A Method for Improving High Temperature Creep Resistance of Magnesium Alloys Using Bending Grain Boundaries

A creep-resistant, magnesium alloy technology is applied to improve the performance of magnesium alloys in the subsequent creep process and the field of high-temperature creep resistance. problems, to achieve the effect of improving creep resistance, good application prospects, and improved creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

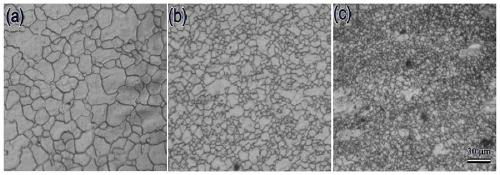

[0027] In this embodiment, the raw material is Mg-3Al-1Zn-0.2Mn magnesium alloy hot extrusion rod. Its average grain size is about 50 μm. The sample is pre-compressed at 400°C, and the compression rate is 0.003s -1 , the true strains are 0.2, 0.3 and 0.5, and the corresponding fine grain ratios are 0.2, 0.4 and 0.8.

[0028] The specimen structure after pressing is as figure 1 shown, where figure 1 (a) is the undeformed sample structure, figure 1 (b) is the sample structure with a true strain of 0.3, figure 1 (c) is the sample structure with a true strain of 0.5. It can be seen from the figure that several fine dynamic recrystallization grains appear at the original grain boundaries, and these dynamic recrystallizations cause the grain boundaries of the original coarse grains to bend to varying degrees. As the degree of deformation increases, the proportion of fine grains increases. , the bending degree of the original grain boundary also increases gradually.

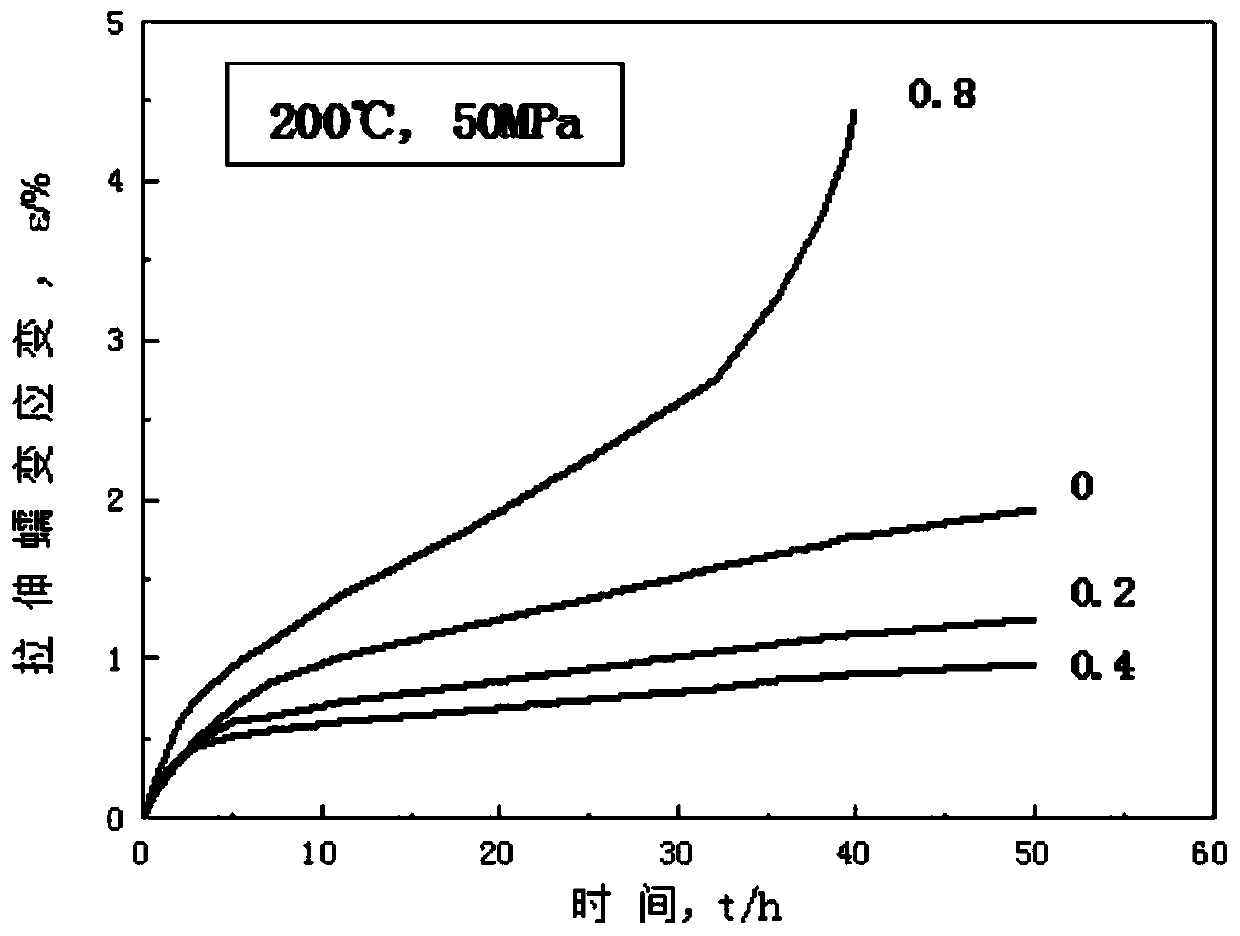

[0029] T...

Embodiment 2

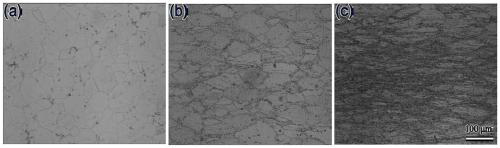

[0031] In this embodiment, the raw material is Mg-4Y rolled plate. Its average grain size is about 80 μm. For one group of samples at 450°C, 0.003s -1 Under pre-compression treatment, the true strain is 0.3. In order to obtain a higher proportion of fine-grained structure, the other two groups of samples were subjected to variable-speed three-step compression treatment at 450°C, and the compression rate of the first step was 0.003s -1 , followed by an intermediate annealing at 400°C for 10min, and then 0.03s -1 Carry out the second step of compression, followed by intermediate annealing at 400°C for 30min, and finally with 0.3s -1 The rate of the third compression step, the total true strain is 1.2 and 1.6, respectively, the three corresponding fine grain ratios are 0.3, 0.5 and 0.7.

[0032] The deformed tissue is as image 3 as shown, image 3 (a) is the undeformed sample structure, image 3 (b) is the sample structure with a true strain of 0.3, image 3 (c) is the s...

Embodiment 3

[0035] The raw material used in this embodiment is cast Mg-9Gd-3Y-0.5Zr. Its average grain size is about 200 μm. For one group of samples at 520°C, 0.003s -1 Under pre-compression treatment, the true strain is 0.3. In order to obtain a higher proportion of fine-grained structure, the other two groups of samples were subjected to variable-speed two-step compression treatment at 520°C, and the compression rate of the first step was 0.003s -1 , followed by intermediate annealing at 520°C for 20min, and finally with 0.3s -1 The second-step compression is carried out at a rate of 1. The total true strains are 1.2 and 1.6, respectively, and the corresponding fine grain ratios of the three are 0.2, 0.5 and 0.8.

[0036] The deformed tissue is as Figure 5 as shown, Figure 5 (a) is the undeformed sample structure, Figure 5 (b) is the sample structure with a true strain of 0.3, Figure 5 (c) is the sample structure with a true strain of 1.2. The microstructure after one-step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com