Low-noise steel rail for bridge crane and preparation method thereof

An overhead crane, low-noise technology, applied in the direction of manufacturing tools, heat treatment equipment, process efficiency improvement, etc., can solve problems such as vibration and noise, increase frequency division vibration and frequency multiplication vibration, and fail to meet mechanical performance indicators, etc. Achieve the effect of improving the sound absorption and shock absorption capacity and the fracture toughness of the material, taking into account the strength and damping, and slowing down the crack growth rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Prepare a low-noise steel rail for bridge cranes, which corresponds to the heavy-duty steel rail with the grade QU120 in the metallurgical industry standard (YB / T5055——2014), and the specific preparation process is as follows:

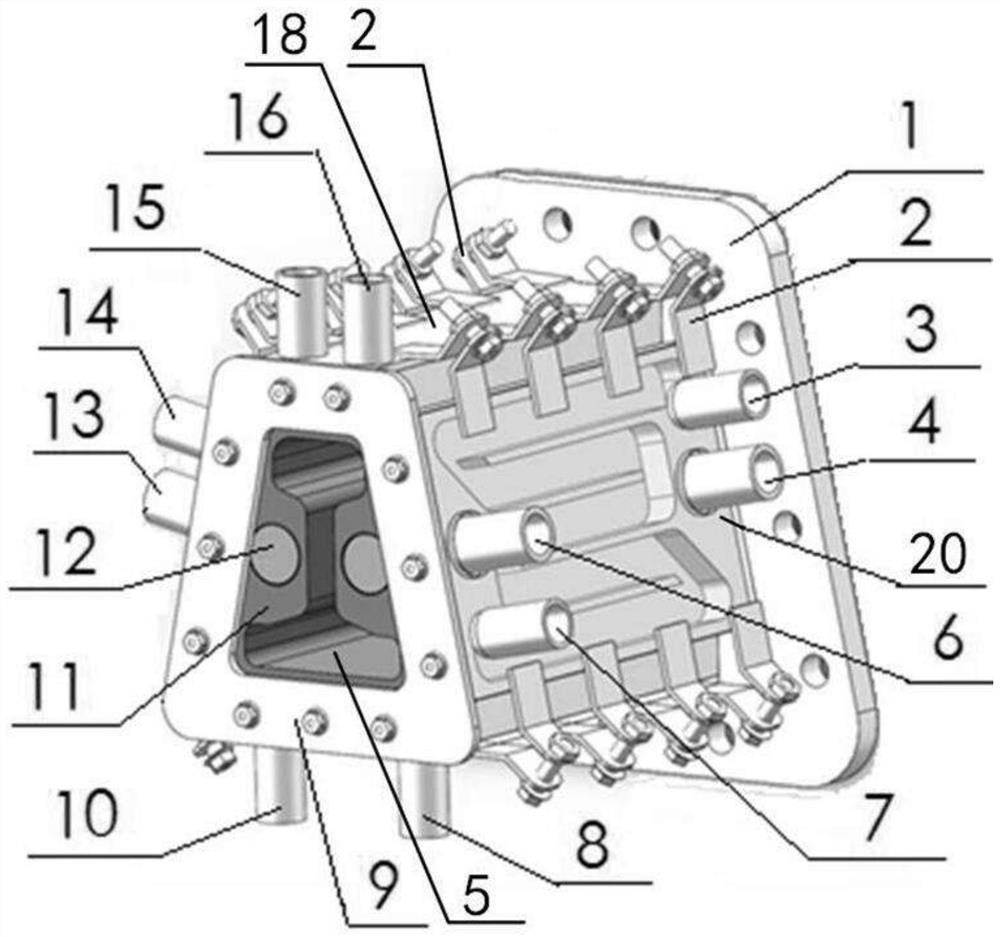

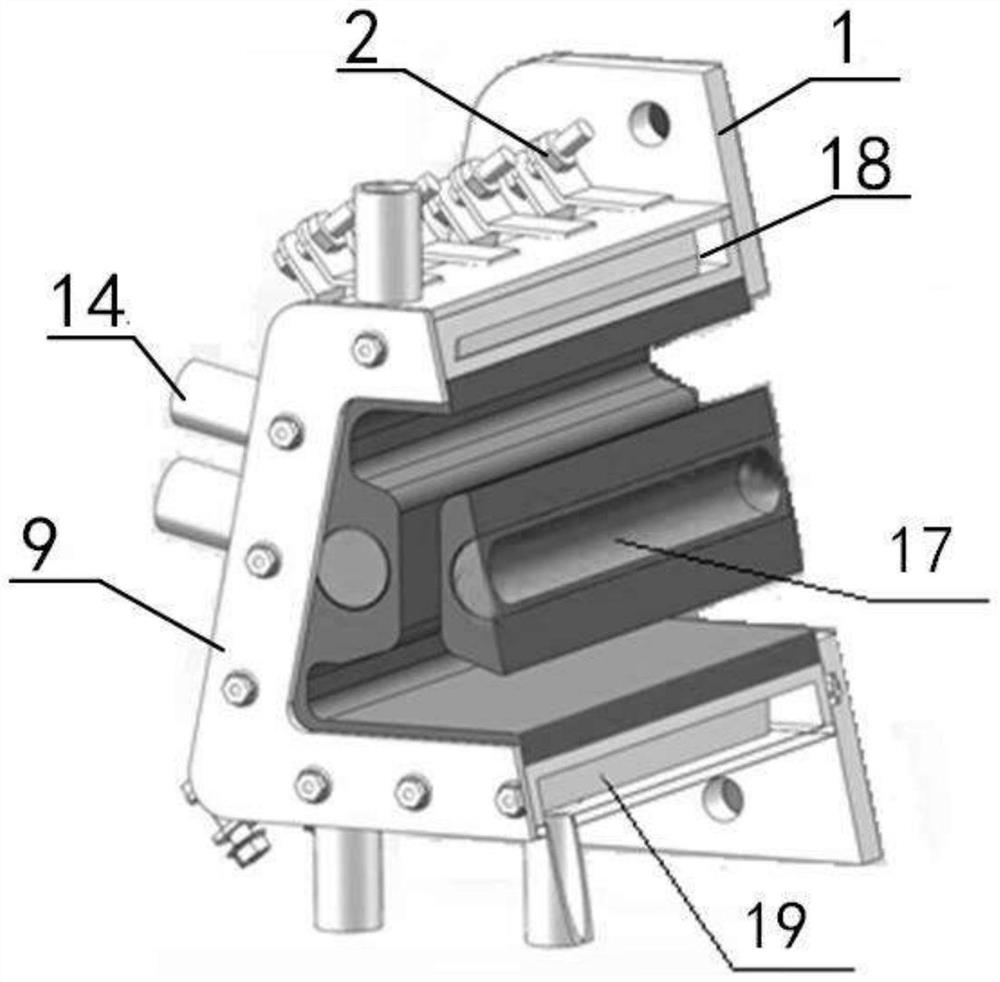

[0055] Step 1, prepare horizontal continuous casting equipment

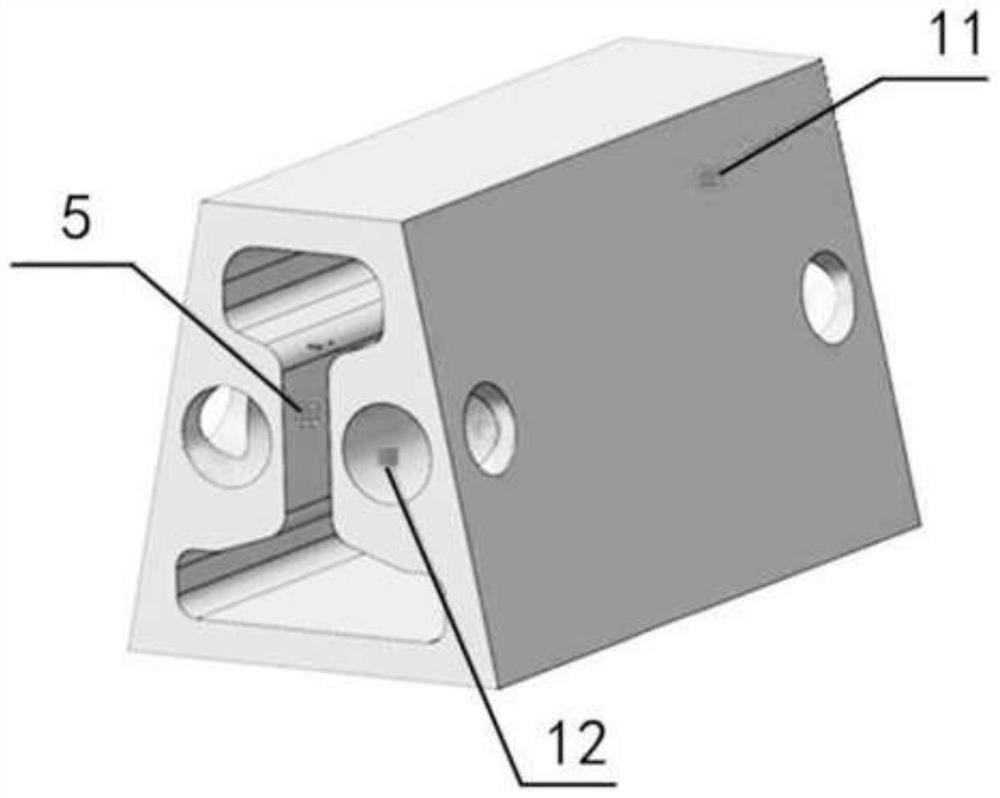

[0056] Step 1.1, make crystallizer, refer to figure 1 and figure 2 , the crystallizer to be used in this application is a combined abdominal cooling crystallizer, including a trapezoidal graphite bushing 11, four water-cooled sandwich plates are arranged on the outer surface of the trapezoidal graphite bushing 11, and adjacent water-cooled sandwich plates are connected by clamping cards 2 Fixed, the inside of the trapezoidal graphite bushing 11 is provided with an I-shaped cavity 5 and two circular through holes 12. The diameter of the through hole is 1.5 inches or 37.5mm. The two through holes 12 are respectively located at the waist of the I-shaped cavity 5 , the distance bet...

Embodiment 2

[0074] A low-noise steel rail for bridge cranes is prepared, which specifically includes the following steps:

[0075] Step 1, preparing horizontal continuous casting equipment, the specific process is the same as in Example 1;

[0076] Step 2, melting the hypoeutectic component material into molten iron in an intermediate frequency induction furnace, wherein the mass percentages of each component in the hypoeutectic component material include: C: 3.4%, Si: 1.55%, Mn: 0.3%, P : ≤0.02%, S: ≤0.02%, Cr: ≤0.3%, Cu: 0.3%, balance Fe, the sum of the mass percentages of each component is 100%. Stop the fire and preheat, start the tractor, insert the seed rod into the crystallizer, and the end of the seed rod reaches the middle of the crystallizer.

[0077] Step 3: Carry out spheroidization treatment, slag removal and inoculation treatment on the molten iron in sequence. First, pour 600Kg of molten iron into the ladle after scalding. The temperature of the first ladle of molten iron ...

Embodiment 3

[0086] A low-noise steel rail for bridge cranes is prepared, which specifically includes the following steps:

[0087] Step 1, preparing horizontal continuous casting equipment, the specific process is the same as in Example 1;

[0088] Step 2, melting the hypoeutectic material into molten iron in an intermediate frequency induction furnace, wherein the mass percentages of each component in the hypoeutectic material include: C: 3.48%, Si: 1.63%, Mn: 0.45%, P : ≤0.02%, S: ≤0.02%, Cr: ≤0.3%, Cu: 0.45%, the balance Fe, the sum of the mass percentages of each component is 100%. Stop the fire and preheat, start the tractor, insert the seed rod into the crystallizer, and the end of the seed rod reaches the middle of the crystallizer.

[0089] Step 3: Carry out spheroidization treatment, slag removal and inoculation treatment on the molten iron in sequence. First, pour 600Kg of molten iron into the ladle after scalding. The temperature of the first ladle of molten iron is 1480 °C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com