Peanut oil and peanut product, and preparation methods thereof

A technology for peanut oil and peanuts, which is applied in the direction of fat oil/fat refining, baked food, and fat production, can solve the problems of easy oxidation, easy occurrence of oil separation, and reduced flavor quality of peanut butter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

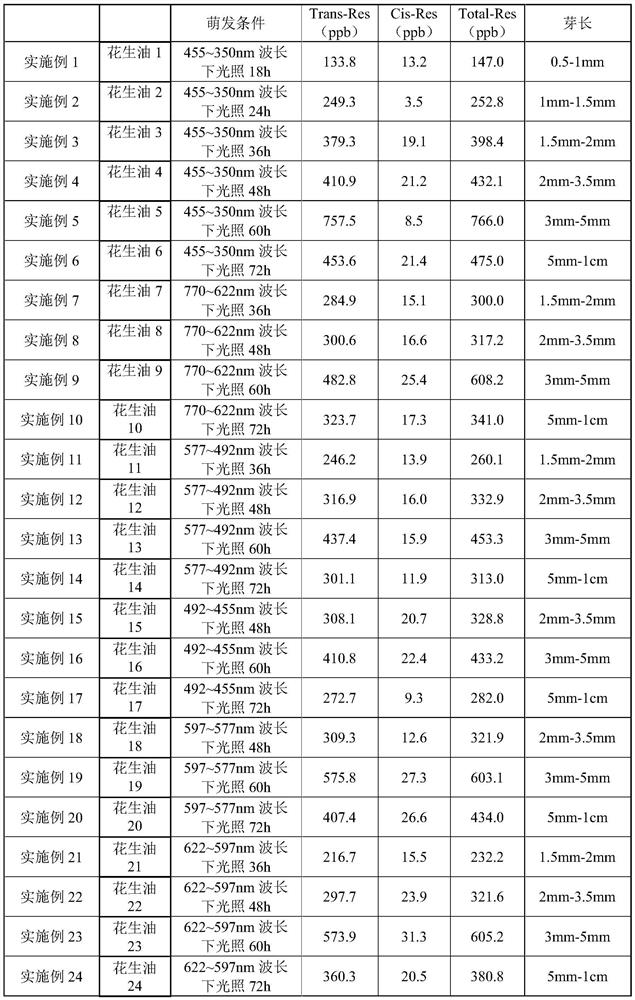

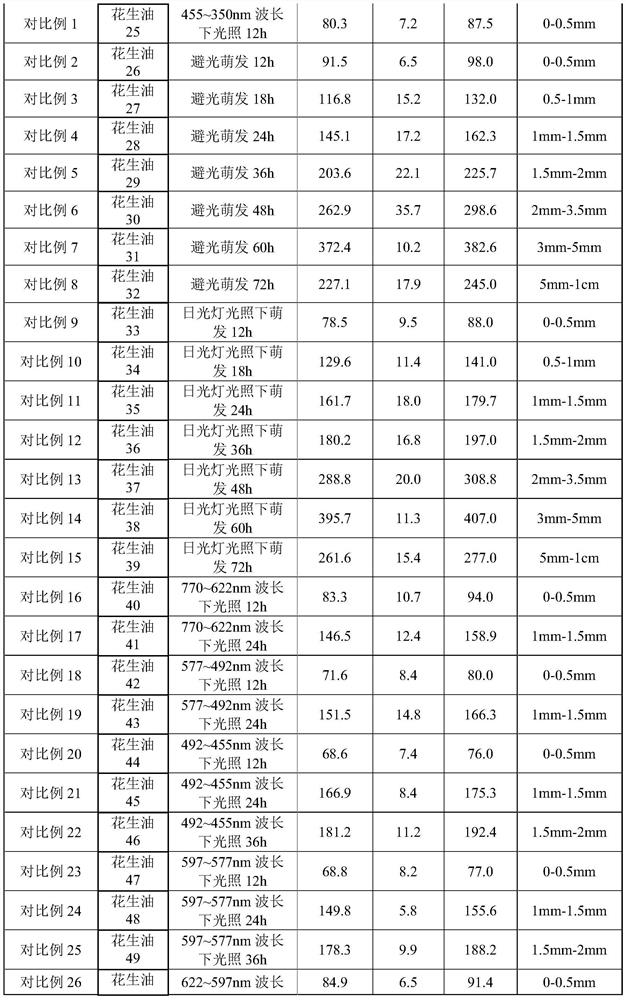

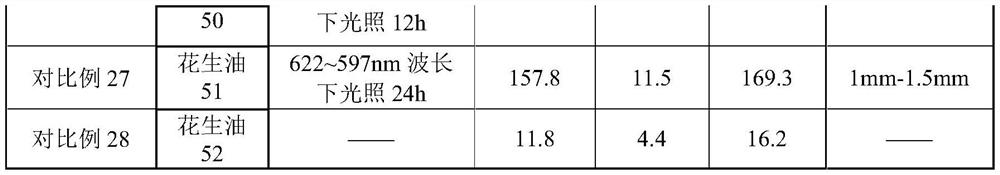

Examples

preparation example Construction

[0089] The preparation process of peanut oil may also include at least one of the following steps: screening, impurity removal, crushing, filtration, clear oil, clarified oil, degumming, deacidification, dewaxing, degreasing, decolorization, transesterification, hydrogenation and / or deodorization.

[0090] In a specific embodiment, the preparation of peanut oil further includes: at least one step of screening, impurity removal, filtration, clear oil, oil clarification, and degumming.

[0091] Usually, the peanuts are soaked in water for a period of time, so that the water absorption rate of the peanuts reaches 30% to 55%. After draining, place them on the germination equipment to make the peanuts in a critical soaking state (such as laying flat on a seedling tray with gauze, Add water to the lower layer of the seedling tray, keep the upper layer on the water surface and the bottom of the upper layer of the seedling tray in a critical infiltration state), carry out light germina...

Embodiment 1

[0141] Take 200g of peanut raw materials with the same particle size and mature plumpness, add 2000g of deionized water to soak for 6 hours after cleaning, the water absorption rate is 31.99%, drain, spread on the seedling tray, and place at constant temperature and humidity (25°C, 100%) In the light laboratory, irradiate at a wavelength of 455-350nm for 18 hours, dry the germinated peanuts, squeeze the oil with a screw oil press, and obtain peanut oil 1 after filtration.

Embodiment 2

[0143] Take 200g of mature and plump peanut raw materials with the same particle size, add 4000g of deionized water to soak for 12h after cleaning, the water absorption rate is 52.18%, drain, spread on the seedling tray, and place at constant temperature and humidity (25°C, 50%) In the light laboratory, irradiate at a wavelength of 455-350nm for 24 hours, dry the germinated peanuts, use a screw oil press to extract oil, and obtain peanut oil 2 after filtration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com