Large-wall-thickness P92 steel welding method

A welding method and technology with large and thick walls, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of cold welding cracks, type IV creep cracks, and low toughness of weld metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

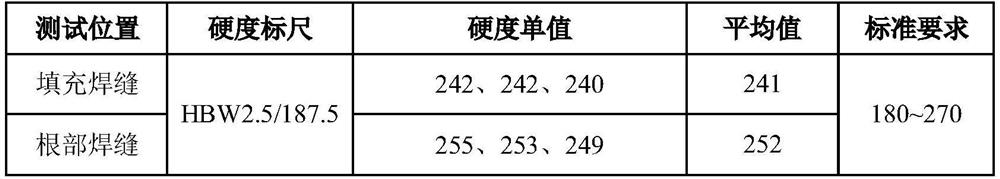

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, and the mode of the present invention includes but not limited to the following examples.

[0027] A welding method for large thick-walled P92 steel, through reasonable control of each parameter in the welding process, reduces the tensile residual stress generated in the welding process, avoids cold cracks, reduces the influence of creep resistance, and avoids the creep stress Generated, the specific implementation process is as follows:

[0028] First, grind the welding seam of P92 steel to make the welding groove. If the equipment has already polished the welding groove, you only need to clean the welding groove. The welding groove can be set to "Y shape" or "V shape". and other shapes, in this embodiment, the welding groove is set as "comprehensive shape" or "double V shape". After the welding groove is polished, the oil, Clean up the paint, scale, rust, etc. until it emits a met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com