High-conductivity composite grounding material and preparation method thereof

A composite grounding, high conductivity technology, applied in the field of power transmission, can solve the problems of low conductivity of cement-based conductive materials, easy passivation and corrosion of steel fibers, etc., to improve plasticity and water retention, improve grounding effect, Corrosion mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

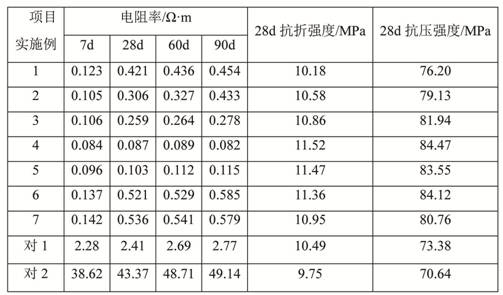

Examples

Embodiment 1

[0029] A high-conductivity composite grounding material, made of the following raw materials in parts by weight: 100 parts of gel material, 90 parts of aggregate fine sand, 30 parts of water, 0.3 parts of water reducing agent, 0.6 parts of defoaming agent, dispersant 0.6 parts, stainless steel fiber 1 part and carbon fiber 0.1 part.

[0030] The gel material is P.O42.5 Portland cement.

[0031] The water reducer is a polycarboxylate high-efficiency water reducer.

[0032] Described defoamer is tributyl phosphate.

[0033] Described dispersant is hydroxypropyl methylcellulose, and viscosity is 20 * 10 4 mPa s.

[0034] The stainless steel fibers are 316L stainless steel fibers with a diameter of 0.02-0.05mm and a length of 8-12mm.

[0035] The carbon fiber has a diameter of 100-200 nm and a length of 30-100 μm.

[0036] The preparation method of the above-mentioned high-conductivity composite grounding material comprises the following steps:

[0037] (1) Mix water reducer,...

Embodiment 2

[0043] A high-conductivity composite grounding material, made of the following raw materials in parts by weight: 100 parts of gel material, 90 parts of aggregate fine sand, 40 parts of water, 0.4 part of water reducer, 0.5 part of defoamer, dispersant 0.5 parts, stainless steel fiber 1.2 parts and carbon fiber 0.2 parts.

[0044] The gel material is P.O42.5 Portland cement.

[0045] The water reducer is a polycarboxylate high-efficiency water reducer.

[0046] Described defoamer is tributyl phosphate.

[0047] Described dispersant is hydroxypropyl methylcellulose, and viscosity is 20 * 10 4 mPa s.

[0048] The stainless steel fibers are 316L stainless steel fibers with a diameter of 0.02-0.05mm and a length of 8-12mm.

[0049] The carbon fiber has a diameter of 100-200 nm and a length of 30-100 μm.

[0050] The preparation method of the above-mentioned high-conductivity composite grounding material comprises the following steps:

[0051] (1) Mix water reducer, defoamer,...

Embodiment 3

[0057] A high-conductivity composite grounding material, made of the following raw materials in parts by weight: 100 parts of gel material, 100 parts of aggregate fine sand, 40 parts of water, 0.6 parts of water reducing agent, 0.5 parts of defoaming agent, dispersant 0.7 parts, stainless steel fiber 1.5 parts and carbon fiber 0.2 parts.

[0058] The gel material is P.O52.5 Portland cement.

[0059] The water reducer is a polycarboxylate high-efficiency water reducer.

[0060] Described defoamer is tributyl phosphate.

[0061] Described dispersant is hydroxypropyl methylcellulose, and viscosity is 20 * 10 4 mPa s.

[0062] The stainless steel fibers are 316L stainless steel fibers with a diameter of 0.02-0.05mm and a length of 8-12mm.

[0063] The carbon fiber has a diameter of 100-200 nm and a length of 30-100 μm.

[0064] The preparation method of the above-mentioned high-conductivity composite grounding material comprises the following steps:

[0065] (1) Mix water r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com