A low-rhenium third-generation nickel-based single crystal alloy and its preparation method

A nickel-based single crystal and alloy technology, which is applied in the field of nickel-based superalloys, can solve the problems that it is difficult to achieve the performance and poor stability of the third-generation alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

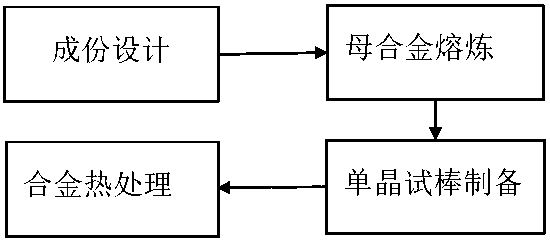

[0056] Follow the attached figure 2 The present invention is described in further detail:

[0057] Ingredient Design

[0058] According to the description of the invention, the theoretical design of the alloy is carried out by using the average electron vacancy number and the d-electron theory, and a suitable composition range is selected;

[0059]

[0060] Where: mi is the molar mass fraction of elements in the alloy;

[0061] (Nv) the number of electron vacancies of each element of i;

[0062] Ci represents the molar mass fraction of elements in the alloy;

[0063] Mdi represents the corresponding Md value of each element in the alloy;

[0064] Boi represents the corresponding Bo value of each element in the alloy.

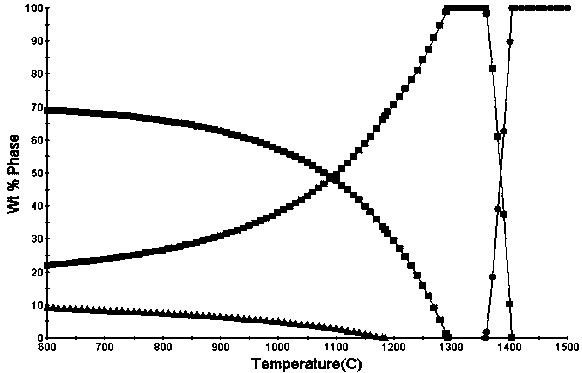

[0065] Table 1 The average number of electron vacancies, d-level orbital energies and covalent bond energies corresponding to each element

[0066]

[0067] According to the data given above, the average number of electron vacancies, d-level orbital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com