A kind of germinated brown rice production optimization process

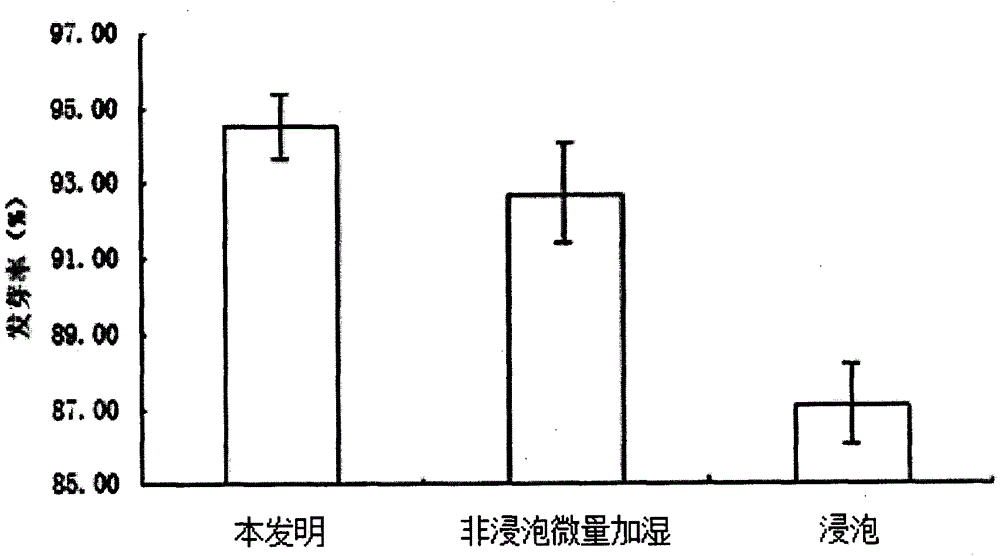

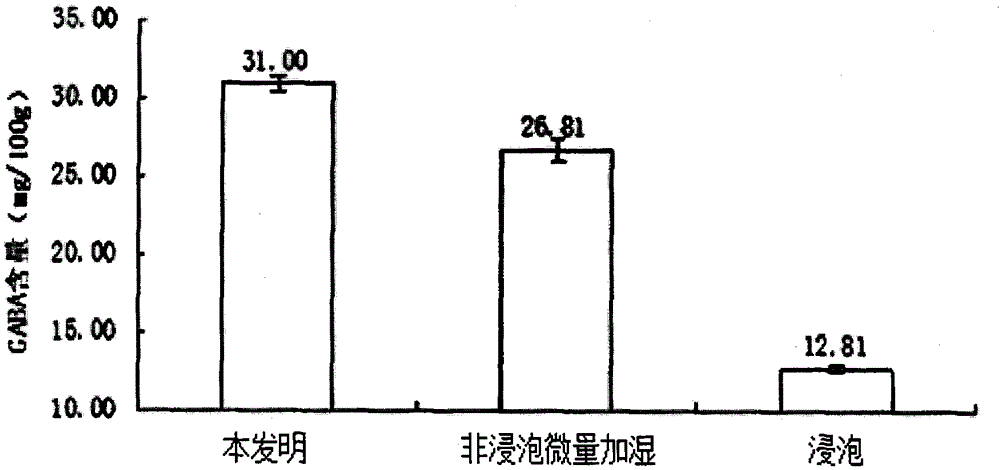

A technology of germinated brown rice and brown rice, which is applied in the field of grain deep processing, can solve problems that do not involve the water absorption characteristics of brown rice, and achieve the effect of low crack growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] (1) Pre-germination treatment of brown rice: remove impurities, broken grains, no germ grains, mildewed grains and heterochromatic grains from the raw brown rice, and then sterilize it with ultraviolet light for 10-15 minutes, measure the moisture content of the raw material to 12%, weigh 10 kg for use .

[0017] (2) brown rice moisture adjustment: the brown rice raw material after step (1) is processed is placed under room temperature condition, and in this example, brown rice raw material quality is 10kg, and initial moisture content is 12%, and material moisture quality is 1.2kg in the initial stage. Through real-time monitoring of the flow rate of the water adding nozzle and the moisture content of the brown rice material, before the moisture content of the material is 18%, the hourly increase rate of the moisture content is selected to be 1.0% / h on average, and the formula: the mass of water to be added = (target moisture content × initial moisture content of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com