Method for improving performance of Inconel 625 nickel-based powder laser cladding layer

A nickel-based powder, laser cladding technology, applied in the direction of coating, metal material coating process, etc., can solve the problems of insufficient hardness, obstacles, etc., to achieve high drying efficiency, improve utilization, and good drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

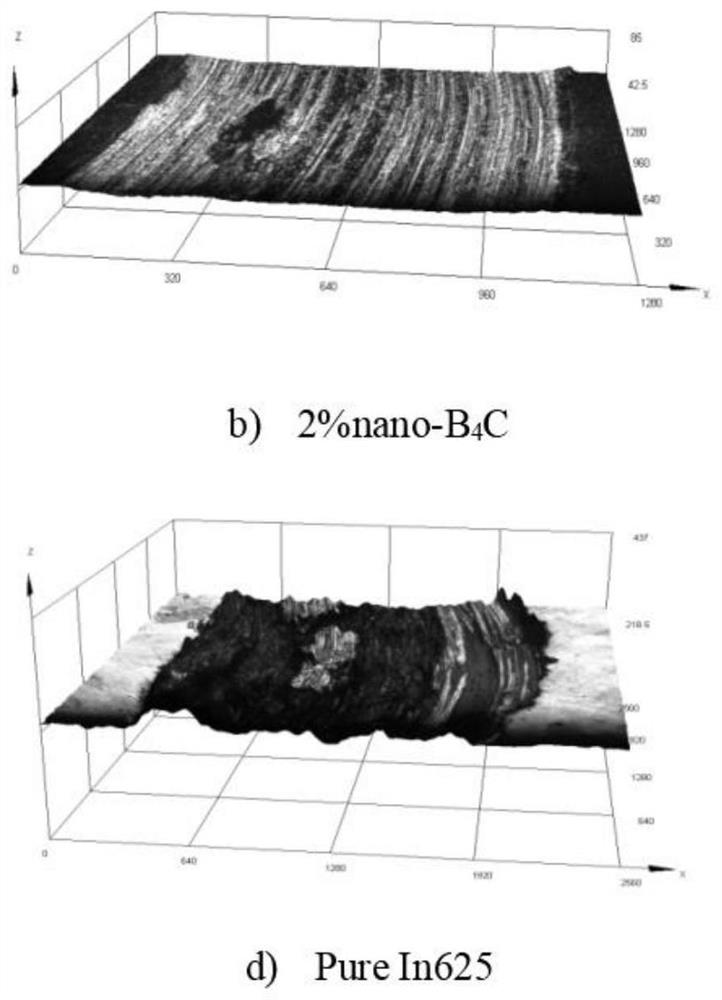

[0039] A method for improving the performance of Inconel625 nickel-based powder laser cladding layer, comprising the following steps:

[0040] (1) Take Inconel625 nickel-based powder and nano-boron carbide as raw materials for configuring strengthening powder;

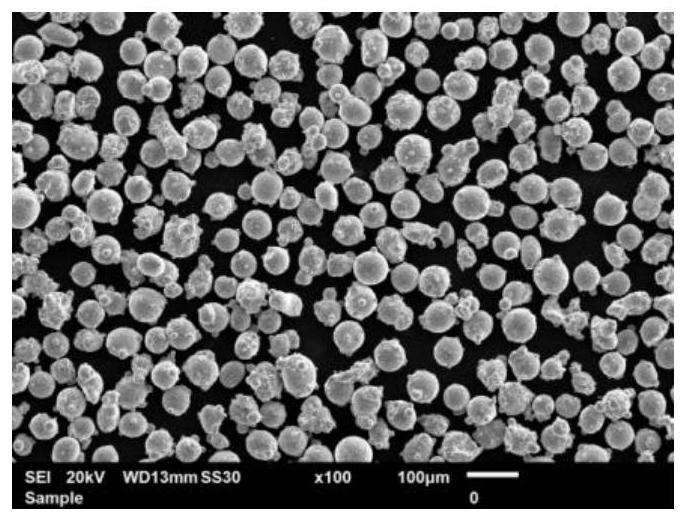

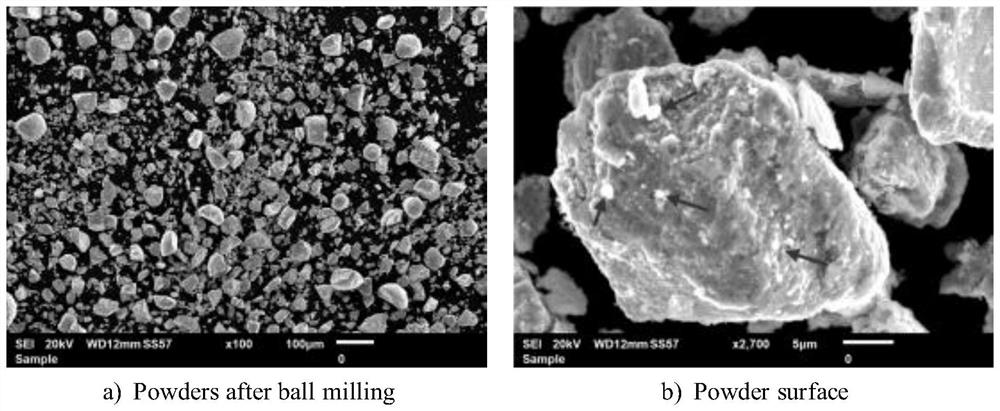

[0041] (2) Using a planetary ball mill, Inconel625 nickel-based powder and nano-boron carbide are mixed by ball milling to obtain the reinforced powder;

[0042] (3) Screening the enhanced powder to make it suitable for the powder feeding equipment used;

[0043](4) drying the strengthened powder after screening; and pretreating the surface of the workpiece to be clad;

[0044] (5) Perform laser cladding on the surface to be clad of the workpiece to be clad after being processed in step (4), form a cladding layer on the surface to be clad of the workpiece to be clad, and perform finishing after cladding is completed , to obtain the laser cladding workpiece.

[0045] In this embodiment, in step (1), the particle diam...

Embodiment 2

[0058] A method for improving the performance of Inconel625 nickel-based powder laser cladding layer, comprising the following steps:

[0059] (1) Take Inconel625 nickel-based powder and nano-boron carbide as raw materials for configuring strengthening powder;

[0060] (2) Using a planetary ball mill, Inconel625 nickel-based powder and nano-boron carbide are mixed by ball milling to obtain the reinforced powder;

[0061] (3) Screening the enhanced powder to make it suitable for the powder feeding equipment used;

[0062] (4) drying the strengthened powder after screening; and pretreating the surface of the workpiece to be clad;

[0063] (5) Perform laser cladding on the surface to be clad of the workpiece to be clad after being processed in step (4), form a cladding layer on the surface to be clad of the workpiece to be clad, and perform finishing after cladding is completed , to obtain the laser cladding workpiece.

[0064] In this embodiment, in step (1), the particle dia...

Embodiment 3

[0081] A method for improving the performance of Inconel625 nickel-based powder laser cladding layer, comprising the following steps:

[0082] (1) Take Inconel625 nickel-based powder and nano-boron carbide as raw materials for configuring strengthening powder;

[0083] (2) Using a planetary ball mill, Inconel625 nickel-based powder and nano-boron carbide are mixed by ball milling to obtain the reinforced powder;

[0084] (3) Screening the enhanced powder to make it suitable for the powder feeding equipment used;

[0085] (4) drying the strengthened powder after screening; and pretreating the surface of the workpiece to be clad;

[0086] (5) Perform laser cladding on the surface to be clad of the workpiece to be clad after being processed in step (4), form a cladding layer on the surface to be clad of the workpiece to be clad, and perform finishing after cladding is completed , to obtain the laser cladding workpiece.

[0087] In step (1), the particle diameters of the Incone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com