Stainless steel alloy, preparation method thereof and stainless steel cladding of fuel assembly

A technology of fuel assembly and stainless steel, which is applied in the field of reactor nuclear fuel assembly, can solve the problems of affecting stainless steel welding performance and thermal processing performance, reducing corrosion resistance, steel brittle corrosion resistance, etc., to improve machining performance and corrosion resistance Performance, effect of reducing Cr content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the first embodiment of the stainless steel alloy of the present invention may comprise the following steps:

[0046] S1. Melting the raw materials of each component according to the mass percentage of each component to obtain a smelting liquid.

[0047] Among them, smelting can be realized by any one of vacuum induction furnace, non-vacuum induction furnace, resistance furnace, electric arc furnace + refining outside the furnace. The raw materials for each component are commercially available.

[0048] S2. Casting to produce a stainless steel alloy. The casting temperature is 1550°C to 1650°C.

[0049]In the first embodiment, each component is added in the form of a single substance, followed by smelting and casting in sequence to obtain a stainless steel alloy.

[0050] The preparation method of the second embodiment of the stainless steel alloy of the present invention may comprise the following steps:

[0051] S1. Prepare an Al-Y master...

Embodiment 1

[0062] The vacuum smelting process is used to pre-prepare Al-Y master alloy, wherein the weight percentage of yttrium is 20%, and the FeCrAl ferritic stainless steel alloy is obtained through metering, batching, smelting and casting by adopting the master alloy secondary feeding method. Among them, the mass percentage (wt%) of each component is as follows: Cr 10%, Al 6%, Nb 0.6%, Mo 3%, Ti 0.3%, Si0.5%, Zr 0.5%, W 0.5%, Y 0.3%, The balance is Fe.

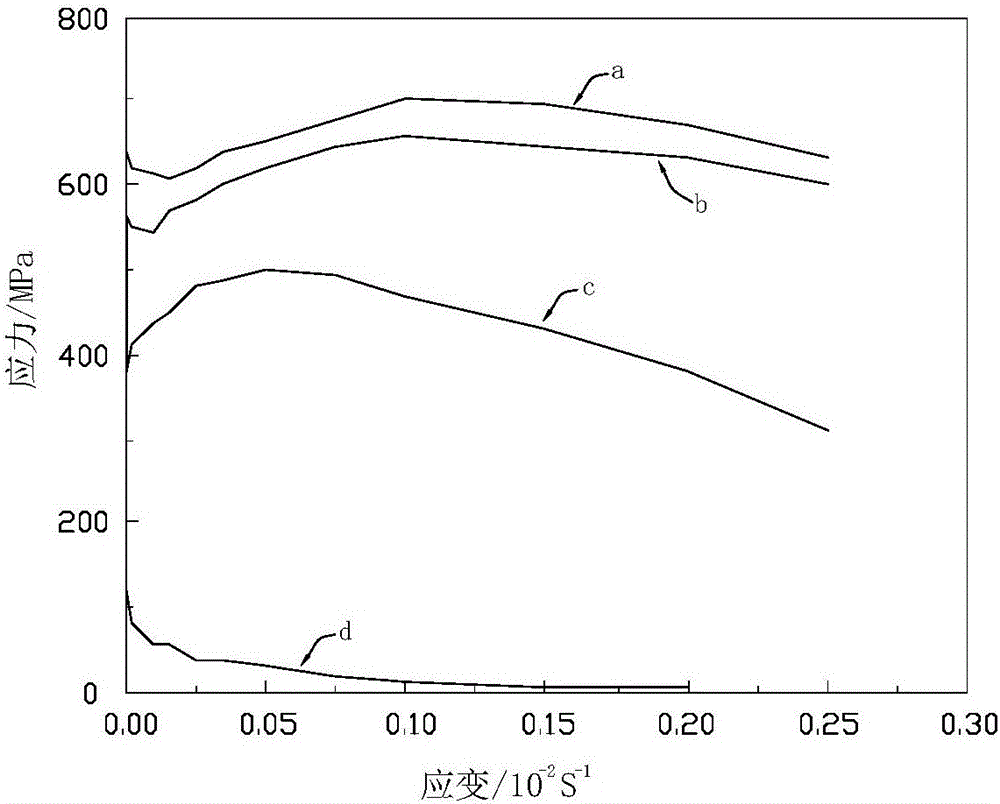

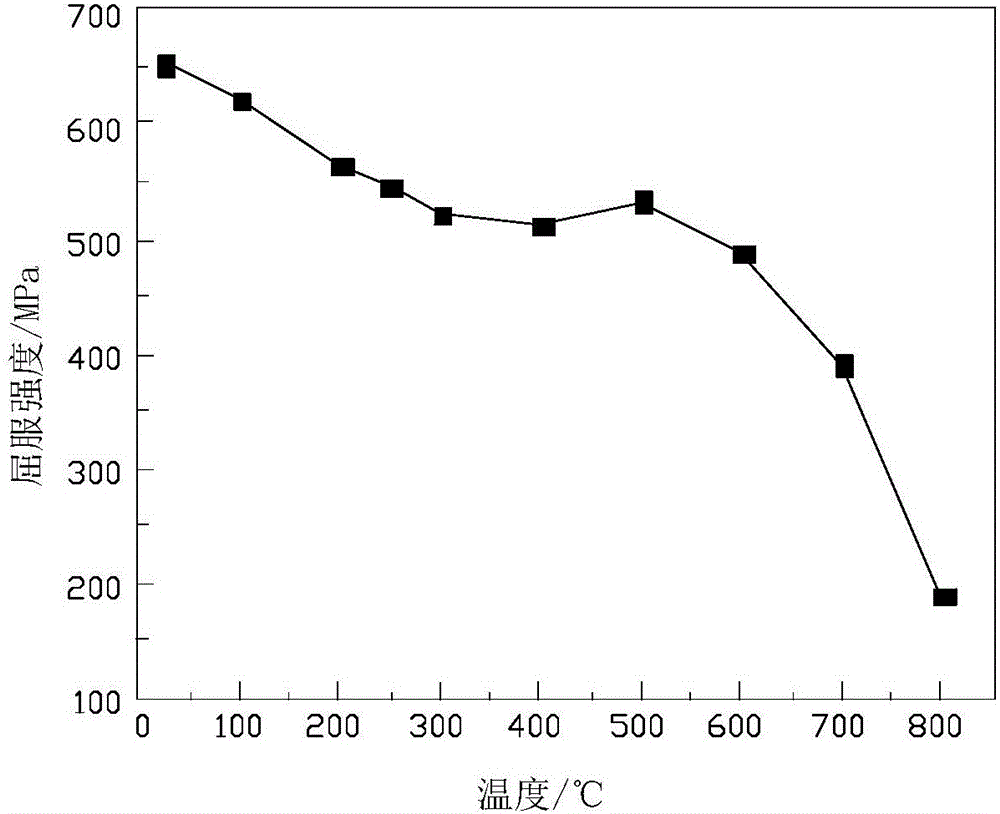

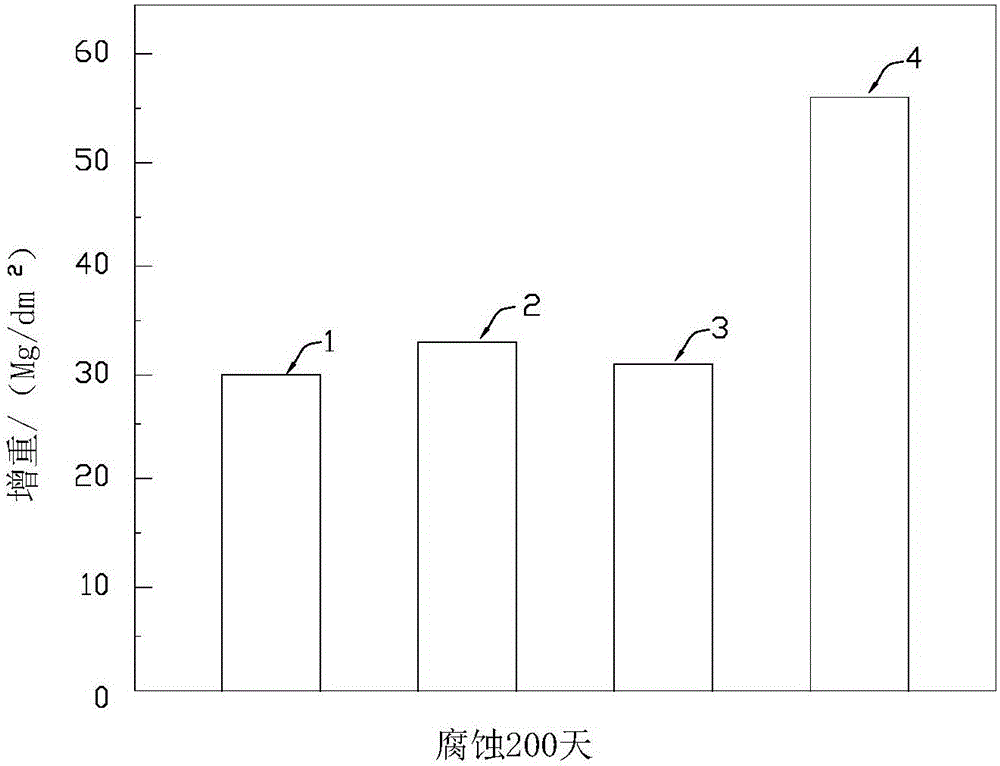

[0063] The yield strength of the prepared stainless steel alloy is greater than 450MPa, the tensile strength is greater than 500MPa, and the elongation at break is greater than 25% at room temperature; at 300°C, the yield strength is greater than 250MPa, and the tensile strength is greater than 400MPa. Alloy ingots are uniformly annealed at 1200°C, forged at 800-1200°C to form bars, then perforated, hot-rolled at 800-1050°C for multiple passes, cold-rolled, intermediate annealed, and finally stress-relieved annealed at 700°C. Corre...

Embodiment 2

[0065] The vacuum smelting process is used to pre-prepare Al-Y master alloy, wherein the weight percentage of yttrium is 20%, and the FeCrAl ferritic stainless steel alloy is obtained through metering, batching, smelting and casting by adopting the master alloy secondary feeding method.

[0066] Among them, the mass percentage (wt%) of each component is as follows: Cr 13%, Al 5%, Nb 0.4%, Mo 1%, Ti0.2%, Si 0.5%, Zr 0.5%, W 0.5%, Y 0.3%, The balance is Fe.

[0067] The yield strength of the prepared stainless steel alloy is greater than 450MPa, the tensile strength is greater than 500MPa, and the elongation at break is greater than 25% at room temperature; at 300°C, the yield strength is greater than 250MPa, and the tensile strength is greater than 400MPa. Alloy ingots are uniformly annealed at 1200°C, forged at 800-1200°C to form bars, then perforated, hot-rolled at 800-1050°C for multiple passes, cold-rolled, intermediate annealed, and finally stress-relieved annealed at 700°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com