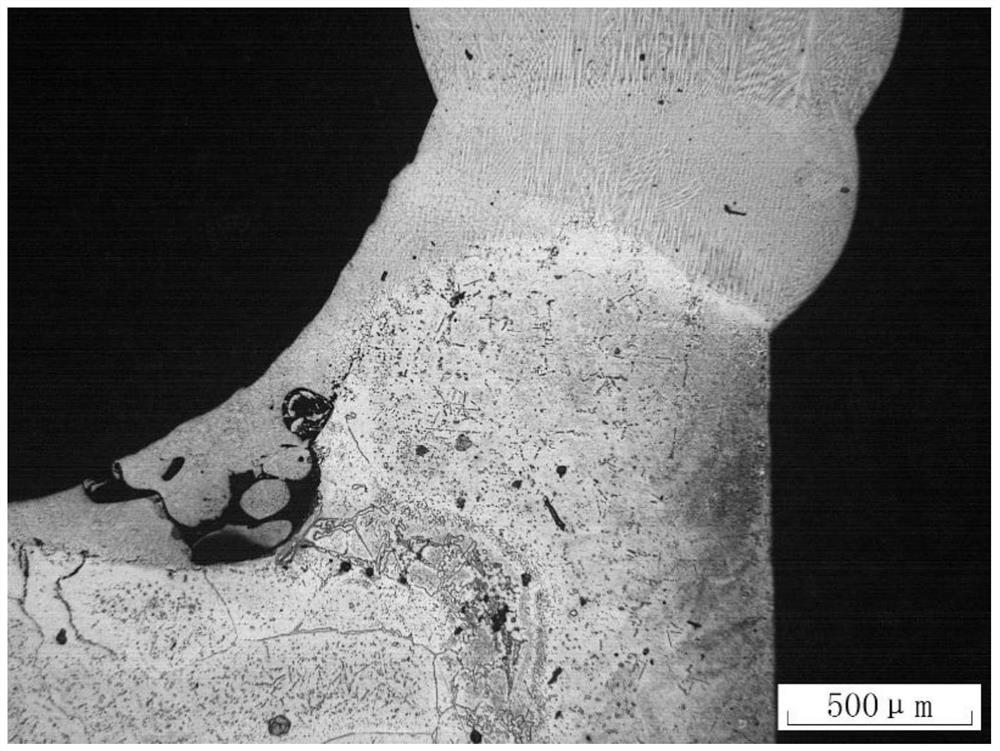

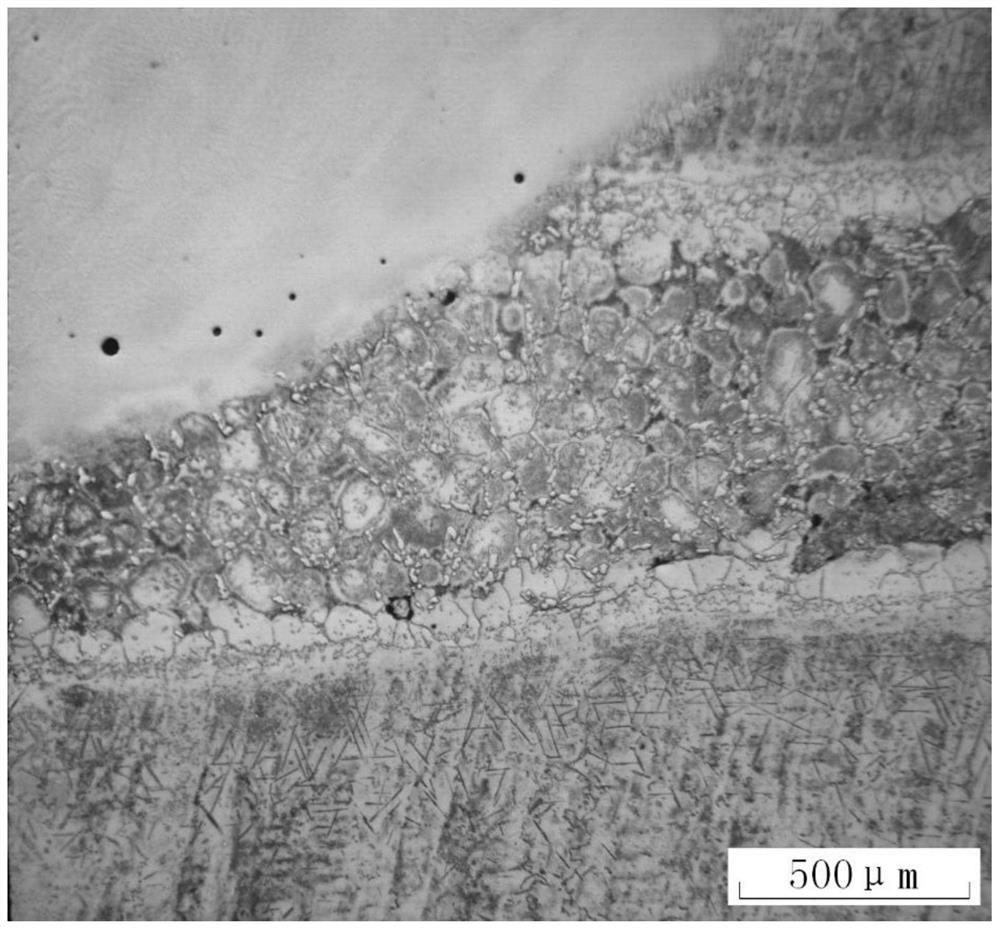

Repair material and repair method for directional solidification crystal turbine blade tip deep cracks

A turbine blade and directional solidification technology, which is applied in the direction of turbines, additive processing, mechanical equipment, etc., can solve problems such as micro-cracks and repair failures, shorten the maintenance cycle, enhance weldability, and ensure repair quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

[0025] The first subject of the present invention is: the repair material for directionally solidified crystal turbine blade tip deep cracks, which is formed by fully mixing 35% to 45% of Inconel625 alloy powder and 55% to 65% of Rene142 alloy powder by mass . The percentage of Inconel625 alloy powder can be any integer between 35 and 45, for example: the mass ratio of Inconel625 alloy powder to Rene142 alloy powder is 40:60. The restorative material is made by mixing two alloy powders, which are physically mixed, and the two alloy powders are existing. In order to ensure the uniformity of the two alloy powders after mixing, the Inconel625 alloy powder and the Rene142 alloy powder are mixed in proportion, and mechanically stirred for at least 24 hours to make the mixture uniform.

[0026] The second subject of the present invention is: the repair method of directionally solidified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com