Highland barley germinated rice with high gamma-aminobutyric acid content, and processing method and application thereof

A technology of aminobutyric acid and a processing method, applied in the field of food processing, can solve the problems of reducing the nutrient content of germinated rice, loss of protein and cellulose in highland barley rice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

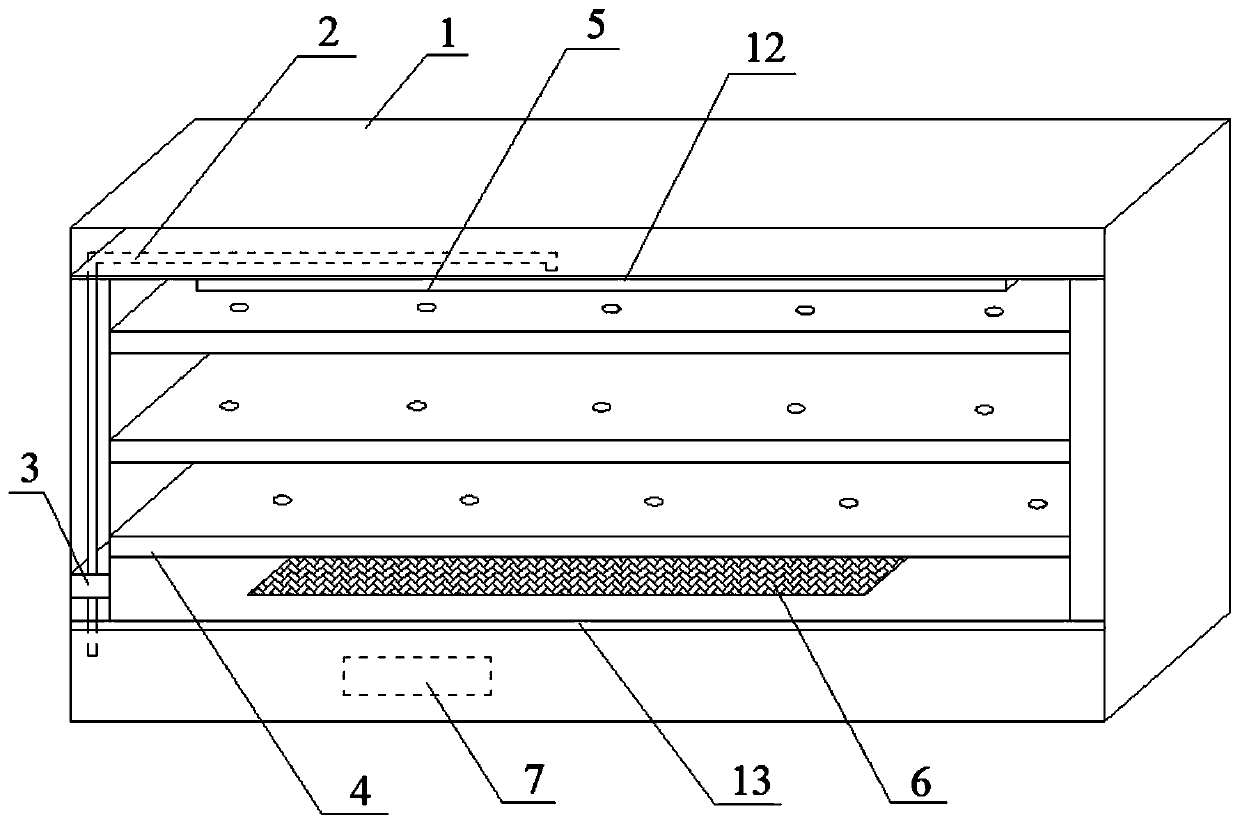

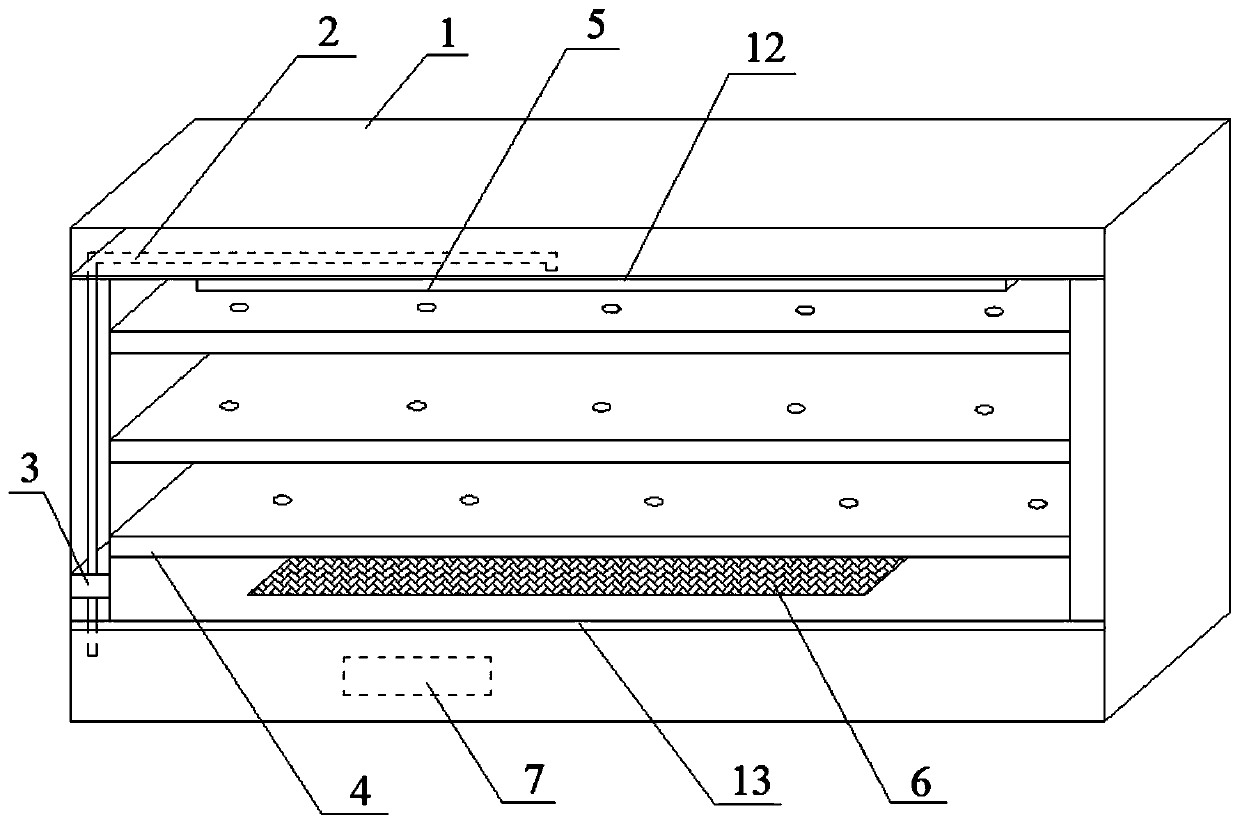

Image

Examples

Embodiment 1

[0034] A method for processing highland barley germinated rice with high gamma-aminobutyric acid content, comprising the following steps:

[0035] Step 1, wash 2 kg of highland barley rice with clear water once, remove dust from the highland barley rice, drain the water until there is no water drop on the surface of the highland barley rice, and obtain clean highland barley rice;

[0036] Step 2, sterilization: put the clean highland barley rice in a high-temperature environment of 55°C for 6 hours to obtain the sterilized highland barley rice;

[0037] Step 3, soaking: soak the sterilized barley rice in warm water at 40°C containing a bacteriostatic agent for 10 hours; the bacteriostatic agent is a 0.5mol / L ferrous chloride solution, and the mass ratio of the sterilized barley rice to the bacteriostatic agent is 1000:0.5;

[0038]Step 4, germination: put the soaked barley rice in an enamel shallow dish with a thickness of 3cm, cover the surface of the barley rice with two la...

Embodiment 2

[0042] A method for processing highland barley germinated rice with high gamma-aminobutyric acid content, comprising the following steps:

[0043] Step 1, wash 2 kg of highland barley rice with clear water once, remove dust from the highland barley rice, drain the water until there is no water drop on the surface of the highland barley rice, and obtain clean highland barley rice;

[0044] Step 2, sterilization: put the clean highland barley rice in a high-temperature environment of 55°C for 6 hours to obtain the sterilized highland barley rice;

[0045] Step 3, soaking: soak the sterilized highland barley rice in warm water at 40°C containing a bacteriostatic agent for 10 hours; the bacteriostatic agent is 1mol / L ferric chloride solution, and the mass ratio of the sterilized highland barley rice to the bacteriostatic agent is 1000 :1;

[0046] Step 4, germination: put the soaked barley rice in an enamel shallow dish with a thickness of 3cm, cover the surface of the barley ric...

Embodiment 3

[0050] A method for processing highland barley germinated rice with high gamma-aminobutyric acid content, comprising the following steps:

[0051] Step 1, wash 2 kg of highland barley rice with clear water once, remove dust from the highland barley rice, drain the water until there is no water drop on the surface of the highland barley rice, and obtain clean highland barley rice;

[0052] Step 2, sterilization: put the clean highland barley rice in a high-temperature environment of 55°C for 6 hours to obtain the sterilized highland barley rice;

[0053] Step 3, soaking: place the sterilized highland barley rice in warm water at 40°C containing a bacteriostatic agent and soak for 10 hours; 1 mixed in volume ratio, the mass ratio of sterilized barley rice and antibacterial agent is 1000:0.1;

[0054] Step 4, germination: put it in an enamel shallow dish with a thickness of 3cm, cover the surface of the highland barley rice with two layers of sterilized gauze, and place it in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com