Patents

Literature

30results about How to "Increase the content of gamma-aminobutyric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of germ and corn composite nutritional powder and product of production process

ActiveCN102754764AIncrease nutritional contentIncrease the content of gamma-aminobutyric acidFood preparationNutritive valuesAdditive ingredient

The invention relates to a production process of germ and corn composite nutritional powder and the product of the production process, and belongs to the technical field of food processing. The production process is characterized in that mixing corn which sprouts in stress with wheat germ which is subjected to microwave enzyme inactivation; performing extrusion and superfine grinding to prepare germ and corn meal; adding carrot meal, spirulina meal, white granulated sugar, maltodextrin and vegetable fat powder into the germ and corn meal; and sterilizing and packaging to prepare the germ and corn composite nutritional powder. The production process is simple and high in industrial degree, so that the germ resource can be further utilized, corn can be completely utilized, and the additional value of agricultural products can be increased. The germ and corn composite nutritional powder produced by the production process is good in dissolubility, fine in taste and high in nutritional value, is rich in gamma-aminobutyric acid, glutathione, octacosanol, dietary fiber and other components, has the functions of improving brain functions, calming nerves, improving sleeping, resisting oxidation, delaying senescence, improving body immunity and the like, and is an ideal health-care nutritional food, wherein the content of gamma-aminobutyric acid in the product is between 20 and 60mg / 100g.

Owner:JIANGSU HENGHUI FOOD CO LTD

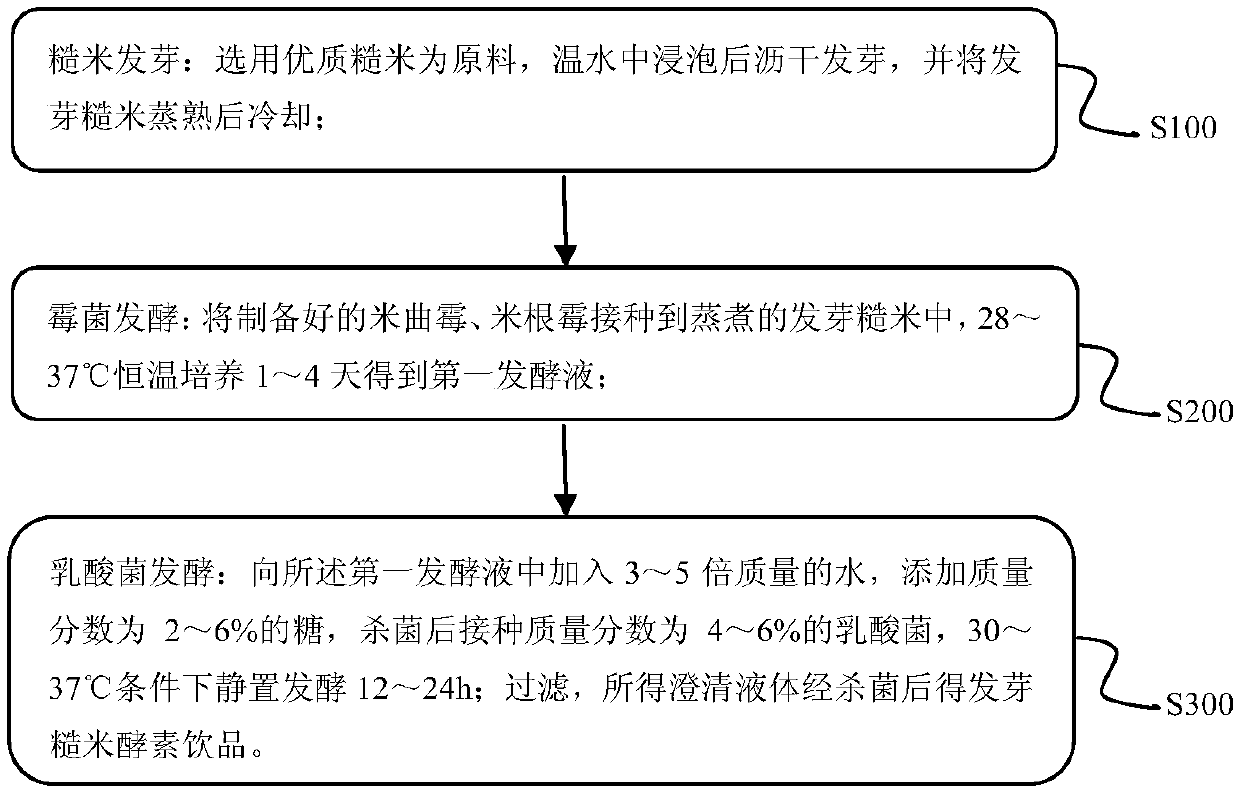

Method for preparing germinated brown rice ferment drink

InactiveCN108013305ASweet and sour tasteEasy to eatFood ingredient functionsAdditive ingredientEnzyme system

The invention relates to a method for preparing a germinated brown rice ferment drink. Germinated brown rice is processed in an Aspergillus oryzae and Rhizopus oryzae mixed culture manner, is decomposed by using the enzyme system complementarity, and is inoculated with lactic acid bacteria to carry out fermentation. The prepared germinated brown rice ferment drink is rich in organic acids, variousfree amino acids, soluble dietary fibers, and active components which are gamma-aminobutyric acid and SOD, and has the advantages of sour-sweet mouthfeel, convenience in drinking, no additives, excellent nutrition and healthcare effects, great improvement of the raw material utilization rate in a two-stage fermentation process, and great solving of resource wastes of existing brown rice having bad mouthfeel.

Owner:WUHAN SUNHY BIOLOGICAL

Processing method of green tea

InactiveCN105494699ASimple processing methodConsistent qualityPre-extraction tea treatmentBudGreen tea

The invention discloses a processing method of green tea. The method includes the steps of picking, withering, fixation, spreading and cooling, rolling, drying and packaging. Fresh leaves of tea trees with three leaves on one bud or four leaves on one bud are picked to serve as raw materials, vacuum anaerobic treatment is conducted on the tea leaves, hot wind withering is conducted, withered leaves are put into a fixation machine, the tea leaves are placed on a screen to be spread and cooled, the spread and cooled leaves are put into a rolling machine to be rolled, the rolled leaves are dried for 10-15 min at the temperature of 110-130 DEG C, the leaves are cooled to the normal temperature and dried for 20-25 min at the temperature of 80-100 DEG C, and the dried tea leaves are sealed, packaged, frozen and subjected to fragrance increase, and the finished product is obtained. The tea leaves processed through the method are firm in appearance, jade green in color and luster, stable in quality, durable in fragrance and thick and fresh in taste, and after the tea leaves are brewed into tea, the liquor color is transparent and bright, leaf bottoms are green and tender, and the taste is pure.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

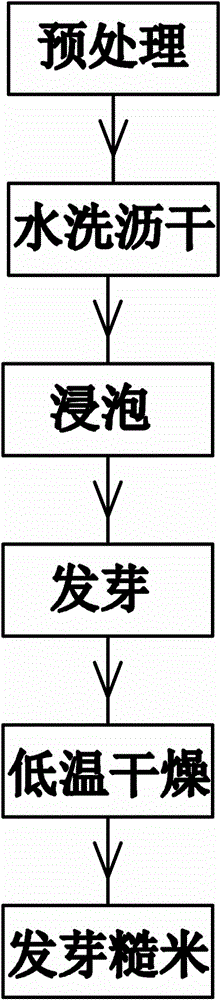

Method for preparing germinated brown rice rich in gamma-aminobutyric acid

InactiveCN104431804AEnhanced inhibitory effectIncrease the content of gamma-aminobutyric acidFood freezingFood ingredient functionsMicroorganismGamma-Aminobutyric acid

The invention discloses a method for preparing germinated brown rice rich in gamma-aminobutyric acid. The method comprises the following steps: step 1, pretreating brown rice raw material by means of freezing stressing; step 2, washing the brown rice obtained in the step 1 by water and draining; step 3, soaking the brown rice obtained in the step 2 in a soaking solution; step 4, geminating the brown rice obtained in the step 3 and then drying at a low temperature to obtain a germinated brown rice finished product. According to the method disclosed by the invention, the soaking solution is added with tea polyphenol in order to play a quite good inhibition effect on microorganisms and floras during germination, so that the content of the gamma-aminobutyric acid in the germinated brown rice can be increased and the taste of the germinated brown rice can be improved as well.

Owner:江西省粮油科学技术研究所

Processing method for green tea

InactiveCN104472740AIncrease contentEliminate green odorPre-extraction tea treatmentChemistryGreen tea

The invention discloses a processing method for green tea. A production method for green tea is modified, the content of gamma-aminobutyric acid in a product is increased, the green odor is eliminated, the integrity of buds and leaves of the tea is good, aromatic substances in the tea are sufficiently converted, beneficial components in the tea are further developed, and the color, aroma and taste of finished tea are better due to the combination of all steps.

Owner:GUIZHOU TEA RES INST

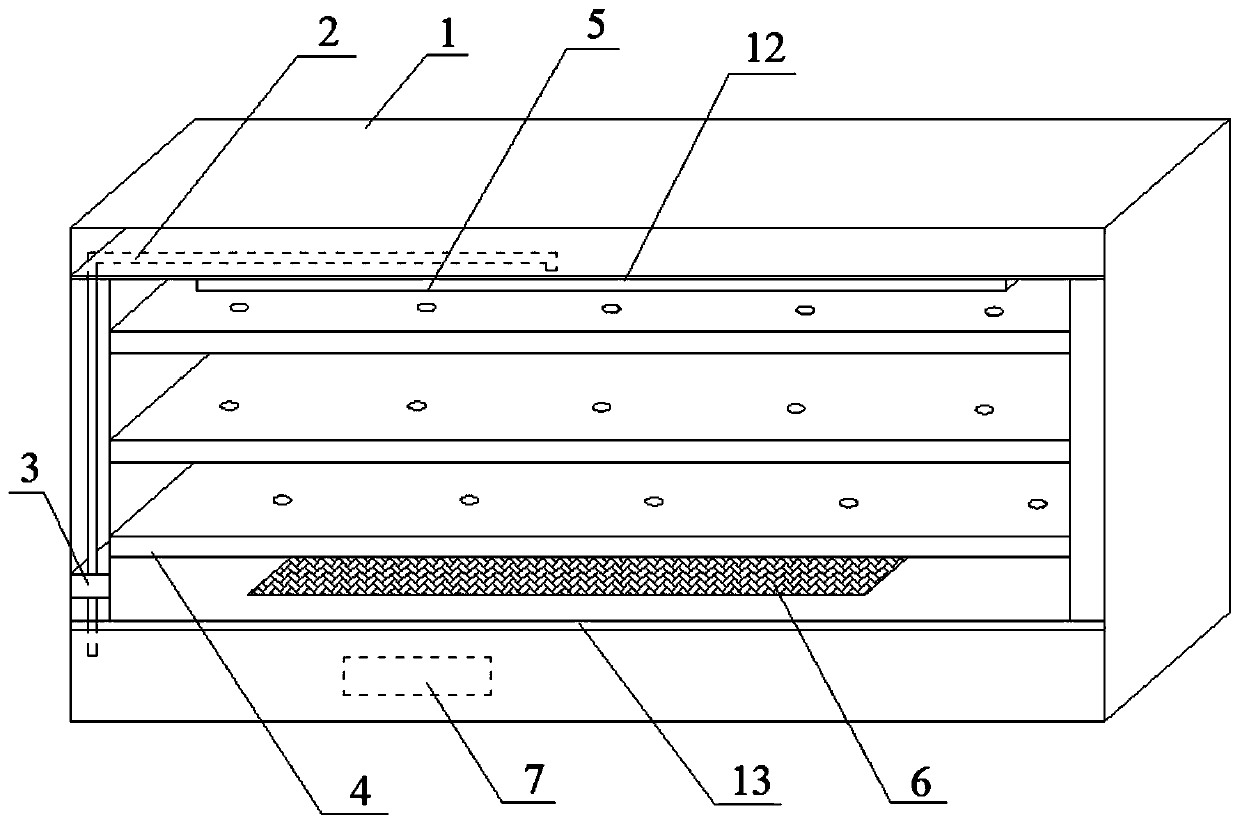

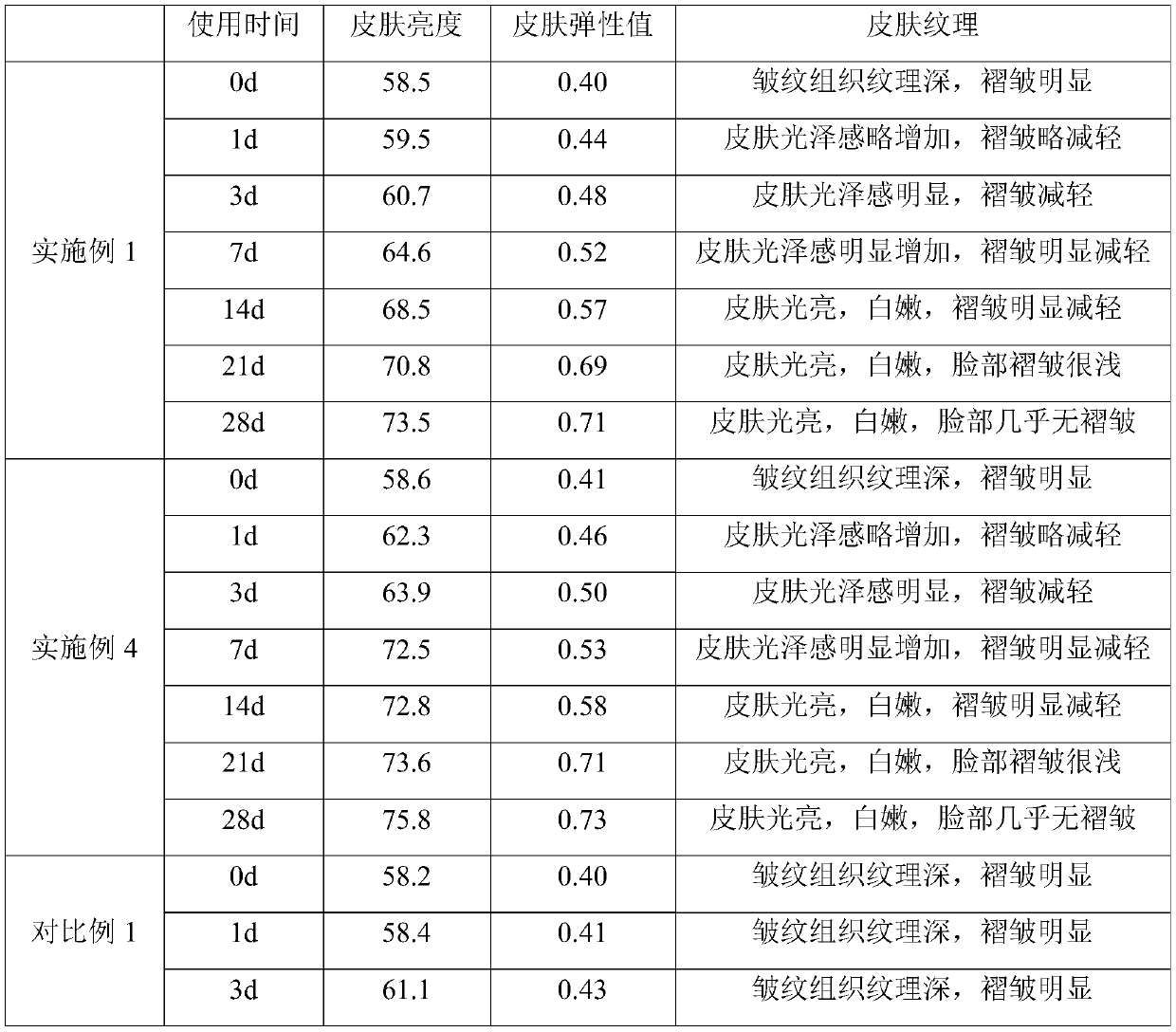

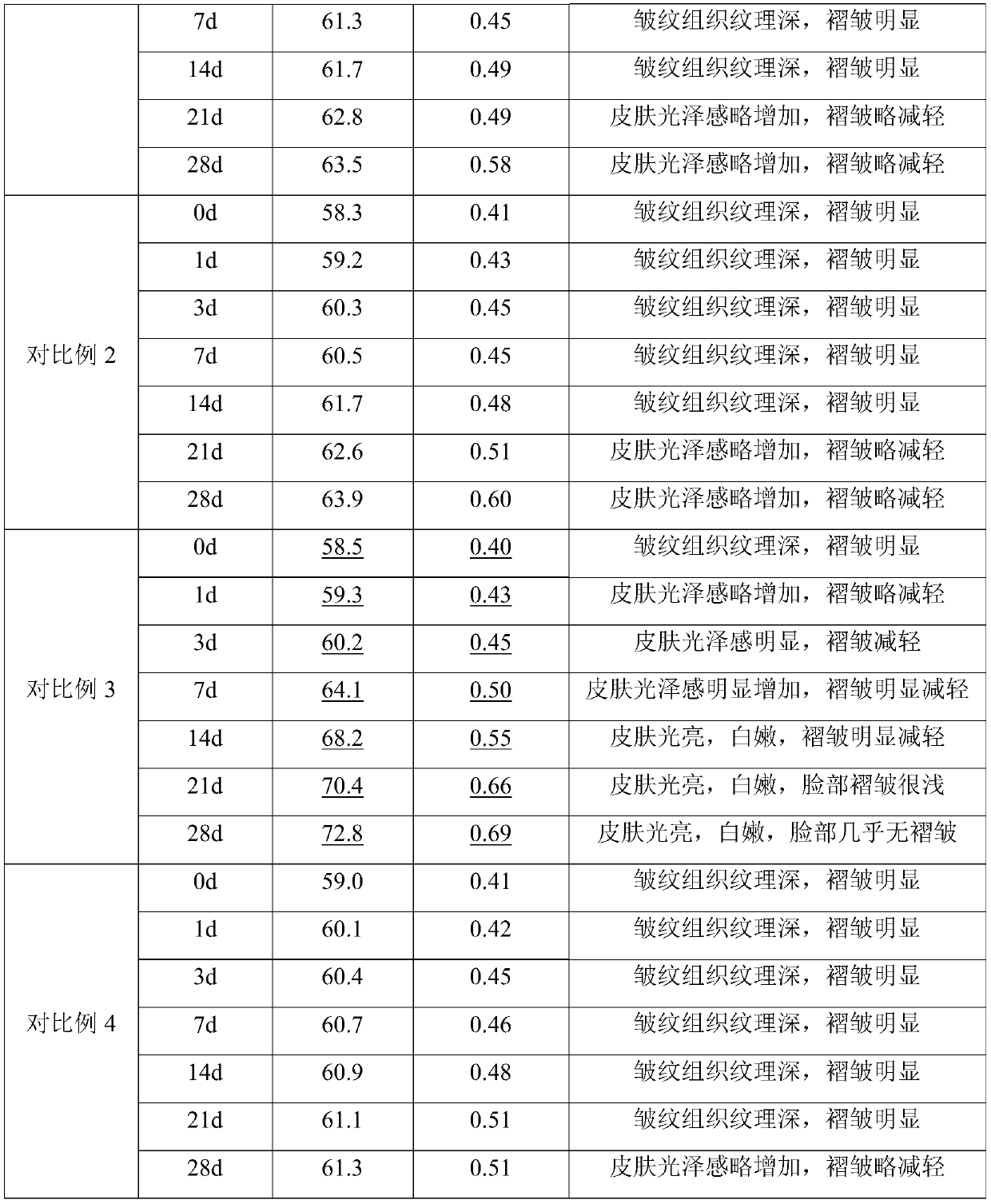

Preparation method for producing fermentation liquor with high [gamma]-aminobutyric acid content by employing lactic acid bacteria, and application of fermentation liquor in cosmetics

ActiveCN110592151AWith whiteningAnti-wrinkleCosmetic preparationsToilet preparationsLactic acid bacteriumFermentation

The invention relates to the field of fermentation technologies and cosmetics, in particular to a preparation method for producing fermentation liquor with a high [gamma]-aminobutyric acid content byemploying lactic acid bacteria, and an application of fermentation liquor in cosmetics. The preparation method comprises the following steps of: (1) enabling brown rice and barley to sprout, mixing the sprouted brown rice and barley with folium mori, and smashing the mixture to obtain a mixed powder; (2) adding water into the mixed powder for dipping, and conducting filtering to obtain a filtrate;and (3) adding glutamic acids or / and glutamate into the filtrate, inoculating fermentative bacteria, and conducting filtering to obtain the fermentation liquor. The fermentation liquor has the advantages of high [gamma]-aminobutyric acid content, good use effect and no side effects when the fermentation liquor is applied to cosmetics.

Owner:哈尔滨美华生物技术股份有限公司

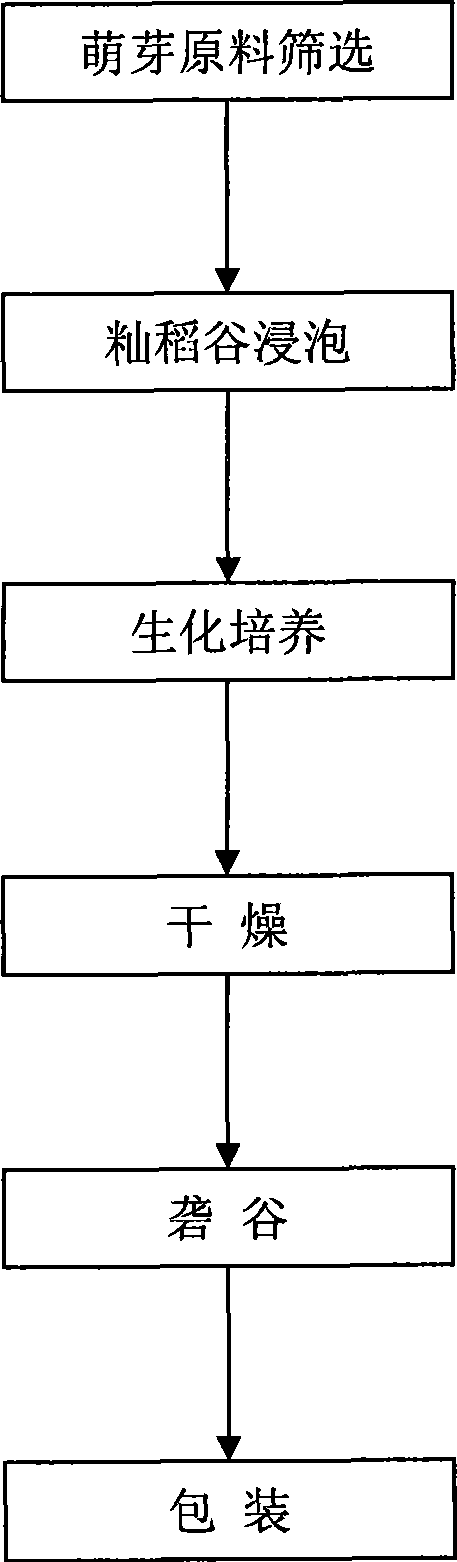

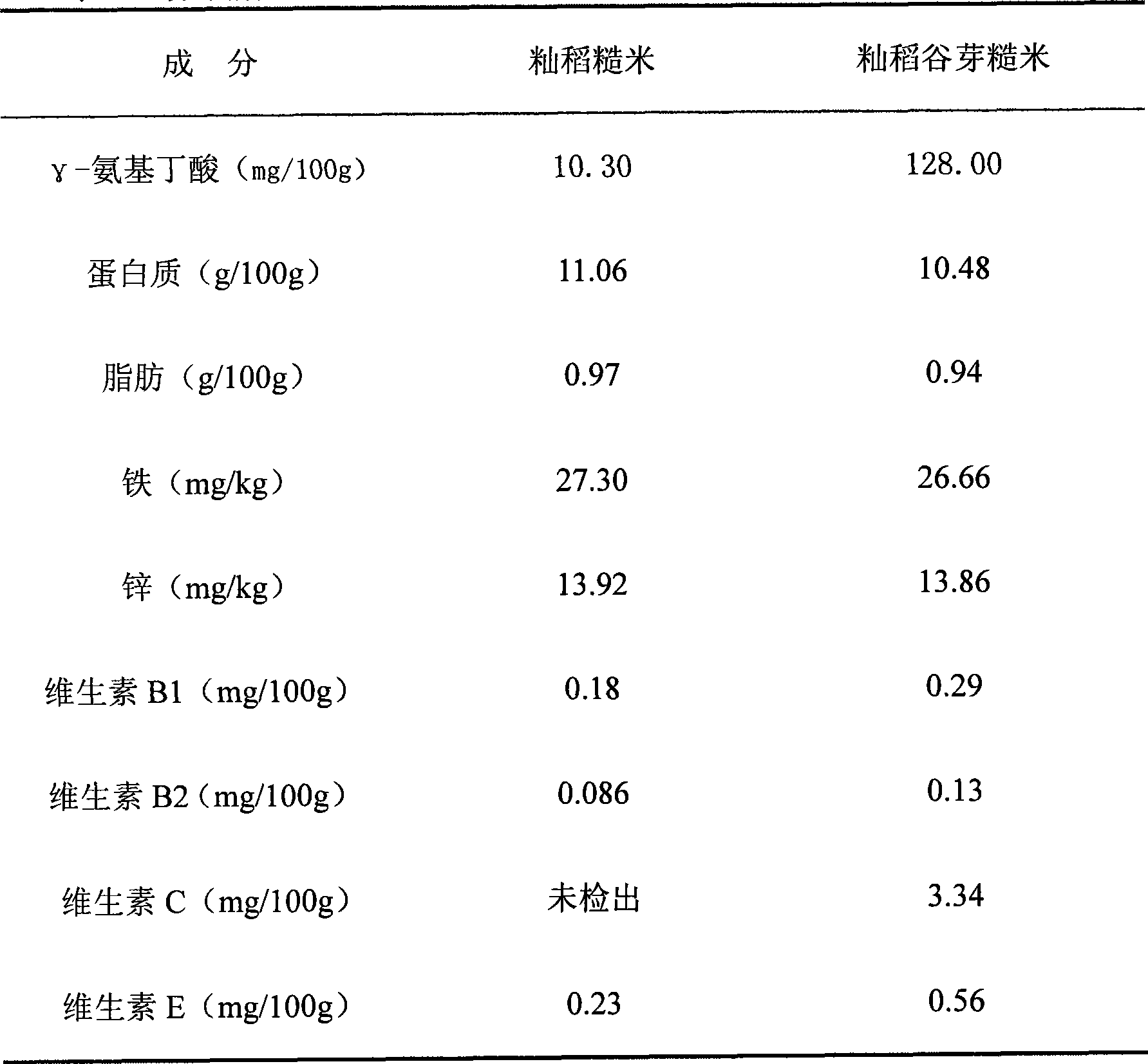

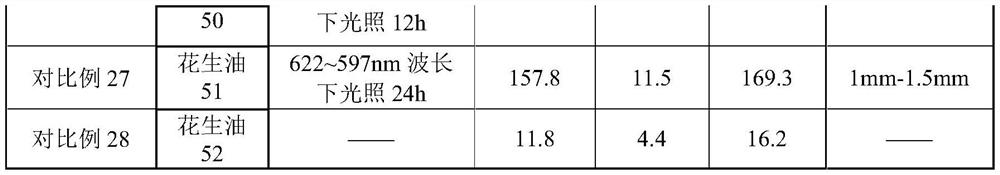

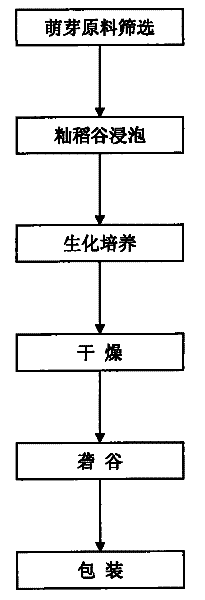

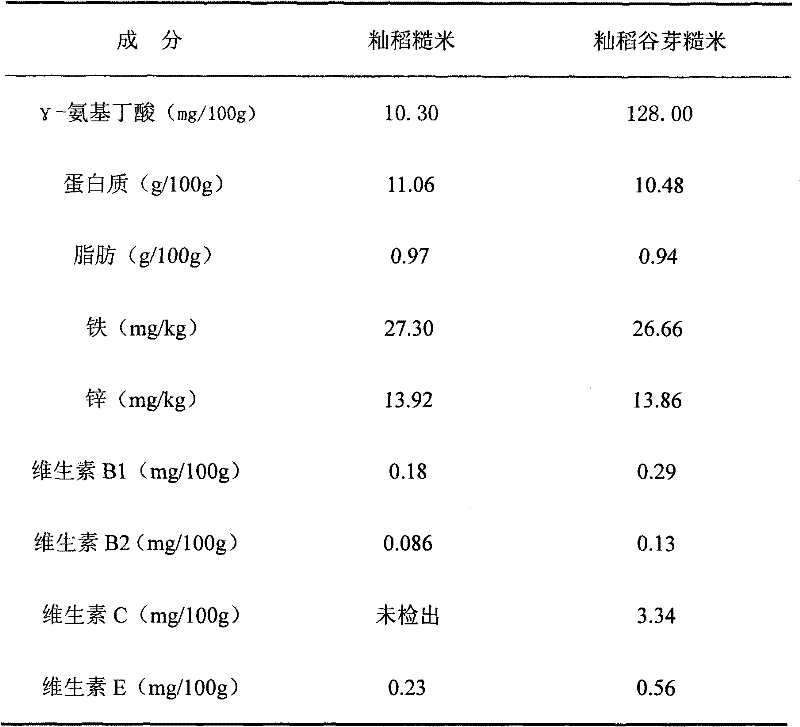

Husked indica-type rice with sprout rich in gamma-aminobutyric acid and preparation method thereof

InactiveCN101433291APromote generationIncrease the content of gamma-aminobutyric acidFood preparationHorticultureRaw material

The invention discloses gamma-aminobutyric acid rich germinated brown rice and a method for preparing the same. The germinated brown rice is prepared by a step that a raw material of brown rice is soaked in a solution of calcium gluconate and then is cultured in a biochemical incubator, dried and hulled. The method can achieve a yield of brown rice of between 79 and 83 percent, prevent the brown rice from fermentation, mouldness and production of flavacin and ensure food safety, and is simple and low in production cost.

Owner:HUAZHONG AGRI UNIV

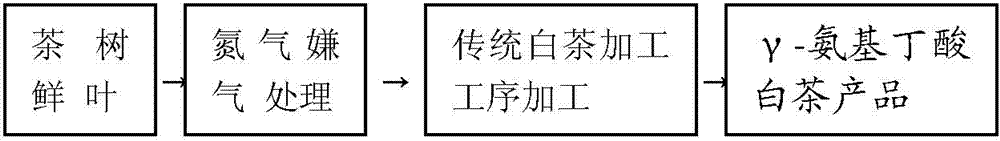

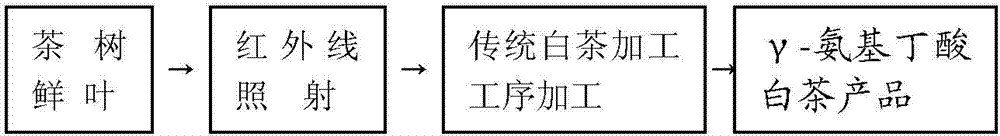

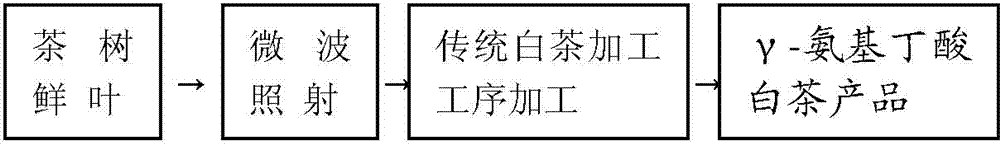

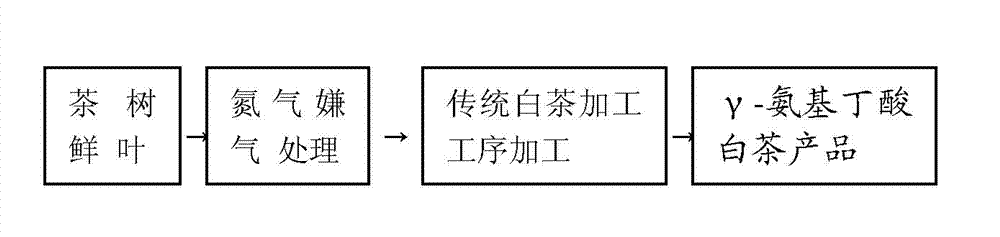

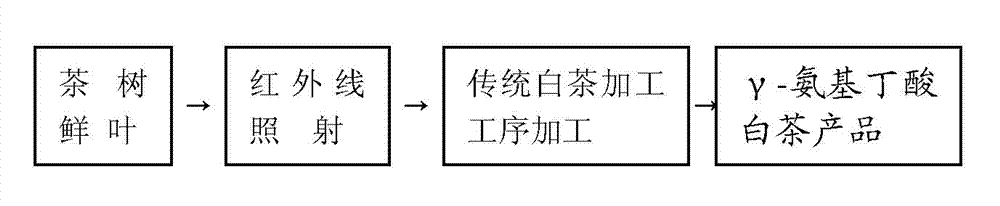

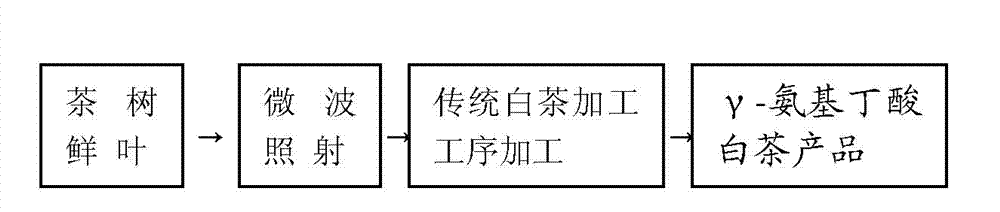

Preparation method for increasing gamma-aminobutyric acid content of tea

ActiveCN102919409AIncrease the content of gamma-aminobutyric acidImprove health benefitsPre-extraction tea treatmentChemistryAnaerobic treatment

The invention provides a preparation method for increasing the gamma-aminobutyric acid content of tea and belongs to the technical field of tea making technology. The preparation method for increasing the gamma-aminobutyric acid content of tea comprises the following steps: (1) vacuum treatment; (2) anaerobic treatment; (3) anaerobic exchange; (4) withering, and aerobic gas alternation; (5) initial drying; (6) drying; (7) stalk preparation; (8) uniform spreading; and (9) obtaining of gamma-aminobutyric acid white tea. The gamma-aminobutyric acid content of the product obtained according to the preparation method provided by the invention is obviously increased so that the healthcare effect of the white tea is increased.

Owner:福建省裕荣香茶业有限公司 +1

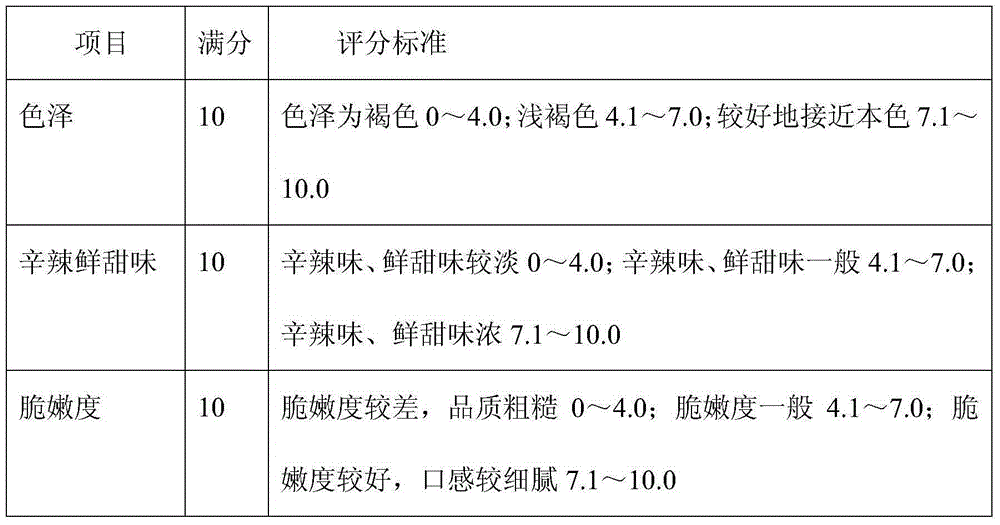

Making method of rehydrated seasoned dried leaf mustard

InactiveCN105053893AEasy to eatStrong spicyFruit and vegetables preservationFood ingredient as taste affecting agentHorticultureAppetite

The invention discloses a making method of rehydrated seasoned dried leaf mustard. The making method comprises the following steps: (1) selecting leaf mustard; (2) sorting and cleaning the selected leaf mustard; (3) cutting the cleaned leaf mustard into filaments, and drying the filaments in sunshine so as to obtain dried leaf mustard; (4) rehydrating the dried leaf mustard: weighing the dried leaf mustard, adding running water, wherein the weight ratio of the dried leaf mustard to the running water is 1:10, soaking the dried leaf mustard in the running water for 2-8 hours, and dehydrating the soaked dried leaf mustard; (5) seasoning the dehydrated dried leaf mustard: weighing the dried leaf mustard, adding seasonings, and uniformly mixing and stirring the weighed dried leaf mustard and the seasonings, wherein the seasonings comprise the following components in percentage by weight by using the weight of the dried leaf mustard as a standard: 0.3-1.0% of gourmet powder, 0.01-0.1% of mint oil, 0.2-0.3% of ascorbic acid, 1-2% of table salt, 0.005-0.01% of proteoglycan, 2% of peanut oil, 0.1-0.2% of white vinegar and 0.2-0.8% of pepper corn; (6) packaging the seasoned dried leaf mustard; (7) performing heat preservation: putting the packaged dried leaf mustard in steam of 45-55 DEG C for heat preservation for 4-6 hours; and (8) disinfecting the dried leaf mustard after heat preservation. According to the making method of the rehydrated seasoned dried leaf mustard made by the making method disclosed by the invention, nutrient components of the leaf mustard are furthest reserved; the made seasoned dried leaf mustard is convenient to eat, is sweet and fresh in mouth feel, is strong in hot taste, can stimulate appetite, invigorate spleens and enhance appetite, and is long in quality guarantee period.

Owner:ANHUI SCI & TECH UNIV

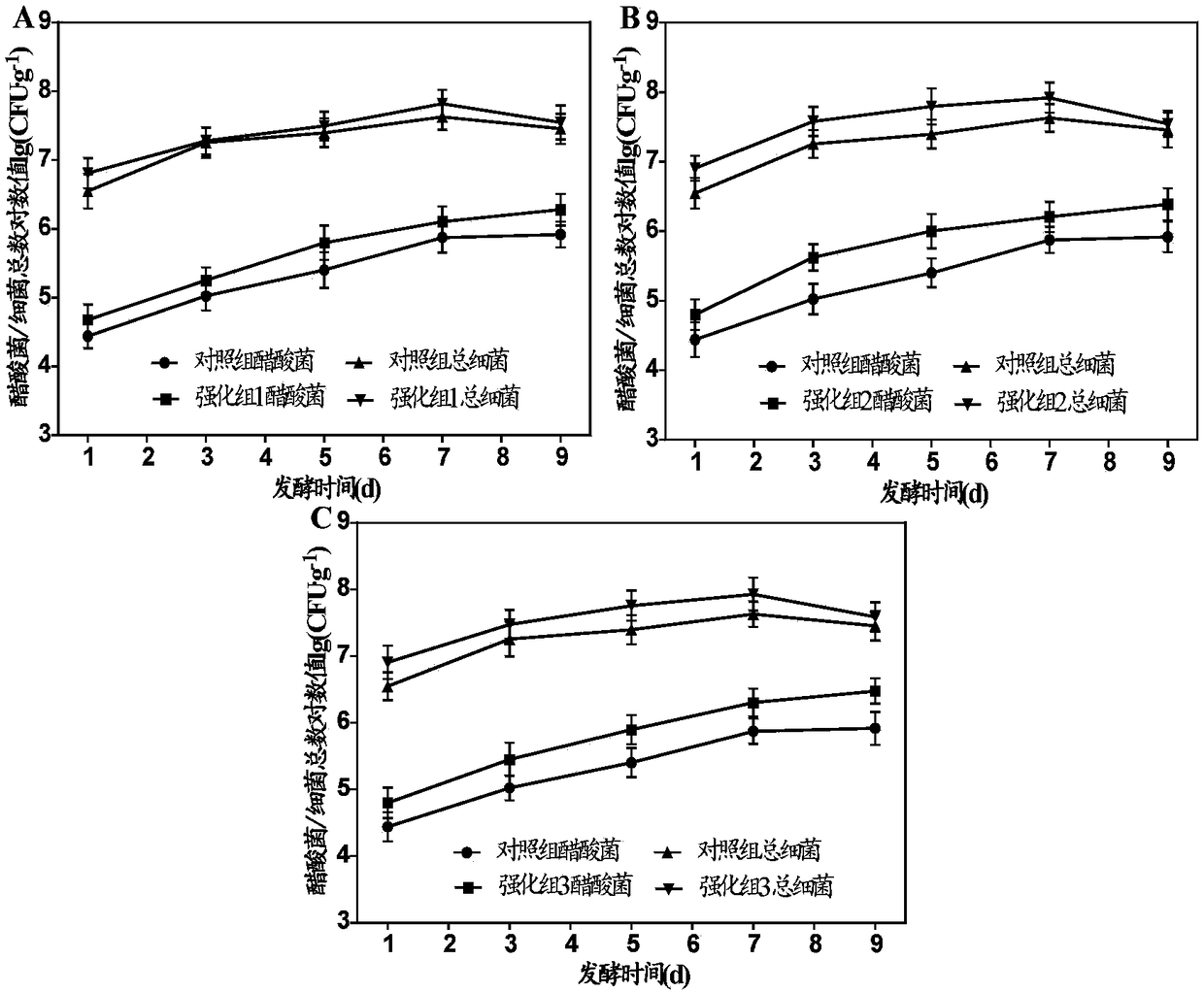

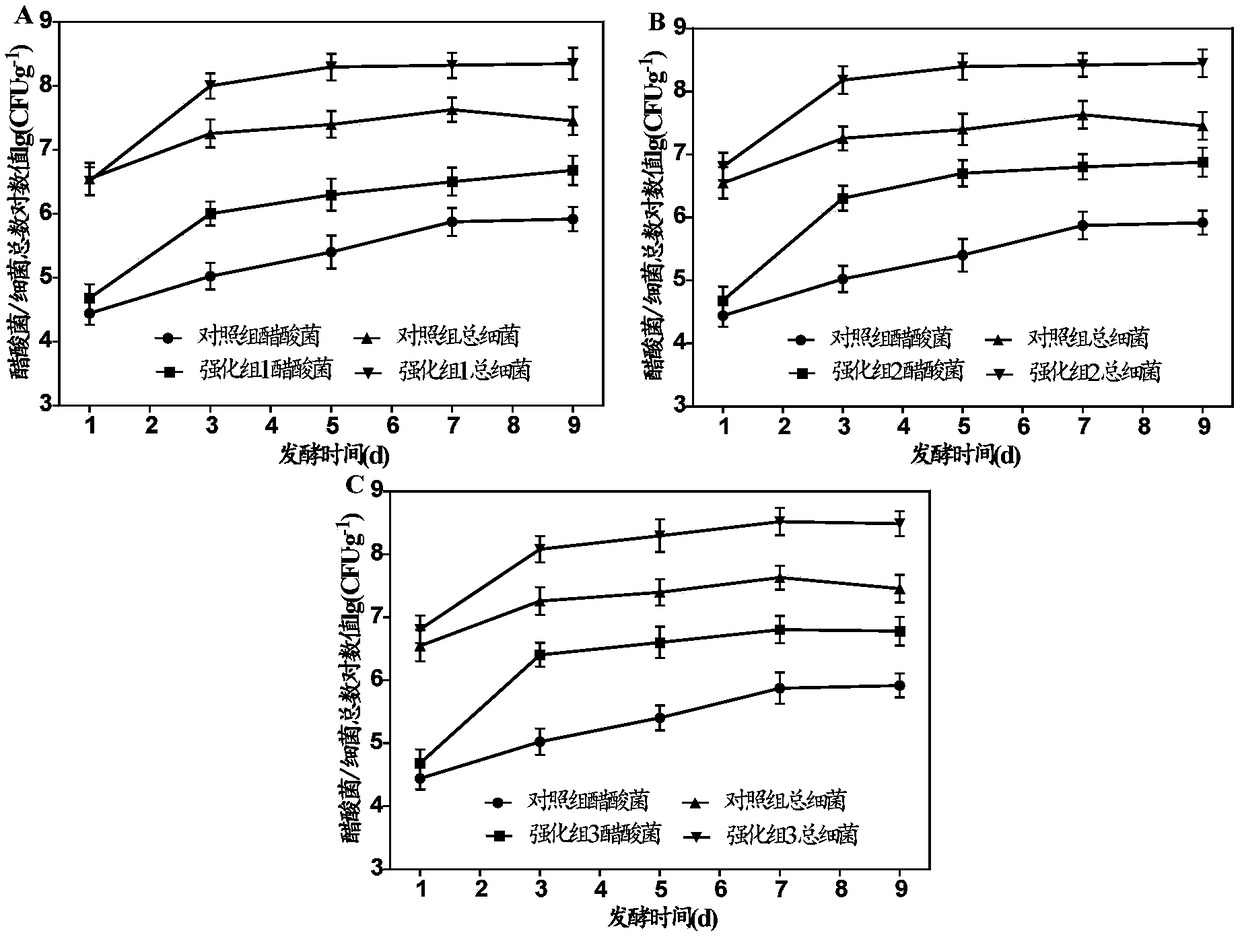

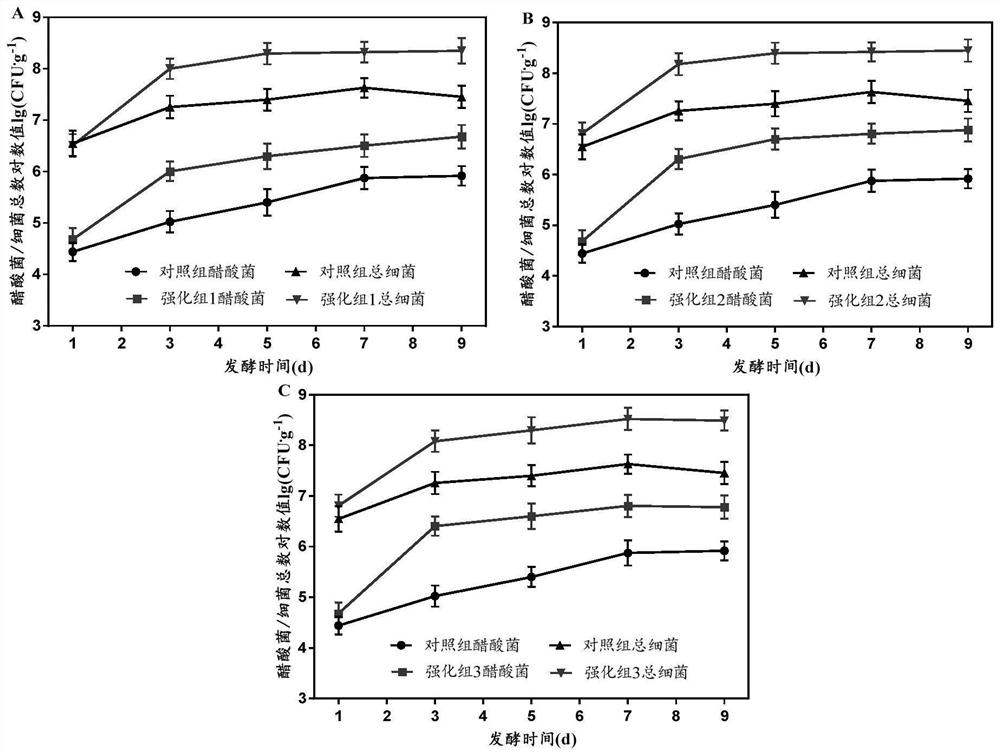

Nutritive salt for directionally regulating and controlling solid state fermentation of vinegar and application of nutritive salt

ActiveCN108624465ATo promote metabolismImprove toleranceBiofuelsVinegar preparationPolydextroseAmmonium sulfate

The invention belongs to the technical field of food fermentation, and particularly relates to nutritive salt for directionally regulating and controlling solid state fermentation of vinegar and application of the nutritive salt. The nutritive salt for directionally regulating and controlling the solid state fermentation of the vinegar is prepared from the following components: 0 to 65 parts of glucose, 0 to 65 parts of lactose, 0 to 15 parts of sodium acetate, 0 to 25 parts of galactooligosaccharide, 0 to 25 parts of polydextrose, 2 to 16 parts of monopotassium phosphate, 0 to 10 parts of ammonium sulfate, 0 to 12 parts of maltitol, 0 to 12 parts of glycine betaine, 2 to 12 parts of compound amino acid and 1 to 4 parts of compound vitamin. According to the nutritive salt and a use methodthereof which are disclosed by the invention, a vinegar solid state fermentation nutritive system can be improved, growth and metabolism of microorganisms are promoted, the vinegar solid state fermentation efficiency is obviously improved, and the fermentation period is shortened; furthermore, the content of flavor substances such as non-volatile acid and amino nitrogen in the vinegar can be increased, and the content of functional components such as gamma-aminobutyric acid and extracellular polysaccharide can also be increased.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

White tea with health-maintaining function and processing technique thereof

InactiveCN106035789AAntioxidantWith whiteningPre-extraction tea treatmentTea flavoringOrganic acidDigestion

The invention provides a white tea with a health-maintaining function and a processing technique thereof and belongs to the technical field of tea processing. The white tea is prepared from the following raw materials in parts by weight: 50-70 parts of fresh tea, 2-5 parts of eucommia ulmoides, 3-6 parts of semen cassia, 3-6 parts of orchid, 3-10 parts of roses, 5-10 parts of roxburgh roses, 1-3 parts of fresh lemon and 1-3 parts of scabish. According to the formula of the white tea with the health-maintaining function, fresh tea, eucommia ulmoides, semen cassia, orchid, roses, roxburgh roses, fresh lemon and scabish are prepared into the white tea with the health-maintaining function; the white tea is rich in vitamin B, carotene, organic acid, more than 20 amino acids and more than 10 kinds of microelements beneficial to human bodies; the white tea has the healthcare functions of resisting oxidation, whitening skin, resisting radiation, resisting aging, invigorating the stomach and promoting digestion, activating blood and removing freckles as well as clearing heat and improving eyesight; and the healthcare effect is promoted.

Owner:JINGCHUNYUAN TEA CO LTD

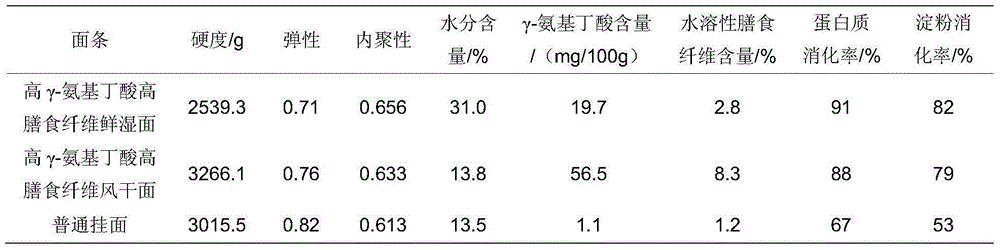

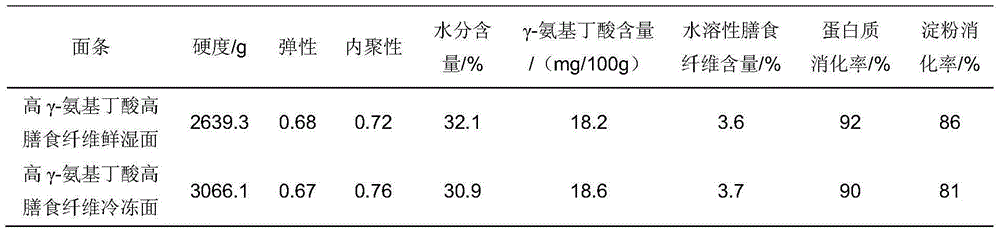

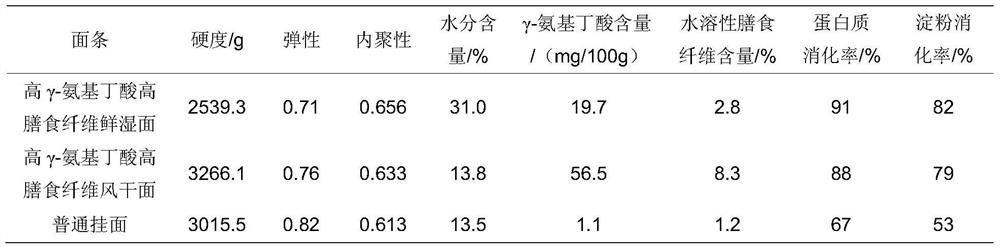

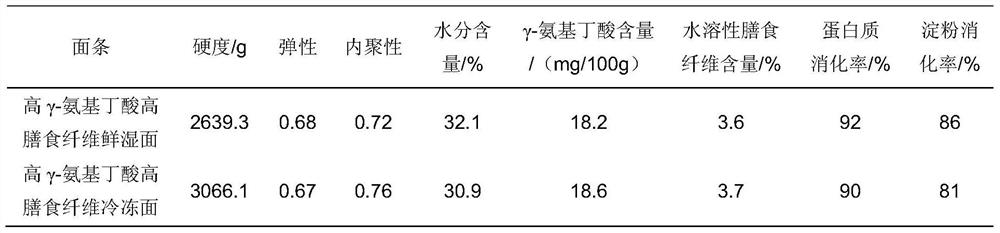

High-gamma-aminobutyric acid high-dietary-fiber noodles and preparation method thereof

ActiveCN104996908AHigh GABAIncrease the content of dietary fiberFood ingredient functionsFood preparationFlavorDietary fiber

The invention provides high-gamma-aminobutyric acid high-dietary-fiber noodles. The noodles have effects of improving intelligence, intestinal functions and the like, and have equivalent hardness, elasticity and cohesiveness with commercial common fine dried noodles. Furthermore, the invention provides a preparation method of the noodles. According to the preparation method, the taste of noodles can be improved by means of super-fine comminution; by means of germination, endogenous enzyme transformation, super-fine comminution and enzyme hydrolysis composition, the content and utilization of gamma-aminobutyric acid and water-soluble dietary fibers can be improved, the content of nutritional factors can be reduced, and the effect can be improved; and the noodles are prepared by utilizing raw stock of germination, so that tenacity and chewing performance of the noodles can be improved, the taste and flavor are good, and the nutritional digestive absorption rate of the noodles can be improved.

Owner:湖北金银丰食品有限公司

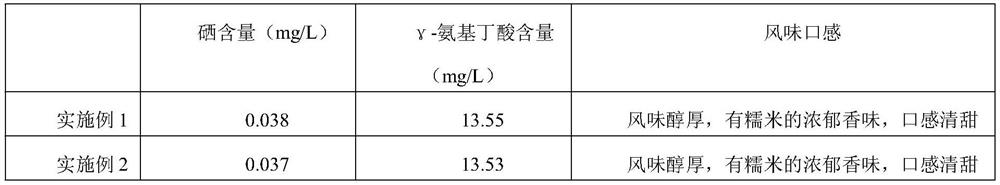

Production process of selenium-enriched rice wine

PendingCN112899103AHigh in Selenium and GABAHigh nutritional valueMicroorganism based processesAlcoholic beverage preparationBiotechnologyNutritive values

The invention provides a selenium-rich rice wine production process. The production process comprises the following steps: firstly, pouring coarse glutinous rice into a sodium selenite aqueous solution, and inducing germination to obtain germ glutinous rice; then grinding the germ glutinous rice into rice flour, spreading the rice flour to be thin, uniformly spraying a sodium selenite aqueous solution on the surface of the rice flour, steaming for the first time, transferring into a square mold, pressing, demolding, and steaming for the second time to obtain a substrate; then, inoculating morchella strains into the substrate, carrying out spawn running, and obtaining glutinous rice blocks with morchella hyphae; crushing the glutinous rice blocks into glutinous rice flour, washing with water, degreasing, steaming, spreading for cooling, mixing with rhizopus koji, fermenting, and filtering to obtain filtrate; and finally, adding Nanguo pear juice into the filtrate, carrying out microwave treatment, naturally cooling, ageing, filtering and sterilizing to obtain the rice wine. According to the present invention, the obtained rice wine is high in selenium and gamma-aminobutyric acid content, and high in nutritive value; and common glutinous rice is used as a raw material, selenium-rich rice does not need to be specially used, and better production flexibility is achieved.

Owner:汪秋兰

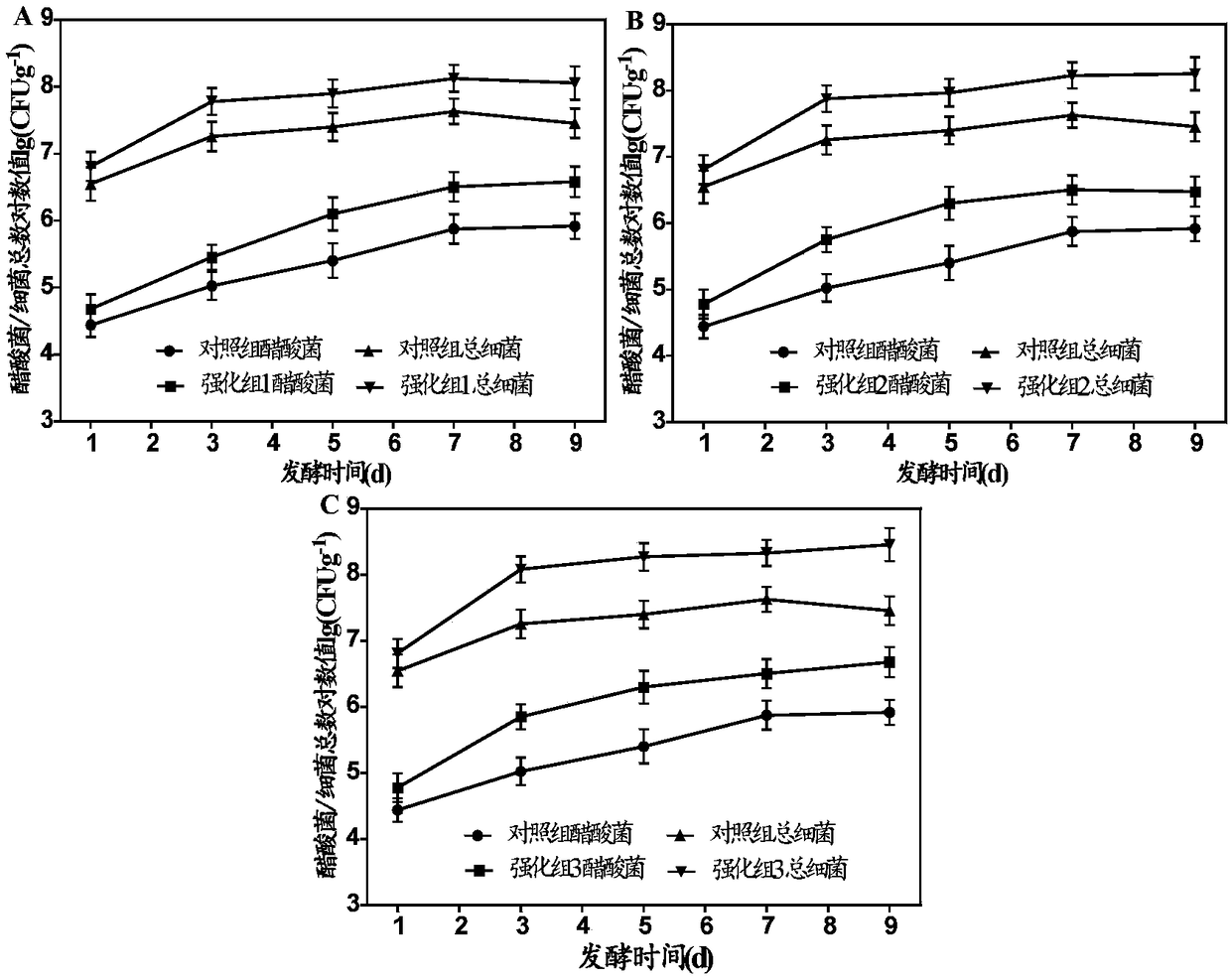

Table vinegar solid-state fermentation nutritive salt and application

ActiveCN113150942ATo promote metabolismImprove toleranceBiofuelsVinegar preparationBiotechnologyNutrition

The invention belongs to the technical field of food fermentation, and particularly relates to table vinegar solid-state fermentation nutritive salt and an application thereof. The table vinegar solid-state fermentation nutritive salt consists of 45-65 parts of lactose, 10-25 parts of galactooligosaccharide, 9-20 parts of polydextrose, 2 parts of monopotassium phosphate, 6-12 parts of compound amino acids and 2 parts of compound vitamins. By utilizing the nutritive salt and a use method thereof disclosed by the invention, the solid-state fermentation nutrition system of the table vinegar can be improved, the growth and metabolism of microorganisms can be promoted, the quality of the table vinegar can be improved on the basis of keeping the flavor of the traditional table vinegar, and the content of important physiological active ingredients in the table vinegar product can be increased.

Owner:TIANJIN UNIV OF SCI & TECH

Processing technology of white tea

InactiveCN106035765AAvoid yellowingAvoid bitternessPre-extraction tea treatmentChlorophyllPolyphenol

The invention provides a processing technology of white tea, belonging to the technical field of tea processing. The processing technology comprises the following steps: picking tea, washing, air-drying, withering, top-speed cooling, low-temperature fermentation, hot-air drying, aroma increasing and bagging, wherein the top-speed cooling refers to that the green-killed tea is cooled to -10-0 DEG C within 50s, and the temperature ranging from -10-0 DEG C is kept for 2-4h. The withered tea belonging to slightly-fermented white tea is especially cooled to -10-0 DEG C at top speed, so that water in the tea is fast condensed; the tissues of chlorophyll can be changed in low-temperature fermentation, so that the large majority of chlorophyll is transformed during low-temperature fermentation and the finished product is whiter; the tea is kept at the temperature ranging from -10-0 DEG C for 2-4h, so that the most of tissues in tea leaves can be damaged, beneficial substances of tea polyphenols and the like are released, and volatile aroma substances in the tea leaves can be condensed to lead the aroma to be heavier during soaking.

Owner:JINGCHUNYUAN TEA CO LTD

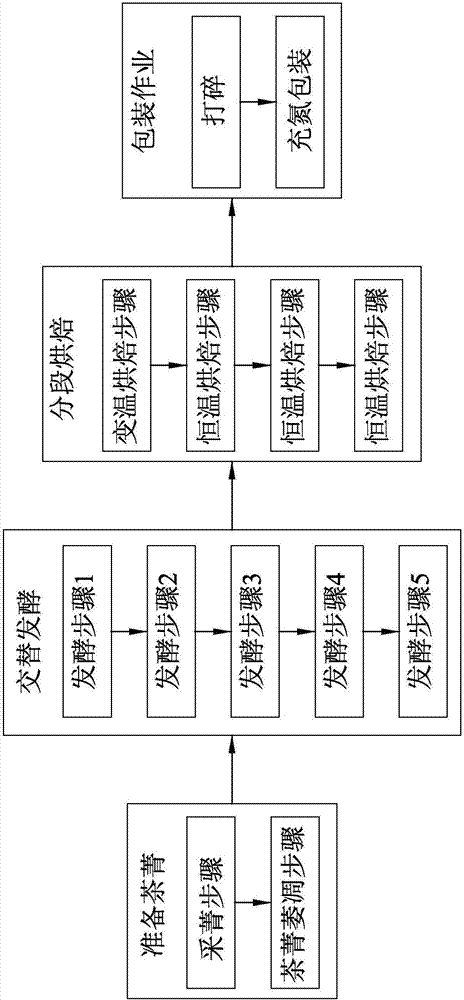

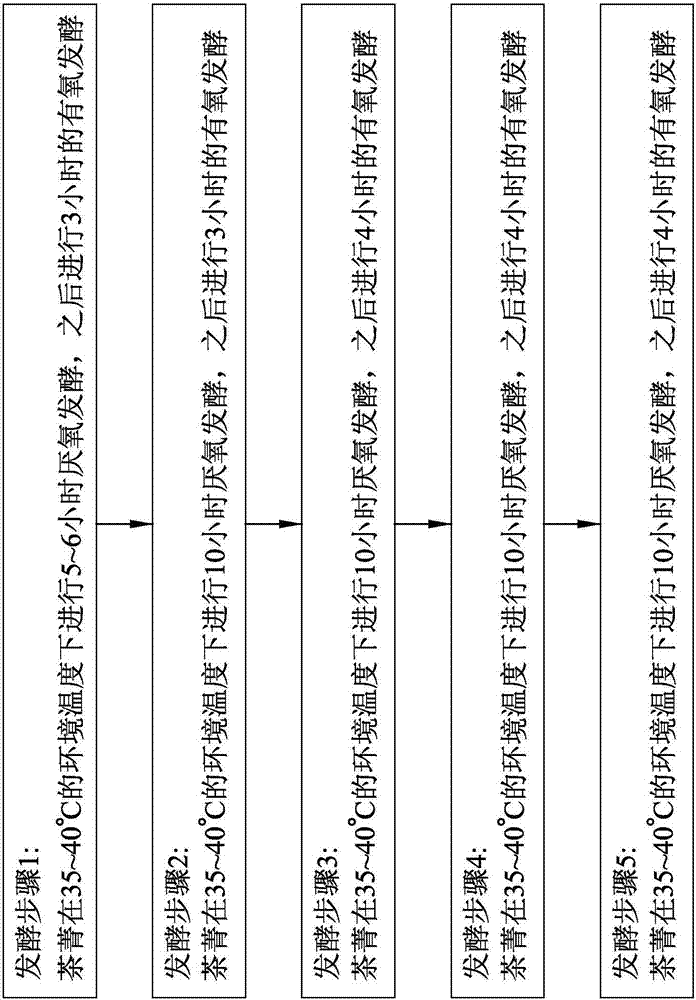

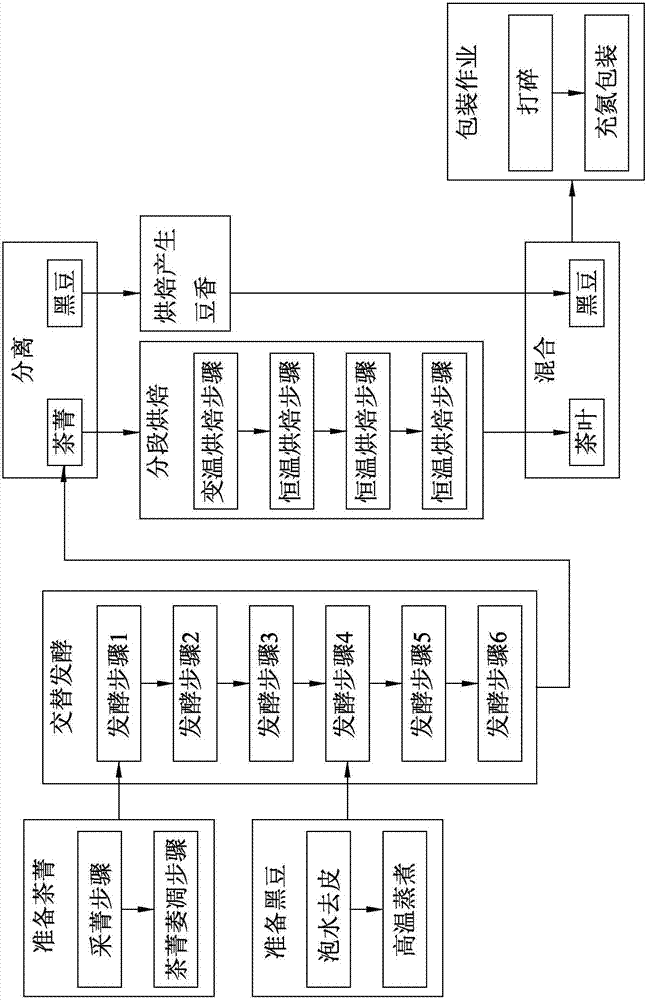

Making method of tea leaves containing gamma-aminobutyric acid

InactiveCN107439731AIncrease the content of gamma-aminobutyric acidImprove sour odorPre-extraction tea treatmentGamma-Aminobutyric acidFermentation

The invention relates to a making method of tea leaves containing gamma-aminobutyric acid. The making method comprises the following preparation processes of preparing fresh tea leaves, performing alternative fermentation, performing segmented baking and the like. In the preparation process of alternative fermentation, at least five fermentation steps are adopted, in each fermentation step, anaerobic fermentation and aerobic fermentation are performed once, and through alternative operation of the anaerobic fermentation and the aerobic fermentation, and through control of processing conditions of fermentation temperature, fermentation time and the like, the made tea leaves have light tartaric acid taste for improving the muffled sour and foul odor caused by simple anaerobic fermentation, and besides, the content of the gamma-aminobutyric acid in the tea leaves can be increased.

Owner:周炳志 +1

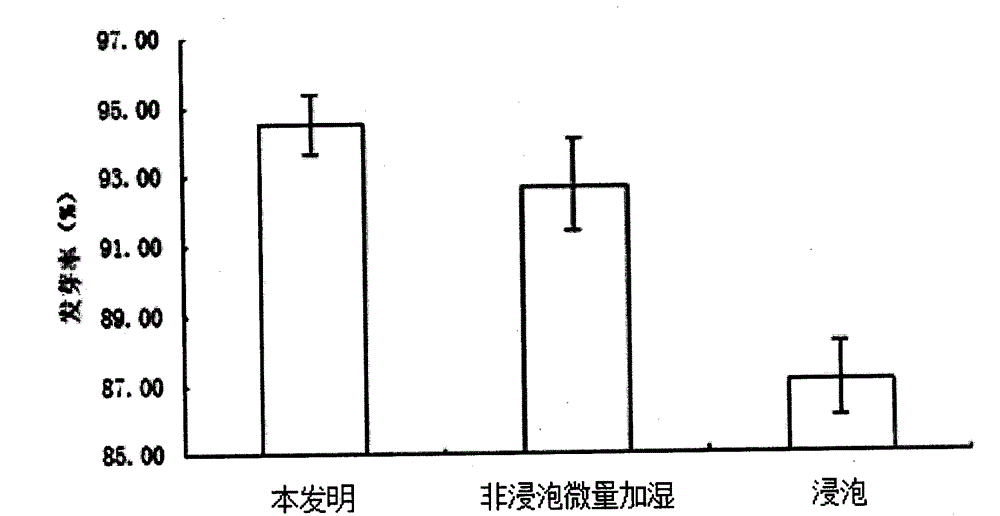

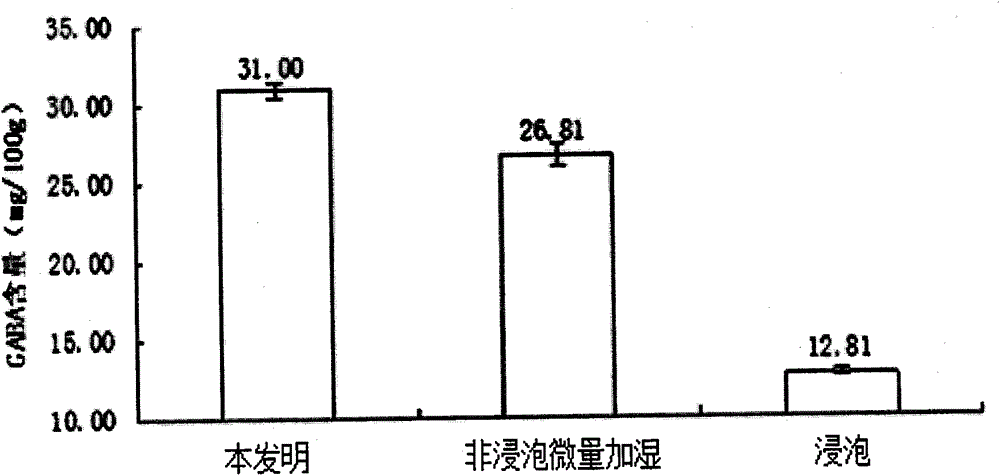

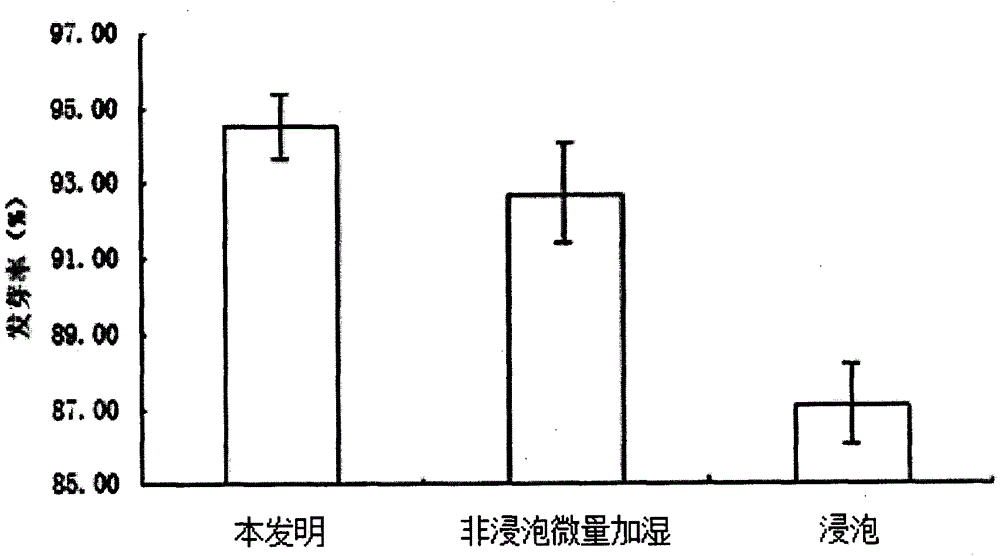

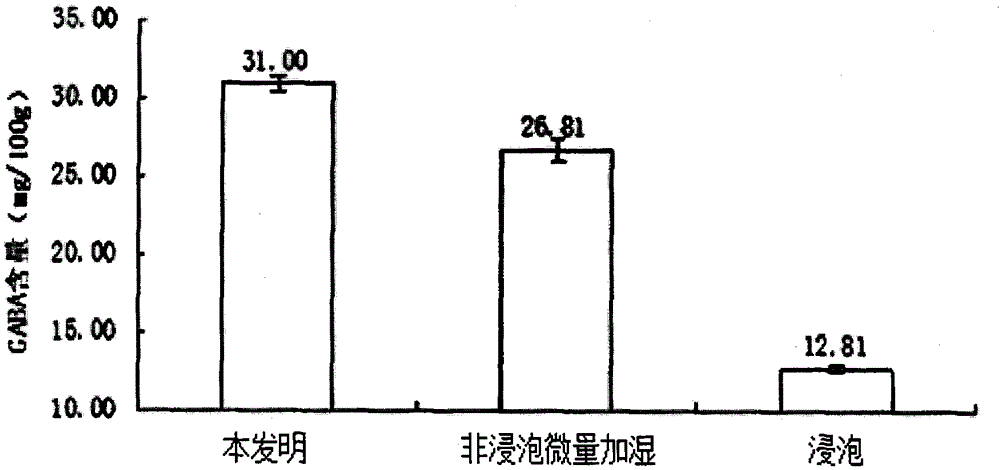

Process for optimizing production of germinated brown rice

InactiveCN103976289AReduce crack growth rateIncrease the content of gamma-aminobutyric acidFood preparationGamma-Aminobutyric acidDissolution

The invention belongs to the technical field of further processing of grain, and in particular relates to a process for optimizing the production of germinated brown rice. The process is characterized in that the engineering method is used to simulate according to the natural germinating process of rice in a soil environment condition, the high germination rate and high gamma-aminobutyric acid content in germinated brown rice are the targets, and on that basis, the optimization process parameter combination meeting the demands on water absorption, temperature, ventilation and other conditions for germination of brown rice are obtained. Compared with the traditional brown rice germination process, the process, provided by the invention, has the advantages that the link of soaking is avoided, so that the natural germination rules of brown rice are met, no sewage is produced, the loss on dissolution of nutritional substances of the brown rice in soaking is avoided, and the energy consumption for drying of the germinated brown rice due to excessive water sucking in the soaking link can also be decreased. With the adoption of the process for optimizing, the germination rate of brown rice can be increased by 5 to 7%, and the gamma-aminobutyric acid content in germinated brown rice can be increased by about 2.4 times.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Preparation method for increasing gamma-aminobutyric acid content of tea

ActiveCN102919409BIncrease the content of gamma-aminobutyric acidImprove health benefitsPre-extraction tea treatmentBiotechnologyBotany

The invention provides a preparation method for increasing the gamma-aminobutyric acid content of tea and belongs to the technical field of tea making technology. The preparation method for increasing the gamma-aminobutyric acid content of tea comprises the following steps: (1) vacuum treatment; (2) anaerobic treatment; (3) anaerobic exchange; (4) withering, and aerobic gas alternation; (5) initial drying; (6) drying; (7) stalk preparation; (8) uniform spreading; and (9) obtaining of gamma-aminobutyric acid white tea. The gamma-aminobutyric acid content of the product obtained according to the preparation method provided by the invention is obviously increased so that the healthcare effect of the white tea is increased.

Owner:福建省裕荣香茶业有限公司 +1

A kind of germinated brown rice production optimization process

InactiveCN103976289BReduce crack growth rateIncrease the content of gamma-aminobutyric acidFood scienceGamma-Aminobutyric acidSewage

The invention belongs to the technical field of further processing of grain, and in particular relates to a process for optimizing the production of germinated brown rice. The process is characterized in that the engineering method is used to simulate according to the natural germinating process of rice in a soil environment condition, the high germination rate and high gamma-aminobutyric acid content in germinated brown rice are the targets, and on that basis, the optimization process parameter combination meeting the demands on water absorption, temperature, ventilation and other conditions for germination of brown rice are obtained. Compared with the traditional brown rice germination process, the process, provided by the invention, has the advantages that the link of soaking is avoided, so that the natural germination rules of brown rice are met, no sewage is produced, the loss on dissolution of nutritional substances of the brown rice in soaking is avoided, and the energy consumption for drying of the germinated brown rice due to excessive water sucking in the soaking link can also be decreased. With the adoption of the process for optimizing, the germination rate of brown rice can be increased by 5 to 7%, and the gamma-aminobutyric acid content in germinated brown rice can be increased by about 2.4 times.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

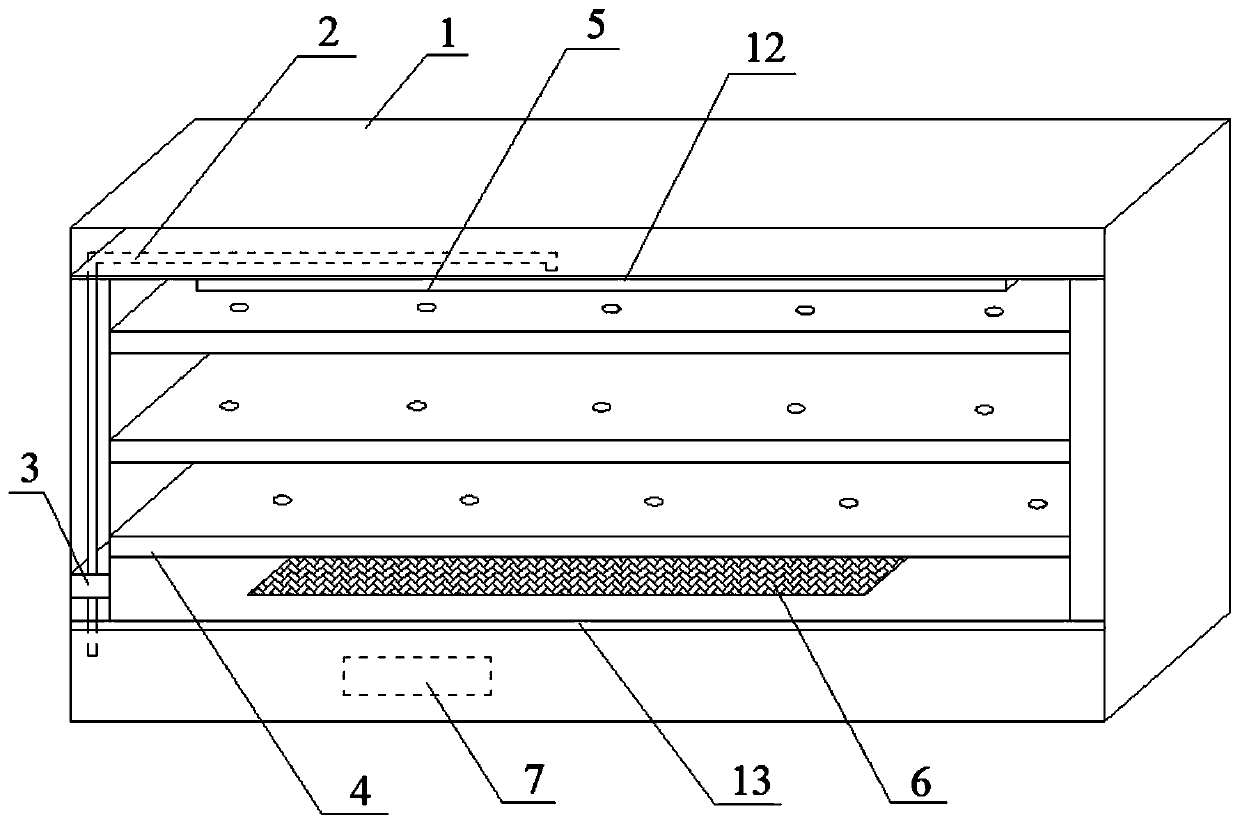

Highland barley germinated rice with high gamma-aminobutyric acid content, and processing method and application thereof

PendingCN111109527ANeatly sproutedBreeding is easyAcidic food ingredientsGerminating apparatusNutrients substancesHorticulture

The invention belongs to the technical field of food processing, and specifically relates to highland barley germinated rice with high gamma-aminobutyric acid content, and a processing method and an application thereof. The processing method comprises the following steps: removing dust from highland barley rice so as to obtain clean highland barley rice; placing the clean highland barley rice in ahigh-temperature environment of 55-70 DEG C for 6-12 h so as to obtain sterilized highland barley rice; soaking the sterilized highland barley rice in warm water containing a bacteriostatic agent at40-50 DEG C for 8-10 h, wherein the bacteriostatic agent is an iron salt solution; performing germination treatment on the soaked highland barley rice by adopting a constant-temperature and constant-humidity incubator or a germination device until germination is finished; and drying the germinated highland barley rice so as to obtain the highland barley germinated rice. With the method provided bythe invention, infectious microbe infections like mildew and rancidity are avoided in the highland barley germination process; loss of nutrient substances is reduced; highland barley germination is neat; the germination rate is 97% or above; meanwhile, the gamma-aminobutyric acid content of the prepared highland barley germinated rice reaches 69.26 mg / 100 g or above.

Owner:QINGHAI UNIVERSITY

Production of lactic acid bacteria fermented liquid high in γ-aminobutyric acid and its application in cosmetics

ActiveCN110592151BIncrease the content of gamma-aminobutyric acidHigh whitenessCosmetic preparationsToilet preparationsBiotechnologyLactic acid bacterium

The invention relates to the field of fermentation technologies and cosmetics, in particular to a preparation method for producing fermentation liquor with a high [gamma]-aminobutyric acid content byemploying lactic acid bacteria, and an application of fermentation liquor in cosmetics. The preparation method comprises the following steps of: (1) enabling brown rice and barley to sprout, mixing the sprouted brown rice and barley with folium mori, and smashing the mixture to obtain a mixed powder; (2) adding water into the mixed powder for dipping, and conducting filtering to obtain a filtrate;and (3) adding glutamic acids or / and glutamate into the filtrate, inoculating fermentative bacteria, and conducting filtering to obtain the fermentation liquor. The fermentation liquor has the advantages of high [gamma]-aminobutyric acid content, good use effect and no side effects when the fermentation liquor is applied to cosmetics.

Owner:哈尔滨美华生物技术股份有限公司

Production process of germ and corn composite nutritional powder and product of production process

ActiveCN102754764BIncrease nutritional contentIncrease the content of gamma-aminobutyric acidFood preparationIngested foodSenescence

The invention relates to a production process of germ and corn composite nutritional powder and the product of the production process, and belongs to the technical field of food processing. The production process is characterized in that mixing corn which sprouts in stress with wheat germ which is subjected to microwave enzyme inactivation; performing extrusion and superfine grinding to prepare germ and corn meal; adding carrot meal, spirulina meal, white granulated sugar, maltodextrin and vegetable fat powder into the germ and corn meal; and sterilizing and packaging to prepare the germ and corn composite nutritional powder. The production process is simple and high in industrial degree, so that the germ resource can be further utilized, corn can be completely utilized, and the additional value of agricultural products can be increased. The germ and corn composite nutritional powder produced by the production process is good in dissolubility, fine in taste and high in nutritional value, is rich in gamma-aminobutyric acid, glutathione, octacosanol, dietary fiber and other components, has the functions of improving brain functions, calming nerves, improving sleeping, resisting oxidation, delaying senescence, improving body immunity and the like, and is an ideal health-care nutritional food, wherein the content of gamma-aminobutyric acid in the product is between 20 and 60mg / 100g.

Owner:JIANGSU HENGHUI FOOD CO LTD

Preparation method of Chenopodium quinoa-Potentilla anserina lozenges containing GABA (gamma-aminobutyric acid)

ActiveCN109123641AIncrease the content of gamma-aminobutyric acidFood shapingPotentilla anserinaFreeze-drying

The invention discloses a preparation method of Chenopodium quinoa-Potentilla anserina lozenges containing GABA (gamma-aminobutyric acid). The method comprises the following steps: (1) raw materials are prepared in parts by weight; (2) Chenopodium quinoa seeds are soaked in a citric acid solution at 25 DEG C; (3) the product in step (2) is processed under low pressure and low temperature for primary germination; (4) the product in step (3) is processed under high pressure and high temperature for secondary germination; (5) the product in step (4) is filtered, and a product is cooked for 10-15min, taken out and freeze-dried until water content is lower than 2%; (6) Potentilla anserina is cleaned, dried until water content is lower than 3%, and cooled for standby application; (7) the Chenopodium quinoa seeds and the Potentilla anserina are mixed and subjected to superfine grinding, and powder A is obtained; (8) dried apple is subjected to superfine grinding, and powder B is obtained; (9) the power A, the power B obtained in step (8) and honey powder are mixed, and then tablet compressing and packaging are performed. The prepared Chenopodium quinoa-Potentilla anserina lozenges have high GABA content.

Owner:青海金祥生物科技发展有限责任公司

A kind of preparation method of quinoa fern hemp lozenges containing γ-aminobutyric acid

The invention discloses a preparation method of quinoa lozenges containing γ-aminobutyric acid, comprising the following steps: (1) preparing raw materials according to parts by weight; (2) soaking quinoa rice in a citric acid solution, 25 ℃, soaking; (3) the product of step (2) is subjected to low-pressure and low-temperature first-stage germination; (4) the product of step (3) is subjected to high-pressure and high-temperature second-stage germination; (5) The product of step (4) is filtered , take it out after cooking for 10-15min, freeze-dry it to a water content of less than 2%; (6) wash the fern, dry it to a water content of less than 3%, and cool it for later use; (7) mix the quinoa rice and the fern, and super Finely pulverize to obtain powder A; (8) ultrafinely pulverize dried apples to obtain powder B; (9) mix powder A, powder B and honey powder obtained in step (8), and then perform tableting, Package. The quinoa fern and hemp lozenges prepared by the invention have high γ-aminobutyric acid content.

Owner:青海金祥生物科技发展有限责任公司

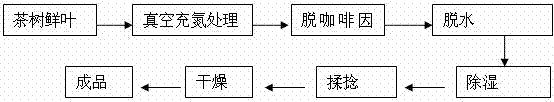

Low-caffeine and high-GABA (Gamma Amino Acid Butyric Acid) health protection tea

ActiveCN103053720BIncrease the content of gamma-aminobutyric acidReduce caffeine levelsPre-extraction tea treatmentBiotechnologyWarm water

The invention discloses low-caffeine and high-GABA (Gamma Amino Acid Butyric Acid) health protection tea, and belongs to the technical field of processing of health protection tea. The health protection tea is prepared by the following steps: fresh tea tree leaves are treated for 3-12 hours in vacuum under the nitrogen charge condition, and are gradually cooled, dipped and rinsed by hot water to remove caffeine and anaerobic smell, then are dehumidified, rubbed and dried to obtain the product, wherein the caffeine is removed through gradually cooling, dipping and rinsing by using the hot water as follows: the treated fresh tea tree leaves are dipped in the hot water, and are kept for 30-300 seconds at the leaf water temperature of 80-90 DEG C; then the tea is quickly dipped in warm water, and is kept for 3-30 minutes at the leaf water temperature of 40-75 DEG C; and finally, the tea is taken out to cool by using cold water.

Owner:SOUTH CHINA AGRI UNIV

A kind of germinated brown rice puffed food suitable for people with diabetes and its production method

ActiveCN105249176BGood treatment effectSpeed up recoverySugar food ingredientsFood ingredient functionsAdditive ingredientGamma-Aminobutyric acid

The invention relates to germinated brown rice puffed food suitable for diabetic patients and a production method thereof and belongs to the field of puffed food processing. The puffed food is characterized in that brown rice or germinated brown rice is used as a main raw material and mixed with peanuts or germinated peanuts and DNJ-enriched folium mori, 75-85% of the brown rice or the germinated brown rice, 15-19% of the peanuts or the germinated peanuts and 1-4% of folium mori powder are mixed according to the mass ratio, the three raw materials are smashed and mixed, and after water content is adjusted, the raw materials are prepared into the puffed food suitable for the diabetic patients to eat by adopting the process of double-screw extruding puffing, cutting forming, drying, cooling and packaging. By means of the production process, the application field of the folium mori and the peanuts is expanded, the produced puffed food is crispy in mouthfeel, balanced in nutrition, rich in nutritional elements such as gamma-aminobutyric acid, DNJ, peanut protein and glutathione and suitable for the diabetic patients to eat, and has the effects of reducing blood sugar and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

A kind of blueberry grape red bean compound pulp beverage and preparation method thereof

The invention discloses a blueberry, grape and red bean composite pulp beverage and a preparation method thereof. The composite pulp beverage is prepared from the following ingredients in percentage by mass: 15 to 20 percent of red bean original pulp, 8 to 15 percent of sucrose, 3 to 5 percent of blueberry original pulp, 3 to 5 percent of grape original pulp, 0.10 to 0.20 percent of sodium carboxymethylcellulose, 0.05 to 0.15 percent of xanthan gum, 0.013 to 0.017 percent of gellan gum and the balance pure water. The blueberry, grape and red bean composite pulp beverage has the advantages that the color is bright; the mouthfeel is fine; the nutrition is balanced; rich gamma-propalanine, anthocyanin and protein are contained; the effects of regulating the cardiovascular disease activity, improving the eyesight, enhancing the body immunity and the like are achieved; meanwhile, the preparation method is simple and convenient; the raw material utilization rate is high; the industrial production can be easily realized; through the parameter control on the work procedures of hypoxia stress red bean gemmation, homogenate incubation processing and the like, the content of gamma-propalanine can be obviously improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

High γ-aminobutyric acid high dietary fiber noodles and preparation method thereof

ActiveCN104996908BHigh GABAIncrease the content of dietary fiberFood ingredient functionsBiotechnologyNutrition

The invention provides a high γ-aminobutyric acid high dietary fiber noodle, which has the effects of improving intelligence and improving intestinal function, and the noodle hardness, elasticity and cohesion are comparable to those of ordinary dried noodles on the market. In addition, the present invention also provides a preparation method thereof, which can improve the taste of noodles through ultra-micronization; can improve γ-aminobutyric acid and water-soluble diet through germination and endogenous enzyme transformation, as well as the combined action of ultra-micronization and enzymatic hydrolysis The content and utilization of fiber can reduce the content of anti-nutritional factors and improve the efficacy; the use of sprouted puree to make noodles can improve the toughness and chewing performance of the noodles, the taste and flavor are good, and the nutrient digestion and absorption rate of the noodles can be improved.

Owner:湖北金银丰食品有限公司

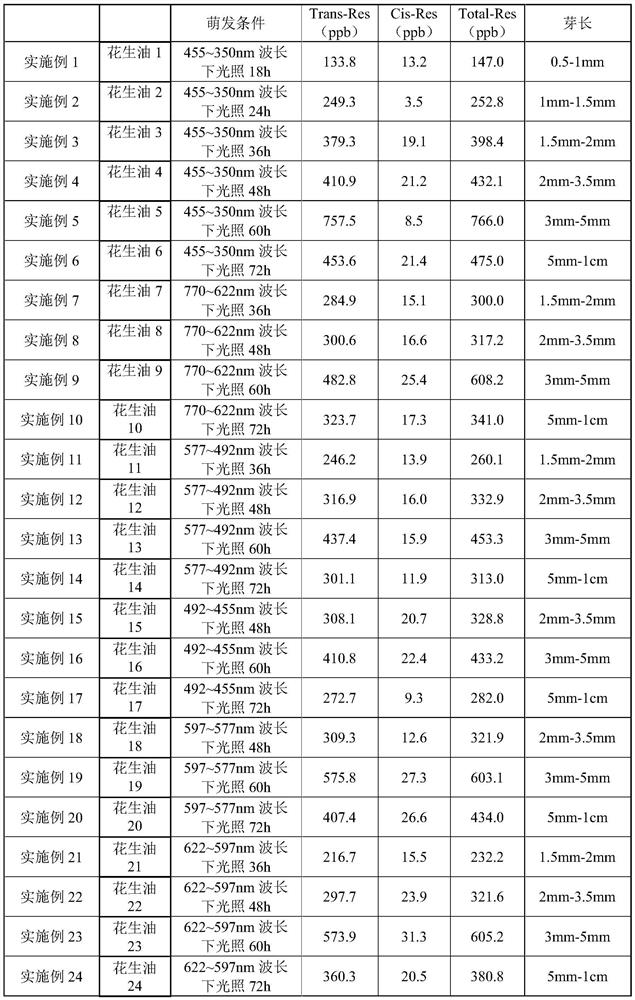

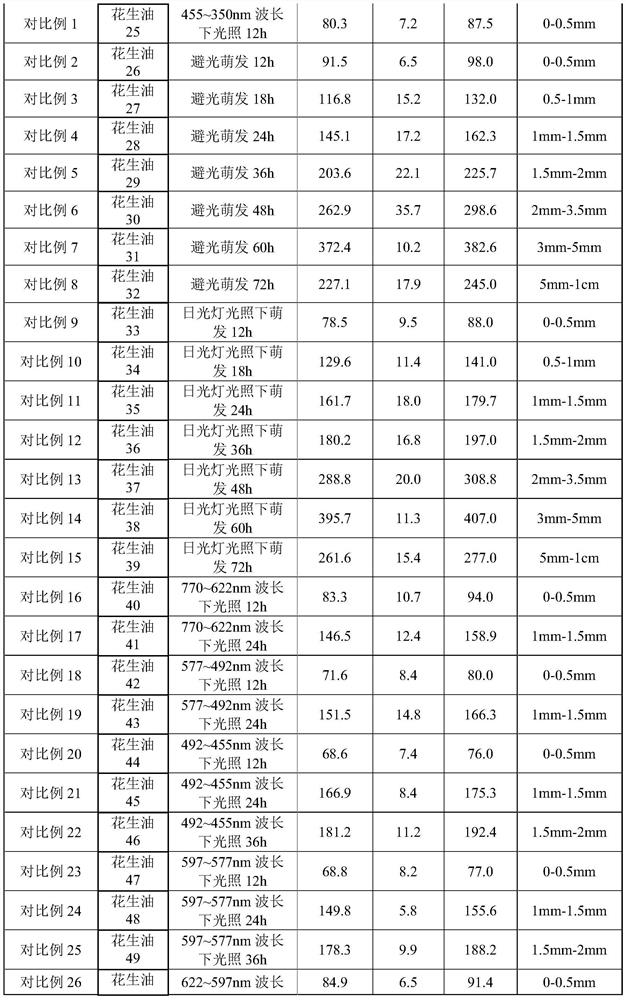

Peanut oil and peanut product, and preparation methods thereof

PendingCN114058436AEasy to operateIncreased resveratrol contentDough treatmentConfectioneryBiotechnologyBotany

The invention provides a peanut product. The peanut product is prepared from peanuts germinated under illumination of a specific wavelength. The peanuts only need to be germinated under illumination of a certain wavelength and then are treated, so operation is easy; the resveratrol content of peanut oil can be obviously improved, and the nutrition and application performance of the peanut oil are improved; and the content of gamma-aminobutyric acid in peanut butter can be remarkably increased, and the nutrition and application performance of the peanut butter are improved.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Husked indica-type rice with sprout rich in gamma-aminobutyric acid and preparation method thereof

InactiveCN101433291BPromote generationHigh in vitaminsFood preparationFood safetyGamma-Aminobutyric acid

The invention discloses gamma-aminobutyric acid rich germinated brown rice and a method for preparing the same. The germinated brown rice is prepared by a step that a raw material of brown rice is soaked in a solution of calcium gluconate and then is cultured in a biochemical incubator, dried and hulled. The method can achieve a yield of brown rice of between 79 and 83 percent, prevent the brown rice from fermentation, mouldness and production of flavacin and ensure food safety, and is simple and low in production cost.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

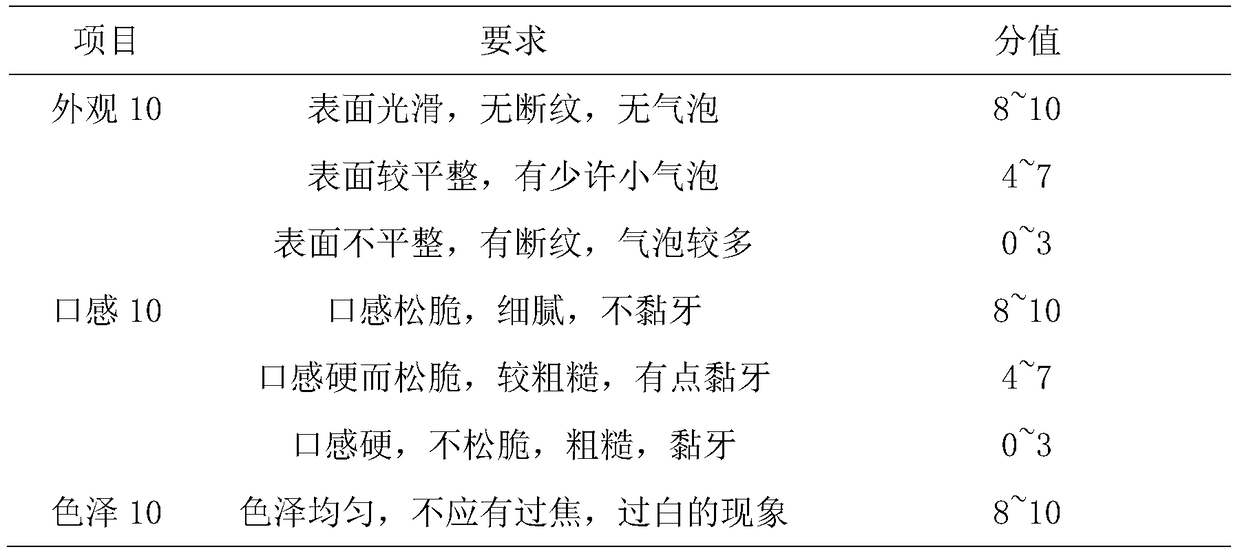

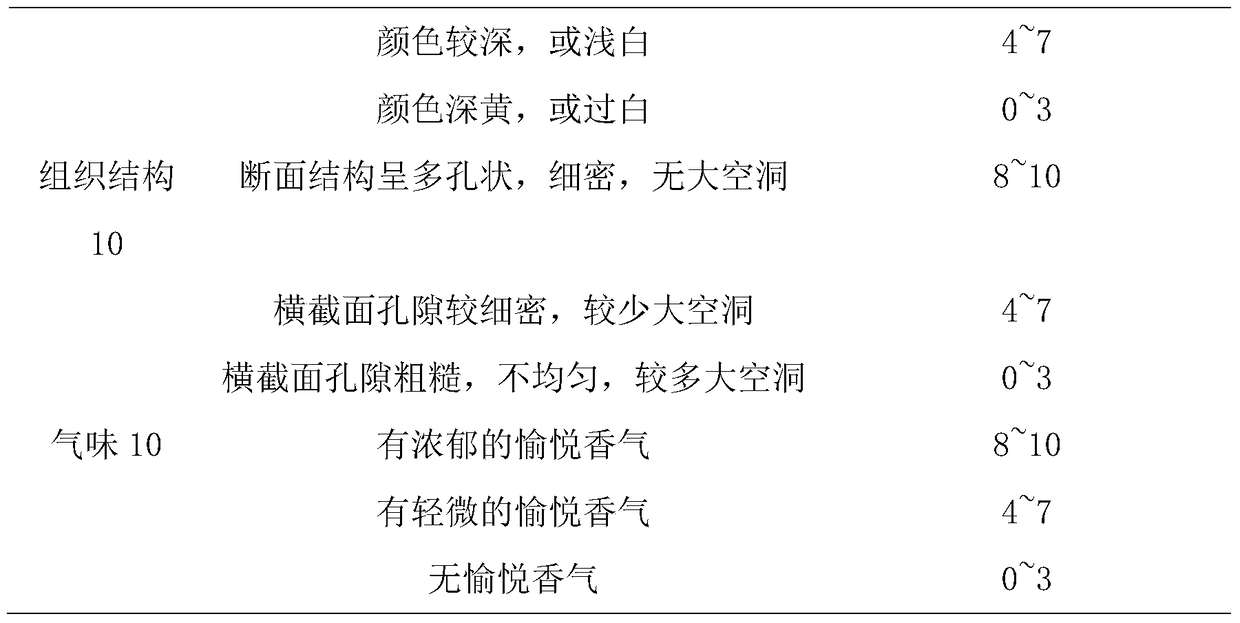

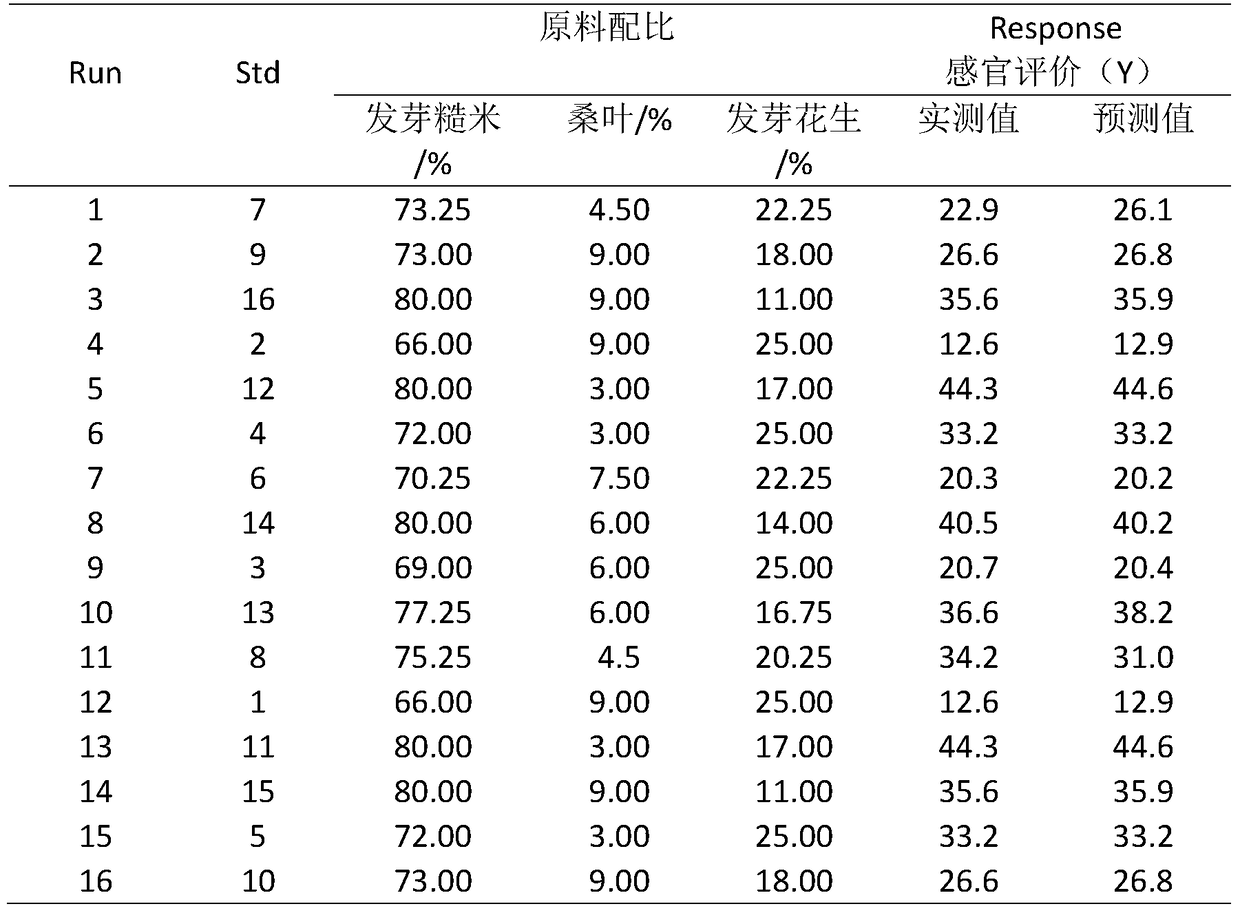

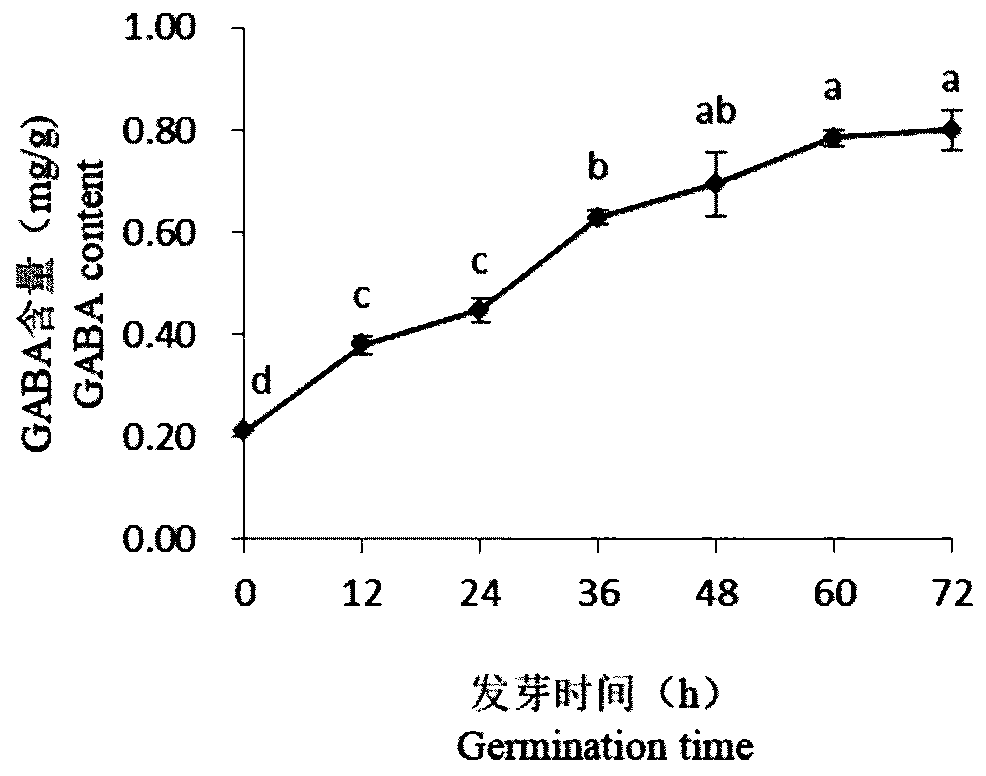

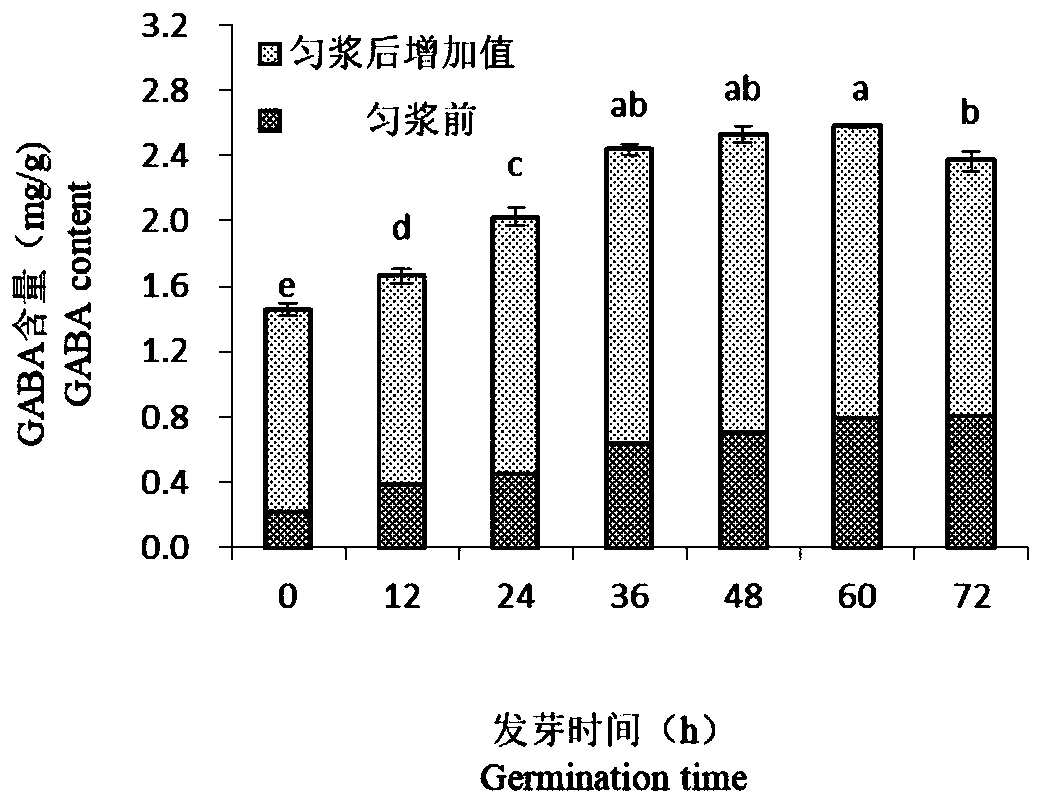

![Preparation method for producing fermentation liquor with high [gamma]-aminobutyric acid content by employing lactic acid bacteria, and application of fermentation liquor in cosmetics Preparation method for producing fermentation liquor with high [gamma]-aminobutyric acid content by employing lactic acid bacteria, and application of fermentation liquor in cosmetics](https://images-eureka.patsnap.com/patent_img/bada9f07-1cf3-4e74-ade7-7906faec362b/BDA0002202100540000091.png)

![Preparation method for producing fermentation liquor with high [gamma]-aminobutyric acid content by employing lactic acid bacteria, and application of fermentation liquor in cosmetics Preparation method for producing fermentation liquor with high [gamma]-aminobutyric acid content by employing lactic acid bacteria, and application of fermentation liquor in cosmetics](https://images-eureka.patsnap.com/patent_img/bada9f07-1cf3-4e74-ade7-7906faec362b/BDA0002202100540000101.png)