A heat treatment method for improving the long service life of friction stir welding welds of magnesium alloys

A technology of friction stir welding and heat treatment method, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low weld strength, easy to crack in advance, unable to fully recrystallize, etc., to solve the problem of coarse grain damage fatigue life and The effect of fine grain loss on creep life, increase in recrystallization nucleation particles, and avoid abnormal grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

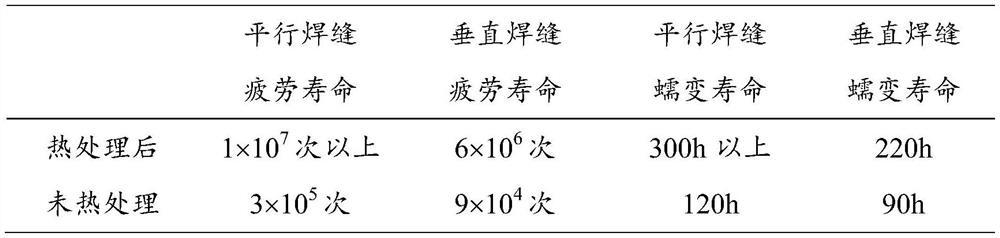

Embodiment 1

[0024] In this example, the raw material is GW123 magnesium alloy. After solid solution treatment, aging treatment and water quenching are carried out at 200°C for 60 hours, and friction stir welding is carried out at room temperature with a rotation speed of 200rpm and a welding speed of 20mm / min. Magnesium alloys were annealed at 300°C for 3 hours, and after annealing, the temperature was directly lowered to 150°C for 6 hours of aging treatment and water quenching; fatigue and creep life tests were performed on the obtained magnesium alloy welds along the parallel and perpendicular directions of the welds. , where the fatigue life test temperature is 150°C and the load is 120MPa, the creep life test temperature is 250°C and the load is 120MPa; as a comparison, the GW123 magnesium alloy weld without heat treatment and directly subjected to friction stir welding is also under the same conditions Fatigue and creep life tests were performed in parallel and perpendicular to the we...

Embodiment 2

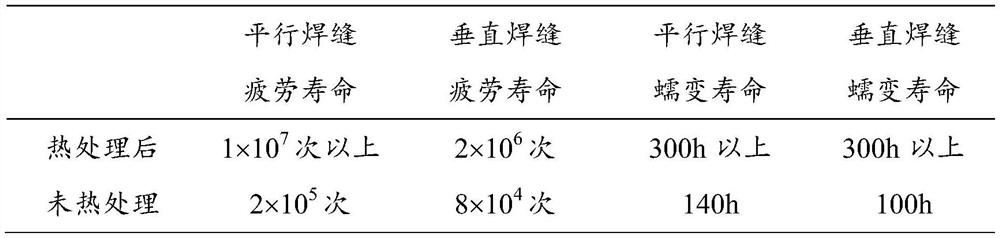

[0029] In this example, the raw material is WE43 magnesium alloy. After solution treatment, aging treatment and water quenching are carried out at 180°C for 72 hours, and friction stir welding is carried out at room temperature. The rotating speed is 1000rpm and the welding speed is 100mm / min. Magnesium alloys were annealed at 250°C for 3 hours, and after annealing, the temperature was directly lowered to 100°C for 6 hours of aging treatment and water quenching; fatigue and creep life tests were carried out on the obtained magnesium alloy welds along the parallel and perpendicular directions of the welds. , where the fatigue life test temperature is room temperature and the load is 100MPa, the creep life test temperature is 200°C and the load is 150MPa; as a comparison, the WE43 magnesium alloy weld without heat treatment and directly subjected to friction stir welding is also under the same conditions Perform fatigue and creep life tests parallel and perpendicular to the weld ...

Embodiment 3

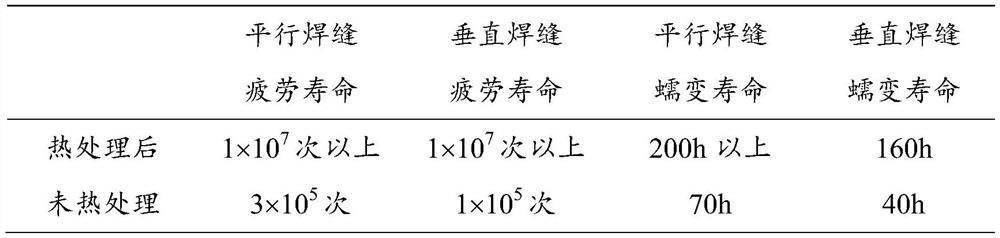

[0034] In this example, the raw material is AZ80 magnesium alloy. After solution treatment, aging treatment and water quenching are carried out at 280°C for 0.5h, and friction stir welding is carried out at room temperature with a rotation speed of 800rpm and a welding speed of 120mm / min. The magnesium alloy was annealed at 350°C for 0.5h, and after annealing, the temperature was directly lowered to 200°C for 0.5h aging treatment and water quenching; the obtained magnesium alloy welds were subjected to fatigue and creep along the parallel and perpendicular weld directions. Variable life test, in which, the fatigue life test temperature is 200 ℃, the load is 60MPa, the creep life test temperature is 300 ℃, the load is 60MPa; as a comparison, the AZ80 magnesium alloy weld without heat treatment and directly subjected to friction stir welding is also Fatigue and creep life tests were performed in parallel and perpendicular to the weld direction under the same conditions. The test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com