Alloy steel high-temperature-resistant high-pressure-resistant sulfur-resistant throttling valve and manufacturing method

A sulfur-resistant throttle valve, high temperature and high pressure technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as difficult to achieve yield strength, and achieve the effects of high design safety factor, improved service life, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

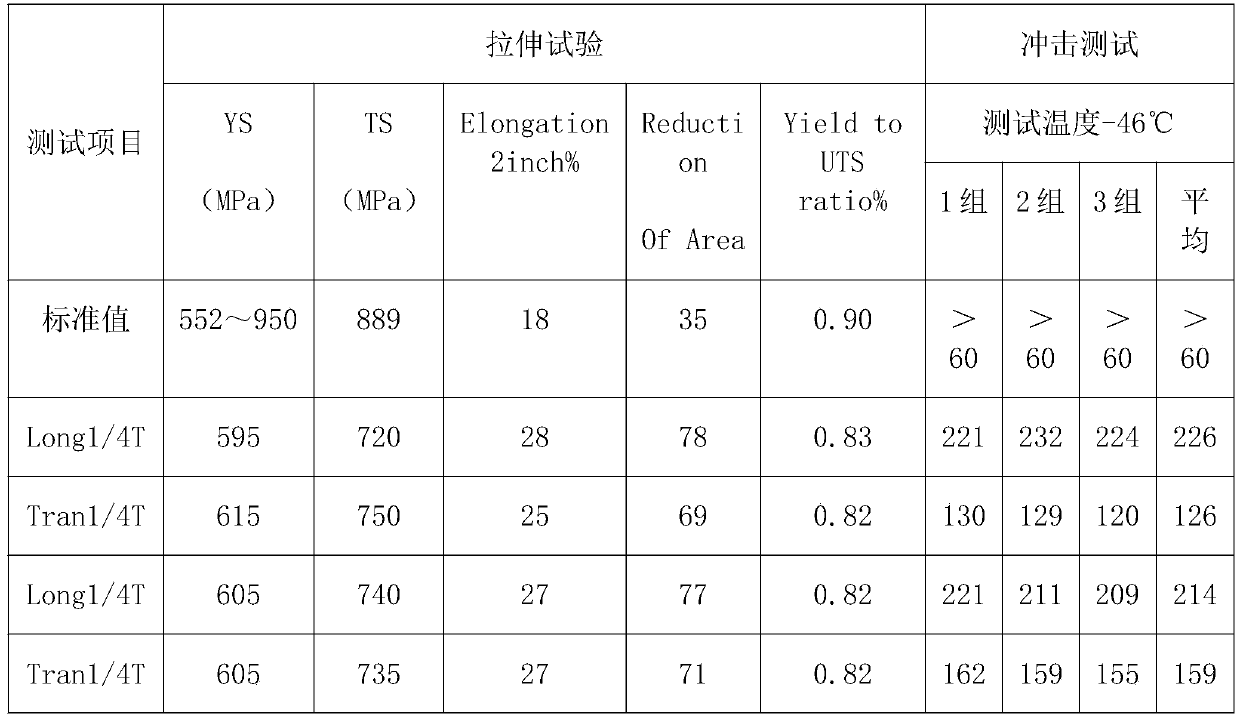

[0017] A method for manufacturing a valve body and a valve cover forging in a high-temperature, high-pressure sulfur-resistant throttle valve component, comprising the following process steps:

[0018] A. The components by weight include: C: 0.120-0.135%, Si: 0.20-0.32%, Mn: 0.4-0.55%, P: 0.008-0.010%, S: 0.005-0.008%, Cr: 2.15-2.35%, Ni: 0.2~0.3%, Mo: 0.90~1.00%, Cu: 0.000~0.083%, Ti: 0.001~0.024%, Bi: 0.001~0.005%, Nb: 0.001~0.010%, Al: 0.020~0.040%, Sn : 0.005~0.007%, V: 0.001~0.030%, B: 0.0001~0.0004%, Pb: 0.000~0.006%, As: 0.004~0.010%, Sb: 0.0010~0.010%, Ca: 0.001~0.004%, and the rest Fe steel ingots are used as raw materials for forging billets. The initial forging temperature is ≤1200°C, the holding time is 0.5 hours / inch to 1.5 hours / inch, and the final forging temperature is 850-950°C. The holding time should not be too long to effectively control the grains Dimensions, forging adopts hydraulic press WHF forging method + forging hammer FM forging method to repeatedl...

Embodiment 2

[0026] The difference from Example 1 is:

[0027]The weight components of steel ingots include: C: 0.10-0.15%, Si: 0.00-0.35%, Mn: 0.3-0.6%, P: 0.000-0.010%, S: 0.000-0.010%, Cr: 2.00-2.5%, Ni : 0.00~0.5%, Mo: 0.90~1.10%, Cu: 0.000~0.083%, Ti: 0.000~0.025%, Bi: 0.000~0.010%, Nb: 0.001~0.040%, Al: 0.000~0.055%, Sn: 0.000~0.007%, V: 0.001~0.06%, B: 0.0000~0.0005%, Pb: 0.000~0.010%, As: 0.000~0.020%, Sb: 0.000~0.020%, Ca: 0.000~0.005%, the rest is Fe .

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com