High-aluminum Inconel 625 alloy and preparation method thereof

An alloy and high-alumina technology, which is applied in the field of preparation of high-aluminum Inconel625 alloy, can solve the problems of poor corrosion resistance and strong corrosion resistance of chloride molten salt, and achieve the effects of simplifying production equipment, reducing Cr content, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

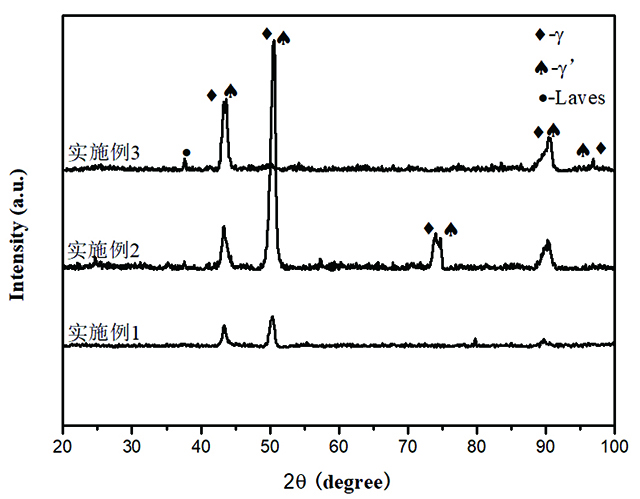

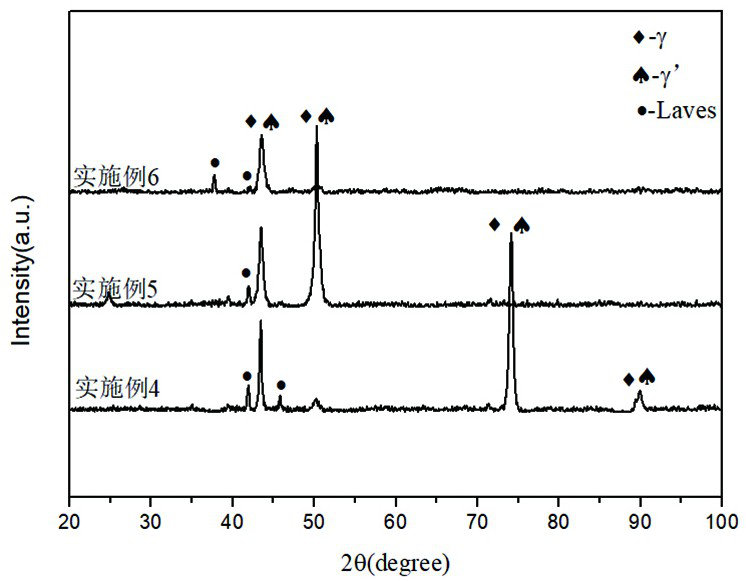

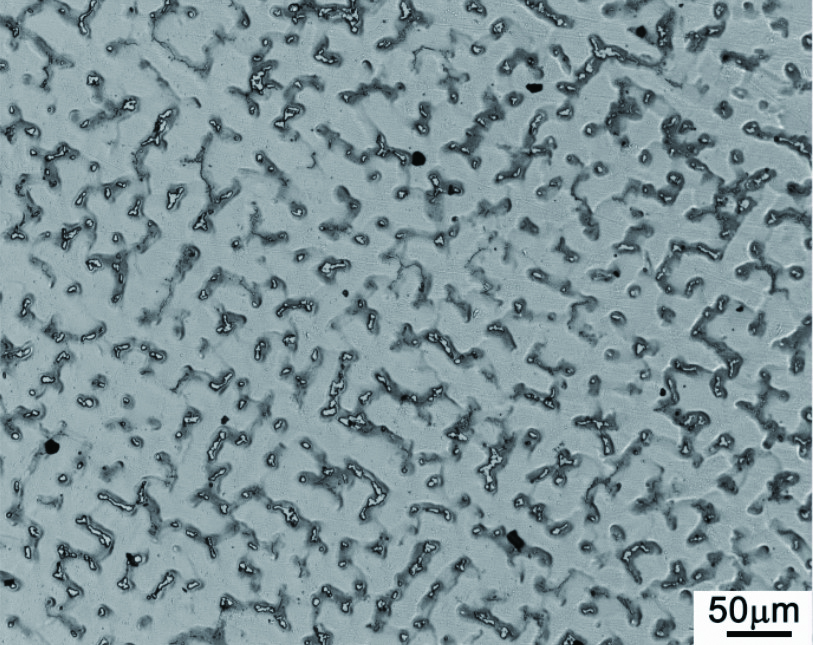

Image

Examples

preparation example Construction

[0015] The high-aluminum Inconel 625 alloy preparation method of the present invention comprises the following steps:

[0016] Step (1) weigh the reaction material according to a preset ratio, and place the reaction material in a planetary ball mill for ball milling;

[0017] Step (2) pressing the ball-milled reaction material on a press into a cake-shaped blank with a diameter of 80 mm and a height of about 50 mm;

[0018] Step (3) put the cake-shaped blank into the reaction kettle, put the igniter on the blank, fill with protective gas for washing, then fill with protective gas to keep the pressure, and continue to heat up until the self-propagating reaction occurs in the system to obtain base metal alloy;

[0019] Step (4) vacuum induction secondary smelting is performed on the base metal alloy to obtain an ingot;

[0020] Step (5) The ingot is solution-treated at 1150° C. for 30 minutes, and water-cooled.

[0021] For the preparation method described above, the paramete...

Embodiment 1

[0029] The aluminothermic method prepares the initial casting billet, and its preparation steps are:

[0030] Table 1 Example 1 High-aluminum Inconel 625 alloy reaction material ratio (wt.%)

[0031]

[0032] (1) Ingredients: Weigh 1kg of reaction raw materials according to the ratio of reaction materials shown in Table 1, and each raw material is evenly divided into four parts and mixed evenly;

[0033] (2) Ball milling: Put the mixed reaction materials into the QM-ISP4 planetary ball mill for ball milling, the speed is 80 r / min, and the ball milling time is 8 hours. Note that the direction of the ball mill is changed every 2 hours to prevent agglomeration. for Al 2 O 3 , the ratio of ball to material is 1:2;

[0034] (3) Preparation by aluminothermic method: After the ball milling, the reaction material was put into the mold, and a pressure of 70 MPa was applied with a hydraulic press. After the pressure was maintained for 4 minutes, the material was pressed into a dia...

Embodiment 2

[0040] The reaction materials of this example are shown in Table 2, and the preparation steps are the same as in Example 1. The test results of mechanical properties at room temperature are: hardness 445.0 HV0.3, tensile strength 1011.64 MPa, and elongation 2.68%.

[0041] Table 2 Example 2 High-aluminum Inconel 625 alloy reaction material ratio (wt.%)

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com