Preparation method of inconel625 nickel-based alloy powder for laser selective melting technology

A laser selective melting, nickel-based alloy technology, applied in the field of additive manufacturing, can solve the problems of low material utilization rate, macro-component segregation, etc., to achieve the effect of high particle sphericity, appropriate ratio relationship, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the Inconel625 nickel base alloy powder that is used for laser selective melting technique comprises the following steps:

[0036] (1) Smelting: Put the Inconel625 nickel-based alloy raw material into a vacuum induction furnace for smelting, and the smelting temperature is controlled at 1450°C. After smelting, an Inconel625 nickel-based alloy bar is obtained. The alloy composition ratio is: Ni: 62%, Cr: 22%, Mo: 9%, Nb: 4.0%, Fe: 2.5%, Al: ≤0.4%, Ti: ≤0.4%, Mn: ≤0.5%, Si: ≤0.5%, C: ≤0.1%, P: ≤0.015% , S: ≤0.015%;

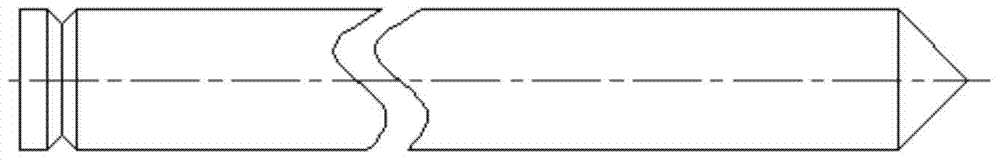

[0037] (2) Processing: Inconel625 nickel-based alloy bar according to figure 1 The structure is processed into a cylindrical rod with a cone angle of 80°;

[0038] (3) Atomization: Vacuum electrode induction melting is performed on the processed Inconel625 nickel-based alloy rod, and the descending speed of the rod is controlled at 20mm / min. Under the impact of the air flow, the atomization forms fine droplets. The atomization gas...

Embodiment 2

[0042] The preparation method of the Inconel625 nickel base alloy powder that is used for laser selective melting technique comprises the following steps:

[0043] (1) Smelting: Put the Inconel625 nickel-based alloy raw material into a vacuum induction furnace for smelting, and the smelting temperature is controlled at 1500 ° C. After smelting, an Inconel625 nickel-based alloy bar is obtained. The alloy composition ratio is: Ni: 62%, Cr: 22 %, Mo: 9%, Nb: 3.6%, Fe: 3.5%, Al: ≤0.4%, Ti: ≤0.4%, Mn: ≤0.5%, Si: ≤0.5%, C: ≤0.1%, P: ≤ 0.015%, S: ≤0.015%;

[0044] (2) Processing: Inconel625 nickel-based alloy rods are processed according to the attached figure 1 Processed into a cylindrical rod with a cone angle of 75°;

[0045] (3) Atomization: Vacuum electrode induction melting is performed on the processed Inconel625 nickel-based alloy rod, and the descending speed of the rod is controlled at 30mm / min. Under the airflow, atomize to form fine droplets. The atomization gas is hig...

Embodiment 3

[0049] The preparation method of the Inconel625 nickel base alloy powder that is used for laser selective melting technique comprises the following steps:

[0050] (1) Smelting: Put the Inconel625 nickel-based alloy raw material into a vacuum induction furnace for smelting, the smelting temperature is controlled at 1550°C, and the Inconel625 nickel-based alloy bar is obtained by smelting. The alloy composition ratio is: Ni: 62%, Cr: 22% , Mo: 9%, Nb: 3.2%, Fe: 4.5%, Al: ≤0.4%, Ti: ≤0.4%, Mn: ≤0.5%, Si: ≤0.5%, C: ≤0.1%, P: ≤0.015 %, S: ≤0.015%;

[0051] (2) Processing: Inconel625 nickel-based alloy rods are processed according to the attached figure 1 Processed into a cylindrical rod with a cone angle of 90°;

[0052] (3) Atomization: Vacuum electrode induction melting is carried out on the processed Inconel625 nickel-based alloy rod, and the descending speed of the rod is controlled at 40mm / min. Under the airflow, atomize to form fine droplets. The atomization gas is high-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com