Making method of tea leaves containing gamma-aminobutyric acid

A manufacturing method and aminobutyric acid technology, applied in the field of tea manufacturing, can solve the problems of tea leaves being stuffy and sour, the amino acid conversion rate is not high, affecting the taste of tea leaves, etc., and achieve the effects of increasing the content and improving the stuffy and sour smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

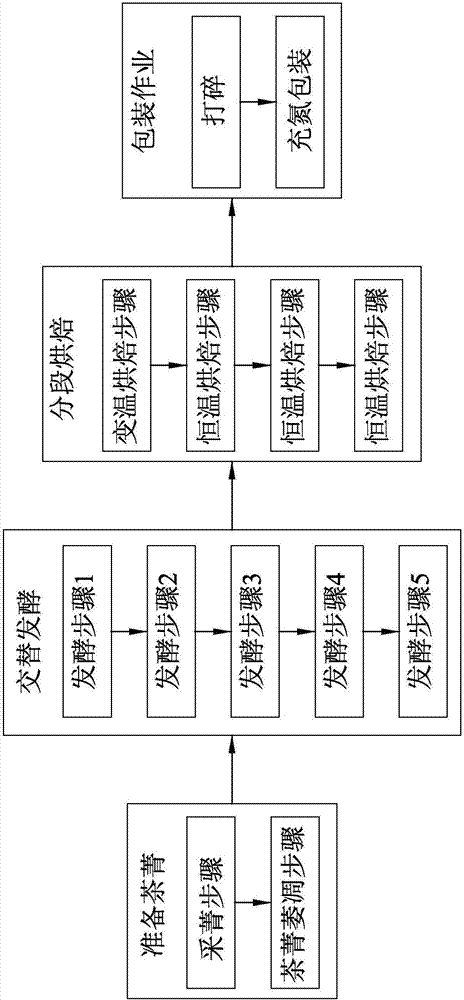

[0028] refer to figure 1 and figure 2 , a first embodiment of the production method of the present invention is specially used to make tea leaves made solely from cyanine, and the tea leaves refer to tea products with a γ-aminobutyric acid content higher than 150 mg%. The manufacturing method includes: preparing tea greens, alternately fermenting, segmented baking, and packaging operations.

[0029] In the process of preparing cyanine, it essentially includes: a cyanine picking step and a tea cyanine withering step. In the cyanine picking step, the raw leaves or tea stalks are directly collected from the tea tree, preferably the core bud of the tea tree, or the first The raw leaves of the second and third leaves. The tea green withering step adopts indoor withering and outdoor withering. It only takes 15 minutes to wither outdoors, and it takes about 20 hours to wither indoors. The purpose is to make the harvested tea greens leak and reduce the water content of the tea gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com