Preparation method of cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance

A corrosion-resistant, crack-free technology, applied in coatings, metal material coating processes, etc., can solve problems such as easy cracking, and achieve the effect of reducing friction coefficient, reducing wear volume, and suppressing cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

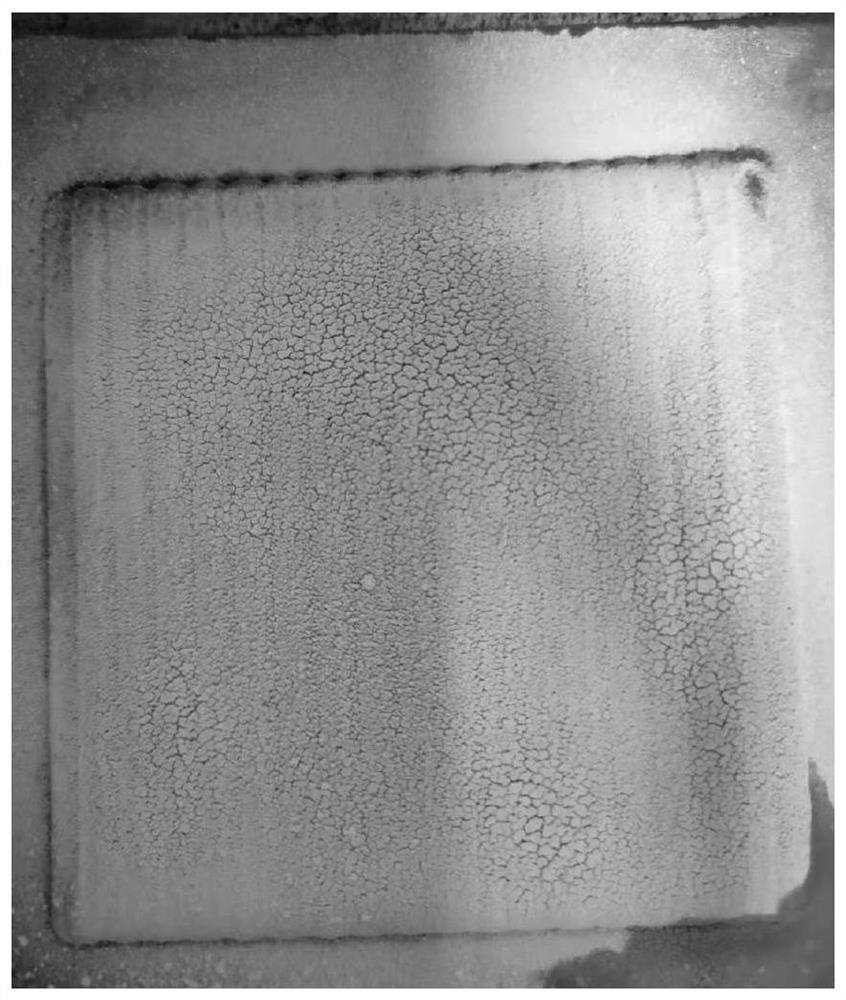

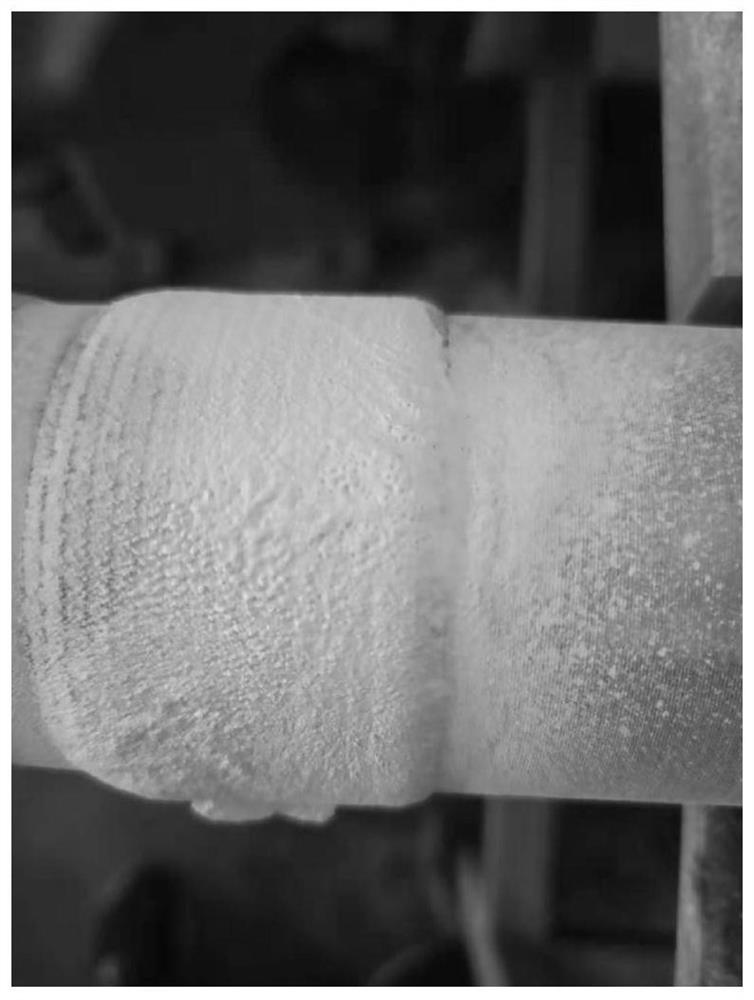

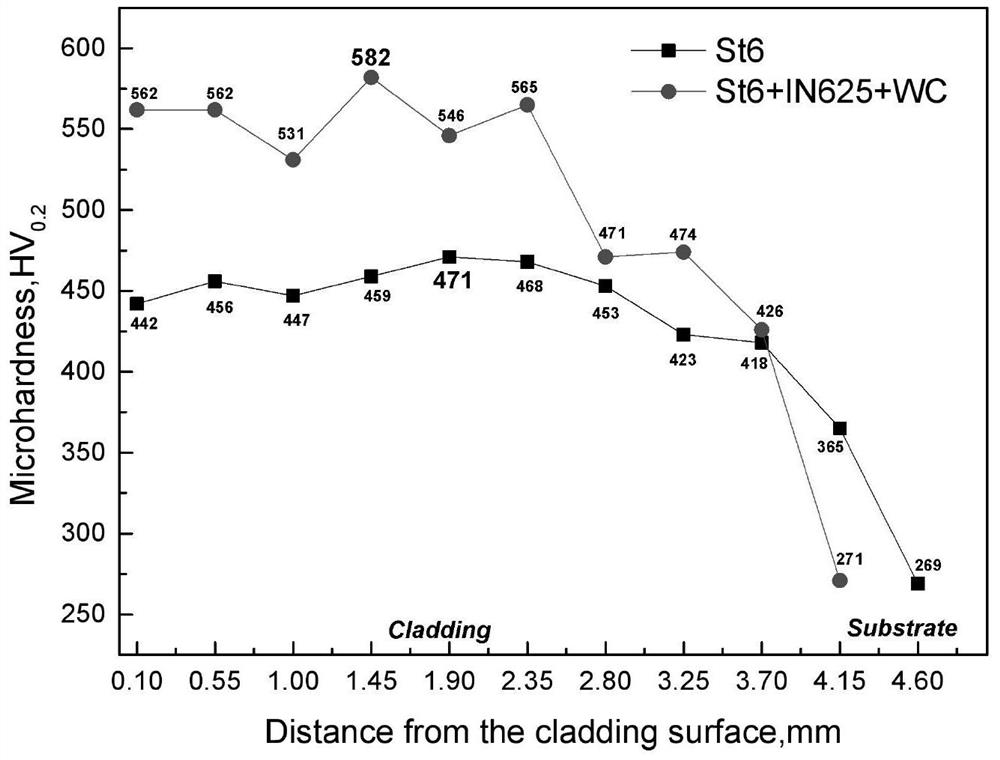

[0038] A method for preparing a cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance, comprising the following steps:

[0039] (1) the scale and oil stains on the surface of the duplex stainless steel substrate are removed;

[0040] (2) Weigh Stellite 6, Inconel 625, WC ceramic particles, three kinds of material powder;

[0041] (3) three kinds of powders are evenly mixed and dried;

[0042] (4) Set the process parameters and perform laser cladding on the surface of the duplex stainless steel substrate;

[0043] (5) Finishing.

[0044] Preferably, in step (1), the duplex stainless steel substrate is clamped on a milling machine, cleaned and air-dried with a cleaning agent, and milled off the surface oxide of the duplex stainless steel substrate to expose a bright and clean metal surface.

[0045] Preferably, in step (2), the cobalt-based composite powder is weighed with an electronic balance, and the three powders in the cobalt-ba...

Embodiment 2

[0054] A method for preparing a cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance, comprising the following steps:

[0055] (1) the scale and oil stains on the surface of the duplex stainless steel substrate are removed;

[0056] (2) Weigh Stellite 6, Inconel 625, WC ceramic particles, three kinds of material powder;

[0057] (3) three kinds of powders are evenly mixed and dried;

[0058] (4) Set the process parameters and perform laser cladding on the surface of the duplex stainless steel substrate;

[0059] (5) Finishing.

[0060] In this embodiment, in step (1), the duplex stainless steel substrate is clamped on a milling machine, cleaned and air-dried with a cleaning agent, and milled off the surface oxide skin of the duplex stainless steel substrate to expose a bright clean metal surface .

[0061] In the present embodiment, in step (2), the cobalt-based composite powder is weighed with an electronic balance, and the th...

Embodiment 3

[0070] A method for preparing a cobalt-based reinforced crack-free coating with excellent wear resistance and corrosion resistance, comprising the following steps:

[0071] (1) the scale and oil stains on the surface of the duplex stainless steel substrate are removed;

[0072] (2) Weigh Stellite 6, Inconel 625, WC ceramic particles, three kinds of material powder;

[0073] (3) three kinds of powders are evenly mixed and dried;

[0074] (4) Set the process parameters and perform laser cladding on the surface of the duplex stainless steel substrate;

[0075] (5) Finishing.

[0076] In this embodiment, in step (1), the duplex stainless steel substrate is clamped on a milling machine, cleaned and air-dried with a cleaning agent, and milled off the surface oxide skin of the duplex stainless steel substrate to expose a bright clean metal surface .

[0077] In the present embodiment, in step (2), the cobalt-based composite powder is weighed with an electronic balance, and the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com