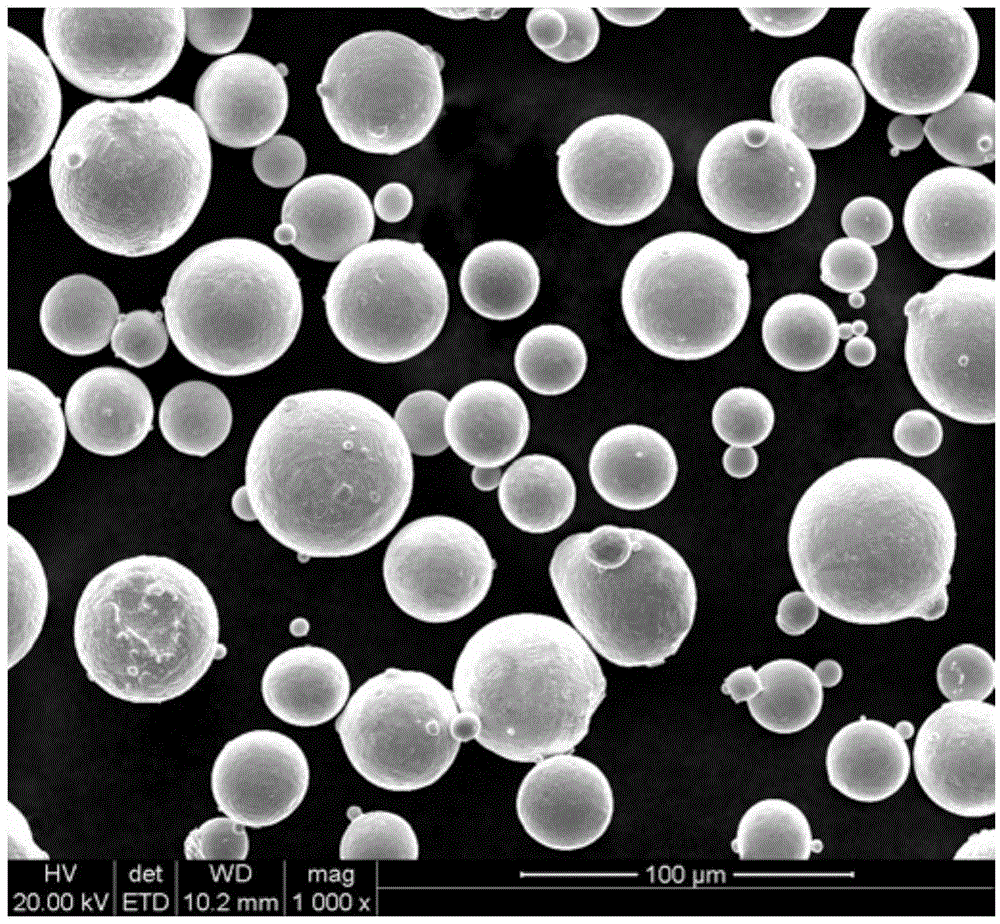

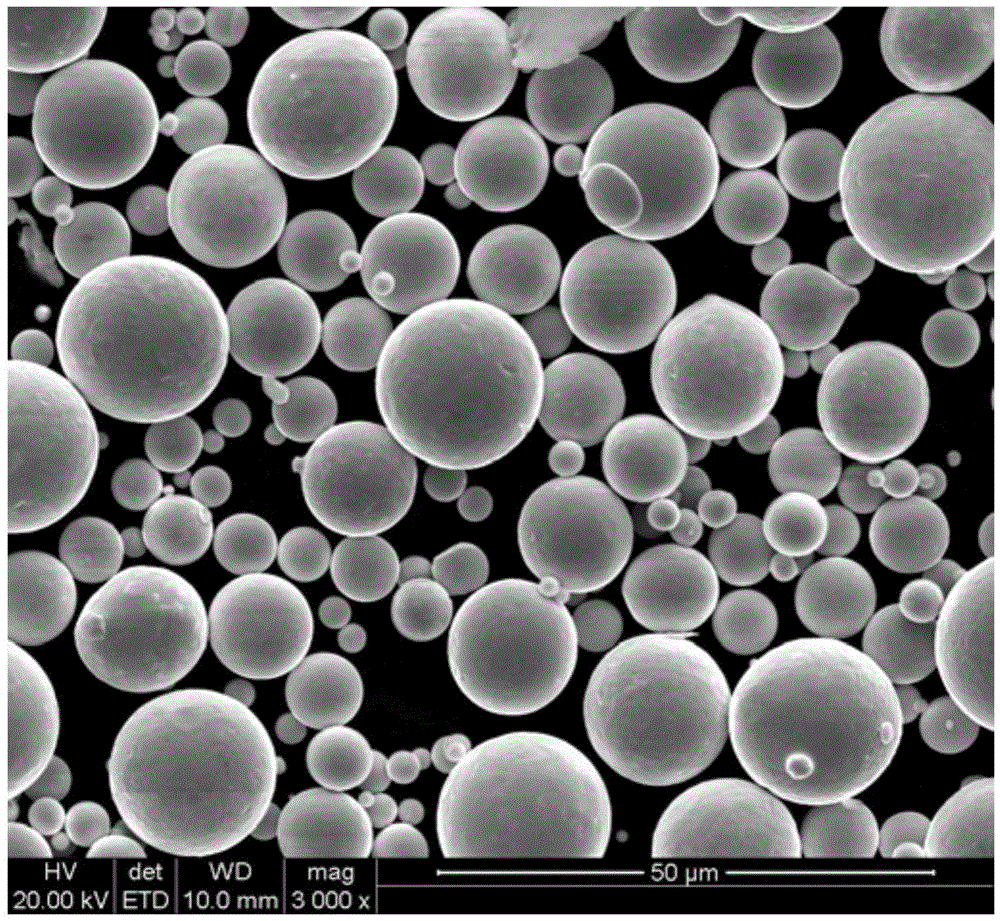

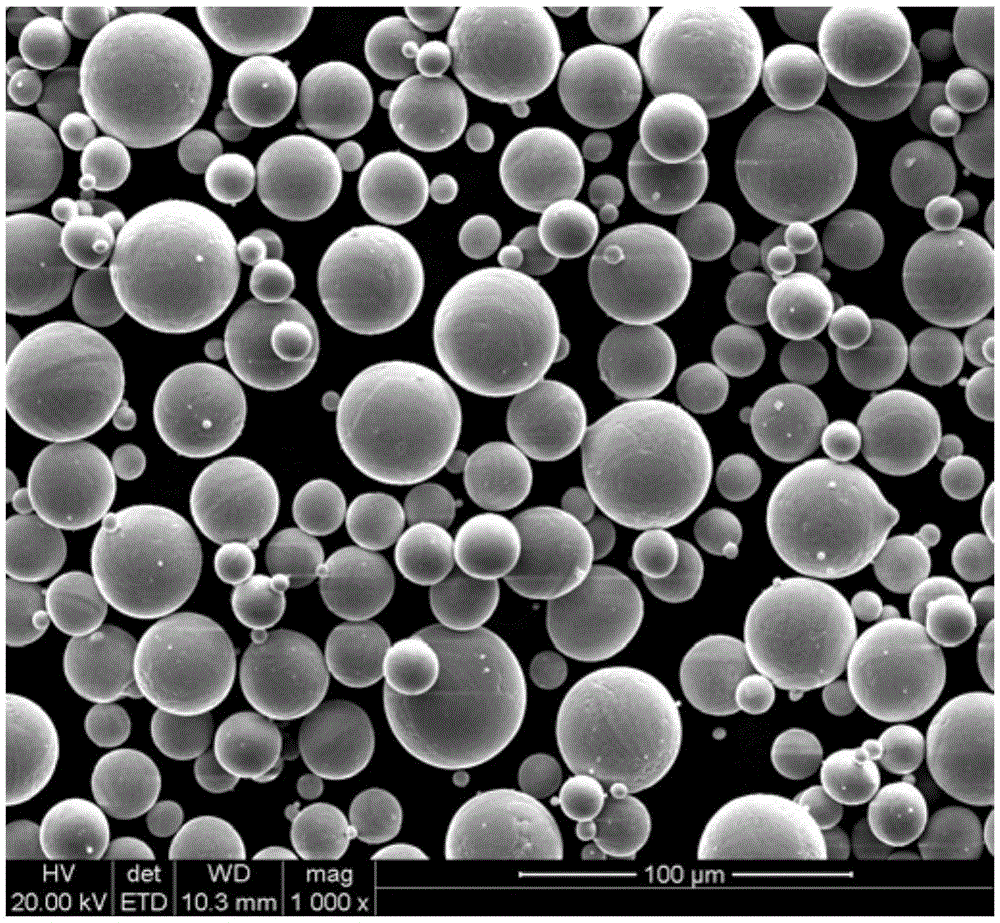

High-sphericity Inconel 625 alloy powder and preparation method and application thereof

A technology of alloy powder and high sphericity, applied in the field of additive manufacturing, can solve the problems affecting the forming quality of 3D printing parts, small packing density of spherical particles, low relative density of formed parts, etc., achieving high sphericity and good powder fluidity , the effect of high loose packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Adopt the following steps to prepare high sphericity Inconel625 alloy powder:

[0039] (1) Alloy remelting: Put 50kg of Inconel625 alloy raw material into vacuum induction furnace for melting, the alloy composition is Ni: 61%, Cr: 21%, Mo: 9%, Nb: 3.5%, Fe: 3.5%, Al: ≤ 0.4%, Ti: ≤0.4%, Mn: ≤0.5%, C: ≤0.1%, P: ≤0.015%, S: ≤0.015%. The vacuum degree of the melting furnace is 3.2MPa, and the melting temperature is controlled at 1500-1600°C. After the raw materials are completely melted, keep the temperature for 20 minutes, and at the same time, heat the middle leakage bag to 1000-1100°C;

[0040] (2) Add Si element: Add 275g of Si element additive (0.55%wt%) in the Inconel625 alloy melt smelted in step (1), continue smelting for 15 minutes, and pour the alloy melt into the middle leakage bag;

[0041] (3) Atomization pulverization: Open the leakage valve, and the alloy melt flows freely downward into the gas atomization furnace through the leakage hole at the bottom of th...

Embodiment 2

[0045] Adopt the following steps to prepare high sphericity Inconel625 alloy powder:

[0046] (1) Alloy remelting: Put 50kg of Inconel625 alloy raw material into vacuum induction furnace for melting, the alloy composition is Ni: 62%, Cr: 22%, Mo: 9%, Nb: 3.7%, Fe: 3.7%, Al: ≤ 0.4%, Ti: ≤0.4%, Mn: ≤0.5%, C: ≤0.1%, P: ≤0.015%, S: ≤0.015%. The vacuum degree of the melting furnace is 3.2MPa, and the melting temperature is controlled at 1500-1600°C. After the raw materials are completely melted, keep the temperature for 20 minutes, and at the same time, heat the middle leakage bag to 1000-1100°C;

[0047] (2) Add Si element: add 300g of Si element additive (0.60wt%) in the Inconel625 alloy melt smelted in step (1), continue smelting for 15 minutes, and pour the alloy melt into the middle leakage bag;

[0048] (3) Atomization pulverization: open the leakage valve, and the alloy melt flows freely downward into the gas atomization furnace through the leakage hole at the bottom of the...

Embodiment 3

[0052] Adopt the following steps to prepare high sphericity Inconel625 alloy powder:

[0053] (1) Alloy remelting: put 50kg of Inconel625 alloy raw material into vacuum induction furnace for melting, the alloy composition is Ni: 61%, Cr: 22%, Mo: 9%, Nb: 4.0%, Fe: 4.0%, Al: ≤ 0.4%, Ti: ≤0.4%, Mn: ≤0.5%, C: ≤0.1%, P: ≤0.015%, S: ≤0.015%. The vacuum degree of the melting furnace is 3.2MPa, and the melting temperature is controlled at 1500-1600°C. After the raw materials are completely melted, keep the temperature for 20 minutes, and at the same time, heat the middle leakage bag to 1000-1100°C;

[0054] (2) Add Si element: Add 325g of Si element additive (0.65wt%) in the Inconel625 alloy melt smelted in step (1), continue smelting for 15 minutes, and pour the alloy melt into the middle leakage bag;

[0055] (3) Atomization pulverization: Open the leakage valve, and the alloy melt flows freely downward into the gas atomization furnace through the leakage hole at the bottom of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com