Production of lactic acid bacteria fermented liquid high in γ-aminobutyric acid and its application in cosmetics

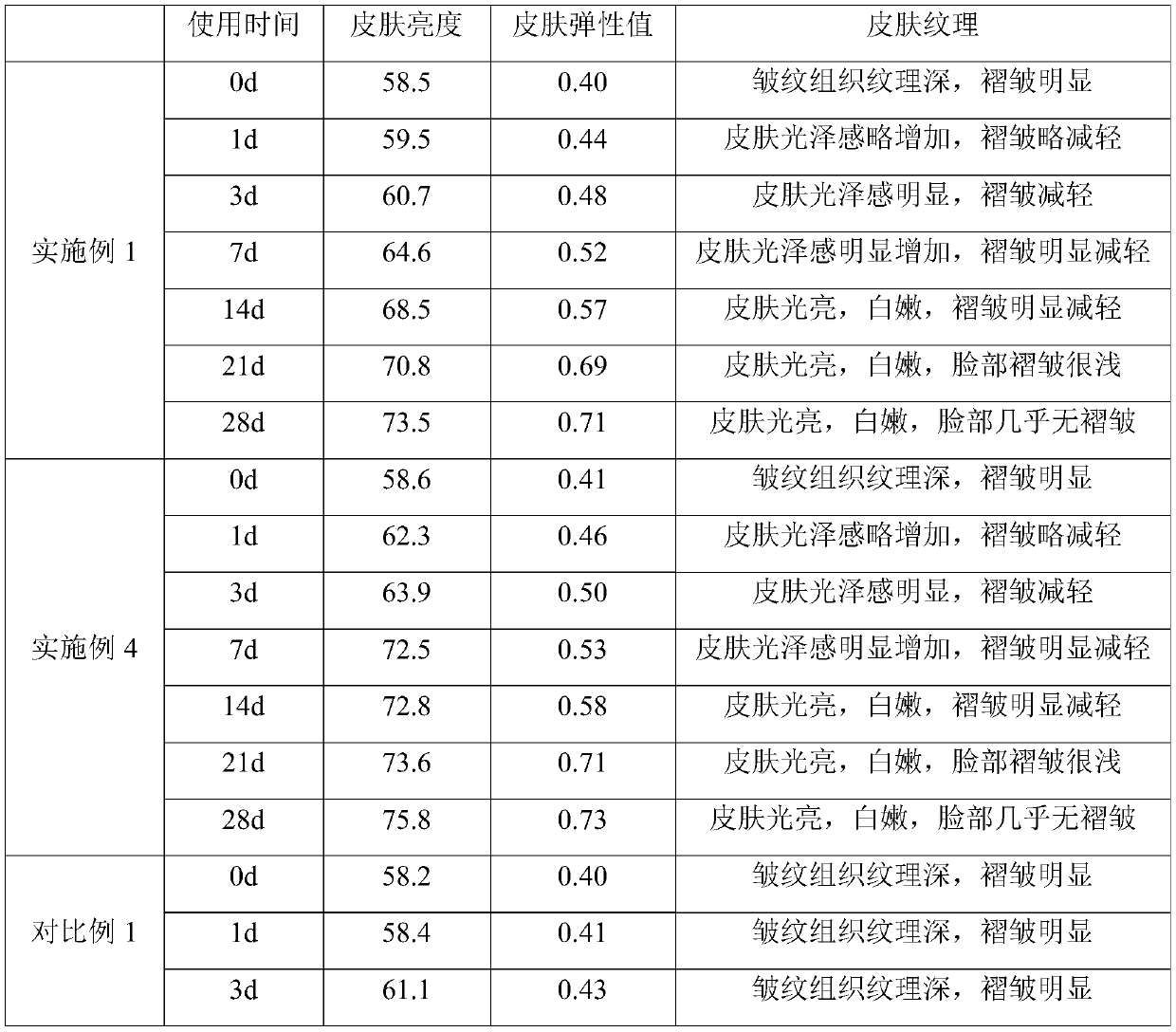

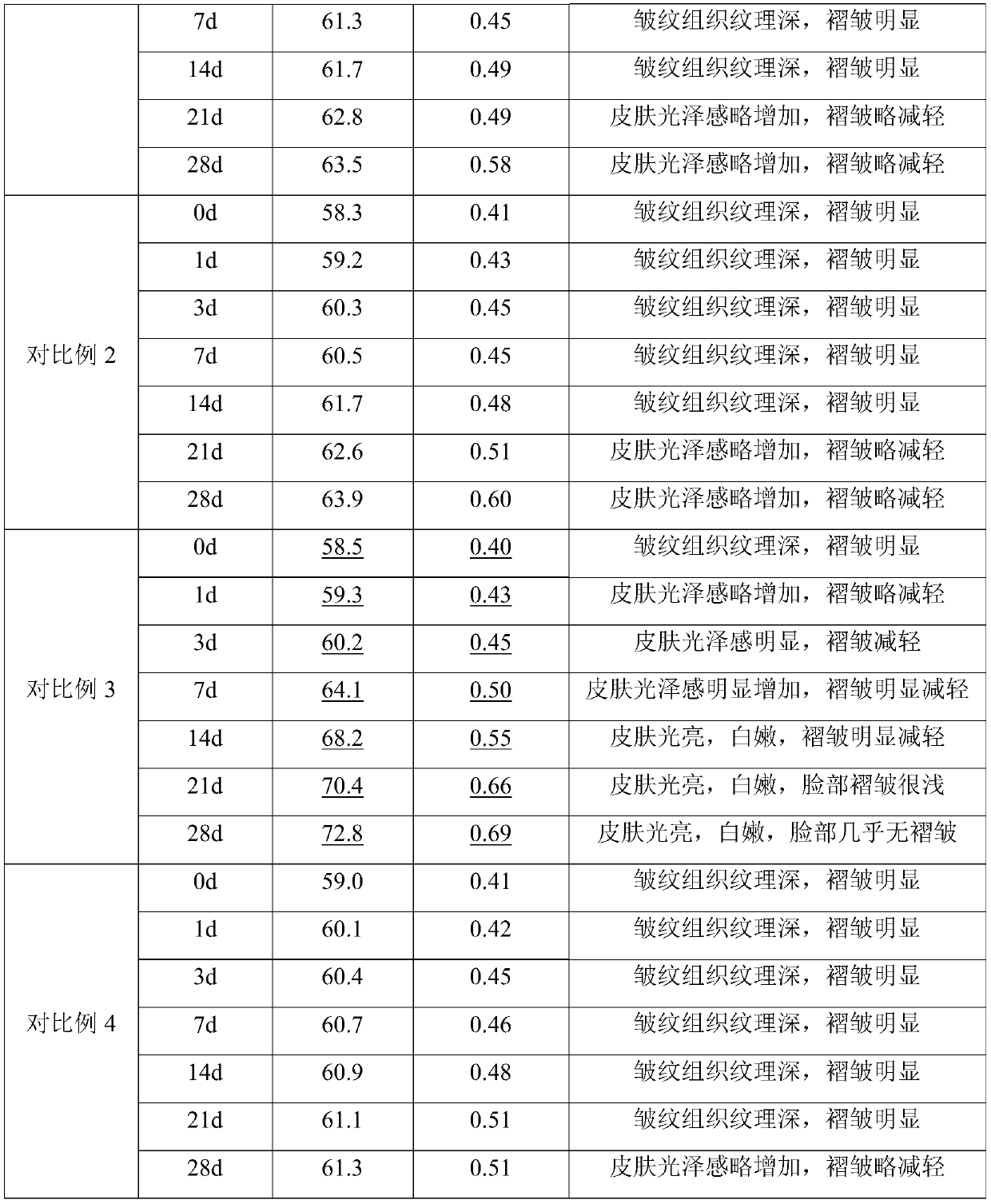

A technology of aminobutyric acid and fermentation liquid, applied in cosmetics, cosmetic preparations, fermentation and other directions, can solve the problems of low content of functional product γ-aminobutyric acid, limited application, limited types and functions of metabolites, etc., so as to improve the skin. Effects of dullness, improvement of skin whiteness, elasticity and moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A lactic acid bacterium produces a fermented liquid high in gamma-aminobutyric acid, the preparation method of which is as follows:

[0053] (1) Germinate brown rice and barley until the leaf bud length is 1 / 3 of the seed, heat to 40°C for 5 minutes, stop germination, and mix with mulberry leaves. The mass ratio of brown rice, barley and mulberry leaves is 1:2:1.5, Pulverize to get mixed powder;

[0054] (2) Soak the mixed powder in water according to the mass volume ratio of 0.25:1g / mL, heat at 55°C for 0.5h, then raise the temperature to 60°C, keep it warm for 2h, and filter while it is hot to obtain the filtrate;

[0055] (3) Add glutamic acid with a mass fraction of 0.5% to the filtrate, heat to 105°C to sterilize for 10 minutes, insert Lactobacillus plantarum, inoculate 1.0%, ferment at 35°C for 6 hours, filter, and the filtrate is produced by lactic acid bacteria Fermentation broth high in γ-aminobutyric acid.

[0056] A cosmetic composition, consisting of the f...

Embodiment 2

[0059] A lactic acid bacterium produces a fermented liquid high in gamma-aminobutyric acid, the preparation method of which is as follows:

[0060] (1) Germinate brown rice and barley until the leaf bud length is 2 / 3 of the seed, heat to 50°C for 15 minutes, stop germination, mix with mulberry leaves, the mass ratio of brown rice, barley and mulberry leaves is 2:1:0.5, Pulverize to get mixed powder;

[0061] (2) Soak the mixed powder in water according to the mass volume ratio of 1.1:1g / mL, heat at 57°C for 1h, then raise the temperature to 65°C, keep it warm for 5h, and filter while it is hot to obtain the filtrate;

[0062] (3) Add sodium glutamate with a mass fraction of 2.5% to the filtrate, heat to 121°C for sterilization for 30 minutes, insert Lactobacillus acidophilus with an inoculum size of 10.0%, ferment at 40°C for 24 hours, filter, and the filtrate is Lactic acid bacteria produce a fermented liquid high in GABA.

[0063] A cosmetic composition, which is composed ...

Embodiment 3

[0066] A lactic acid bacterium produces a fermented liquid high in gamma-aminobutyric acid, the preparation method of which is as follows:

[0067] (1) Germinate brown rice and barley until the leaf bud length is 1 / 2 of the seed, heat to 45°C for 10 minutes, stop germination, mix with mulberry leaves, the mass ratio of brown rice, barley and mulberry leaves is 2:2:1, Pulverize to get mixed powder;

[0068] (2) Soak the mixed powder in water according to the mass volume ratio of 0.7:1g / mL, heat at 56°C for 0.75h, then raise the temperature to 62.5°C, keep it warm for 4h, and filter while it is hot to obtain the filtrate;

[0069] (3) Add glutamic acid with a mass fraction of 1.5% to the filtrate, heat to 113°C to sterilize for 20 minutes, insert Lactobacillus casei, inoculate 5.5%, ferment at 38°C for 15 hours, filter, and the filtrate is produced by lactic acid bacteria Fermentation broth high in γ-aminobutyric acid.

[0070] A cosmetic composition, consisting of the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com