Preparation method for increasing gamma-aminobutyric acid content of tea

A technology of aminobutyric acid and content, applied in tea treatment before extraction, etc., can solve problems affecting tea quality, poor flavor, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

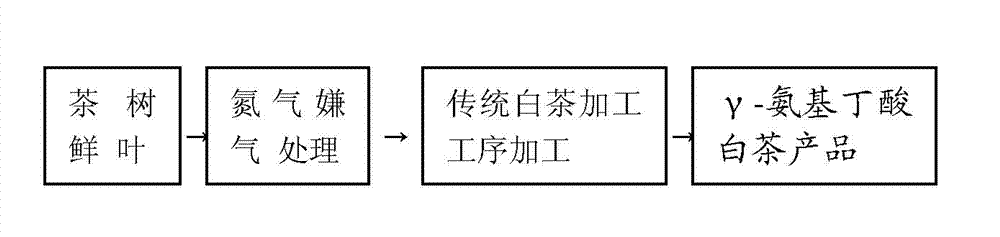

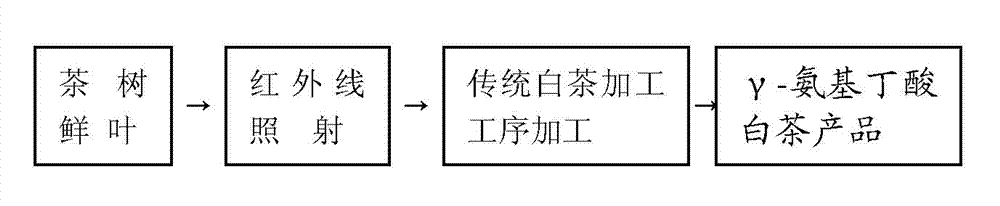

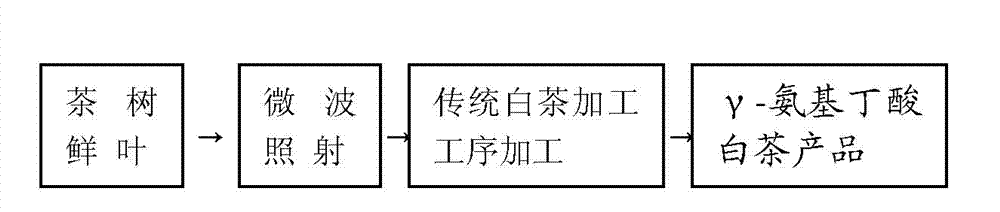

Image

Examples

preparation example Construction

[0018] Please combine with Figure 5, a preparation method for increasing the content of γ-aminobutyric acid in white tea, the preparation method includes the following steps: (1) vacuum treatment; (2) anaerobic treatment; (3) anaerobic exchange; (4) ) withering, alternating good and bad; (5) gentle; (6) dry; (7) picking; (8) pile evenly; (9) get γ-aminobutyric acid white tea. specifically:

[0019] In the step (1), the vacuum treatment time is 3-12 hours, the vacuum degree is 0.04-0.1MPa, and the treatment temperature is 4-40°C;

[0020] In the step (2), the anaerobic time may be 7-9 hours.

[0021] In the step (3), the gas exchange time is 7-9 hours.

[0022] In the step (4), the withering and aerobic alternation time is 18-26 hours, depending on temperature and humidity.

[0023] For example, when the temperature is high and the humidity is high (specifically, the temperature is 6°C and the humidity is 30%), it is 18 hours, and the temperature is low and the humidity is l...

Embodiment 1

[0029] A preparation method for increasing the content of γ-aminobutyric acid in white tea in Example 1. Specifically, in the step (1), the vacuum treatment time is 3 hours, the vacuum degree is 0.1 MPa, and the treatment temperature is 4°C; In the step (2), the anaerobic time can be 7 hours; in the step (3), the anaerobic exchange time is 7 hours; in the step (4), the withering and aerobic alternating time is 18 hours, depending on the temperature , humidity; specifically, for example, the temperature is 6°C and the humidity is 30%; in the step (5), the initial drying temperature is 90°C and the time is 25 minutes; in the step (6), the drying temperature is 100°C , and the time is 20 minutes; in the step (7), pick and remove the stems, wax leaves, thick, old and deformed tea leaves, pick out the tea seeds and tea stems, and the middle and upper tea after screening are first After being sorted by the 73-type stem machine, the stems are sorted by a ladder-type stem sorter or an...

Embodiment 2

[0031] The steps of Example 1 are basically the same, except that: in the step (1), the vacuum treatment time is 5 hours, the vacuum degree is 0.08MPa, and the treatment temperature is 10°C; in the step (2), the anaerobic The time is 8 hours; in the step (3), the air is exchanged for 8 hours; in the step (4), the air is withered and the air is alternated for 20 hours; in the step (5), the initial baking is at 100°C for 24 minutes; In the step (6), the drying temperature is 103° C. for 18 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com