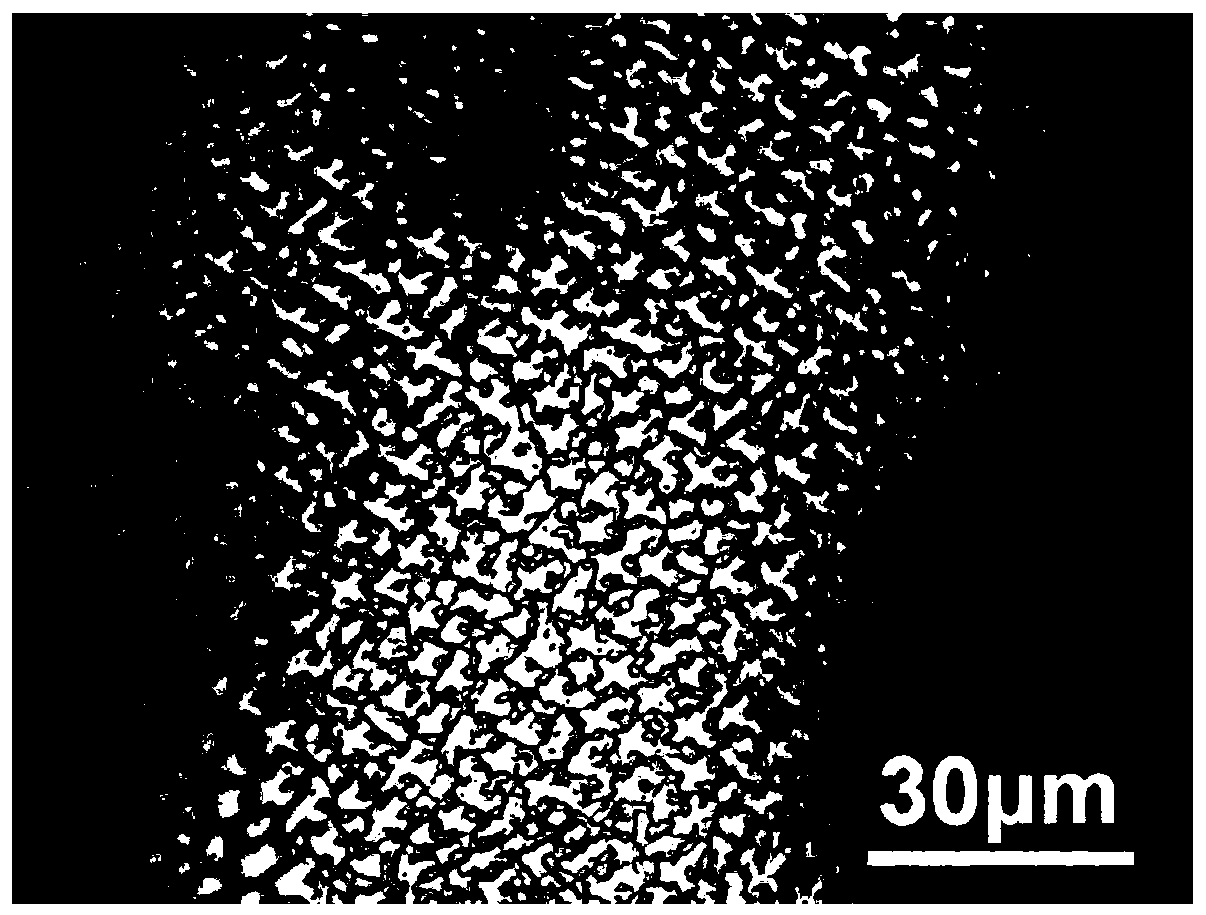

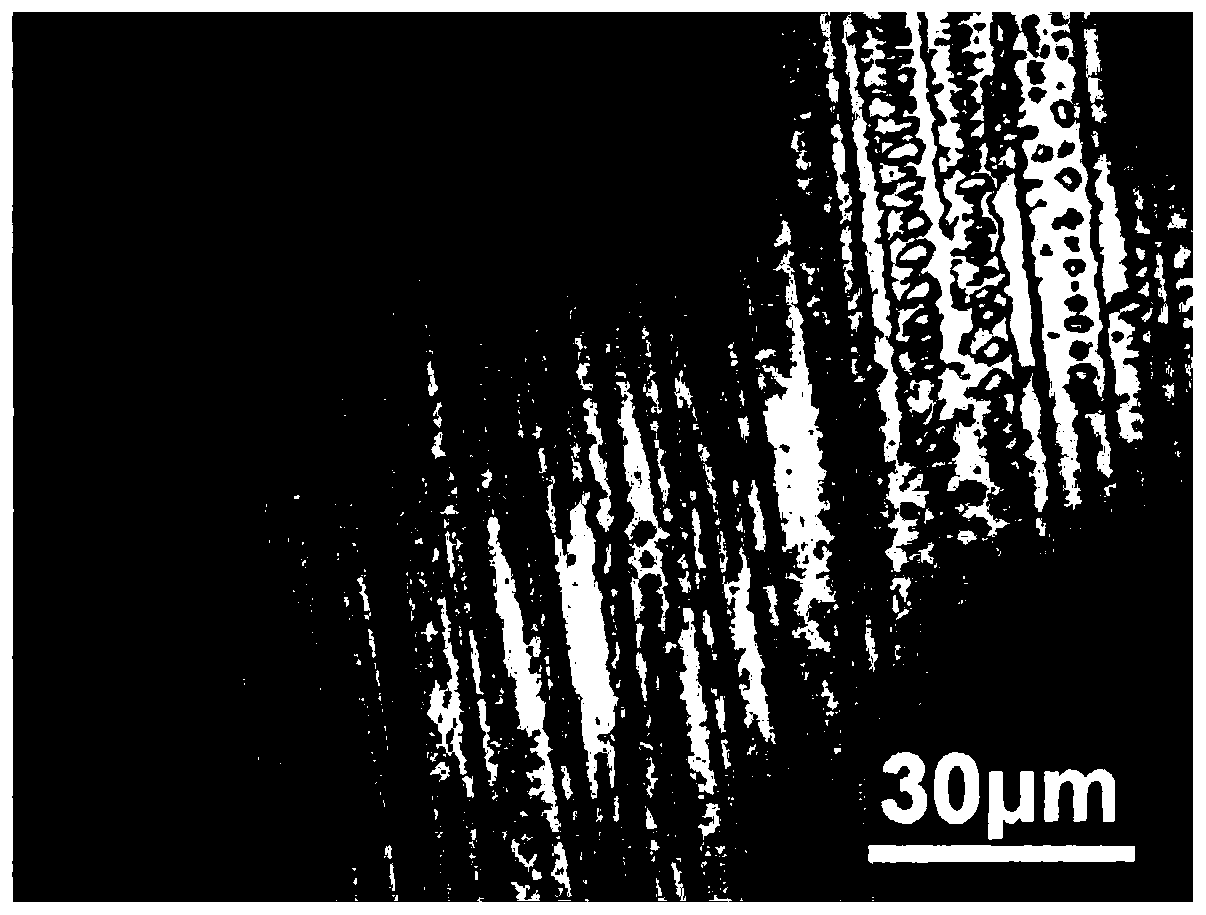

Inconel 625 alloy dendrite morphology method

An alloy and morphology technology, applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problem of lack of control of cobalt-based superalloy dendrite morphology, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for Inconel625 alloy dendrite morphology, comprising the following steps:

[0022] (1) Set the main parameters of the laser additive manufacturing process, the laser peak power P is 500-1000W, the scanning speed V is 5-13mm / s, and the spot diameter D is 0.5-2.5mm;

[0023] (2) Use the parameters set in step (1) to perform laser additive forming on the Inconel625 alloy, and record the temperature change of the molten pool passing through the middle of the single-pass cladding layer during the laser additive forming process of the Inconel625 alloy to obtain a fixed-point temperature change curve;

[0024] (3) Obtain the fixed-point temperature change curve according to the step (2), calculate the peak temperature T of the fixed-point temperature change curve, the intercept t of the liquidus line and the temperature curve, and the average cooling rate ξ of the molten pool cooling stage;

[0025] (4) Repeat step (2) and step (3) 2 to 3 times, according to the fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com