Homogenizing heat treatment method for 7xxx series aluminum alloy with low Cu content

A technology of homogenizing heat treatment and aluminum alloy, applied in the field of metal heat treatment, it can solve problems such as long holding time, and achieve the effect of high efficiency, saving heat treatment time, and speeding up the resolubilization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The aluminum alloy composition is Al-4.5Zn-1.0Mg-0.2Cu-0.25Mn-0.25Cr-0.20Fe-0.20Si (wt.%), and the ingot size is Φ220mm.

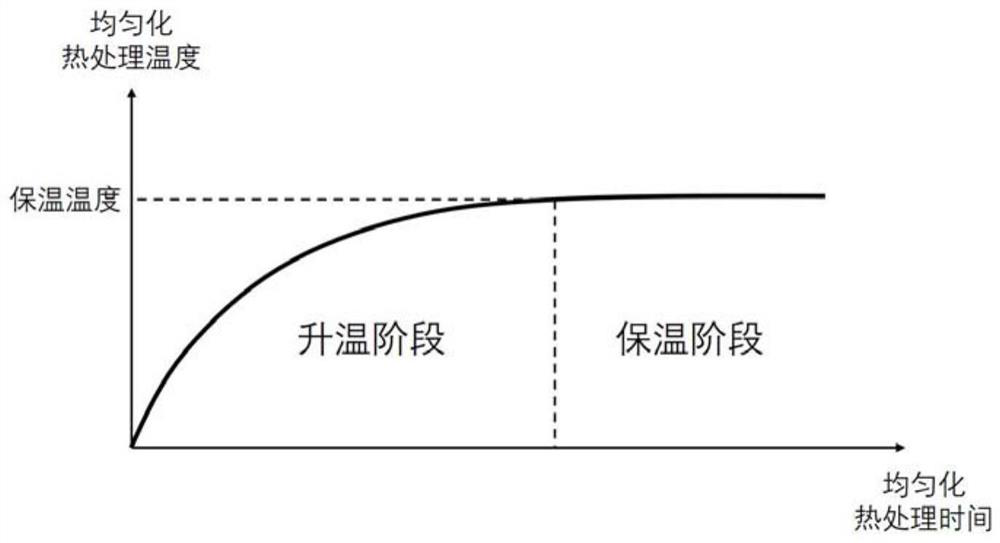

[0038]The alloy is homogenized by the method of the present invention, and the specific process is as follows: starting from room temperature at a heating rate of 400°C / h, and the heating rate gradually decreases; when the alloy temperature reaches 400°C, the heating rate is reduced to 15°C / h; When the alloy temperature reaches 430°C, the heating rate is reduced to 10°C / h; when the alloy temperature reaches 465°C, the heating rate is reduced to 5°C / h; when the alloy temperature reaches 475°C, the heating rate is reduced to 2°C / h, which takes 2h ; The overall heating time is 14h. It was then incubated at 475°C for 15h.

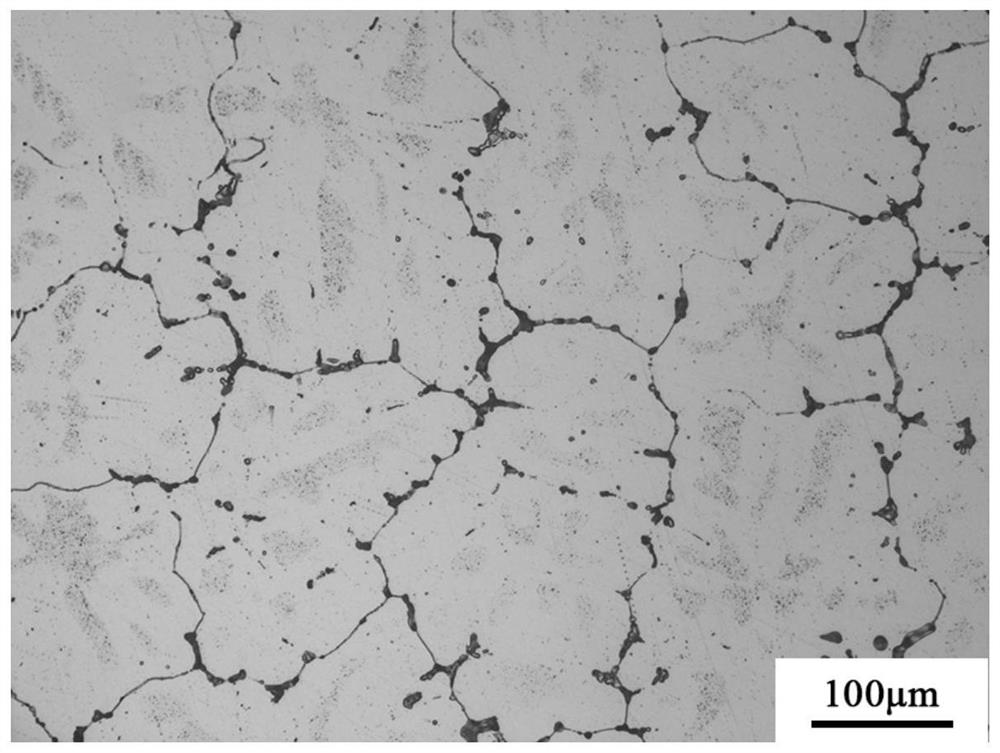

[0039] like figure 2 As shown in the figure, it is the metallographic structure of the alloy of Example 1 after the heating process is completed. It can be seen from the figure that the second phase has been redissolved to a certa...

Embodiment 2

[0047] The ingot used in Example 1 is used for homogenization treatment, and the specific process is as follows: the heating process is the same as that in Example 1, and then the temperature is kept at 475° C. for 18 hours.

Embodiment 3

[0049] The ingot used in Example 1 is used for homogenization treatment, and the specific process is as follows: starting from room temperature at a heating rate of 350 °C / h, and the heating rate gradually decreases; when the alloy temperature reaches 400 °C, the heating rate is reduced to 10 °C / h ; When the alloy temperature reaches 430°C, the heating rate is reduced to 5°C / h; when the alloy temperature reaches 465°C, the heating rate is reduced to 2°C / h, and the heating rate is maintained, and the temperature is raised to 475°C for 4h; the overall heating time is 18h. It was then incubated at 475°C for 15h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com