Directional solidification nickel-base high-temperature alloy and heat treatment process thereof

A nickel-based superalloy, directional solidification technology, applied in the field of guide vane materials, can solve the problems of large thermal load of the blade, damage of the blade, etc., and achieve the effect of improving thermal fatigue performance, long-lasting life and high initial melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The alloy is melted in a vacuum induction furnace. The refining temperature is 1550℃~1600℃, the refining time is 5min~10min, and the vacuum degree is 10 -1 ~10 -2 Pa, the pouring temperature is 1450℃~1500℃.

[0026] The alloy composition of this embodiment is shown in Table 1. The density of the alloy is 8.10g / cm 3 , The initial melting temperature measured by DTA is 1348°C. Table 2 lists the density and initial melting temperature of some common guide vane materials in China. Among them, K417G is a polycrystalline nickel-based superalloy, DZ4 is a oriented nickel-based superalloy, DZ40M is a cobalt-based oriented superalloy, and DD4 is a single crystal superalloy. It can be seen that the alloy has a lower density and a higher initial melting temperature than other guide vane materials.

[0027] The composition (percentage by weight) of table 1 embodiment 1 alloy

[0028] B

[0029] Table 2 Density and initial melting temperature of common guide vane m...

Embodiment 2

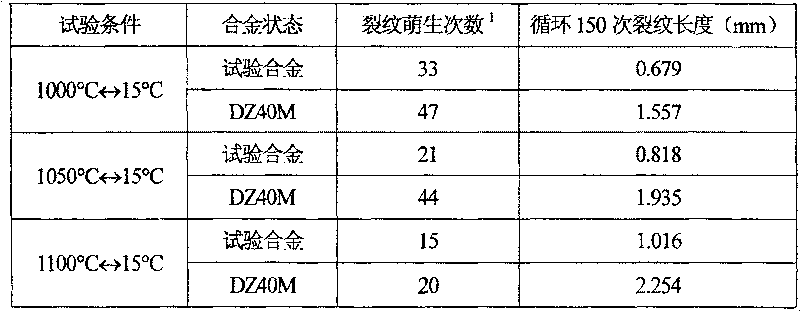

[0033] The alloy composition of this example is the same as that of Example 1. Table 3 lists the thermal fatigue properties of the test alloy of the present invention and DZ40M (oriented cobalt-based superalloy). It can be seen from the table that the cold and hot fatigue performance of this alloy is better than that of DZ40M.

[0034] Table 3 The cold and hot fatigue performance of the test alloy

[0035]

[0036] Note: The number of cycles when the crack length is 0.2mm is taken as the number of crack initiation

Embodiment 3

[0038] The alloy composition of this example is the same as that of Example 1. Table 4 shows the segregation ratio of different elements in the dendrite stem and between dendrites. It can be seen from Table 4 that in the as-cast alloy, the distribution of elements between dendrites and dendrite stems is uneven. Co, W and other elements are more in the dendrites, while Al, Nb, Mo are more in the dendrites. After the alloy is heat treated, the difference in the composition of each element is reduced, that is, the distribution of the elements in the entire alloy is more uniform. Table 5 shows the distribution of each element in the γ and γ′ phases. It can be seen from Table 5 that the content of Cr, Co and Mo is more in the γ phase, and that of Al and Nb is more in the γ′. After the alloy is heat treated, the segregation of W and Mo in the two phases decreases, and the distribution of γ forming elements Cr, Co and γ′ forming elements Al and Nb is more reasonable, which makes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com