Aging heat treatment process for efficiently strengthening nickel-based superalloy

A nickel-based superalloy and aging heat treatment technology, applied in the field of superalloys, can solve the problems of insufficient mechanical properties of single-phase nickel-based superalloys, high cost, time-consuming second-phase structure, etc. The effect of speeding up the generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A high-efficiency aging heat treatment process for strengthening nickel-based superalloys, comprising the following steps:

[0029] S1: Machining the Inconel 625 alloy sample into a specified size to meet the needs of the box-type resistance furnace and ensure uniform heating; put refractory bricks in the furnace so that the Inconel 625 alloy can be placed in the middle of the furnace after being placed on the refractory bricks; start heating , raise the temperature to 650°C at a speed of 10°C / min, then raise the temperature to 950°C at a speed of 5°C / min, and finally raise the temperature to 1130°C at a speed of 3° / min. ) min, where, d is the direct cross-sectional area of the Inconel 625 alloy, in mm;

[0030] S2: Take out the Inconel 625 alloy, put it into water for quenching, and the quenching water temperature is 20°C;

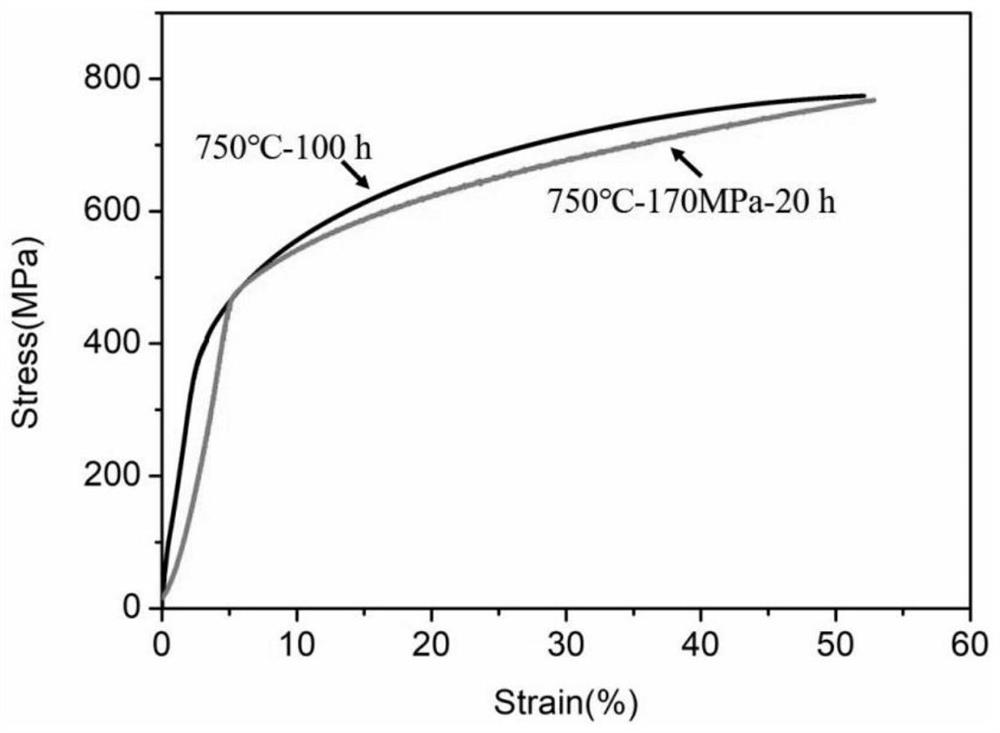

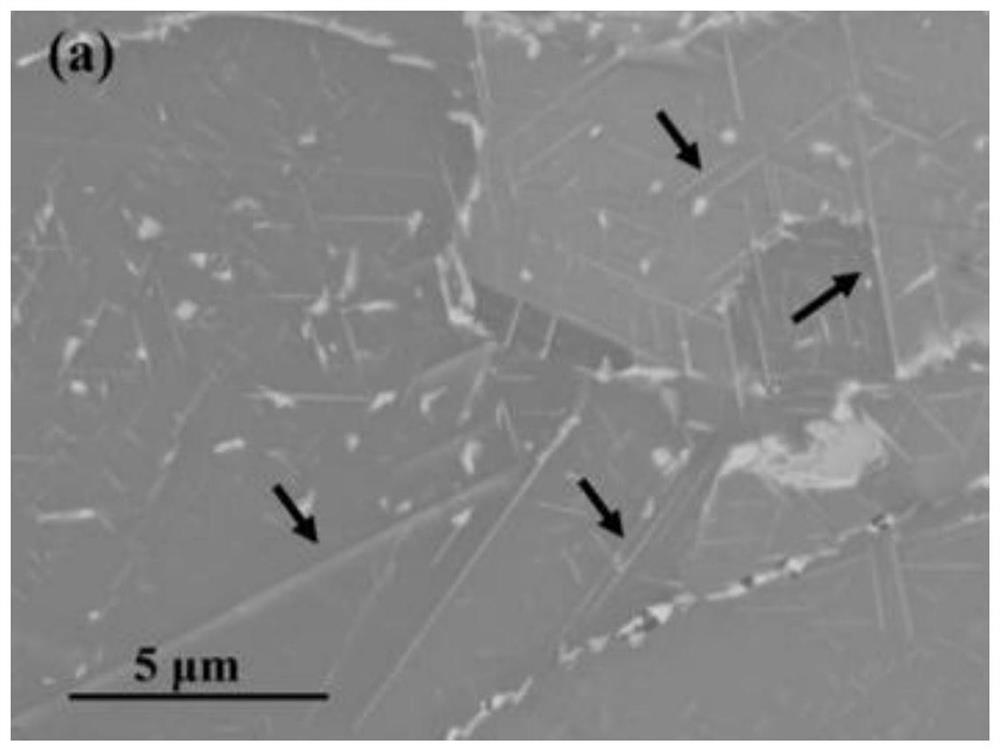

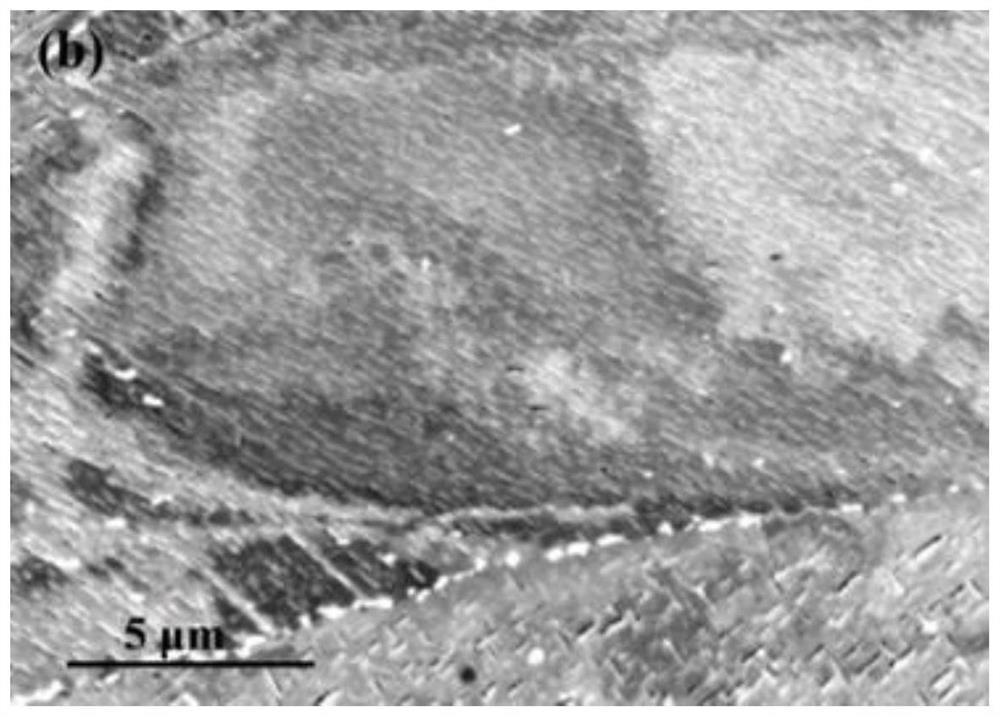

[0031] S3: put the Inconel 625 alloy after primary quenching into the furnace at 750°C again, apply tensile stress, and keep it w...

Embodiment 2

[0037] Embodiment 2: An aging heat treatment process for efficiently strengthening nickel-based superalloys, comprising the following steps:

[0038] S1: Machining the Inconel 625 alloy sample into a specified size to meet the needs of the box-type resistance furnace and ensure uniform heating; put refractory bricks in the furnace so that the Inconel 625 alloy can be placed in the middle of the furnace after being placed on the refractory bricks; start heating , raise the temperature to 650°C at a speed of 10°C / min, then raise the temperature to 950°C at a speed of 5°C / min, and finally raise the temperature to 1130°C at a speed of 3° / min. ) min, where, d is the direct cross-sectional area of the Inconel 625 alloy, in mm;

[0039] S2: Take out the Inconel 625 alloy, put it into water for quenching, and the quenching water temperature is 20°C;

[0040] S3: Put the Inconel 625 alloy after primary quenching into the furnace at 750°C again, apply tensile stress, and keep it warm...

Embodiment 3

[0046] Embodiment 3: An aging heat treatment process for efficiently strengthening nickel-based superalloys, comprising the following steps:

[0047] S1: Machining the Inconel 625 alloy sample into a specified size to meet the needs of the box-type resistance furnace and ensure uniform heating; put refractory bricks in the furnace so that the Inconel 625 alloy can be placed in the middle of the furnace after being placed on the refractory bricks; start heating , raise the temperature to 650°C at a speed of 10°C / min, then raise the temperature to 950°C at a speed of 5°C / min, and finally raise the temperature to 1130°C at a speed of 3° / min. ) min, where, d is the direct cross-sectional area of the Inconel 625 alloy, in mm;

[0048] S2: Take out the Inconel 625 alloy, put it into water for quenching, and the quenching water temperature is 20°C;

[0049] S3: put the Inconel 625 alloy after primary quenching into the furnace at 800°C again, apply tensile stress, and keep it warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com