High Nb-TiAl alloy added with nano yttrium oxide and preparation method of high Nb-TiAl alloy

A nano-yttrium oxide and alloy technology, which is applied in the field of intermetallic compounds and their preparation processes, can solve the problems of poor high temperature mechanical properties and weak creep resistance of TiAl alloys, and achieves improved nucleation rate, improved mechanical properties, and refined Effect of grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

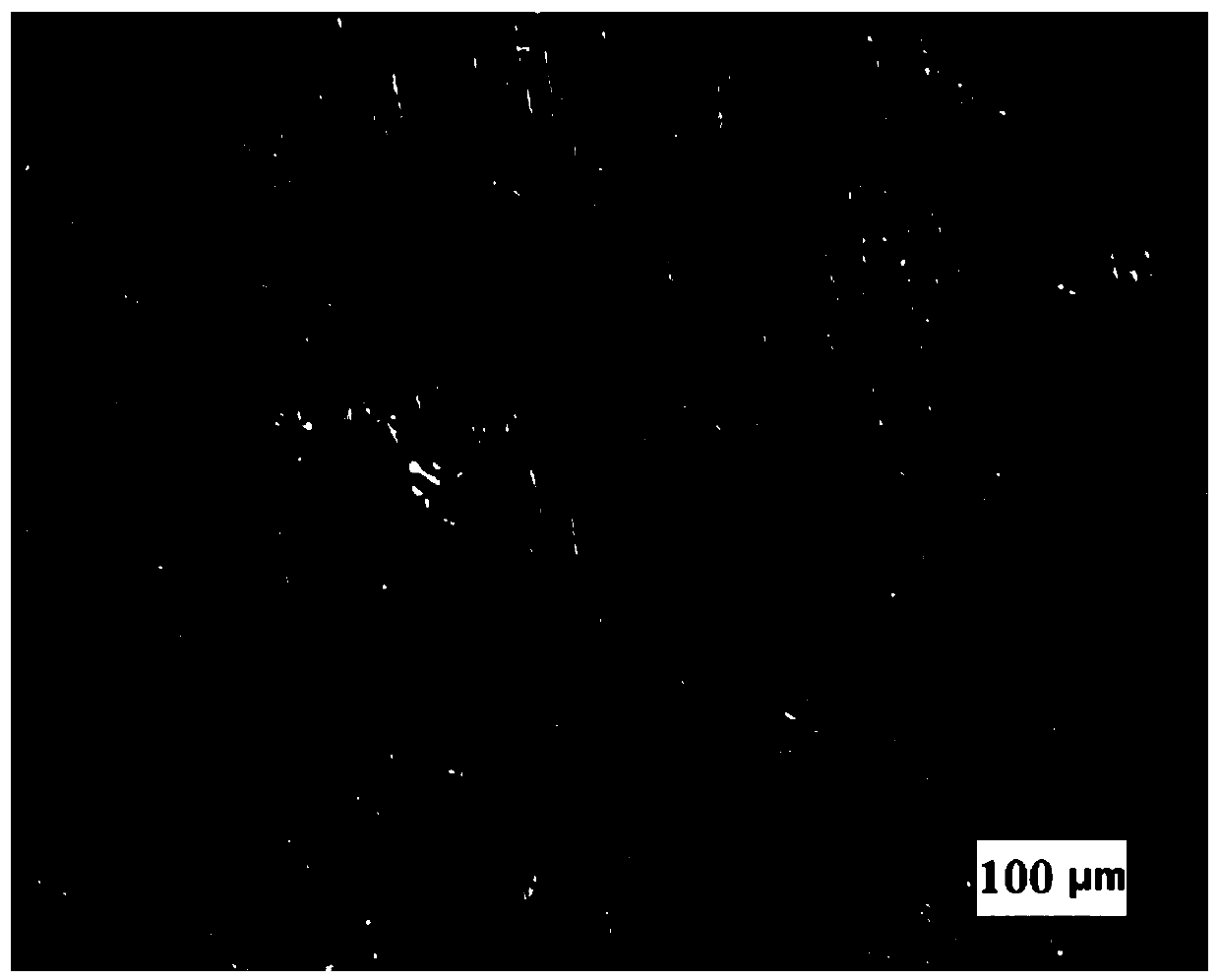

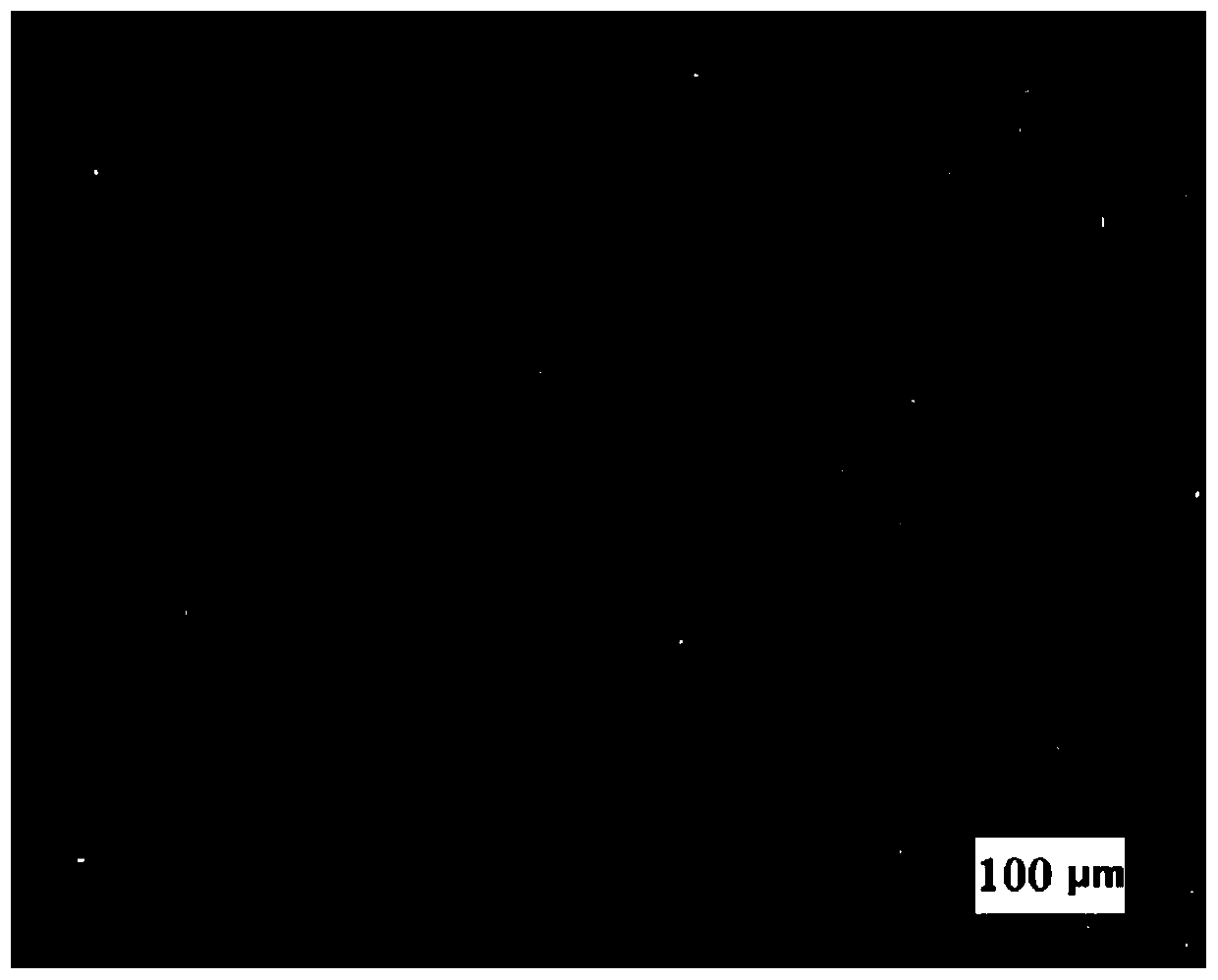

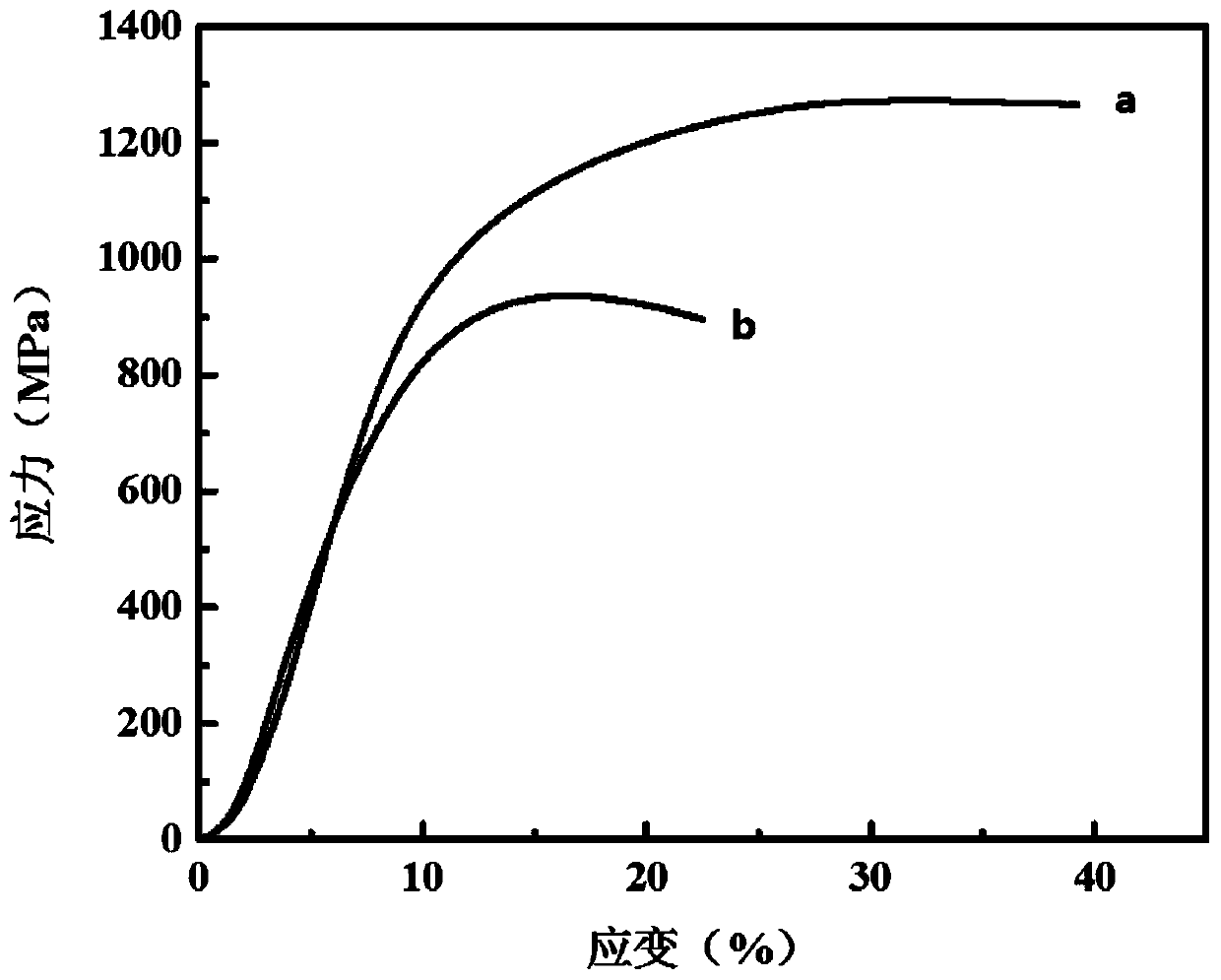

Image

Examples

specific Embodiment approach 1

[0028] Specific Embodiment 1: In this embodiment, a high Nb-TiAl alloy added with nanometer yttrium oxide, the molar percentage of the alloy composition is: 45% to 48% for Al, 6% to 10% for Nb, and 2.5% for V %~3.5%, Nano Y 2 o 3 0.05% to 3% and the rest of Ti.

specific Embodiment approach 2

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mole percentage of the alloy composition is: 45% for Al, 6% for Nb, 2.5% for V, nanometer Y 2 o 3 Ti is 0.15% and the balance. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: a kind of preparation method of adding the high Nb-TiAl alloy of nanometer yttrium oxide described in specific embodiment one, specifically carry out according to the following steps:

[0031] 1. Cleaning: remove the scale of titanium rod, titanium sponge, high-purity aluminum, aluminum-niobium master alloy and aluminum-vanadium master alloy, perform ultrasonic cleaning in alcohol, and blow dry;

[0032] 2. Weighing: Weighing nanometer Y 2 o 3 Powder, titanium rod after step 1 treatment, titanium sponge, high-purity aluminum, aluminum-niobium master alloy and aluminum-vanadium master alloy, nano Y 2 o 3 The powder is pressed into multiple yttrium oxide prefabricated blocks;

[0033] Or weigh nano Y 2 o 3 Powder, dispersed metal powder, titanium rod after step 1 treatment, titanium sponge, high-purity aluminum, aluminum-niobium master alloy and aluminum-vanadium master alloy, nanometer Y 2 o 3 The powder and dispersed metal powder are unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com